wheel torque SKODA CITIGO 2013 1.G Owner's Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 2013, Model line: CITIGO, Model: SKODA CITIGO 2013 1.GPages: 176, PDF Size: 10.54 MB

Page 142 of 176

WARNINGObserve the following information regarding the wheel bolts.■The wheel bolts must be clean and must turn easily. Never apply grease or

oil.■

The prescribed tightening torque for the wheel bolts is 110 Nm for steel and

light alloy wheel rims.

■

If the wheel bolts are tightened to an insufficient tightening torque, the

rims may come loose when the car is moving – risk of accident! A tightening

torque which is too high can damage the bolts and threads and this can result

in permanent deformation of the contact surfaces on the rim.

■

If the wheel bolts are handled incorrectly, the wheel may come loose when

the car is moving – risk of accident!

WARNINGObserve the following information regarding the spare wheel.■Only use the spare wheel for as long as is necessary.■

Never drive with more than one spare wheel attached.

■

The snow chains cannot be used on the spare wheel.

CAUTION

■ If a spare wheel is used that is not identical to the fitted tyres, the following

must be observed » page 141, Spare wheel .■

Protect the tyres from contact with oil, grease and fuel.

■

Replace lost valve caps.

■

If, in the event of a puncture, it is necessary to fit a spare wheel with a tyre

without a dedicated running direction or with the opposite direction of rotation, drive carefully as the optimal characteristics of the tyre are no longer applicable in

this situation.

For the sake of the environment

Tyres that are insufficiently inflated increase your fuel consumption.

Note

■ We recommend that any work on the wheels or tyres be carried out by a spe-

cialist garage.■

We recommend that you use wheel rims, tyres, full wheel trims and snow chains

from ŠKODA Original Accessories.

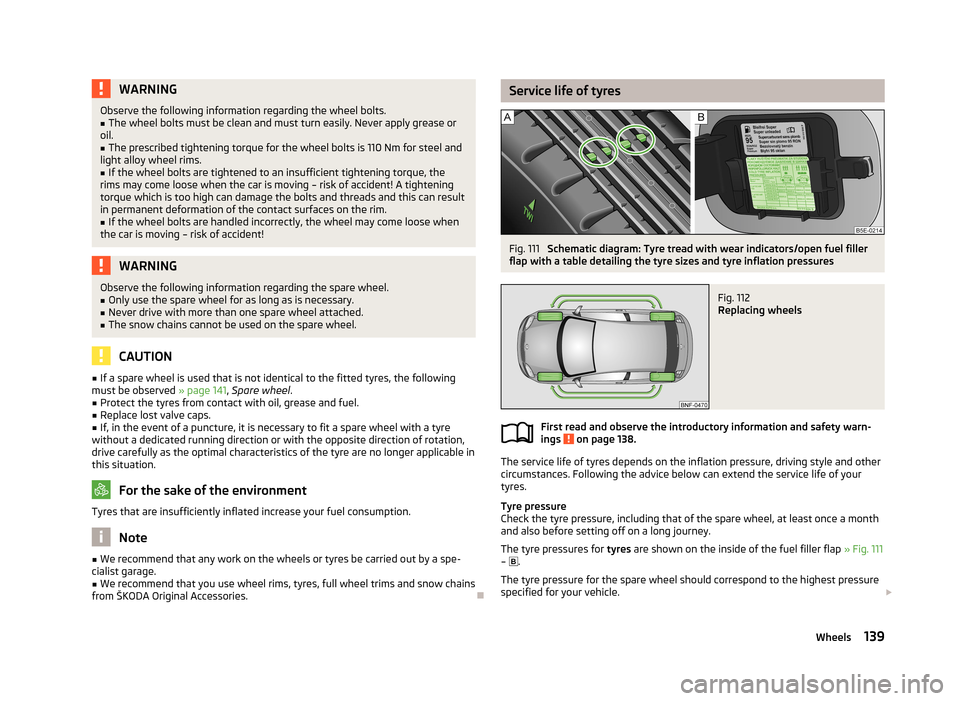

Service life of tyresFig. 111

Schematic diagram: Tyre tread with wear indicators/open fuel filler

flap with a table detailing the tyre sizes and tyre inflation pressures

Fig. 112

Replacing wheels

First read and observe the introductory information and safety warn-

ings on page 138.

The service life of tyres depends on the inflation pressure, driving style and other

circumstances. Following the advice below can extend the service life of your

tyres.

Tyre pressure

Check the tyre pressure, including that of the spare wheel, at least once a month and also before setting off on a long journey.

The tyre pressures for tyres are shown on the inside of the fuel filler flap » Fig. 111

– .

The tyre pressure for the spare wheel should correspond to the highest pressure

specified for your vehicle.

139Wheels

Page 148 of 176

WARNING■The factory-supplied lifting jack is only intended for your model of vehicle.

Under no circumstances use it to lift heavier vehicles or other loads – risk of

injury!■

Ensure that the vehicle tool kit is safely secured in the luggage compart-

ment.

■

Ensure that the box is always secured with the strap.

Changing a wheel

Introduction

This chapter contains information on the following subjects:

Preliminary work

145

Changing a wheel

146

Follow-up work

146

Loosening/tightening wheel bolts

146

Raising the vehicle

147

Securing wheels against theft

148WARNING■ If you are in flowing traffic, switch on the hazard warning light system and

set up the warning triangle at the prescribed distance! The national legal re-

quirements must be observed.■

Park the vehicle as far away as possible from the flow of traffic. Park on as

flat and firm a surface as possible.

■

The following instructions must be followed if the vehicle is subsequently

fitted with tyres or rims that differ from the factory-fitted ones » page 140,

New tyres .

WARNINGObserve the following instructions for lifting the vehicle.■If the wheel has to be changed on a slope, first of all block the opposite

wheel with a stone or similar object to prevent the vehicle from unexpectedly

rolling away.■

Secure the base plate of the lifting jack with suitable means to prevent pos-

sible moving. A soft and slippery ground under the base plate may move the lifting jack, causing the vehicle to fall down. It is therefore always necessary to

place the lifting jack on a solid surface or use a wide and stable base. Use a non-slip base (e.g. a rubber foot mat) if the surface is smooth, such as cobbled

stones, tiled floor, etc.

■

Only attach the lifting jack to the attachment points provided for this pur-

pose.

■

Always raise the vehicle with the doors closed.

■

Never position any body parts, such as arms or legs under the vehicle, while

the vehicle is raised with a lifting jack.

■

Never start the engine when the vehicle is raised – risk of injury.

CAUTION

■ The prescribed tightening torque of the wheel bolts for steel and light alloy

wheels is 110 Nm.■

If the wheel bolts are fastened too tightly, this can cause damage to the anti-

theft wheel bolt or the adapter.

Note

The national legal requirements must be observed when changing a wheel.

Preliminary work

First read and observe the introductory information and safety warn-ings

on page 145.

Always change a wheel on a level surface as far as possible.

The following steps must be carried out before actually changing the wheel:

›

Let all of the occupants get out. While changing a tyre, the occupants of the

vehicle should not stand on the road (instead they should remain behind a crash

barrier).

145Emergency equipment and self-help

Page 149 of 176

›Switch off the engine.›Move the gearshift lever into

Neutral or, for an automatic gearbox, move the

selector lever into position N.›

Firmly apply the handbrake.

›

Remove the vehicle tool kit » page 144 and the spare wheel » page 141 from

the boot.

Changing a wheel

First read and observe the introductory information and safety warn-

ings

on page 145.

›

Remove the full wheel trim » page 142 or caps » page 142 .

›

First of all slacken the anti-theft wheel bolt and then the other wheel

bolts » page 146 .

›

Jack up the vehicle until the wheel that needs changing is clear of the

ground » page 147 .

›

Unscrew the wheel bolts and place them on a clean surface (cloth, paper, etc.).

›

Remove the wheel carefully.

›

Attach the spare wheel and slightly screw on the wheel bolts.

›

Lower the vehicle.

›

Alternately tighten wheel bolts opposite (diagonally) with the wheel wrench.

Tighten the anti-theft wheel bolt last » page 146.

›

Replace the wheel trim or the caps.

Note

■

All bolts must be clean and must turn easily.■Under no circumstances grease or oil the wheel bolts!■

When fitting unidirectional tyres, ensure that the direction of rotation is cor-

rect » page 138 .

Follow-up work

First read and observe the introductory information and safety warn-

ings

on page 145.

The following steps must also be performed after changing the wheel.

› Stow and attach the replaced wheel in the spare wheel well using a special

bolt » page 141 .›

Stow the tool kit in the space provided and secure using the band.

›

Check the tyre pressure on the installed spare wheel as soon as possible.

›

Have the tightening torque of the wheel bolts checked with a torque wrench

as soon as possible.

›

Replace the damaged wheel or consult a specialist garage about repair options.

Note

■ If it is determined that the wheel bolts are corroded and difficult to turn when

changing the wheel, the bolts must be replaced before checking the tightening

torque.■

Drive cautiously and only at a moderate speed until the tightening torque has

been checked.

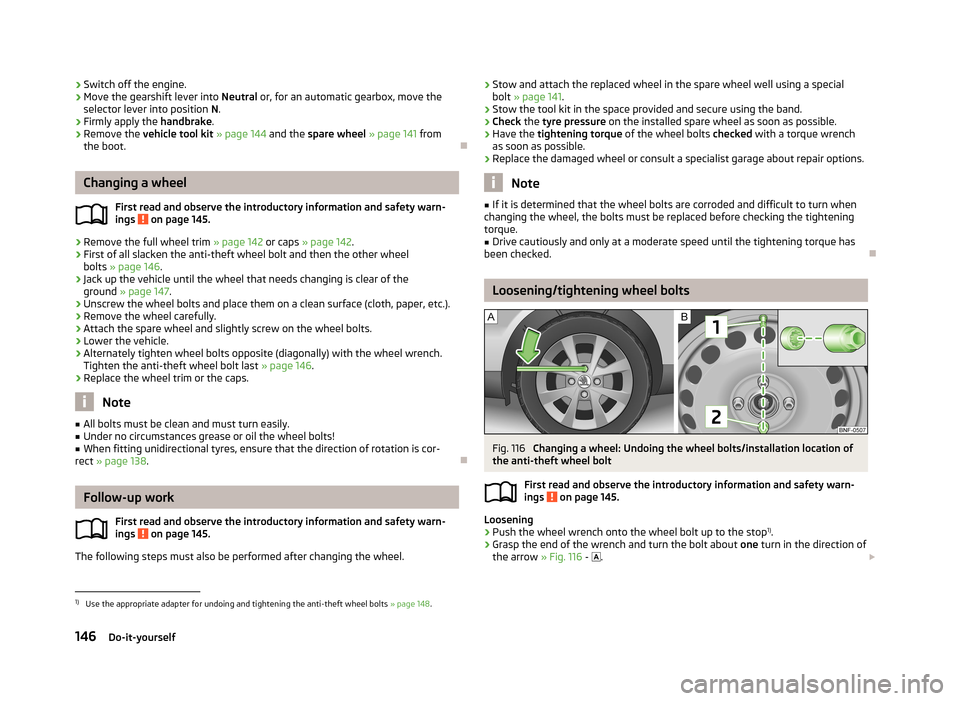

Loosening/tightening wheel bolts

Fig. 116

Changing a wheel: Undoing the wheel bolts/installation location of

the anti-theft wheel bolt

First read and observe the introductory information and safety warn-

ings

on page 145.

Loosening

›

Push the wheel wrench onto the wheel bolt up to the stop 1)

.

›

Grasp the end of the wrench and turn the bolt about one turn in the direction of

the arrow » Fig. 116 -

.

1)

Use the appropriate adapter for undoing and tightening the anti-theft wheel bolts

» page 148.

146Do-it-yourself

Page 151 of 176

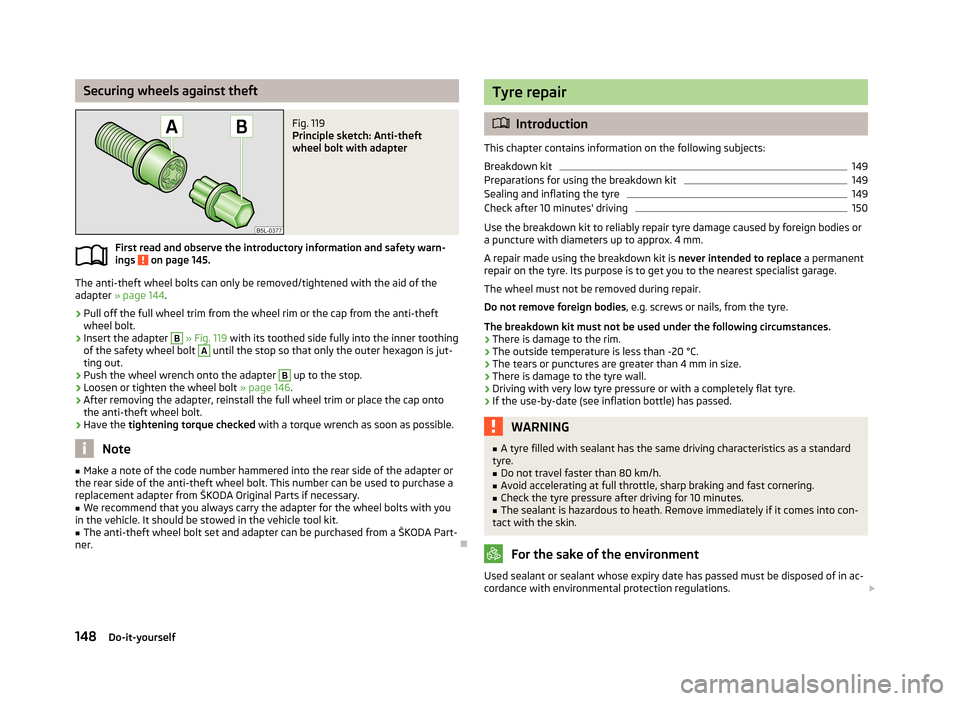

Securing wheels against theftFig. 119

Principle sketch: Anti-theft

wheel bolt with adapter

First read and observe the introductory information and safety warn-

ings on page 145.

The anti-theft wheel bolts can only be removed/tightened with the aid of the

adapter » page 144 .

›

Pull off the full wheel trim from the wheel rim or the cap from the anti-theft

wheel bolt.

›

Insert the adapter

B

» Fig. 119 with its toothed side fully into the inner toothing

of the safety wheel bolt

A

until the stop so that only the outer hexagon is jut-

ting out.

›

Push the wheel wrench onto the adapter

B

up to the stop.

›

Loosen or tighten the wheel bolt » page 146.

›

After removing the adapter, reinstall the full wheel trim or place the cap onto

the anti-theft wheel bolt.

›

Have the tightening torque checked with a torque wrench as soon as possible.

Note

■

Make a note of the code number hammered into the rear side of the adapter or

the rear side of the anti-theft wheel bolt. This number can be used to purchase a

replacement adapter from ŠKODA Original Parts if necessary.■

We recommend that you always carry the adapter for the wheel bolts with you

in the vehicle. It should be stowed in the vehicle tool kit.

■

The anti-theft wheel bolt set and adapter can be purchased from a ŠKODA Part-

ner.

Tyre repair

Introduction

This chapter contains information on the following subjects:

Breakdown kit

149

Preparations for using the breakdown kit

149

Sealing and inflating the tyre

149

Check after 10 minutes' driving

150

Use the breakdown kit to reliably repair tyre damage caused by foreign bodies or

a puncture with diameters up to approx. 4 mm.

A repair made using the breakdown kit is never intended to replace a permanent

repair on the tyre. Its purpose is to get you to the nearest specialist garage.

The wheel must not be removed during repair.Do not remove foreign bodies , e.g. screws or nails, from the tyre.

The breakdown kit must not be used under the following circumstances. › There is damage to the rim.

› The outside temperature is less than -20 °C.

› The tears or punctures are greater than 4 mm in size.

› There is damage to the tyre wall.

› Driving with very low tyre pressure or with a completely flat tyre.

› If the use-by-date (see inflation bottle) has passed.

WARNING■

A tyre filled with sealant has the same driving characteristics as a standard

tyre.■

Do not travel faster than 80 km/h.

■

Avoid accelerating at full throttle, sharp braking and fast cornering.

■

Check the tyre pressure after driving for 10 minutes.

■

The sealant is hazardous to heath. Remove immediately if it comes into con-

tact with the skin.

For the sake of the environment

Used sealant or sealant whose expiry date has passed must be disposed of in ac- cordance with environmental protection regulations. 148Do-it-yourself