fuse box SKODA 120LE 1980 Workshop Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 1980, Model line: 120LE, Model: SKODA 120LE 1980Pages: 238, PDF Size: 47.09 MB

Page 16 of 238

Lifting

the cor with o

Power iock -

When

r-rsing o service

Power iock, let the

cor rest on

the points

shown in Fi1.1.412.

To tow the cor, hook the towing rope on

to

the brocket under

the cor nose. Threod the pin

through the loop of the rope

ond the brocket

lugs ond secure the pin

with o cotter pin (both

thL pin

ond the cotter pin

ore included in the

cor occessories).

1.5 SPARE WHEEL

AND FUEL TANK

Spore wheel -

After having opened the

lug-

goge boot lid, pull the hondle of the spore

wheel corrier releose

rod.

The corrier is

re-

leosed ond swings

down (speciol equipment of

the cor includes

o sofety lotch behind the

bumper which hos to be pushecl

oside to

releose the corrier

) . After

hoving closed the corrier (by

lifting it),

push the releose lever under

the bumper to the

right os for os it will go.

Fuel tonk -

The filler neck with cop is in the

reor on the right-hond

side of the cor- lt con

be locked ond unlocked by meons of

the re'

spective key.

1.6 STARTING THE

ENGINE AND CHECKING

ITS CORRECT RUNNING

1. Moke sure thot the geor

lever is in its

neutrol position,

switch on the ignition (pos-

ition I on the switch box) ond wotch the

coming on of the oil pressure ond chorging

worning lights, i.

e. check the function of the

olternotor -

see the informotion in porogroph

4.

Prepore the engine

to its temperoture:

- Storting from cold in

the occelerotor pedol

- Storting from cold in

the occelerotor pedol

choke for

storting occording

winter -

do not touch

ond use the full choke

summer -

do not touch

ond use only holf of the

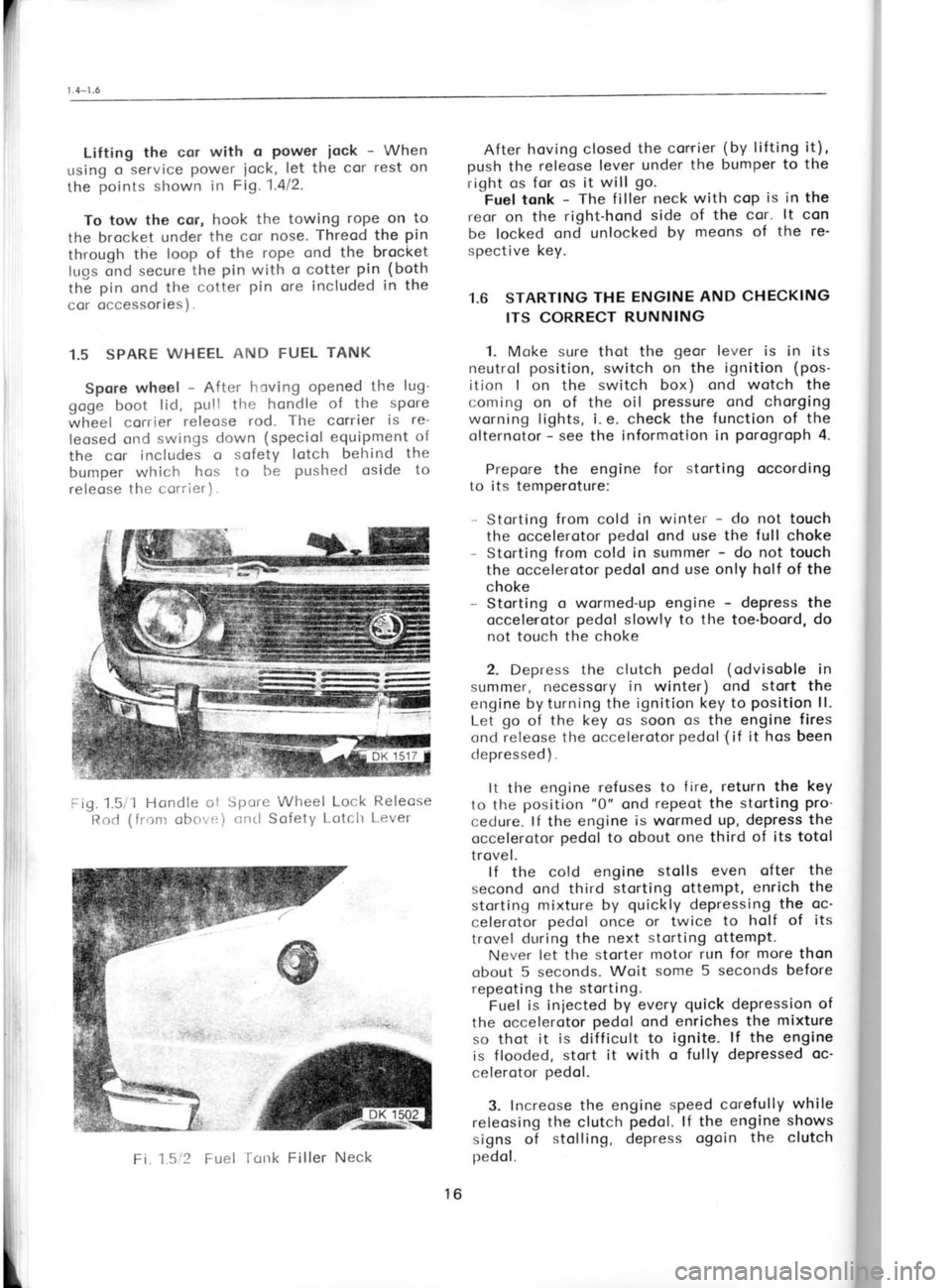

Fig. 1.5/1 Hondle ot

Rod (f ronr obove )Spcre

Wheel Lock

crnrl Safety Lotch -

Storting o wormed-up engine -

depress the

occelerotor pedol

slowly to tlre

toe-boord, do

not touch the choke

2. Depress the clutch pedol

(odvisoble

in

summer, necessory in

winter) ond stort

the

engine by turning the ignition key to position

ll.

Let go

of the key os soon os the engine fires

ond releose the occelerotor pedol

{if it hos

been

clepressed).

It the engine ,refuses

to fire, return the key

to the position "0"

ond rePeot the

storting

Pro-

cedure. lf the engine is wormed up, depress the

occelerotor pedol

to obout one third of its totol

trovel. lf the cold engine stolls even

ofter the

second ond third storting ottemPt, enrich the

storting mixture by quickly

depressing the

oc-

celerotor pedol

once or twice to holf of its

trovel during the next storting ottemPt.

Never let tlre storter motor run for more

thon

obout 5 seconds. Woit

some 5 seconds before

repeoting the storting.

Fuel is injected

by every quick

depression of

the occelerotor pedol

ond enriches the mixture

so thot it is difficult to ignite. lf the engine

is flooded, stort

it

with o fully depressed oc-

celerotor pedol.

3. Increose the engine speed corefully while

releosing the clutch pedol. lf the

engine shows

signs of stolling, depress

ogoin the clutch

pedol.

Relecse

L.ever

Fi.1.5t2 Fuel Tcrtrk Filler

Neck

16

Page 161 of 238

1

1

1

1

1

1:

1r

1l

't,

1',

1:

1:

1l?

ffi{,

ll

---r---

i

fdll

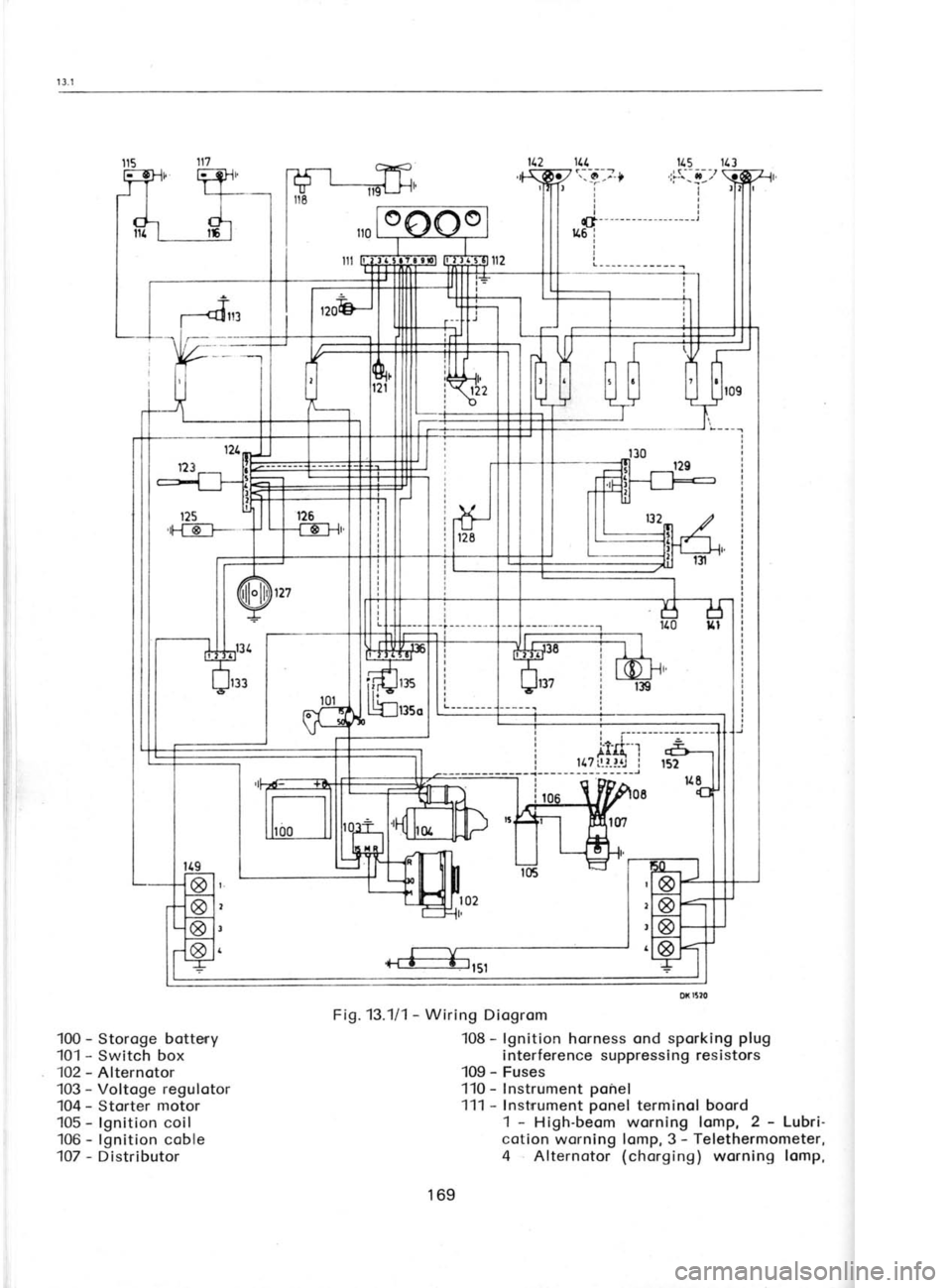

100 -

Storoge botteny

101 -

Switch box

102 -

Alternotor

103 -

Voltoge regulotor

104 -

Storter motor

105 -

lgnition coil

106 -

lgnition coble

107 -

Distributor 115

113

'l7s:,!--,t

ir

rl

tl

tl

t|- -

- --

- - -- - - --- --- -l

116 i

I

I

L--_-___---__ I

Fig. 13.111 -

Wiring Diogrom

108 -

lgnition horness ond sporking plug

interference suppressing resistors

109 -

Fuses

'110 - Instrument ponel

111 -

Instrrument ponel

terminol boord

1 -

High-beom worning lomp, 2 -

Lubri-

cotion worning lomp, 3 -

Telethermometer,

4 Alternotor (chorging)

worning lomp,

169

Page 165 of 238

'i

iiiI 14. Fuse box

Centrol connection of conductors -

do not

seporote them from the bunch!

15. Direction indicotor switches, dip switch,

and horn switch

eight-pole terminol

boord

six-pole terminol boord

16. Porking light switch ond high beom feeder four-pole terminol boord

17. Switch box femole connectors 5.5 with symbols "15",

"30", ond '50"

to be

connected to symbols

"15u, "30', ond '50"

on the switch box

18. Instrument ponel

ten-pole terminol boord

six-pole terminol boord

eorthing coble with lug

'19. Heoter switch

four-pole terminol boord

20. Switch of disobility lights

six-pole terminol boord

21. Door switch, right-hond

green -

femole connector 5.5

22. Dome light,

right-hond

green -

femole connector 5.5

red -

femole connector 5.5

23. Stop switches

forked (yellow) -

femole connectors 5.5 .

red -

femole connector 5.5

white -

femole connector 5.5upper ond lower

switch

upper switch lower switch

24.Fuel gouge block -

femole connector 5.5

yellow -

femole connector 5.5

blue -

femole connector 5.5

to be connected to the respective pins

(blodes) of the some colour of the fuel gouge

25. Storter motor, reversing

lomp switch

conductors with lugs stater motor moin

terminol boord

storter motor

control switch

green -

femole connectors 5.5 heodlomp switch

26. Oil pressure

gouge,

thermometer, corburettor

iet seporotor

green -

femole connector 5.5 yellow

-

femole connector 5.5

green - telethermometer

primory element

femole connector 7.

corburettor

iet seporotor

27. lgnition coil, voltoge regulotor, olternotor,

tochometer

conductor with femole connector ond

bronching lug

femole connector-regulotor terminol 15/54

lug -

ignition coil terminol 15

blue -

femole connector 5.5,

symbol "R"

. regulotor terminol "R"

yellow -

femole connector 5.5,

symbol "M"

regulotor terminol "M"

blue -

connector "R"

. olternotor terminol "R"

yellow -

connector "M".

olternotor terminol "M"

lug terminol "+B"

conductor with

lug ignition coilterminol "1"

(tochometer operotion

)

28. Toil lomp cluster, right.hond

yellow -

femole connector 5.5 toil light

block -

femole connector 5.5 direction indicotors

red -

femole connector 5.5 stop light

green -

femole connector 5.5 reversing lomp

29. Licence plote light

conductors with femole connectors 5.5

30. Toil lomp cluster, left.hond

se point

28.

b) Connection

of free conductors

1. Storoge bottery

bottery coble positive

(*)

terminol -

storter motor

bottery eorthing strip negotive (-)

terminal -

bodywork (eorthing conductor)

2. Engine engine eorthing strip (fostening

lug) -

engine cross beorer (eorthing conductor)

3. Distributor speciol coble from distributor to

ignition

coil; end with interference suppressing

terminol to distributor

coble from distributor to ignition coil

terminol "1"

cylindricol

(pin)

connector

pressure gouge172

Page 179 of 238

(

1

z

Strike the

slip-over ring off the circlip

(towords the motor windlng). Open the circlip

ond pull

it off the shoft together with the re-

leosed ports.

8. lf necessory, re-turn the commutotor ond

scrope or mill out the insulotion between the

lominotions. "Mikonit"

should be 0.4 to 0.8 mm

below the octive surfoce.

Note: The

switch connot be further token

opat. lf

defective, lt hcs to be reploced with

o new one. When cleoning ports

of the storter

motor, do not dip the ormoture or the pinion

with the idler into petrol

or onother degreosing

ogent.The some opplles to the end shieldswith

beorings. By dipping them in o degreosing

ogent, the beorings become procticolly

worth-

less"

Storter Motor Reossembly 1. Lubricote the hellx of the ormoture shoft

with greose -

see Chopter 15.2 'Lubriconts

of

foreing mokeu ond fit the pinion

with the idler

ond the slip-over ring in posltion.

Fit the

circlip

into the groove

in the shoft, ond drive the slip-

on ring over it. The pinion

with the idler must

move freely olong the shoft.

2. Slip the respective

woshers on the shoft in

their originol sequence (corrier

ring, distonce

ring, fibre ring, distonce ring) ond insert the

ormoture with the engoging lever

into the drive

end shield. 3. Suspend the switch

ormoture into the

pre-engoging lever ond bolt down the switch

lightly. Fit the lever pin

into the drive

end

shield ond lock it in position

with the retoiner.

4. Tighten the copscrews of the switch

ond

fit the stotor on the drive

end shield.

5. Instoll the respective

woshers into

the

commutotor end shield in

their originol se-

quence (the dished wosher with its centre

focing the shield, then the ploin

wosher, the

toothed wosher, ond the drive wosher).

6. Fit the commutotor end shield with lifted

brushes on the shoft (in

the position

occording

to the recess

for the excitotion outlet ond the

notch) ond screw in the clomping bolts.

7. Instoll the brush interconnecting strip ond

bolt it down together with the field winding

outlets to the positive

brush holders, lower the

brushes. 8. Fit the Insuloting strip in position

ond bolt

down the cover. 9. Test the storter mottr.

Diognosing Storter Motor Defects in Cor

o) lf the storter motor refuses

to operote, look

first for on interrupted connection between

the bottery ond

the storter

motor, the engine

eorthing ond the storter

motor, or the engine

eorthing ond the bottery. lf these connec-

tions ore in order (current

flows to the ter' DK

1575

Fig. 13.10/3 -

Storter Motor Testlng Connection

minols u30"

ond "50"

with switched on

ignition), stort looking for o foilure of the

storter motor switch. Even in this instonce,

the couse con be o fully dischorged or foulty

bottery.

b) lf the storter motor

continues running

even

ofter the ignition key hos been switched in

the switch box from the position "START",

it hos to be stopped without ony deloy by

disconnecting the bottery (using

its eorthed

pole).

c) lf the storter motor hos no power

to cronk

the engine, stort with switched-on heod-

lights. A

morked dimming indicotes c poorly

chorged bottery.

Tentotive Checking of

Storter Motor

Outside Cor

Connect the terminol "30'of

the storter

motor to o properly

chorged bottery ond incor'

porote on ommeter with o wide

meosuring ronge

into the circuit -

see Fig. 13.10/3.

Stort the

engine (feed

current to the terminol "50").

The

volue of the current ot idling speed must

not

exceed 65 omperes (not

considering the peok

ot

the first momentous deflection).

The storter motor must run noiselessly,

smoothly, ond the pinion

must move smoothly

into ond out of the rest position

(engoge

ond

diesengoge). The engoged pinion

must not ro-

tote direct on the foce of the slip-on ring. The

run-out of the storter motor must not lost longer

thon 8 seconds ofter the disconnection of the

switch from the current supply.

Inspect the brush pressure

springs. The

brushes must

beor on the commutotor by ot

leost two thirds of their surfoce ond they must

move freely in their cells.

The ormoture should hove o noticeoble oxiol

cleoronce (ploy)

not exceeding 0.7 mm.

At

o slight rototion of the pinion

in the direction

of the storter motor rototion,

the idlor must

slip

freely.

186