manual transmission SKODA CITIGO 2017 User Guide

[x] Cancel search | Manufacturer: SKODA, Model Year: 2017, Model line: CITIGO, Model: SKODA CITIGO 2017Pages: 172, PDF Size: 24.54 MB

Page 136 of 172

Wheel wrench

Extraction pliers for the wheel bolt caps

Breakdown kitWARNING■ The factory-supplied lifting jack is only intended for your model of vehicle.

Under no circumstances attempt to lift other vehicles or loads with it –

there is a risk of injury.■

Always stow the tool safely in the box and make sure that it is attached

with the belt to the spare wheel - otherwise it could cause injury to the oc-

cupants if breaking suddenly or colliding with another vehicle.

CAUTION

Screw the jack back to its starting position prior to putting it back in its box -

risk of damage to the box.

Note

The declaration of conformity is included with the jack or the log folder.

Changing a wheel

Preliminary work

For safety's sake, the following instructions must be observed before

changing a wheel on the road.

›

As far as possible park the vehicle as far as possible away from the traffic

flow - choose a place with a flat and firm surface.

›

Switch off the engine.

›

For vehicles with manual transmission select 1st gear .

›

For vehicles with

automated transmission shift the lever to position D or R.

›

Firmly apply the handbrake.

›

Switch on the hazard warning lights and set up the warning triangle at the

prescribed distance.

›

Have all the occupants get out . The passengers should not stand on the

road while the wheel is being changed (they should remain behind a crash

barrier, for instance).

Changing a wheel

›

Take out the emergency or spare wheel » page 135.

›

Remove the full wheel trim » page 135 or caps » page 135 .

678›Loosen the wheel bolts

» page 136 » .›Jack up the vehicle until the wheel that needs changing, is clear of the

ground » page 136 .›

Unscrew the wheel bolts and place them on a clean surface (cloth, paper,

etc.).

›

Remove the wheel carefully.

›

Attach the spare wheel and slightly screw on the wheel bolts.

›

Lower the vehicle.

›

Tighten the wheel bolts opposite each other using the wheel wrench (“pull- ing crossways”) » page 136.

›

Replace the wheel trim » page 135 and caps » page 135 .

When fitting unidirectional tyres, ensure that the direction of rotation is cor-

rect » page 129 .

All bolts must be clean and must turn easily. If screws are corroded and diffi-

cult to move, these must be replaced.

WARNING■ Undo the wheel bolts just a little (about one turn), provided the vehicle

has not yet been jacked up. Otherwise the wheel could come loose and fall

off – risk of injury.■

Under no circumstances must the bolts be greased or oiled - cause an ac-

cident.

Subsequent steps

After changing the wheel, the following work must be carried out.

›

Stow the replaced wheel in the well under the floor covering of the luggage

compartment and secure it with a nut.

›

Stow the tool kit in the space provided and secure using the band.

›

Check tyre pressure on the mounted wheel and adjust if necessary and, with

vehicles with tyre pressure monitoring, save the tyre pressure values in the

system » page 109 .

›

Have the tightening torque of the wheel bolts checked as soon as possible.

The prescribed tightening torque is 110 Nm.

Replace the damaged wheel or consult a specialist garage about repair op-

tions.

134Do-it-yourself

Page 140 of 172

Description of the breakdown kitFig. 154

Description of the breakdown kit

Read and observe

on page 137 first.

The kit is located in a box under the floor covering in the luggage compart-

ment.

Sticker with speed designation “max. 80 km/h”/“max. 50 mph”Valve remover

Inflation hose with plug

12 volt cable connector

Tyre inflation pressure indicator

Screw for tyre pressure reduction

Air compressor (the layout of the controls may be different depending on

the type of air compressor delivered with the vehicle)

Tyre inflation hose

ON and OFF switch

Tyre inflator bottle with sealing agent

Replacement valve core

Note

The declaration of conformity is included with the air compressor or the log

folder.1234567891011Preparing to use the breakdown kit

Read and observe

on page 137 first.

For safety's sake, the following instructions must be observed before

undertaking a wheel repair on a road.

›

Park the vehicle as far as possible away from the traffic flow - choose a place

with a flat and firm surface.

›

Switch off the engine.

›

For vehicles with manual transmission select 1st gear .

›

For vehicles with automated transmission shift the lever to position D or R.

›

Firmly apply the handbrake.

›

Switch on the hazard warning lights and set up the warning triangle at the

prescribed distance.

›

Have all the occupants get out . While the repair is being carried out, the pas-

sengers should not stand on the road (instead they should remain behind a

crash barrier, for instance).

Sealing and inflating tyres

Read and observe

on page 137 first.

Sealing

›

Unscrew the valve cap from the damaged tyre.

›

Insert the valve remover

2

» Fig. 154 on page 138 on the valve insert, so that

the valve insert fits into the slot of the valve remover.

›

Unscrew the valve insert and place it on a clean base (rag, paper etc.).

›

Forcefully shake bottle

10

» Fig. 154 on page 138 several times.

›

Firmly screw the inflation hose

3

onto the tyre inflater bottle

10

. The film

on the bottle cap is pierced.

›

Remove the plug from the inflation hose

3

and insert the bottle onto the

tyre valve.

›

Hold the bottle

10

with the bottom facing upwards and fill all of the sealing

agent from the tyre inflator bottle into the tyre.

›

Remove the filler plug from the tyre valve.

›

Screw in the valve insert with the valve remover

2

.

Inflating

›

Screw the tyre inflation hose

8

» Fig. 154 on page 138 firmly onto the tyre

valve.

›

For vehicles with manual transmission set the gearshift lever to the neutral

position.

138Do-it-yourself

Page 141 of 172

›For vehicles with

automated manual transmission leave the selector lever in

position N.›

Check that the screw for the tire pressure reduction

6

is closed.

›

Start the engine.

›

Plug the connector

4

into 12 volt socket » page 63, 12-volt socket .

›

Switch on the air compressor with the ON and OFF switch

9

.

›

Once tyre inflation pressure of 2.0-2.5 bar has been reached, turn off the air

compressor. Maximum run time of 6 minutes » .

›

If you cannot reach an air pressure of 2.0 - 2.5 bar, unscrew the tyre inflation

hose

8

from the tyre valve.

›

Drive the vehicle 10 metres forwards or backwards to allow the sealing agent

to “distribute” in the tyre.

›

Firmly screw the tyre inflation hose

8

back onto the tyre valve and repeat

the inflation process.

›

Stick the sticker

1

» Fig. 154 on page 138 on the dash panel in the driver's

field of view.

At a tyre inflation pressure of 2.0 – 2.5 bar, the journey can be continued at a maximum speed of 80 km/h or 50 mph.

WARNING■ If the tire does not inflate at least. 2.0 bar, the damage is too great. The

sealing agent cannot be used to seal the tyre. Stop driving! Seek help

from a specialist garage.■

The tyre inflation hose and air compressor may get hot as the tyre is be-

ing inflated – risk of burning.

CAUTION

Switch off the air compressor if it has been running for as much as 6 minutes –

risk of damage to the compressor! Allow the air compressor to cool a few mi-

nutes before switching it on again.

Information on driving with repaired tyres

Read and observe

on page 137 first.

The inflation pressure of the repaired tyre must be checked after driving for 10minutes.

If the tyre pressure is 1.3 bar or less

›

The tyre cannot be properly sealed with the breakdown kit.

Do not contin-

ue to drive! Seek help from a specialist garage.

If the tyre pressure is 1.3 bar or more›Set the tyre pressure back to the correct value » page 129.›

Continue driving carefully to the nearest specialist garage at a maximum

speed of 80 km/h (50 mph).

WARNINGA tyre filled with sealant has the same driving characteristics as a standard

tyre. The following guidelines must therefore be observed.■

Do not drive faster than 80 km/h (50 mph).

■

Avoid accelerating at full throttle, sharp braking and fast cornering.

Jump-starting

Introduction

This chapter contains information on the following subjects:

Jump-starting using the battery from another vehicle

140WARNING■ The following instructions must be followed at all times when working on

the engine compartment » page 120.■

When handling the vehicle battery, the following warnings must be ob-

served » page 126 .

■

A discharged vehicle battery may already freeze at temperatures just be-

low 0 °C. If the battery is frozen, do not carry out a jump start with the bat-

tery of another vehicle – risk of explosion and injury!

■

Never jump-start vehicle batteries with an electrolyte level that is too low

– risk of explosion and caustic burns.

139Emergency equipment and self-help

Page 142 of 172

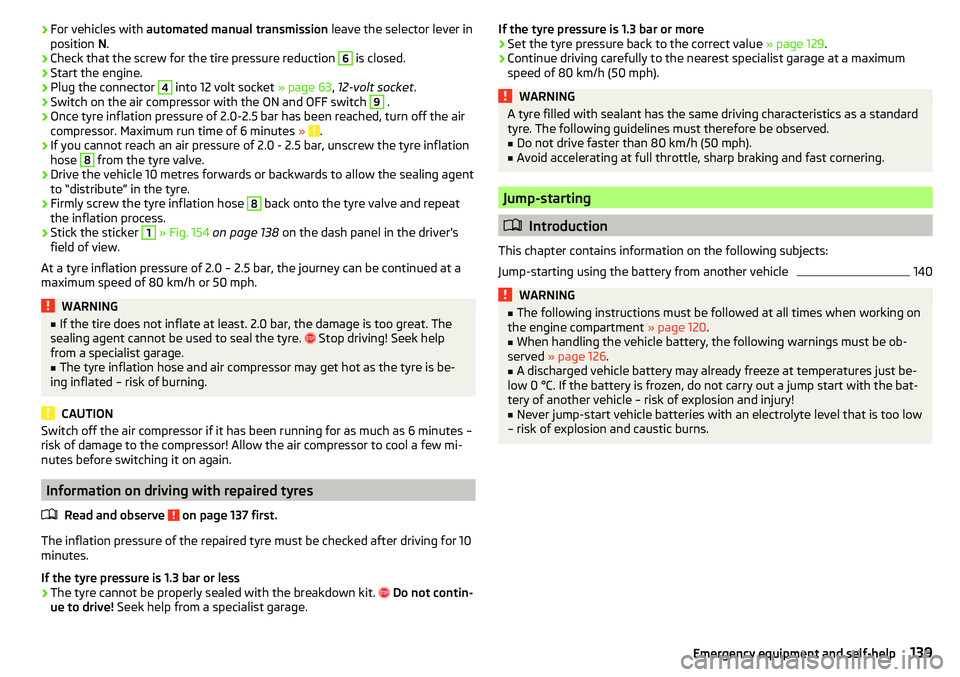

Jump-starting using the battery from another vehicleFig. 155

Jump-starting:

- Discharged battery,

- power-supplying bat-

tery / ground point of the engine for the START-STOP system

Read and observe

on page 139 first.

If, because of a discharged battery, it is not possible to start the engine, the

battery of another vehicle can be used to start the engine. To do this, jump-

start cables are required which have a sufficiently large cross-section and in-

sulated terminal clamps.

The rated voltage of the two batteries must be 12 V. The capacity (Ah) of the

power-supplying battery must not be significantly lower than the capacity of

the discharged battery. Otherwise, the vehicle may not start with the dis-

charged battery.

The jump-start cables must be attached in the following sequence.

›

Attach clamp

1

to the positive terminal of the discharged battery.

›

Attach clamp

2

to the positive terminal of the power-supplying battery.

›

Attach clamp

3

to the negative terminal of the power-supplying battery.

›

For vehicles with the START-STOPsystem, attach clamp

4

to the ground

point of the engine

A

» Fig. 155 .

›

For vehicles without the START-STOPsystem, attach clamp

4

to a solid

metal part firmly attached to the engine block or directly to the engine block.

Starting engine

›

Start the engine on the vehicle providing the power and allow it to idle.

›

Initiate the starting process in the vehicle with the discharged battery.

›

If the engine does not start within 10 s, then cancel the starting procedure

and repeat after half a minute.

›

Remove the jump start cables in the reverse order as attachment.

WARNING■

Never clamp the jump cable to the negative terminal of the discharged

battery - risk of explosion.■

The non-insulated parts of the terminal clamps must never touch each

other – there is a risk of short circuit.

■

The jump-start cable connected to the positive terminal of the battery

must not come into contact with electrically conducting parts of the vehicle

– there is a risk of short circuit.

■

Position the jump cables so that they cannot be caught in rotating parts

in the engine compartment - danger of injuries and the risk of vehicle dam-

age.

Towing the vehicle

Information about the towing process

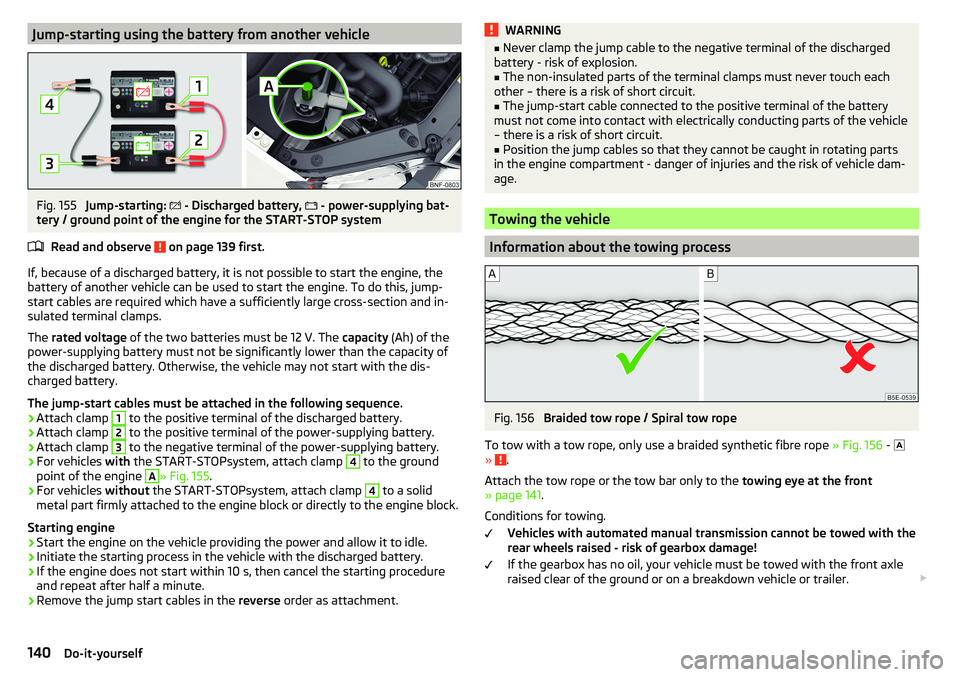

Fig. 156

Braided tow rope / Spiral tow rope

To tow with a tow rope, only use a braided synthetic fibre rope » Fig. 156 -

»

.

Attach the tow rope or the tow bar only to the towing eye at the front

» page 141 .

Conditions for towing. Vehicles with automated manual transmission cannot be towed with the

rear wheels raised - risk of gearbox damage!

If the gearbox has no oil, your vehicle must be towed with the front axle

raised clear of the ground or on a breakdown vehicle or trailer.

140Do-it-yourself

Page 159 of 172

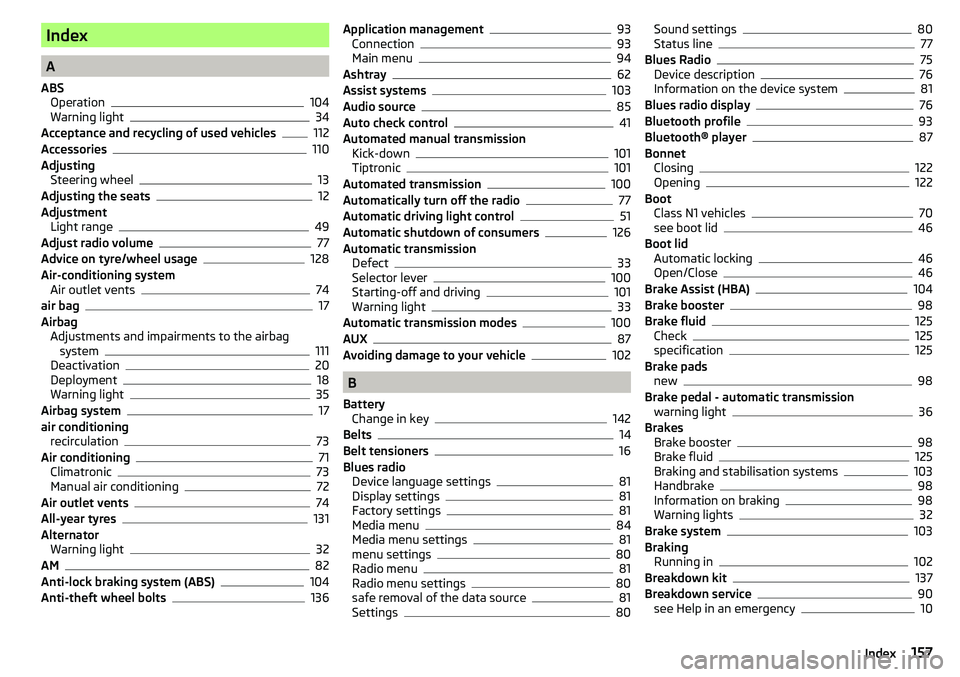

Index

A

ABS Operation

104

Warning light34

Acceptance and recycling of used vehicles

112

Accessories110

Adjusting Steering wheel

13

Adjusting the seats12

Adjustment Light range

49

Adjust radio volume77

Advice on tyre/wheel usage128

Air-conditioning system Air outlet vents

74

air bag17

Airbag Adjustments and impairments to the airbagsystem

111

Deactivation20

Deployment18

Warning light35

Airbag system17

air conditioning recirculation

73

Air conditioning71

Climatronic73

Manual air conditioning72

Air outlet vents74

All-year tyres131

Alternator Warning light

32

AM82

Anti-lock braking system (ABS)104

Anti-theft wheel bolts136

Application management93

Connection93

Main menu94

Ashtray62

Assist systems103

Audio source85

Auto check control41

Automated manual transmission Kick-down

101

Tiptronic101

Automated transmission100

Automatically turn off the radio77

Automatic driving light control51

Automatic shutdown of consumers126

Automatic transmission Defect

33

Selector lever100

Starting-off and driving101

Warning light33

Automatic transmission modes100

AUX87

Avoiding damage to your vehicle102

B

Battery Change in key

142

Belts14

Belt tensioners16

Blues radio Device language settings

81

Display settings81

Factory settings81

Media menu84

Media menu settings81

menu settings80

Radio menu81

Radio menu settings80

safe removal of the data source81

Settings80

Sound settings80

Status line77

Blues Radio75

Device description76

Information on the device system81

Blues radio display76

Bluetooth profile93

Bluetooth® player87

Bonnet Closing

122

Opening122

Boot Class N1 vehicles

70

see boot lid46

Boot lid Automatic locking

46

Open/Close46

Brake Assist (HBA)104

Brake booster98

Brake fluid125

Check125

specification125

Brake pads new

98

Brake pedal - automatic transmission warning light

36

Brakes Brake booster

98

Brake fluid125

Braking and stabilisation systems103

Handbrake98

Information on braking98

Warning lights32

Brake system103

Braking Running in

102

Breakdown kit137

Breakdown service90

see Help in an emergency10

157Index