ECU SKODA CITIGO 2017 User Guide

[x] Cancel search | Manufacturer: SKODA, Model Year: 2017, Model line: CITIGO, Model: SKODA CITIGO 2017Pages: 172, PDF Size: 24.54 MB

Page 69 of 172

Remove adapter›Push the release buttonB in the direction of arrow 3 and remove the

adapter in the direction of arrow 4

» Fig. 76 .

›

Seal the opening in the dashboard with the cover.

WARNINGAn incorrectly mounted adapter can break loose from the dashboard in sud-

den manoeuvre or an accident - there is risk of injury!

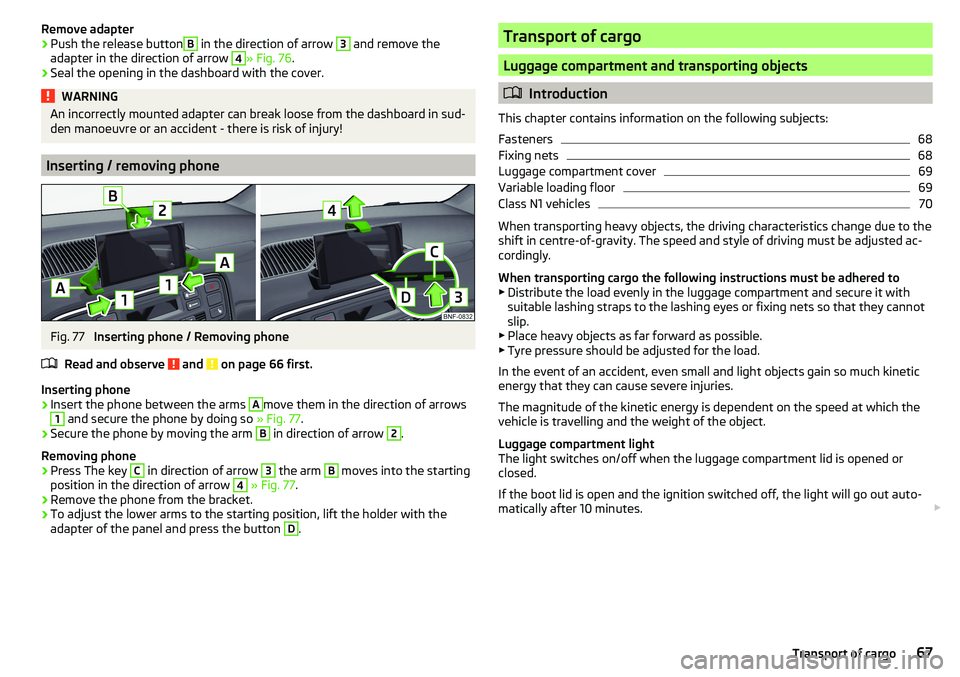

Inserting / removing phone

Fig. 77

Inserting phone / Removing phone

Read and observe

and on page 66 first.

Inserting phone

›

Insert the phone between the arms

A

move them in the direction of arrows

1

and secure the phone by doing so » Fig. 77.

›

Secure the phone by moving the arm

B

in direction of arrow

2

.

Removing phone

›

Press The key

C

in direction of arrow

3

the arm

B

moves into the starting

position in the direction of arrow

4

» Fig. 77 .

›

Remove the phone from the bracket.

›

To adjust the lower arms to the starting position, lift the holder with the

adapter of the panel and press the button

D

.

Transport of cargo

Luggage compartment and transporting objects

Introduction

This chapter contains information on the following subjects:

Fasteners

68

Fixing nets

68

Luggage compartment cover

69

Variable loading floor

69

Class N1 vehicles

70

When transporting heavy objects, the driving characteristics change due to the

shift in centre-of-gravity. The speed and style of driving must be adjusted ac-

cordingly.

When transporting cargo the following instructions must be adhered to

▶ Distribute the load evenly in the luggage compartment and secure it with

suitable lashing straps to the lashing eyes or fixing nets so that they cannot

slip.

▶ Place heavy objects as far forward as possible.

▶ Tyre pressure should be adjusted for the load.

In the event of an accident, even small and light objects gain so much kinetic

energy that they can cause severe injuries.

The magnitude of the kinetic energy is dependent on the speed at which the

vehicle is travelling and the weight of the object.

Luggage compartment light

The light switches on/off when the luggage compartment lid is opened or

closed.

If the boot lid is open and the ignition switched off, the light will go out auto-

matically after 10 minutes.

67Transport of cargo

Page 70 of 172

WARNING■Never exceed the maximum permissible load of the respective fasteners,

nets, hooks etc. If heavy objects have not been suitably secured, there is a

risk of injury!■

Do not exceed the permissible axle loads and permissible gross weight of

the vehicle – risk of accident!

■

An unsecured dirt or improperly attached load could slip during a sudden

manoeuvre or in an accident - danger of injury!

■

Loose cargo could hit a deployed airbag and injure occupants – danger of

death!

■

When transporting loads in the luggage compartment that has been en-

larged by folding one of the rear seats forward, care should be taken to en-

sure the safety of passengers transported on the other rear seat.

CAUTION

■ Never exceed the maximum permissible load for the respective fasteners,

nets, hooks etc. - these could be damaged.■

Please ensure that the heating elements for the rear window heater are not

damaged as a result of abrasive objects.

■

Do not place any sharp objects in the nets in the luggage compartment -

there is a risk of damage to the nets.

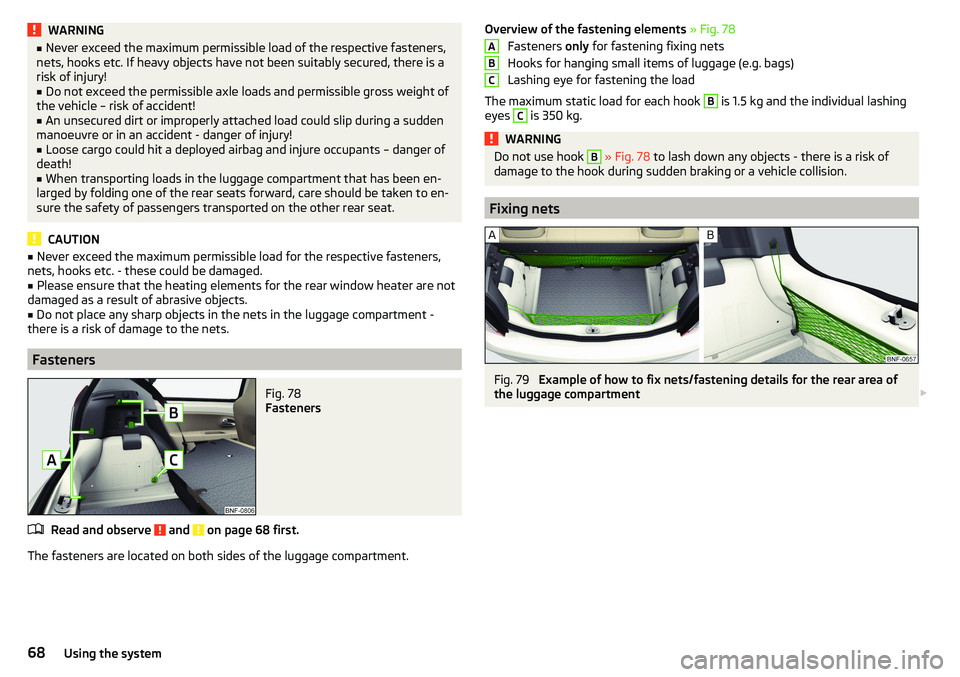

Fasteners

Fig. 78

Fasteners

Read and observe and on page 68 first.

The fasteners are located on both sides of the luggage compartment.

Overview of the fastening elements » Fig. 78

Fasteners only for fastening fixing nets

Hooks for hanging small items of luggage (e.g. bags)

Lashing eye for fastening the load

The maximum static load for each hook B

is 1.5 kg and the individual lashing

eyes

C

is 350 kg.

WARNINGDo not use hook B » Fig. 78 to lash down any objects - there is a risk of

damage to the hook during sudden braking or a vehicle collision.

Fixing nets

Fig. 79

Example of how to fix nets/fastening details for the rear area of

the luggage compartment

ABC68Using the system

Page 72 of 172

Fig. 83

Variable loading floor: lower / lowered

Read and observe

and on page 68 first.

›

To raise the loading floor, grasp handle

A

and raise as far as the stop in the

direction of arrow

1

» Fig. 82 .

›

To lower it, lift the loading floor, push it into the grooves in the direction of

arrow

2

insert and lay it on the luggage compartment floor in direction of

arrow

3

.

Class N1 vehicles

Read and observe

and on page 68 first.

In class N1 vehicles that are not fitted with a protective grille, a lashing set that

complies with the EN 12195 standard (1-4) must be used for fastening the load.

For safe vehicle operation, the proper functioning of the electrical installation

is essential. It is important to ensure that it is not damaged in adaptation as

well as the loading and unloading of the cargo space.

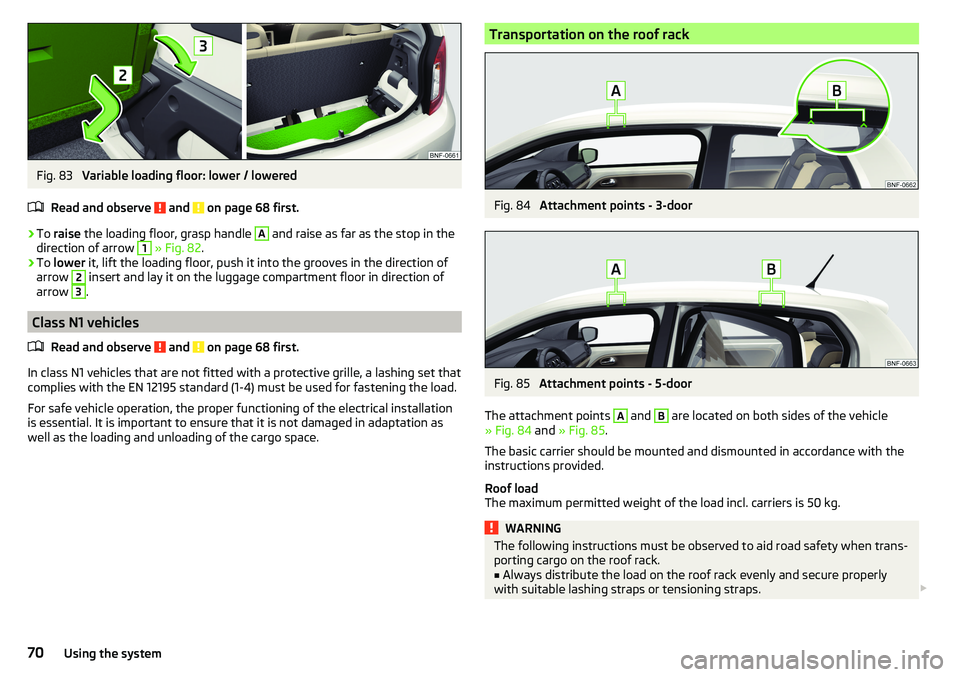

Transportation on the roof rackFig. 84

Attachment points - 3-door

Fig. 85

Attachment points - 5-door

The attachment points

A

and

B

are located on both sides of the vehicle

» Fig. 84 and » Fig. 85 .

The basic carrier should be mounted and dismounted in accordance with the

instructions provided.

Roof load

The maximum permitted weight of the load incl. carriers is 50 kg.

WARNINGThe following instructions must be observed to aid road safety when trans- porting cargo on the roof rack.■

Always distribute the load on the roof rack evenly and secure properly

with suitable lashing straps or tensioning straps.

70Using the system

Page 85 of 172

Scan through the stations one after the other (SCAN)

The function scans through all the available stations in the current frequency range in succession, for a few seconds each.›

To start/finish automatic playback of the available stations, press the dial in

the Radio main menu

.

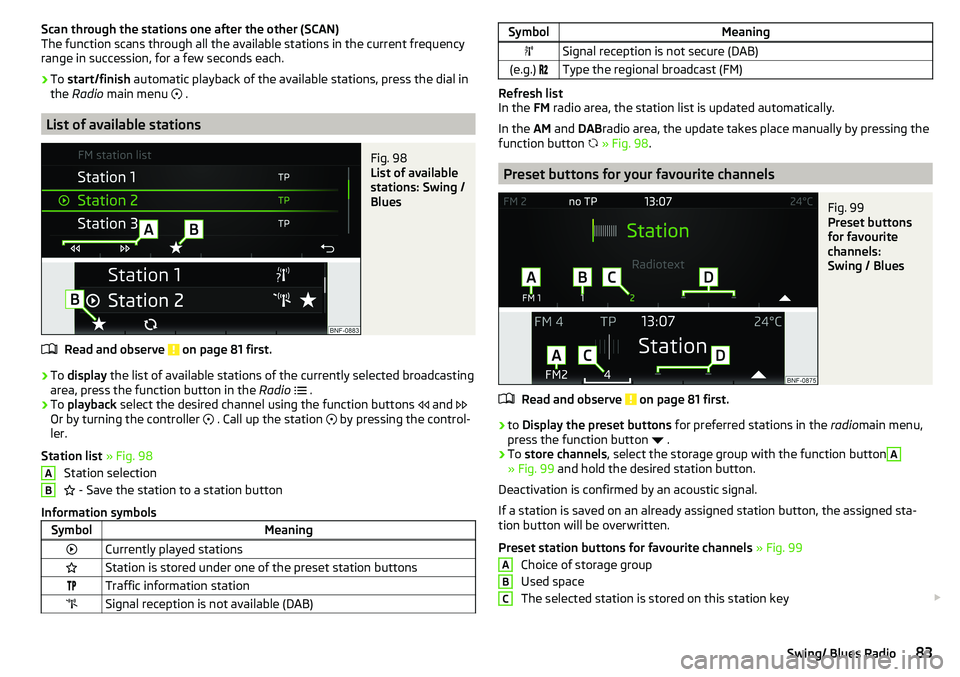

List of available stations

Fig. 98

List of available

stations: Swing /

Blues

Read and observe on page 81 first.

›

To display the list of available stations of the currently selected broadcasting

area, press the function button in the Radio

.

›

To playback select the desired channel using the function buttons

and

Or by turning the controller

. Call up the station

by pressing the control-

ler.

Station list » Fig. 98

Station selection

- Save the station to a station button

Information symbols

SymbolMeaningCurrently played stationsStation is stored under one of the preset station buttonsTraffic information stationSignal reception is not available (DAB)ABSymbolMeaningSignal reception is not secure (DAB)(e.g.) Type the regional broadcast (FM)

Refresh list

In the FM radio area, the station list is updated automatically.

In the AM and DABradio area, the update takes place manually by pressing the

function button

» Fig. 98 .

Preset buttons for your favourite channels

Fig. 99

Preset buttons

for favourite

channels:

Swing / Blues

Read and observe on page 81 first.

›

to Display the preset buttons for preferred stations in the radiomain menu,

press the function button

.

›

To store channels , select the storage group with the function button

A

» Fig. 99 and hold the desired station button.

Deactivation is confirmed by an acoustic signal.

If a station is saved on an already assigned station button, the assigned sta-

tion button will be overwritten.

Preset station buttons for favourite channels » Fig. 99

Choice of storage group

Used space

The selected station is stored on this station key

ABC83Swing/ Blues Radio

Page 100 of 172

Brakes and Parking

Introduction

This chapter contains information on the following subjects:

Handbrake

98

Parking

99

The wear and tear on the brake pads is dependent on the operating condi-

tions and driving style. In difficult conditions (e.g. urban, sporty driving), the

condition of the brakes should be checked between services by a specialist ga-

rage.

Brake response can be slower if the brakes are covered in moisture or, in win-

ter, have a layer of ice or salt on them . The brakes should be cleaned and

dried by applying the brakes many times over »

.

Corrosion on the brake discs and dirt on the brake pads can occur if the vehicle

has been parked for a long period and if you do not make much use of the

braking system. The brakes are cleaned by applying the brakes several times

over »

.

Before negotiating a long or steep gradient , reduce speed and shift down a

gear. As a result, the braking effect of the engine will be used, reducing the

load on the brakes. If, nevertheless, there is a need for additional braking, it

should be carried out at intervals.

Emergency braking warning - If it is necessary to brake hard, the system may

cause the brake lights to automatically flash, to alert the traffic behind.

New brake pads must first be ““run in”” because these do not initially have the

best possible braking effect. Drive especially carefully for the first 200 km or

so.

If the brake fluid level is too low, it can cause faults in the braking system ;

the warning light will light up in the instrument cluster » page 32

,

Braking

system . If the warning light does not light up, yet the stopping distance is per-

ceived to be longer than before, the driving style should be adapted in view of

the unknown cause of the problem, and braking kept to a minimum - seek the

help of a specialist garage without delay.

The brake booster increases the pressure generated with the brake pedal. The

brake booster only operates when the engine is running.

WARNING■ Greater physical effort is required for braking when the engine is switch-

ed off – risk of accident!■

When braking in a vehicle with manual transmission, when the vehicle is

in gear and at low revs, the clutch pedal must be depressed. Otherwise, the

functionality of the brake system may be impaired – risk of accident!

■

Do not depress the brake pedal, if there is no requirement to slow down.

This causes the brakes to overheat and can also result in a longer braking

distance and excessive wear - risk of accident!

■

Only brake for the purpose of drying and cleaning the brake discs if the

traffic conditions permit this. Do not place any other road users in jeopardy.

■

Recommendations for new brake pads should be followed.

■

When stopping and parking, the parking brake should always be applied

firmly, otherwise the vehicle could move off - risk of accident!

■

If a front spoiler, full wheel trim, etc. is mounted retrospectively, it must

be ensured that the air supply to the front wheel brakes is not reduced.

Otherwise, the front brakes could be in danger of overheating – risk of acci-

dent!

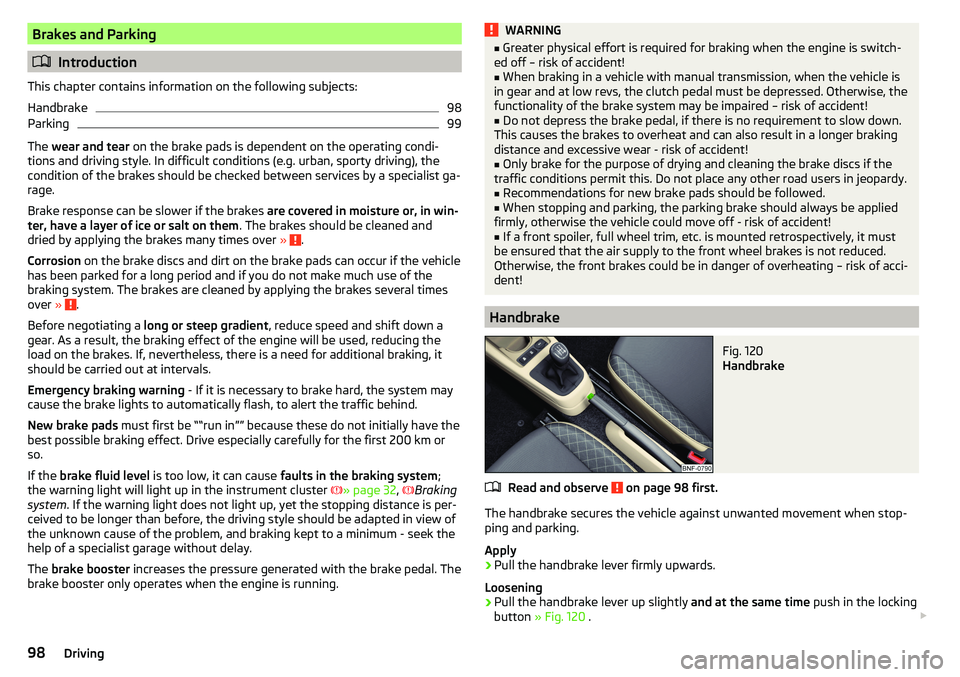

Handbrake

Fig. 120

Handbrake

Read and observe on page 98 first.

The handbrake secures the vehicle against unwanted movement when stop- ping and parking.

Apply

›

Pull the handbrake lever firmly upwards.

Loosening

›

Pull the handbrake lever up slightly and at the same time push in the locking

button » Fig. 120 .

98Driving

Page 102 of 172

CAUTIONIf not in the process of changing gear, do not leave your hand on the gearshift

lever while driving. The pressure from the hand can cause the gearshift mech-

anism to wear excessively.

Pedals

The operation of the pedals must not be hindered under any circumstances!

Only a floor mat (ex-factory or from the ŠKODA Original Accessories range)

which can be secured to the attachment points should be used in the driver's

footwell.

WARNINGThere should be no objects in the driver's footwell, otherwise the pedal op-

eration can be impeded - risk of accident!

Automated transmission

Introduction

This chapter contains information on the following subjects:

Select lever position

100

Manual shifting (Tiptronic)

101

Starting-off and driving

101

The automatic transmission changes gears automatically based on how the

engine and accelerator are being worked, the vehicle speed and the selected

driving mode.

The automatic transmission modes are set by the driver by means of the selec-

tor lever.

WARNING■ Do not accelerate when selecting drive mode prior to moving off - risk of

accident!■

Never move the selector lever to mode R when driving – risk of accident!

■

Always firmly apply the handbrake before leaving the vehicle! Otherwise,

the vehicle could be automatically set in motion - there is a risk of acci-

dents!

CAUTIONWhen stopping on a slope, never try to hold the vehicle using the accelerator

pedal – this may lead to gear damage.

Note

■ The engine can only be left on in position N, when the brake pedal is de-

pressed .■

If the selector lever position N is accidentally selected while driving, it is first

necessary to release pressure on the accelerator pedal and wait for the idling

speed of the engine to be reached before the selector lever can be engaged in

the drive position.

■

If the N symbol flashes next to the selector lever, engage the selector lever

position N.

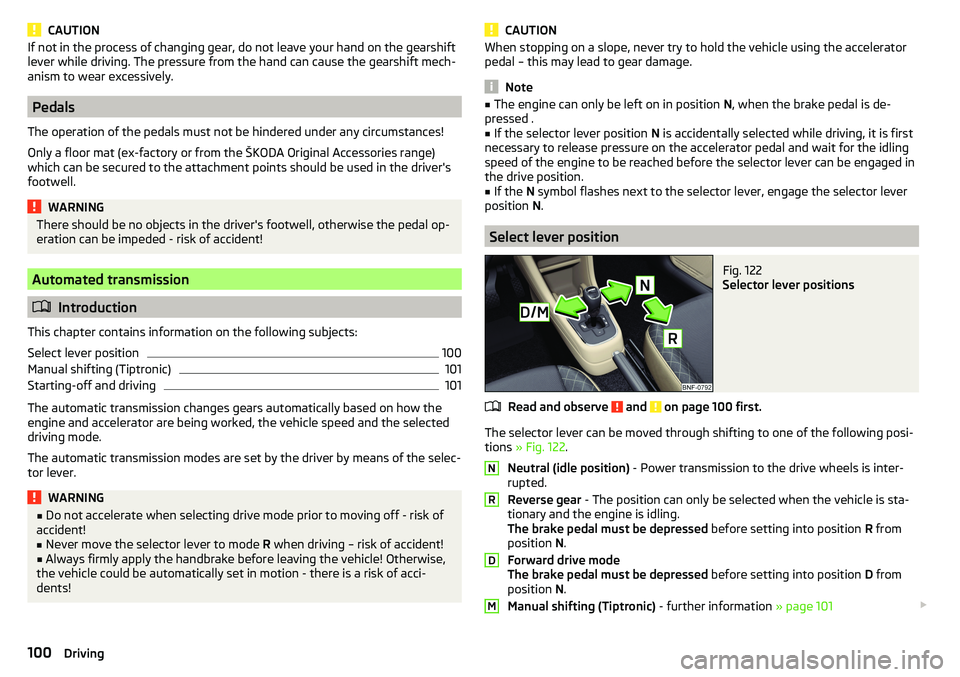

Select lever position

Fig. 122

Selector lever positions

Read and observe and on page 100 first.

The selector lever can be moved through shifting to one of the following posi-

tions » Fig. 122 .

Neutral (idle position) - Power transmission to the drive wheels is inter-

rupted.

Reverse gear - The position can only be selected when the vehicle is sta-

tionary and the engine is idling.

The brake pedal must be depressed before setting into position R from

position N.

Forward drive mode

The brake pedal must be depressed before setting into position D from

position N.

Manual shifting (Tiptronic) - further information » page 101

NRDM100Driving

Page 115 of 172

Overview of service intervalsFig. 131

Vehicle data carrier: service in-

terval

The service interval specified by the manufacturer is indicated on the vehicle

data carrier » Fig. 131 which can be found both in this Owner's Manual as well

as in the vehicle.

One of the following service intervals applies for your vehicle: ▶ Fixed service interval QI1.

▶ Fixed service interval QI2.

▶ Fixed service interval QI3.

▶ Fixed service interval QI4.

Fixed service intervals QI1 - QI4

Oil change serv-

ice

QI1Every 5,000 km or every 1 year a)

.QI2Every 7,500 km or every 1 year a)

.QI3Every 10,000 km or every 1 year a)

.QI4Every 15,000 km or every 1 year a)

.Inspection b)

Variant 1

QI1 - QI4

After the first 30,000 km or 2 years a)

, then every

30,000 km or every 1 year a)

.Inspection b)

Variant 2Every 15,000 km or every 1 year a)

.Inspection b)

Variant 3Every 10,000 km or every 1 year a)

.Brake fluid

changeQI1 - QI4First change after 3 years, then every 2 years.a)

Depending on which comes first.

b)

For information about the variant that applies to your vehicle, please contact a ŠKODA partner.

WARNINGThe brake fluid must always be changed after the first 3 years and then ev-

ery 2 years. Longer intervals between changing the brake fluid can cause

vapour bubbles to form in the brake system when braking sharply. This can

impair the efficiency of the brakes – risk of accident!

Digital Service Plan

A specialist garage will not record the work carried out in a service evidence in

this Owner's Manual, but in the service information system called Digital Serv-

ice Plan.

We therefore recommend that you always have the record of work carried out

in a service printed out for you.

Benefits of the Digital Service Plan

▶ High level of security preventing manipulation of the entries.

▶ Transparent documentation of service work carried out.

▶ Protection against loss or damage of the entries – you receive a complete re-

cord of the work carried out, if required.

▶ Option to receive the record in electronic form.

▶ The vehicle can be serviced in any specialist garage (also abroad) – the data-

base is accessible worldwide.

▶ Increased transparency when purchasing a used vehicle due to entries being

stored centrally.

▶ The system entries support you in making a claim on the ŠKODA extended

warranty and mobility guarantees.

Cleaning and care

Introduction

This chapter contains information on the following subjects:

Car washing

114

Exterior car care

115

Caring for the interior

116

Regular and thorough care helps to retain the value of your vehicle.

The instructions for use on the packaging must be observed when using care

products. We recommend that you use ŠKODA Original Accessories care prod-

ucts.

113Care and maintenance

Page 117 of 172

Exterior car careRead and observe

and on page 114 first.

Vehicle compo- nentsCircumstancesRemedy

Paint

Spilled fuelClear water, cloth, (clean as soon as

possible)No water drop-

lets form on the

paintUse hard wax preserve (at least twice a

year), apply wax to clean and dry bodyPaint has gone

mattUse polish, then wax (if the polish does

not contain any preservative ingredi-

ents)Plastic partsSoilingClear water, cloth / sponge, possibly

cleaners provided for this purposeChrome

and anodised

partsSoilingclear water, cloth, possibly cleaners

provided for this purpose, clean then

polish with a soft dry clothFilmsSoilingSoft sponge and mild soap solution a)Windowpanes

and door mirrorsSoilingWash with clean water and dry with a

wipe specifically for that purposeHead / tail lightsSoilingSoft sponge and mild soap solution a)Door lock cylin-

dersSnow/iceDe-icing fluid specifically for that pur-

poseWiper / wiper

bladesSoilingWindscreen cleaner, sponge or clothWheelsSoilingClear water, then apply appropriate

substancea)

Mild soap solution = 2 tablespoons of natural soap to 1 litre of lukewarm water.

The jack is maintenance-free. If necessary, the moving parts of the jack should

be lubricated with a suitable lubricant.

Protection of cavities

All the cavities of your vehicle which are at risk from corrosion are protected by

a layer of long-lasting protective wax applied in the factory.

If any small amount of wax flow out of the cavities at high temperatures, these

must be removed with a plastic scraper and the stains cleaned using a petrole-

um cleaner.

Underbody

The underside of your vehicle is already permanently protected by the factory

against chemical and mechanical influences.

We recommend having the protective coating — preferably before the begin-

ning of winter and at the end of winter.

Product life of the films

Environmental influences (eg. sunlight, humidity, air pollution, chipping) will af-

fect the life of the films. Films will age and become brittle - this is entirely nor-

mal; this is not a fault.

The sunlight may also affect the strength of the film colour.

When transporting a load on the roof rack (e.g. roof box or similar) there is an

increased risk of film damage (e.g. of chipping from the secured load).

CAUTION

■ Vehicle paint

■ Repair damaged areas as soon as possible.

■ Matt-painted parts should not be treated with polishes or hard waxes.

■ Do not polish in a dusty environment - risk of paint scratches.

■ Do not apply any paint care products to door seals or window guides.■

Plastic parts

■ Do not use paint polish.

■

Chromed and anodised parts

■ Do not polish in a dusty environment - risk of surface scratches.

■

Films

The following instructions must be observed, otherwise there is a risk of film

damage. ■ Do not use dirty cloths or sponges for cleaning.

■ Do not use a scraper or other means to remove ice and snow.

■ Do not polish the films

■ Do not use a high pressure cleaner on the films.

■

Rubber seals

■ Do not treat the door seals and window guides deal with anything - the

protective varnish coating could be damaged.

115Care and maintenance

Page 124 of 172

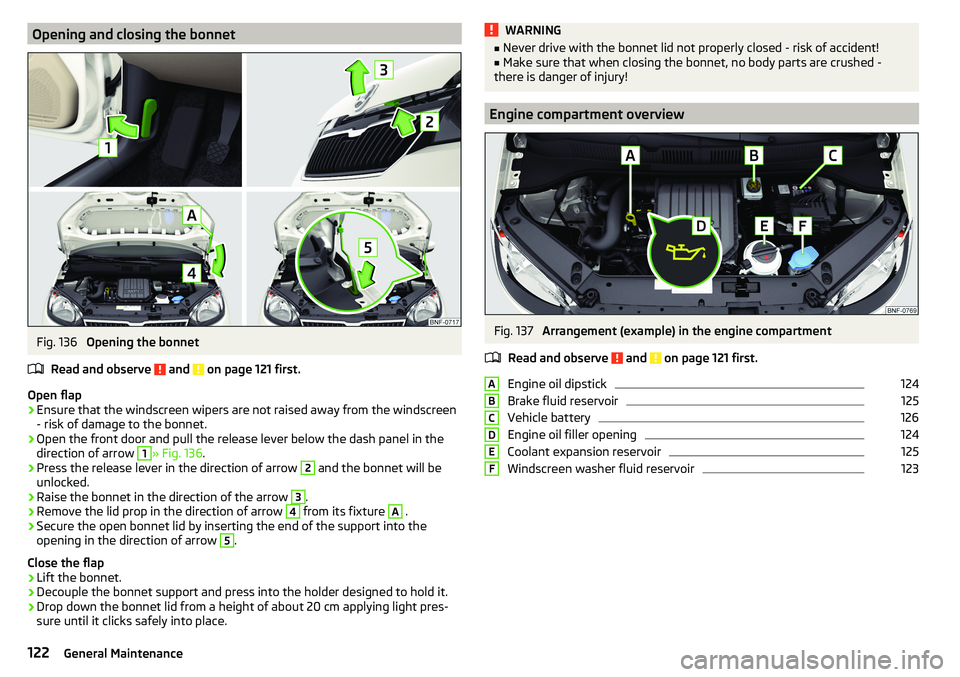

Opening and closing the bonnetFig. 136

Opening the bonnet

Read and observe

and on page 121 first.

Open flap

›

Ensure that the windscreen wipers are not raised away from the windscreen

- risk of damage to the bonnet.

›

Open the front door and pull the release lever below the dash panel in the

direction of arrow

1

» Fig. 136 .

›

Press the release lever in the direction of arrow

2

and the bonnet will be

unlocked.

›

Raise the bonnet in the direction of the arrow

3

.

›

Remove the lid prop in the direction of arrow

4

from its fixture

A

.

›

Secure the open bonnet lid by inserting the end of the support into the

opening in the direction of arrow

5

.

Close the flap

›

Lift the bonnet.

›

Decouple the bonnet support and press into the holder designed to hold it.

›

Drop down the bonnet lid from a height of about 20 cm applying light pres-

sure until it clicks safely into place.

WARNING■ Never drive with the bonnet lid not properly closed - risk of accident!■Make sure that when closing the bonnet, no body parts are crushed -

there is danger of injury!

Engine compartment overview

Fig. 137

Arrangement (example) in the engine compartment

Read and observe

and on page 121 first.

Engine oil dipstick

124

Brake fluid reservoir

125

Vehicle battery

126

Engine oil filler opening

124

Coolant expansion reservoir

125

Windscreen washer fluid reservoir

123ABCDEF122General Maintenance

Page 135 of 172

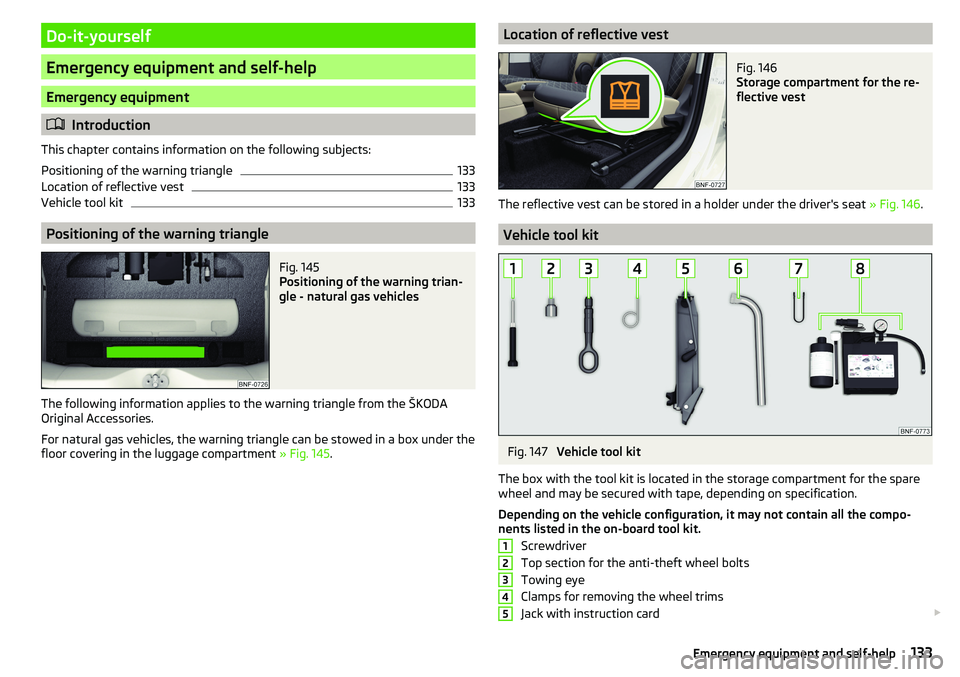

Do-it-yourself

Emergency equipment and self-help

Emergency equipment

Introduction

This chapter contains information on the following subjects:

Positioning of the warning triangle

133

Location of reflective vest

133

Vehicle tool kit

133

Positioning of the warning triangle

Fig. 145

Positioning of the warning trian-

gle - natural gas vehicles

The following information applies to the warning triangle from the ŠKODA

Original Accessories.

For natural gas vehicles, the warning triangle can be stowed in a box under the

floor covering in the luggage compartment » Fig. 145.

Location of reflective vestFig. 146

Storage compartment for the re-

flective vest

The reflective vest can be stored in a holder under the driver's seat » Fig. 146.

Vehicle tool kit

Fig. 147

Vehicle tool kit

The box with the tool kit is located in the storage compartment for the spare

wheel and may be secured with tape, depending on specification.

Depending on the vehicle configuration, it may not contain all the compo-

nents listed in the on-board tool kit.

Screwdriver

Top section for the anti-theft wheel bolts

Towing eye

Clamps for removing the wheel trims

Jack with instruction card

12345133Emergency equipment and self-help