change time SKODA CITIGO 2017 User Guide

[x] Cancel search | Manufacturer: SKODA, Model Year: 2017, Model line: CITIGO, Model: SKODA CITIGO 2017Pages: 172, PDF Size: 24.54 MB

Page 125 of 172

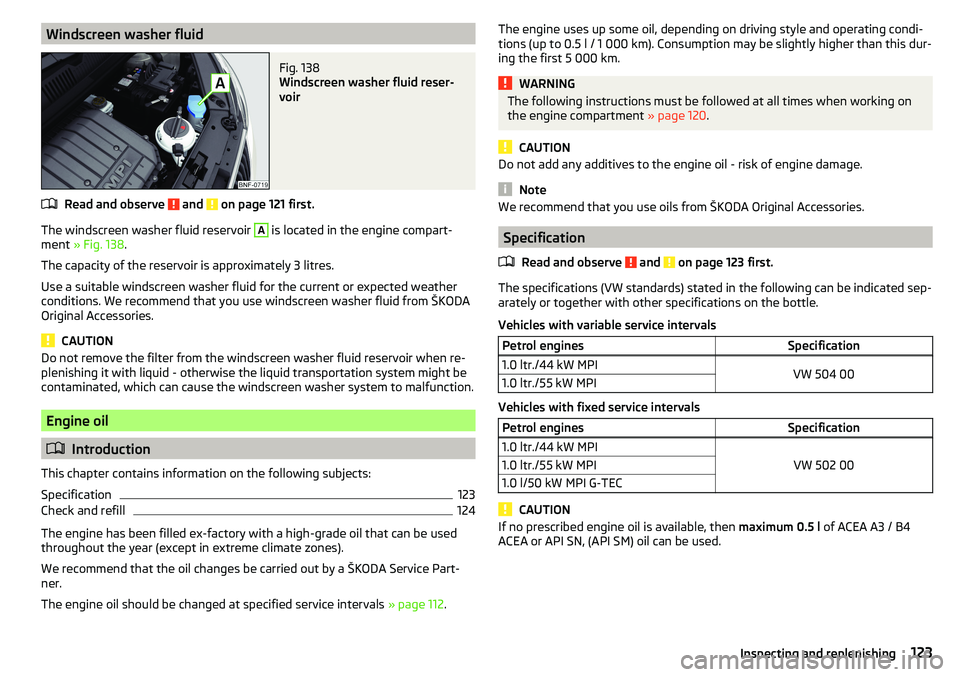

Windscreen washer fluidFig. 138

Windscreen washer fluid reser-

voir

Read and observe and on page 121 first.

The windscreen washer fluid reservoir

A

is located in the engine compart-

ment » Fig. 138 .

The capacity of the reservoir is approximately 3 litres.

Use a suitable windscreen washer fluid for the current or expected weather

conditions. We recommend that you use windscreen washer fluid from ŠKODA

Original Accessories.

CAUTION

Do not remove the filter from the windscreen washer fluid reservoir when re-

plenishing it with liquid - otherwise the liquid transportation system might be

contaminated, which can cause the windscreen washer system to malfunction.

Engine oil

Introduction

This chapter contains information on the following subjects:

Specification

123

Check and refill

124

The engine has been filled ex-factory with a high-grade oil that can be used

throughout the year (except in extreme climate zones).

We recommend that the oil changes be carried out by a ŠKODA Service Part-

ner.

The engine oil should be changed at specified service intervals » page 112.

The engine uses up some oil, depending on driving style and operating condi-

tions (up to 0.5 l / 1 000 km). Consumption may be slightly higher than this dur-

ing the first 5 000 km.WARNINGThe following instructions must be followed at all times when working on

the engine compartment » page 120.

CAUTION

Do not add any additives to the engine oil - risk of engine damage.

Note

We recommend that you use oils from ŠKODA Original Accessories.

Specification

Read and observe

and on page 123 first.

The specifications (VW standards) stated in the following can be indicated sep-arately or together with other specifications on the bottle.

Vehicles with variable service intervals

Petrol enginesSpecification1.0 ltr./44 kW MPIVW 504 001.0 ltr./55 kW MPI

Vehicles with fixed service intervals

Petrol enginesSpecification1.0 ltr./44 kW MPI

VW 502 00

1.0 ltr./55 kW MPI1.0 l/50 kW MPI G-TEC

CAUTION

If no prescribed engine oil is available, then maximum 0.5 l of ACEA A3 / B4

ACEA or API SN, (API SM) oil can be used.123Inspecting and replenishing

Page 128 of 172

Specification - The brake fluid must comply with the standard VW 501 14 (this

standard meets the requirements of FMVSS 116 DOT4).WARNING■ The following instructions must be followed at all times when working on

the engine compartment » page 120.■

If the fluid level drops significantly within a short time or if it drops below

the “MIN” » Fig. 141mark, this may be an indication of a leak in the brake

system.

Stop driving - There is a risk of an accident! Seek help from a

specialist garage.

Note

■ The brake fluid is changed as part of a compulsory inspection service.■A low brake fluid level is indicated by the warning light in the instrument

cluster » page 32 ,

Braking system . We still recommend inspecting the brake

fluid level in the reservoir from time to time.

Vehicle battery

Introduction

This chapter contains information on the following subjects:

Checking the battery condition

127

Charging

127

Disconnect/reconnect and change

127

The vehicle battery represents a power source for the motor to start and for

the supply of electrical consumers in the car.

Automatic shutdown of consumers - vehicle battery discharge protection

The on-board power supply system tries to prevent the vehicle battery from

discharging in the following ways when it is subject to heavy loading. ▶ By increasing the engine idle speed.

▶ Through the power limitation of certain consumers.

▶ By switching off some consumers (heated seats, heated rear window) for as

long as necessary.

Warning symbols on the vehicle batterySymbolImportanceAlways wear eye protection.Battery acid is severely caustic. Always wear gloves and eye pro-

tection.Keep fire, sparks, open flames and lit cigarettes well clear of the

vehicle battery.When charging the vehicle battery, a highly explosive gas mixture

is produced.Keep children away from the vehicle battery.WARNINGBattery acid is highly corrosive - it can cause injury, chemical burns or poi-

soning! Corrosive vapours in the air irritate and damage the respiratory

tract and the eyes. The following guidelines must be observed.■

Always wear protective gloves, eye and skin protection when handling

the vehicle battery.

■

If your eyes or skin come into contact with the electrolytic fluid, immedi-

ately wash the affected area for a few minutes with a lot of water. Get

medical assistance without delay.

■

Keep the vehicle battery away from people who are not completely inde-

pendent (e.g. children).

■

Do not tilt the battery otherwise battery electrolyte may flow out of the

battery vent openings.

WARNINGWorking on the car battery may cause explosion, fire, injury or chemical

burn! The following guidelines must be observed.■

Do not smoke, use open flames or light or transmitting devices.

■

A discharged vehicle battery may freeze slightly. Never charge up a fro-

zen or thawed vehicle battery. Replace a frozen vehicle battery.

■

Never use a damaged vehicle battery.

■

Do not connect the battery terminals, bridging the two poles will cause a

short circuit.

126General Maintenance

Page 130 of 172

›To

disconnect , switch off the ignition and disconnect the negative terminal

first , then disconnect the positive terminal .›

When reconnecting the battery, reconnect the positive terminal first

, then

connect the negative terminal

.

If the battery is disconnected and reconnected, it is possible that the time dis-

play is reset » page 37.

CAUTION

■

Disconnect the battery only with the ignition and consumers turned off - risk

of damaging the electrical system of the vehicle.■

Before disconnecting the battery, always close the power windows and the

tilt/slide sunroof - otherwise the electrics for these may malfunction.

■

Under no circumstances mix up the charging cables – risk of fire.

Note

After disconnecting and reconnecting the vehicle battery, we recommend hav-

ing the vehicle checked by a specialist to ensure that the full functionality of

the vehicle is guaranteed.Wheels

Wheels and tyres

Introduction

This chapter contains information on the following subjects:

Advice on tyre/wheel usage

128

Tyre pressure

129

Tyre wear and wheel change

130

Spare wheel

130

Spare wheel

130

Tyre marking

131

Advice on tyre/wheel usage

During the first 500 km, new tyres do not offer optimum grip; appropriate care

should therefore be taken when driving.

Tyres with the deeper profiles should always be fitted to the front wheels.

Rims and wheel bolts are matched to each other in terms of design. We rec-

ommend that you use rims and wheel bolts from ŠKODA Original Accessories.

Wheels and tyres should always be stored in a cool, dry and dark place. The

tyres themselves should be stored vertically.

Tyre life

Tyres age and lose their original characteristics, even if they are not being

used. We recommend that you do not use tyres that are more than 6 years old.

The manufacturing date is indicated on the tyre sidewall (possibly on the in-

side ). For example, DOT ... 10 16...means, for example, that the tyre was manu-

factured in the 10. week of 2016.

Tyre damage

We recommend checking your tyres and wheel rims for damage (punctures,

cuts, splits and bulges etc.) on a regular basis.

Remove any foreign objects in the tyre’s profile immediately (e.g. small stones).

Foreign bodies which have penetrated into the tyre (e.g. screws or nails)

should not be removed and help should be sought from a specialist garage.

128General Maintenance

Page 131 of 172

Fitting new tyres

Only fit approved radial tyres of the same type, size (rolling circumference) and

the same tread pattern on one axle on all four wheels.

When mounting new tires the tires have to be replaced axle by axle.

Unidirectional tyres

The direction of rotation of the tyres is marked by arrows on the wall of the

tyre .

The specified running direction must be strictly adhered to, otherwise the fol-

lowing tyre characteristics may be degraded. ▶ Driving stability.

▶ Traction.

▶ Tyre noise and tyre wear.WARNING■ Never use tyres if you do not know anything about their condition and

age - risk of accidents.■

Never drive with damaged tyres – risk of accident.

CAUTION

■ The tyres must be protected from contact with substances (e.g. oil, grease

and fuel) which could damage them. If the tyres come into contact with these

substances, then we recommend you have this checked out in a specialist

workshop.■

Do not use rims with ground or polished surfaces in winter conditions - there

is a risk of rim damage (e.g through salt spreading).

Note

■ We recommend that any work on the wheels or tyres be carried out by a spe-

cialist garage.■

We recommend that you use tyres, snow chains and full wheel trims from

ŠKODA Original Accessories.

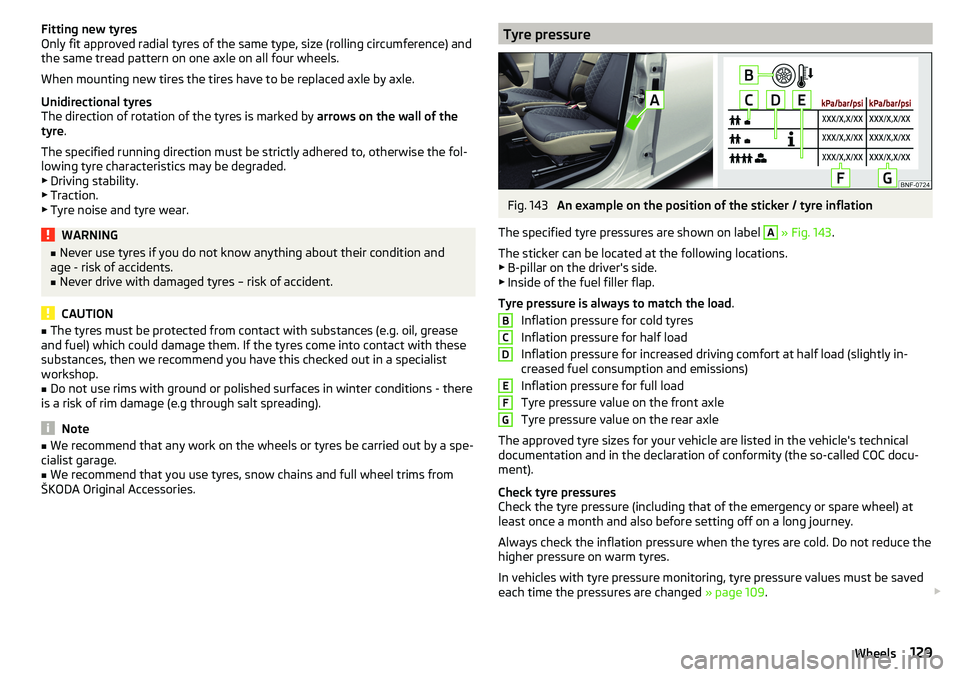

Tyre pressureFig. 143

An example on the position of the sticker / tyre inflation

The specified tyre pressures are shown on label

A

» Fig. 143 .

The sticker can be located at the following locations.

▶ B-pillar on the driver's side.

▶ Inside of the fuel filler flap.

Tyre pressure is always to match the load .

Inflation pressure for cold tyres

Inflation pressure for half load

Inflation pressure for increased driving comfort at half load (slightly in-

creased fuel consumption and emissions)

Inflation pressure for full load

Tyre pressure value on the front axle

Tyre pressure value on the rear axle

The approved tyre sizes for your vehicle are listed in the vehicle's technical

documentation and in the declaration of conformity (the so-called COC docu-

ment).

Check tyre pressures

Check the tyre pressure (including that of the emergency or spare wheel) at

least once a month and also before setting off on a long journey.

Always check the inflation pressure when the tyres are cold. Do not reduce the

higher pressure on warm tyres.

In vehicles with tyre pressure monitoring, tyre pressure values must be saved

each time the pressures are changed » page 109.

BCDEFG129Wheels

Page 149 of 172

No.Consumer3Radio4DC-DC voltage converter, motor starter, bar with buttons5Air conditioning system6Not assigned7Not assigned8Not assigned9Vehicle lighting - right side10Vehicle lighting - left side11Starter12DC-DC voltage converter, ABS, instrument cluster, radio

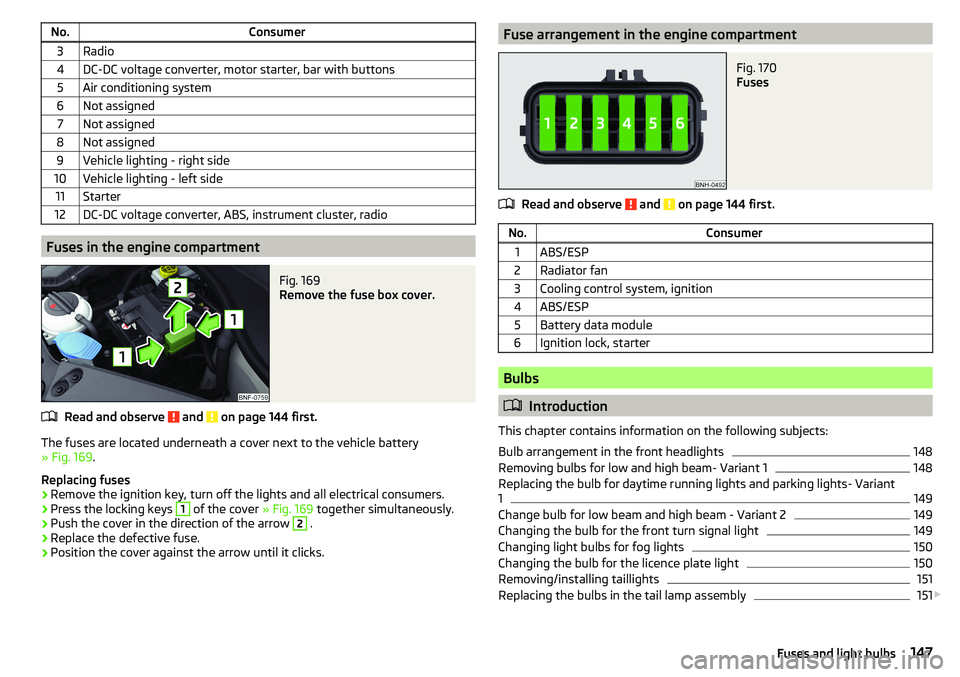

Fuses in the engine compartment

Fig. 169

Remove the fuse box cover.

Read and observe and on page 144 first.

The fuses are located underneath a cover next to the vehicle battery

» Fig. 169 .

Replacing fuses

›

Remove the ignition key, turn off the lights and all electrical consumers.

›

Press the locking keys

1

of the cover » Fig. 169 together simultaneously.

›

Push the cover in the direction of the arrow

2

.

›

Replace the defective fuse.

›

Position the cover against the arrow until it clicks.

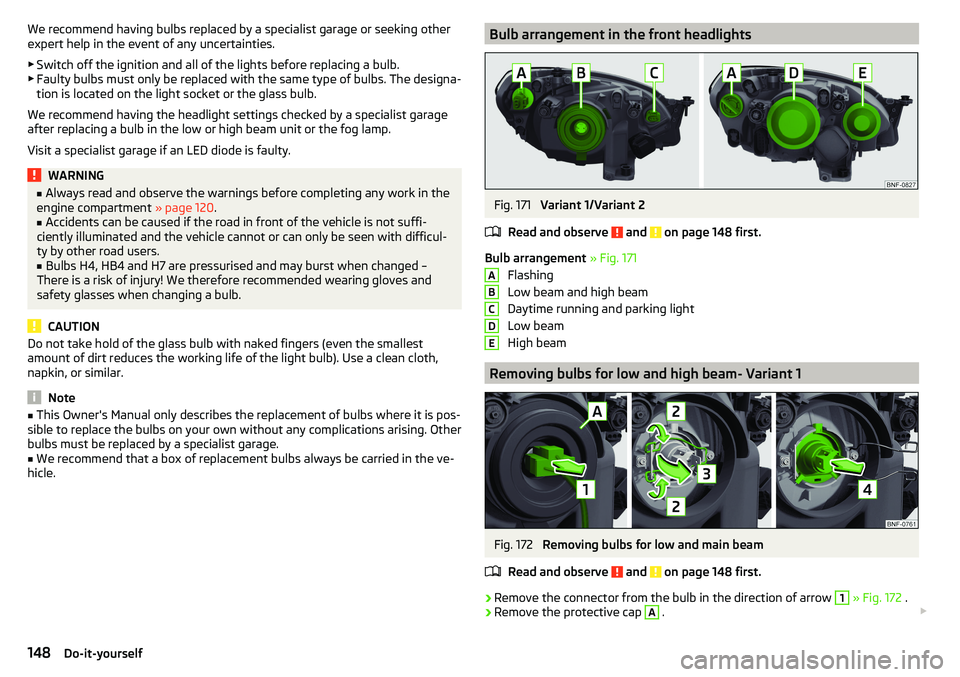

Fuse arrangement in the engine compartmentFig. 170

Fuses

Read and observe and on page 144 first.

No.Consumer1ABS/ESP2Radiator fan3Cooling control system, ignition4ABS/ESP5Battery data module6Ignition lock, starter

Bulbs

Introduction

This chapter contains information on the following subjects:

Bulb arrangement in the front headlights

148

Removing bulbs for low and high beam- Variant 1

148

Replacing the bulb for daytime running lights and parking lights- Variant

1

149

Change bulb for low beam and high beam - Variant 2

149

Changing the bulb for the front turn signal light

149

Changing light bulbs for fog lights

150

Changing the bulb for the licence plate light

150

Removing/installing taillights

151

Replacing the bulbs in the tail lamp assembly

151

147Fuses and light bulbs

Page 150 of 172

We recommend having bulbs replaced by a specialist garage or seeking other

expert help in the event of any uncertainties.

▶ Switch off the ignition and all of the lights before replacing a bulb.

▶ Faulty bulbs must only be replaced with the same type of bulbs. The designa-

tion is located on the light socket or the glass bulb.

We recommend having the headlight settings checked by a specialist garage after replacing a bulb in the low or high beam unit or the fog lamp.

Visit a specialist garage if an LED diode is faulty.WARNING■ Always read and observe the warnings before completing any work in the

engine compartment » page 120.■

Accidents can be caused if the road in front of the vehicle is not suffi-

ciently illuminated and the vehicle cannot or can only be seen with difficul-

ty by other road users.

■

Bulbs H4, HB4 and H7 are pressurised and may burst when changed –

There is a risk of injury! We therefore recommended wearing gloves and

safety glasses when changing a bulb.

CAUTION

Do not take hold of the glass bulb with naked fingers (even the smallest

amount of dirt reduces the working life of the light bulb). Use a clean cloth,

napkin, or similar.

Note

■ This Owner's Manual only describes the replacement of bulbs where it is pos-

sible to replace the bulbs on your own without any complications arising. Other

bulbs must be replaced by a specialist garage.■

We recommend that a box of replacement bulbs always be carried in the ve-

hicle.

Bulb arrangement in the front headlightsFig. 171

Variant 1/Variant 2

Read and observe

and on page 148 first.

Bulb arrangement » Fig. 171

Flashing

Low beam and high beam

Daytime running and parking light

Low beam

High beam

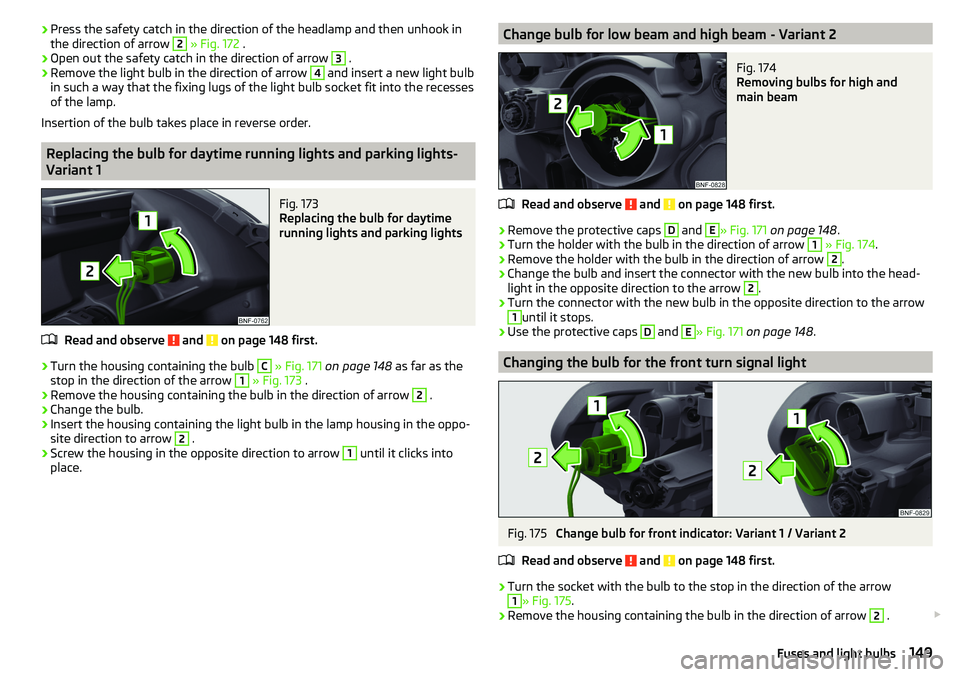

Removing bulbs for low and high beam- Variant 1

Fig. 172

Removing bulbs for low and main beam

Read and observe

and on page 148 first.

›

Remove the connector from the bulb in the direction of arrow

1

» Fig. 172 .

›

Remove the protective cap

A

.

ABCDE148Do-it-yourself

Page 151 of 172

›Press the safety catch in the direction of the headlamp and then unhook in

the direction of arrow 2 » Fig. 172 .›

Open out the safety catch in the direction of arrow

3

.

›

Remove the light bulb in the direction of arrow

4

and insert a new light bulb

in such a way that the fixing lugs of the light bulb socket fit into the recesses

of the lamp.

Insertion of the bulb takes place in reverse order.

Replacing the bulb for daytime running lights and parking lights-

Variant 1

Fig. 173

Replacing the bulb for daytime

running lights and parking lights

Read and observe and on page 148 first.

›

Turn the housing containing the bulb

C

» Fig. 171 on page 148 as far as the

stop in the direction of the arrow

1

» Fig. 173 .

›

Remove the housing containing the bulb in the direction of arrow

2

.

›

Change the bulb.

›

Insert the housing containing the light bulb in the lamp housing in the oppo-

site direction to arrow

2

.

›

Screw the housing in the opposite direction to arrow

1

until it clicks into

place.

Change bulb for low beam and high beam - Variant 2Fig. 174

Removing bulbs for high and

main beam

Read and observe and on page 148 first.

›

Remove the protective caps

D

and

E

» Fig. 171 on page 148 .

›

Turn the holder with the bulb in the direction of arrow

1

» Fig. 174 .

›

Remove the holder with the bulb in the direction of arrow

2

.

›

Change the bulb and insert the connector with the new bulb into the head-

light in the opposite direction to the arrow

2

.

›

Turn the connector with the new bulb in the opposite direction to the arrow

1

until it stops.

›

Use the protective caps

D

and

E

» Fig. 171 on page 148 .

Changing the bulb for the front turn signal light

Fig. 175

Change bulb for front indicator: Variant 1 / Variant 2

Read and observe

and on page 148 first.

›

Turn the socket with the bulb to the stop in the direction of the arrow

1

» Fig. 175 .

›

Remove the housing containing the bulb in the direction of arrow

2

.

149Fuses and light bulbs