light SKODA CITIGO 2017 Repair Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 2017, Model line: CITIGO, Model: SKODA CITIGO 2017Pages: 172, PDF Size: 24.54 MB

Page 131 of 172

Fitting new tyres

Only fit approved radial tyres of the same type, size (rolling circumference) and

the same tread pattern on one axle on all four wheels.

When mounting new tires the tires have to be replaced axle by axle.

Unidirectional tyres

The direction of rotation of the tyres is marked by arrows on the wall of the

tyre .

The specified running direction must be strictly adhered to, otherwise the fol-

lowing tyre characteristics may be degraded. ▶ Driving stability.

▶ Traction.

▶ Tyre noise and tyre wear.WARNING■ Never use tyres if you do not know anything about their condition and

age - risk of accidents.■

Never drive with damaged tyres – risk of accident.

CAUTION

■ The tyres must be protected from contact with substances (e.g. oil, grease

and fuel) which could damage them. If the tyres come into contact with these

substances, then we recommend you have this checked out in a specialist

workshop.■

Do not use rims with ground or polished surfaces in winter conditions - there

is a risk of rim damage (e.g through salt spreading).

Note

■ We recommend that any work on the wheels or tyres be carried out by a spe-

cialist garage.■

We recommend that you use tyres, snow chains and full wheel trims from

ŠKODA Original Accessories.

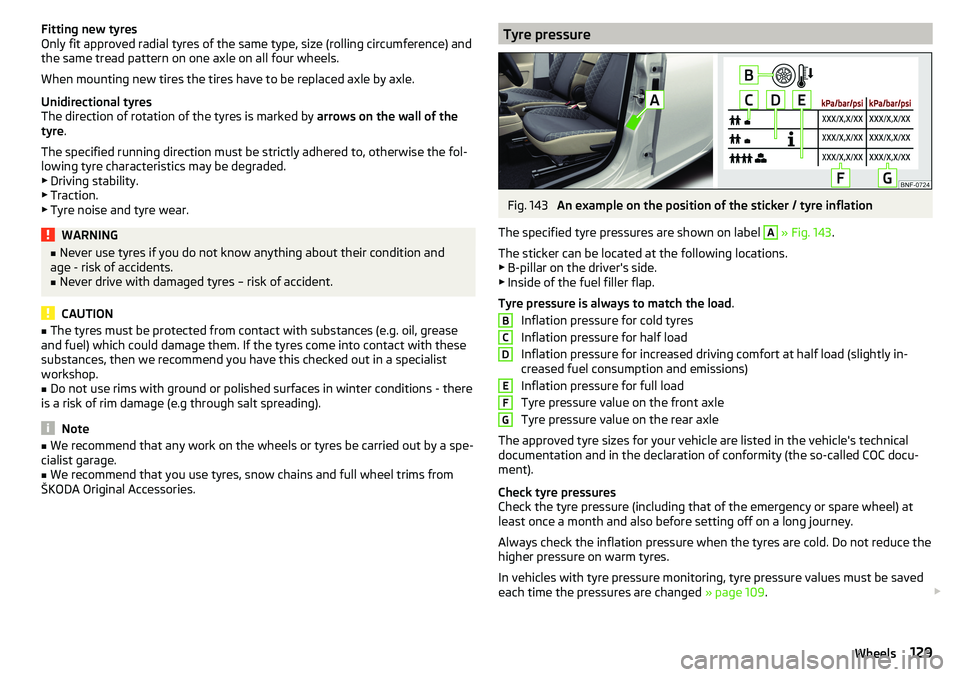

Tyre pressureFig. 143

An example on the position of the sticker / tyre inflation

The specified tyre pressures are shown on label

A

» Fig. 143 .

The sticker can be located at the following locations.

▶ B-pillar on the driver's side.

▶ Inside of the fuel filler flap.

Tyre pressure is always to match the load .

Inflation pressure for cold tyres

Inflation pressure for half load

Inflation pressure for increased driving comfort at half load (slightly in-

creased fuel consumption and emissions)

Inflation pressure for full load

Tyre pressure value on the front axle

Tyre pressure value on the rear axle

The approved tyre sizes for your vehicle are listed in the vehicle's technical

documentation and in the declaration of conformity (the so-called COC docu-

ment).

Check tyre pressures

Check the tyre pressure (including that of the emergency or spare wheel) at

least once a month and also before setting off on a long journey.

Always check the inflation pressure when the tyres are cold. Do not reduce the

higher pressure on warm tyres.

In vehicles with tyre pressure monitoring, tyre pressure values must be saved

each time the pressures are changed » page 109.

BCDEFG129Wheels

Page 136 of 172

Wheel wrench

Extraction pliers for the wheel bolt caps

Breakdown kitWARNING■ The factory-supplied lifting jack is only intended for your model of vehicle.

Under no circumstances attempt to lift other vehicles or loads with it –

there is a risk of injury.■

Always stow the tool safely in the box and make sure that it is attached

with the belt to the spare wheel - otherwise it could cause injury to the oc-

cupants if breaking suddenly or colliding with another vehicle.

CAUTION

Screw the jack back to its starting position prior to putting it back in its box -

risk of damage to the box.

Note

The declaration of conformity is included with the jack or the log folder.

Changing a wheel

Preliminary work

For safety's sake, the following instructions must be observed before

changing a wheel on the road.

›

As far as possible park the vehicle as far as possible away from the traffic

flow - choose a place with a flat and firm surface.

›

Switch off the engine.

›

For vehicles with manual transmission select 1st gear .

›

For vehicles with

automated transmission shift the lever to position D or R.

›

Firmly apply the handbrake.

›

Switch on the hazard warning lights and set up the warning triangle at the

prescribed distance.

›

Have all the occupants get out . The passengers should not stand on the

road while the wheel is being changed (they should remain behind a crash

barrier, for instance).

Changing a wheel

›

Take out the emergency or spare wheel » page 135.

›

Remove the full wheel trim » page 135 or caps » page 135 .

678›Loosen the wheel bolts

» page 136 » .›Jack up the vehicle until the wheel that needs changing, is clear of the

ground » page 136 .›

Unscrew the wheel bolts and place them on a clean surface (cloth, paper,

etc.).

›

Remove the wheel carefully.

›

Attach the spare wheel and slightly screw on the wheel bolts.

›

Lower the vehicle.

›

Tighten the wheel bolts opposite each other using the wheel wrench (“pull- ing crossways”) » page 136.

›

Replace the wheel trim » page 135 and caps » page 135 .

When fitting unidirectional tyres, ensure that the direction of rotation is cor-

rect » page 129 .

All bolts must be clean and must turn easily. If screws are corroded and diffi-

cult to move, these must be replaced.

WARNING■ Undo the wheel bolts just a little (about one turn), provided the vehicle

has not yet been jacked up. Otherwise the wheel could come loose and fall

off – risk of injury.■

Under no circumstances must the bolts be greased or oiled - cause an ac-

cident.

Subsequent steps

After changing the wheel, the following work must be carried out.

›

Stow the replaced wheel in the well under the floor covering of the luggage

compartment and secure it with a nut.

›

Stow the tool kit in the space provided and secure using the band.

›

Check tyre pressure on the mounted wheel and adjust if necessary and, with

vehicles with tyre pressure monitoring, save the tyre pressure values in the

system » page 109 .

›

Have the tightening torque of the wheel bolts checked as soon as possible.

The prescribed tightening torque is 110 Nm.

Replace the damaged wheel or consult a specialist garage about repair op-

tions.

134Do-it-yourself

Page 140 of 172

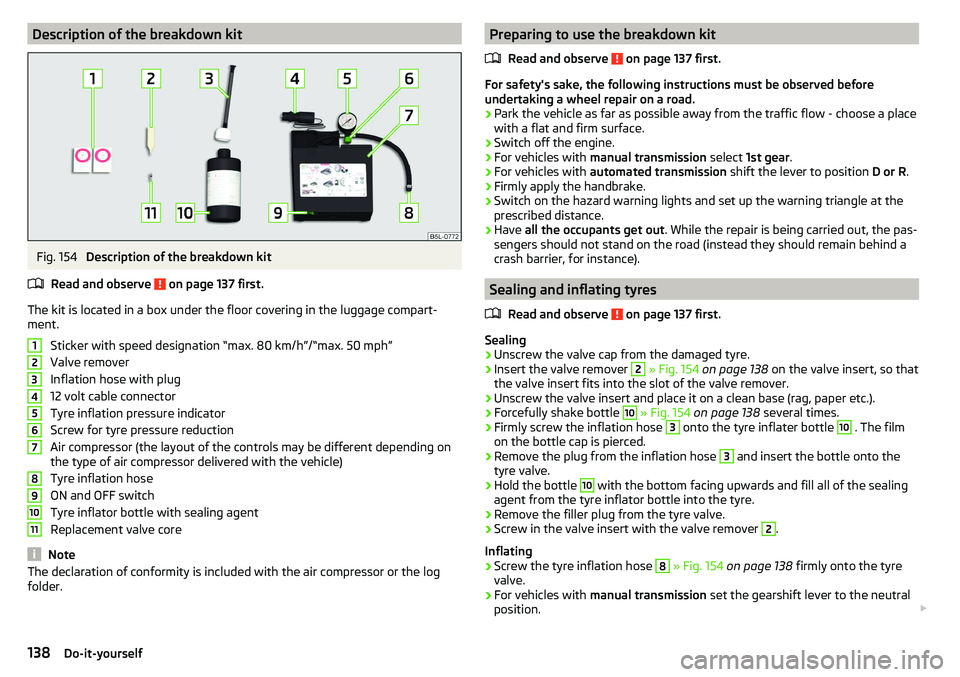

Description of the breakdown kitFig. 154

Description of the breakdown kit

Read and observe

on page 137 first.

The kit is located in a box under the floor covering in the luggage compart-

ment.

Sticker with speed designation “max. 80 km/h”/“max. 50 mph”Valve remover

Inflation hose with plug

12 volt cable connector

Tyre inflation pressure indicator

Screw for tyre pressure reduction

Air compressor (the layout of the controls may be different depending on

the type of air compressor delivered with the vehicle)

Tyre inflation hose

ON and OFF switch

Tyre inflator bottle with sealing agent

Replacement valve core

Note

The declaration of conformity is included with the air compressor or the log

folder.1234567891011Preparing to use the breakdown kit

Read and observe

on page 137 first.

For safety's sake, the following instructions must be observed before

undertaking a wheel repair on a road.

›

Park the vehicle as far as possible away from the traffic flow - choose a place

with a flat and firm surface.

›

Switch off the engine.

›

For vehicles with manual transmission select 1st gear .

›

For vehicles with automated transmission shift the lever to position D or R.

›

Firmly apply the handbrake.

›

Switch on the hazard warning lights and set up the warning triangle at the

prescribed distance.

›

Have all the occupants get out . While the repair is being carried out, the pas-

sengers should not stand on the road (instead they should remain behind a

crash barrier, for instance).

Sealing and inflating tyres

Read and observe

on page 137 first.

Sealing

›

Unscrew the valve cap from the damaged tyre.

›

Insert the valve remover

2

» Fig. 154 on page 138 on the valve insert, so that

the valve insert fits into the slot of the valve remover.

›

Unscrew the valve insert and place it on a clean base (rag, paper etc.).

›

Forcefully shake bottle

10

» Fig. 154 on page 138 several times.

›

Firmly screw the inflation hose

3

onto the tyre inflater bottle

10

. The film

on the bottle cap is pierced.

›

Remove the plug from the inflation hose

3

and insert the bottle onto the

tyre valve.

›

Hold the bottle

10

with the bottom facing upwards and fill all of the sealing

agent from the tyre inflator bottle into the tyre.

›

Remove the filler plug from the tyre valve.

›

Screw in the valve insert with the valve remover

2

.

Inflating

›

Screw the tyre inflation hose

8

» Fig. 154 on page 138 firmly onto the tyre

valve.

›

For vehicles with manual transmission set the gearshift lever to the neutral

position.

138Do-it-yourself

Page 143 of 172

The maximum towing speed is 50 km/h.

The vehicle must be transported on a special breakdown vehicle or trailer

if it is not possible to tow in the vehicle in the way described or if the tow-

ing distance is greater than 50 km.

Driver of the towed vehicle›

If possible, the vehicle should be towed with the engine running. The brake

booster and power steering only operate if the engine is running, otherwise

much greater force has to be applied to the brake pedal and more power has

to be expended for steering.

›

If it is not possible to start the engine, switch on the ignition so that the

steering wheel does not lock and so that the turn signal lights, windscreen

wipers and windscreen washer system can be used.

›

Take the vehicle out of gear or move the selector lever into position N if the

vehicle is fitted with an automated transmission.

›

Keep the tow rope taut at all times during the towing procedure.

WARNING■ Spiral tow ropes must not be used for towing » Fig. 156- , the towing

eye may unscrew out of the vehicle - risk of accident.■

Ensure tow rope is not twisted - risk of accident.

CAUTION

■ Do not tow-start the engine – risk of damaging the engine! The battery from

another vehicle can be used as a jump-start aid » page 139, Jump-starting .■

For off-road towing manoeuvres, there is a risk to both vehicles that the fas-

teners may become overloaded and damaged.

Note

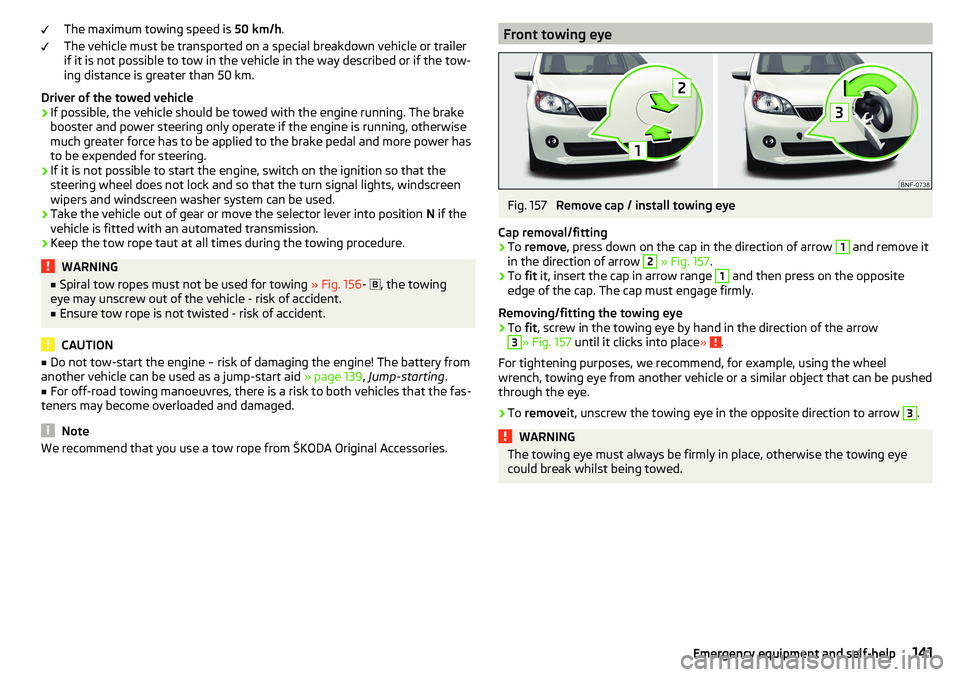

We recommend that you use a tow rope from ŠKODA Original Accessories.Front towing eyeFig. 157

Remove cap / install towing eye

Cap removal/fitting

›

To remove , press down on the cap in the direction of arrow

1

and remove it

in the direction of arrow

2

» Fig. 157 .

›

To fit it, insert the cap in arrow range

1

and then press on the opposite

edge of the cap. The cap must engage firmly.

Removing/fitting the towing eye

›

To fit, screw in the towing eye by hand in the direction of the arrow

3

» Fig. 157 until it clicks into place » .

For tightening purposes, we recommend, for example, using the wheel

wrench, towing eye from another vehicle or a similar object that can be pushed

through the eye.

›

To remove it, unscrew the towing eye in the opposite direction to arrow

3

.

WARNINGThe towing eye must always be firmly in place, otherwise the towing eye

could break whilst being towed.141Emergency equipment and self-help

Page 146 of 172

›Remove the wiper blade in the direction of the arrow 3.

Attaching the windscreen wiper blade›

Slide the windscreen wiper blade in the opposite direction to arrow

3

until it

locks into place. Check that the windscreen wiper blade is correctly attached.

›

Fold the windscreen wiper arm back to the windscreen.

Fuses and light bulbs

Fuses

Introduction

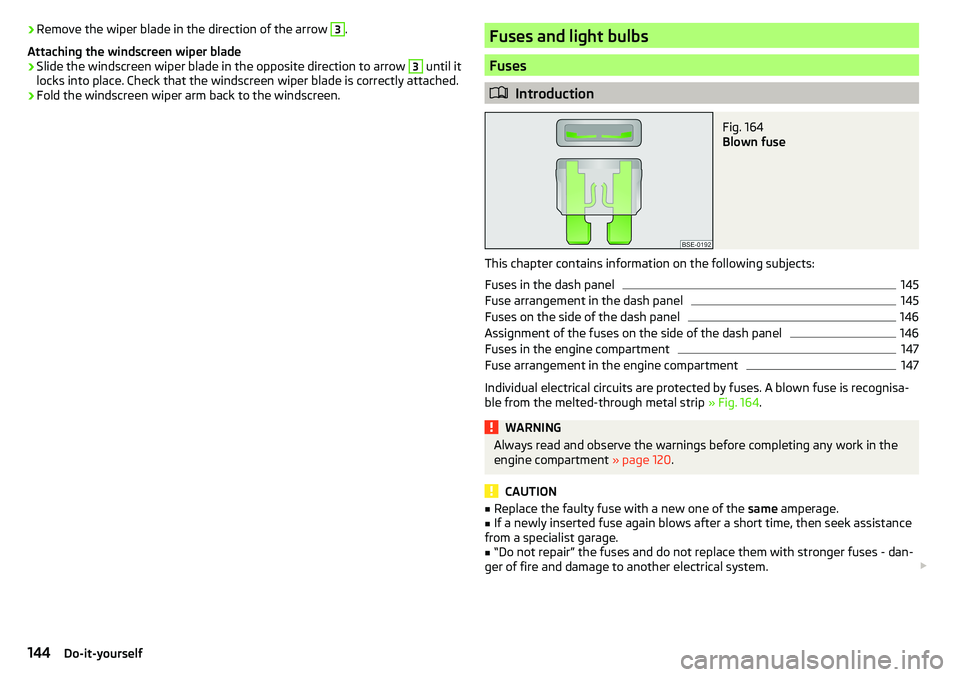

Fig. 164

Blown fuse

This chapter contains information on the following subjects:

Fuses in the dash panel

145

Fuse arrangement in the dash panel

145

Fuses on the side of the dash panel

146

Assignment of the fuses on the side of the dash panel

146

Fuses in the engine compartment

147

Fuse arrangement in the engine compartment

147

Individual electrical circuits are protected by fuses. A blown fuse is recognisa-

ble from the melted-through metal strip » Fig. 164.

WARNINGAlways read and observe the warnings before completing any work in the

engine compartment » page 120.

CAUTION

■

Replace the faulty fuse with a new one of the same amperage.■If a newly inserted fuse again blows after a short time, then seek assistance

from a specialist garage.■

“Do not repair” the fuses and do not replace them with stronger fuses - dan-

ger of fire and damage to another electrical system.

144Do-it-yourself

Page 147 of 172

Note■We recommend always carrying replacement fuses in the vehicle.■There can be several power consuming devices for one fuse. Multiple fuses

may exist for a single power consuming device.

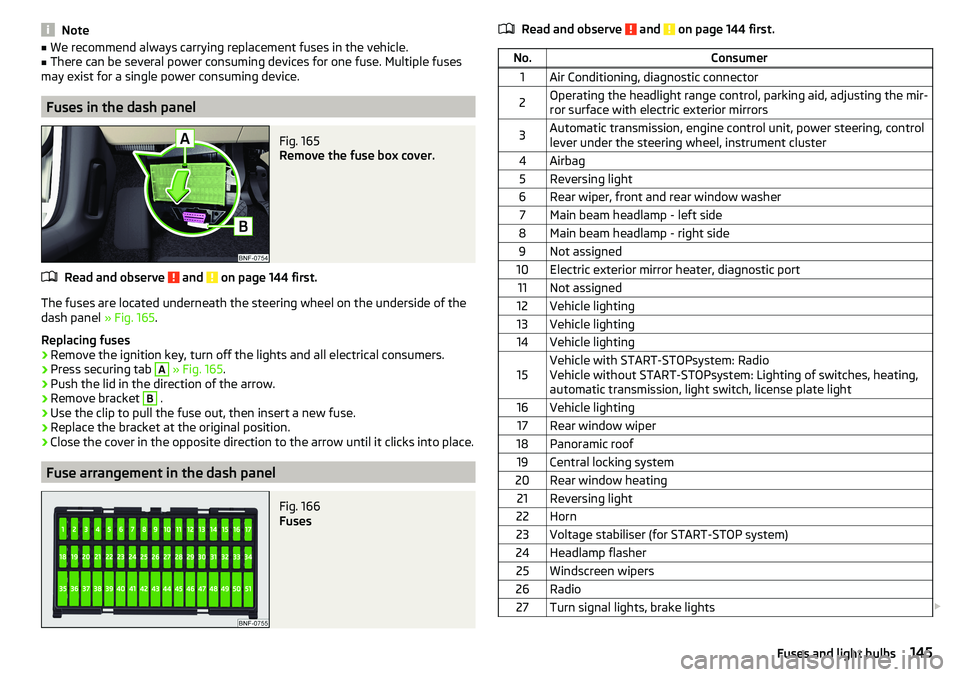

Fuses in the dash panel

Fig. 165

Remove the fuse box cover.

Read and observe and on page 144 first.

The fuses are located underneath the steering wheel on the underside of the

dash panel » Fig. 165.

Replacing fuses

›

Remove the ignition key, turn off the lights and all electrical consumers.

›

Press securing tab

A

» Fig. 165 .

›

Push the lid in the direction of the arrow.

›

Remove bracket

B

.

›

Use the clip to pull the fuse out, then insert a new fuse.

›

Replace the bracket at the original position.

›

Close the cover in the opposite direction to the arrow until it clicks into place.

Fuse arrangement in the dash panel

Fig. 166

Fuses

Read and observe and on page 144 first.No.Consumer1Air Conditioning, diagnostic connector2Operating the headlight range control, parking aid, adjusting the mir-

ror surface with electric exterior mirrors3Automatic transmission, engine control unit, power steering, control

lever under the steering wheel, instrument cluster4Airbag5Reversing light6Rear wiper, front and rear window washer7Main beam headlamp - left side8Main beam headlamp - right side9Not assigned10Electric exterior mirror heater, diagnostic port11Not assigned12Vehicle lighting13Vehicle lighting14Vehicle lighting15Vehicle with START-STOPsystem: Radio

Vehicle without START-STOPsystem: Lighting of switches, heating,

automatic transmission, light switch, license plate light16Vehicle lighting17Rear window wiper18Panoramic roof19Central locking system20Rear window heating21Reversing light22Horn23Voltage stabiliser (for START-STOP system)24Headlamp flasher25Windscreen wipers26Radio27Turn signal lights, brake lights 145Fuses and light bulbs

Page 148 of 172

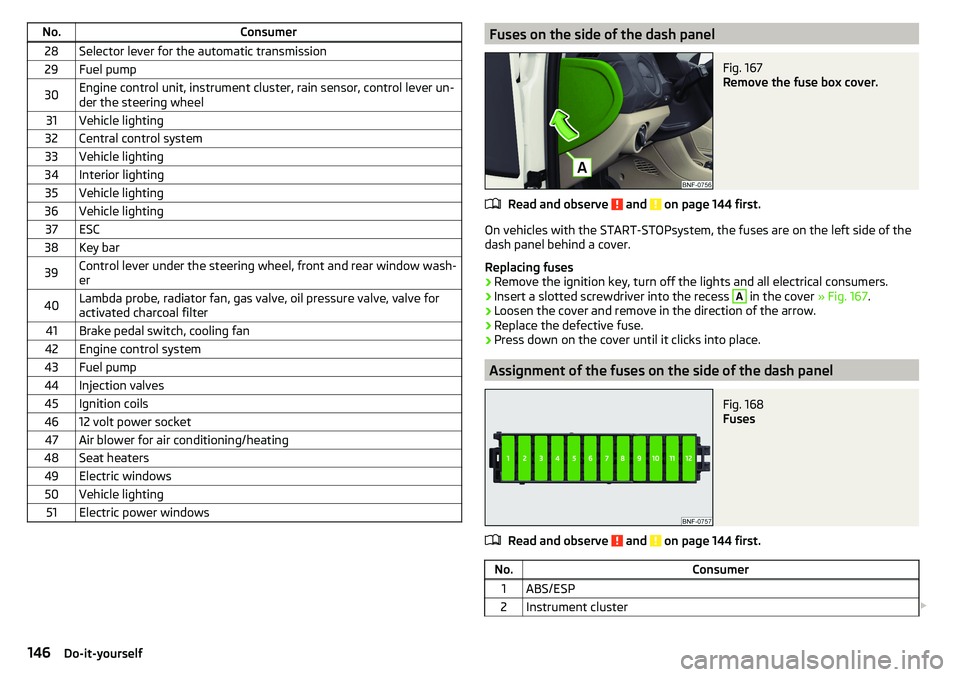

No.Consumer28Selector lever for the automatic transmission29Fuel pump30Engine control unit, instrument cluster, rain sensor, control lever un-

der the steering wheel31Vehicle lighting32Central control system33Vehicle lighting34Interior lighting35Vehicle lighting36Vehicle lighting37ESC38Key bar39Control lever under the steering wheel, front and rear window wash- er40Lambda probe, radiator fan, gas valve, oil pressure valve, valve for

activated charcoal filter41Brake pedal switch, cooling fan42Engine control system43Fuel pump44Injection valves45Ignition coils4612 volt power socket47Air blower for air conditioning/heating48Seat heaters49Electric windows50Vehicle lighting51Electric power windowsFuses on the side of the dash panelFig. 167

Remove the fuse box cover.

Read and observe and on page 144 first.

On vehicles with the START-STOPsystem, the fuses are on the left side of the

dash panel behind a cover.

Replacing fuses

›

Remove the ignition key, turn off the lights and all electrical consumers.

›

Insert a slotted screwdriver into the recess

A

in the cover » Fig. 167.

›

Loosen the cover and remove in the direction of the arrow.

›

Replace the defective fuse.

›

Press down on the cover until it clicks into place.

Assignment of the fuses on the side of the dash panel

Fig. 168

Fuses

Read and observe and on page 144 first.

No.Consumer1ABS/ESP2Instrument cluster 146Do-it-yourself

Page 149 of 172

No.Consumer3Radio4DC-DC voltage converter, motor starter, bar with buttons5Air conditioning system6Not assigned7Not assigned8Not assigned9Vehicle lighting - right side10Vehicle lighting - left side11Starter12DC-DC voltage converter, ABS, instrument cluster, radio

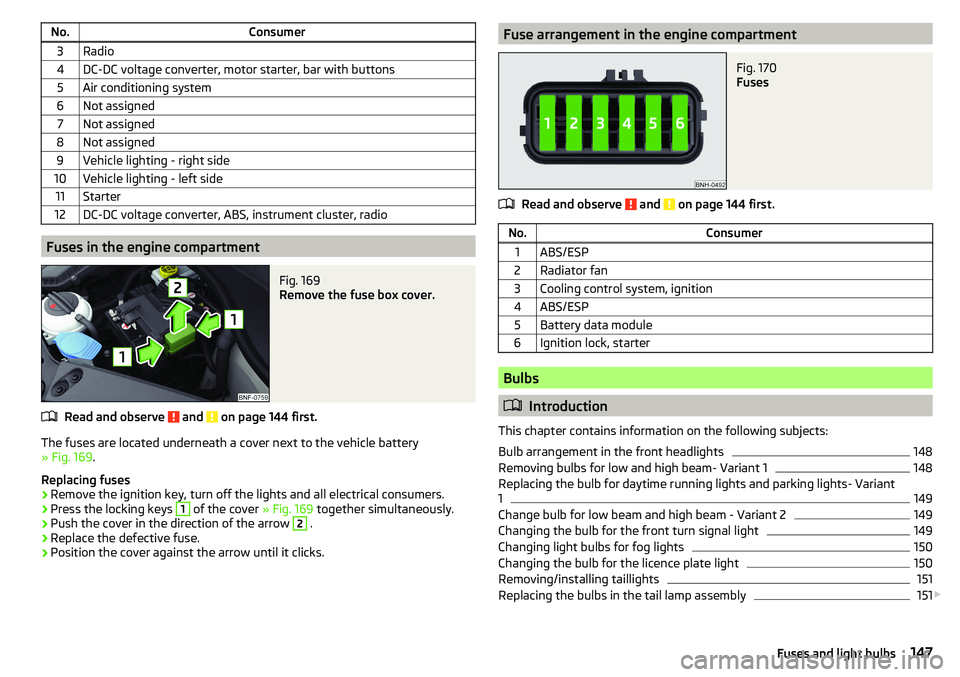

Fuses in the engine compartment

Fig. 169

Remove the fuse box cover.

Read and observe and on page 144 first.

The fuses are located underneath a cover next to the vehicle battery

» Fig. 169 .

Replacing fuses

›

Remove the ignition key, turn off the lights and all electrical consumers.

›

Press the locking keys

1

of the cover » Fig. 169 together simultaneously.

›

Push the cover in the direction of the arrow

2

.

›

Replace the defective fuse.

›

Position the cover against the arrow until it clicks.

Fuse arrangement in the engine compartmentFig. 170

Fuses

Read and observe and on page 144 first.

No.Consumer1ABS/ESP2Radiator fan3Cooling control system, ignition4ABS/ESP5Battery data module6Ignition lock, starter

Bulbs

Introduction

This chapter contains information on the following subjects:

Bulb arrangement in the front headlights

148

Removing bulbs for low and high beam- Variant 1

148

Replacing the bulb for daytime running lights and parking lights- Variant

1

149

Change bulb for low beam and high beam - Variant 2

149

Changing the bulb for the front turn signal light

149

Changing light bulbs for fog lights

150

Changing the bulb for the licence plate light

150

Removing/installing taillights

151

Replacing the bulbs in the tail lamp assembly

151

147Fuses and light bulbs

Page 150 of 172

We recommend having bulbs replaced by a specialist garage or seeking other

expert help in the event of any uncertainties.

▶ Switch off the ignition and all of the lights before replacing a bulb.

▶ Faulty bulbs must only be replaced with the same type of bulbs. The designa-

tion is located on the light socket or the glass bulb.

We recommend having the headlight settings checked by a specialist garage after replacing a bulb in the low or high beam unit or the fog lamp.

Visit a specialist garage if an LED diode is faulty.WARNING■ Always read and observe the warnings before completing any work in the

engine compartment » page 120.■

Accidents can be caused if the road in front of the vehicle is not suffi-

ciently illuminated and the vehicle cannot or can only be seen with difficul-

ty by other road users.

■

Bulbs H4, HB4 and H7 are pressurised and may burst when changed –

There is a risk of injury! We therefore recommended wearing gloves and

safety glasses when changing a bulb.

CAUTION

Do not take hold of the glass bulb with naked fingers (even the smallest

amount of dirt reduces the working life of the light bulb). Use a clean cloth,

napkin, or similar.

Note

■ This Owner's Manual only describes the replacement of bulbs where it is pos-

sible to replace the bulbs on your own without any complications arising. Other

bulbs must be replaced by a specialist garage.■

We recommend that a box of replacement bulbs always be carried in the ve-

hicle.

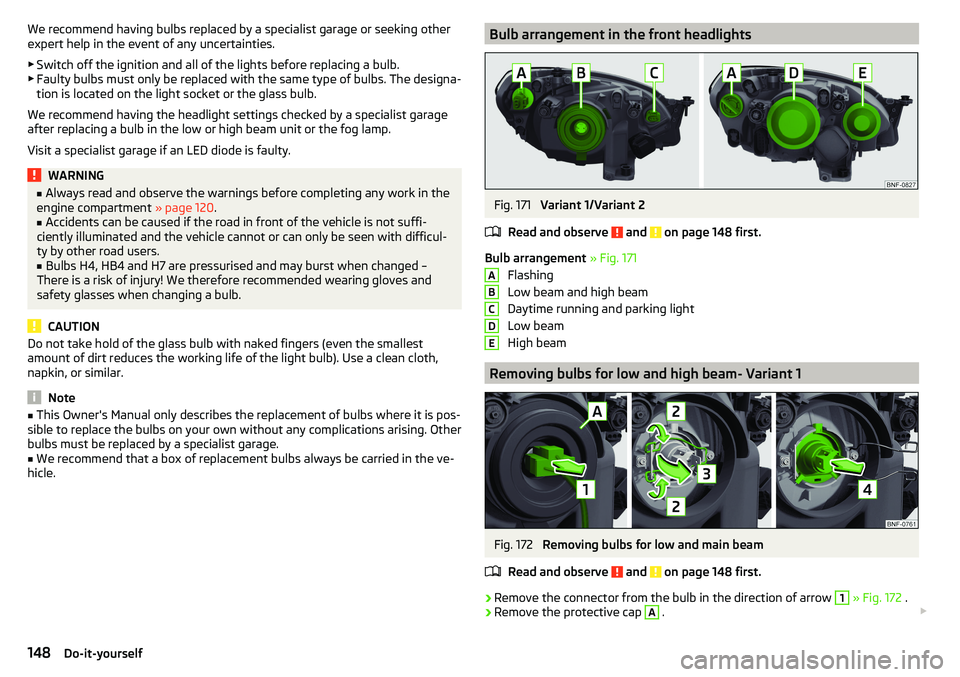

Bulb arrangement in the front headlightsFig. 171

Variant 1/Variant 2

Read and observe

and on page 148 first.

Bulb arrangement » Fig. 171

Flashing

Low beam and high beam

Daytime running and parking light

Low beam

High beam

Removing bulbs for low and high beam- Variant 1

Fig. 172

Removing bulbs for low and main beam

Read and observe

and on page 148 first.

›

Remove the connector from the bulb in the direction of arrow

1

» Fig. 172 .

›

Remove the protective cap

A

.

ABCDE148Do-it-yourself

Page 151 of 172

›Press the safety catch in the direction of the headlamp and then unhook in

the direction of arrow 2 » Fig. 172 .›

Open out the safety catch in the direction of arrow

3

.

›

Remove the light bulb in the direction of arrow

4

and insert a new light bulb

in such a way that the fixing lugs of the light bulb socket fit into the recesses

of the lamp.

Insertion of the bulb takes place in reverse order.

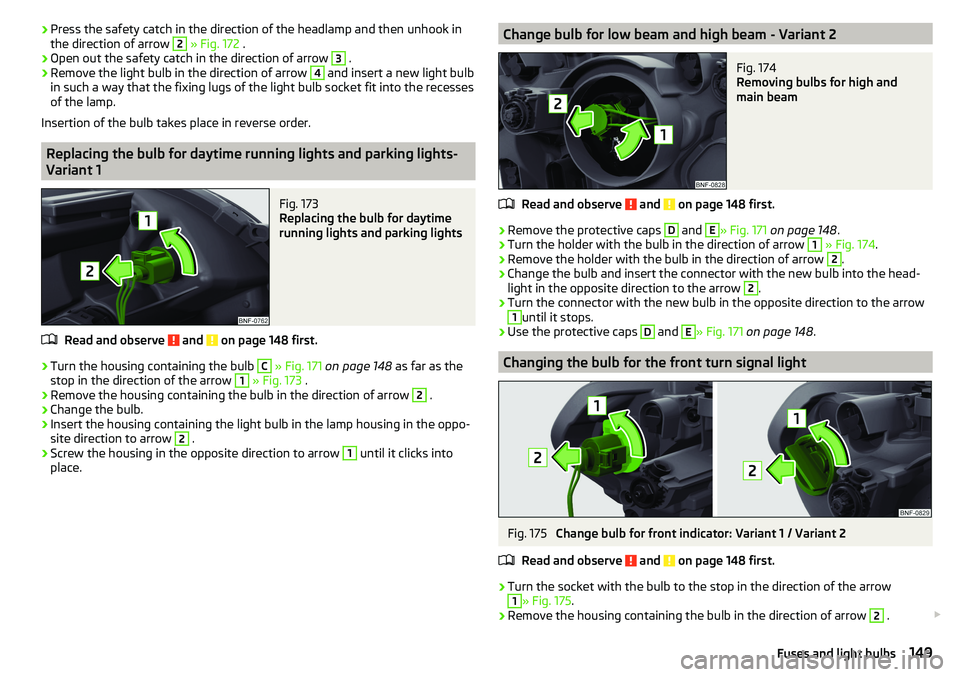

Replacing the bulb for daytime running lights and parking lights-

Variant 1

Fig. 173

Replacing the bulb for daytime

running lights and parking lights

Read and observe and on page 148 first.

›

Turn the housing containing the bulb

C

» Fig. 171 on page 148 as far as the

stop in the direction of the arrow

1

» Fig. 173 .

›

Remove the housing containing the bulb in the direction of arrow

2

.

›

Change the bulb.

›

Insert the housing containing the light bulb in the lamp housing in the oppo-

site direction to arrow

2

.

›

Screw the housing in the opposite direction to arrow

1

until it clicks into

place.

Change bulb for low beam and high beam - Variant 2Fig. 174

Removing bulbs for high and

main beam

Read and observe and on page 148 first.

›

Remove the protective caps

D

and

E

» Fig. 171 on page 148 .

›

Turn the holder with the bulb in the direction of arrow

1

» Fig. 174 .

›

Remove the holder with the bulb in the direction of arrow

2

.

›

Change the bulb and insert the connector with the new bulb into the head-

light in the opposite direction to the arrow

2

.

›

Turn the connector with the new bulb in the opposite direction to the arrow

1

until it stops.

›

Use the protective caps

D

and

E

» Fig. 171 on page 148 .

Changing the bulb for the front turn signal light

Fig. 175

Change bulb for front indicator: Variant 1 / Variant 2

Read and observe

and on page 148 first.

›

Turn the socket with the bulb to the stop in the direction of the arrow

1

» Fig. 175 .

›

Remove the housing containing the bulb in the direction of arrow

2

.

149Fuses and light bulbs