check engine SKODA FABIA 2000 1.G / 6Y User Guide

[x] Cancel search | Manufacturer: SKODA, Model Year: 2000, Model line: FABIA, Model: SKODA FABIA 2000 1.G / 6YPages: 86, PDF Size: 3.58 MB

Page 27 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

EnginesEdition 09.04

S00.5301.14.2002-3 page 7 02

Replace engine oil filter

Vehicles with petrol engine

Special tools, test and measuring equipment and

auxiliary items required

♦Oil filter wrench

–Release oil filter (e.g. Würth, Hazet) and remove.

–Clean sealing surface at engine.

–Oil rubber seal slightly.

–Screw in new filter and tighten by hand.

–After filling with oil, run engine until it is at operating

temperature and inspect for leaks.

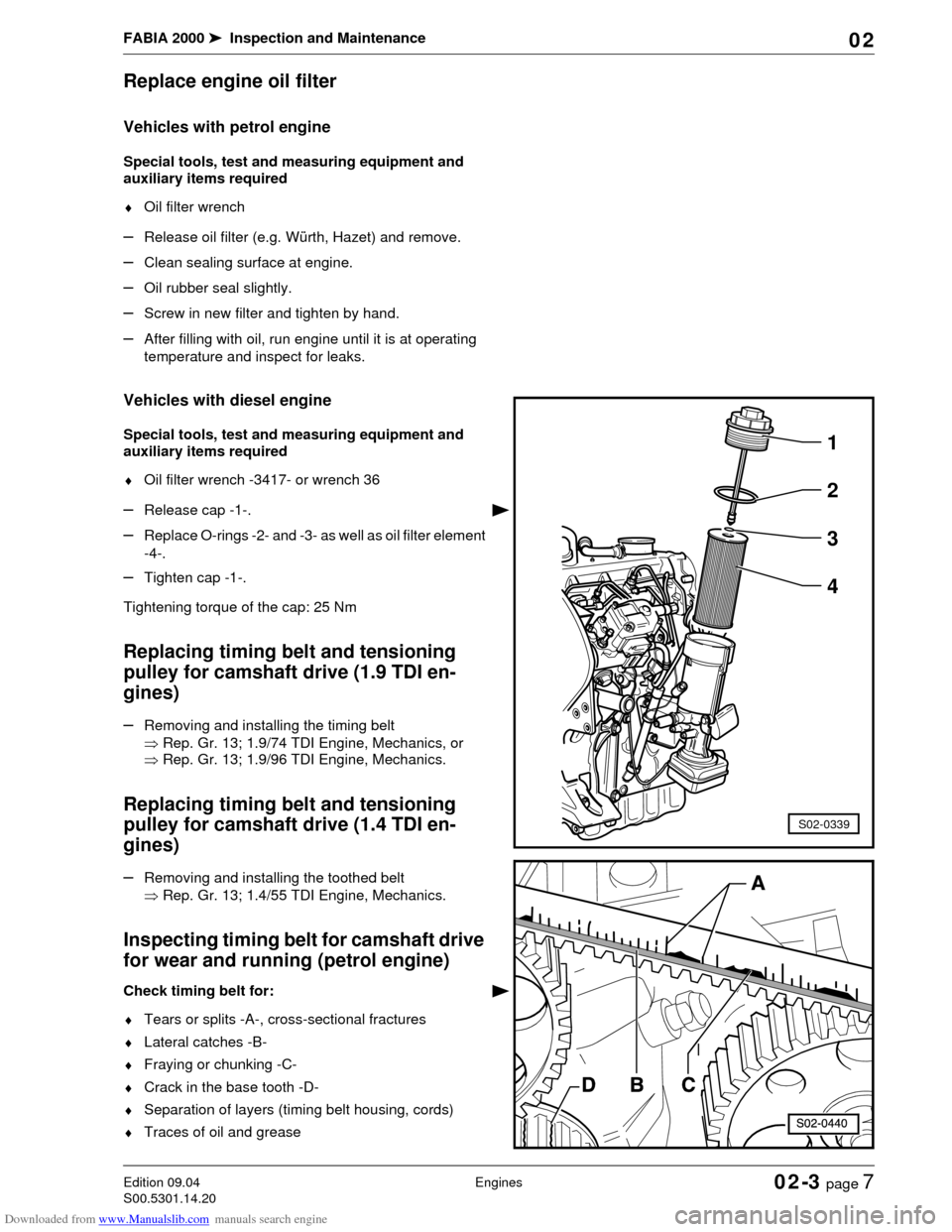

Vehicles with diesel engine

Special tools, test and measuring equipment and

auxiliary items required

♦Oil filter wrench -3417- or wrench 36

–Release cap -1-.

–Replace O-rings -2- and -3- as well as oil filter element

-4-.

–Tighten cap -1-.

Tightening torque of the cap: 25 Nm

Replacing timing belt and tensioning

pulley for camshaft drive (1.9 TDI en-

gines)

–Removing and installing the timing belt

⇒Rep. Gr. 13; 1.9/74 TDI Engine, Mechanics, or

⇒Rep. Gr. 13; 1.9/96 TDI Engine, Mechanics.

Replacing timing belt and tensioning

pulley for camshaft drive (1.4 TDI en-

gines)

–Removing and installing the toothed belt

⇒Rep. Gr. 13; 1.4/55 TDI Engine, Mechanics.

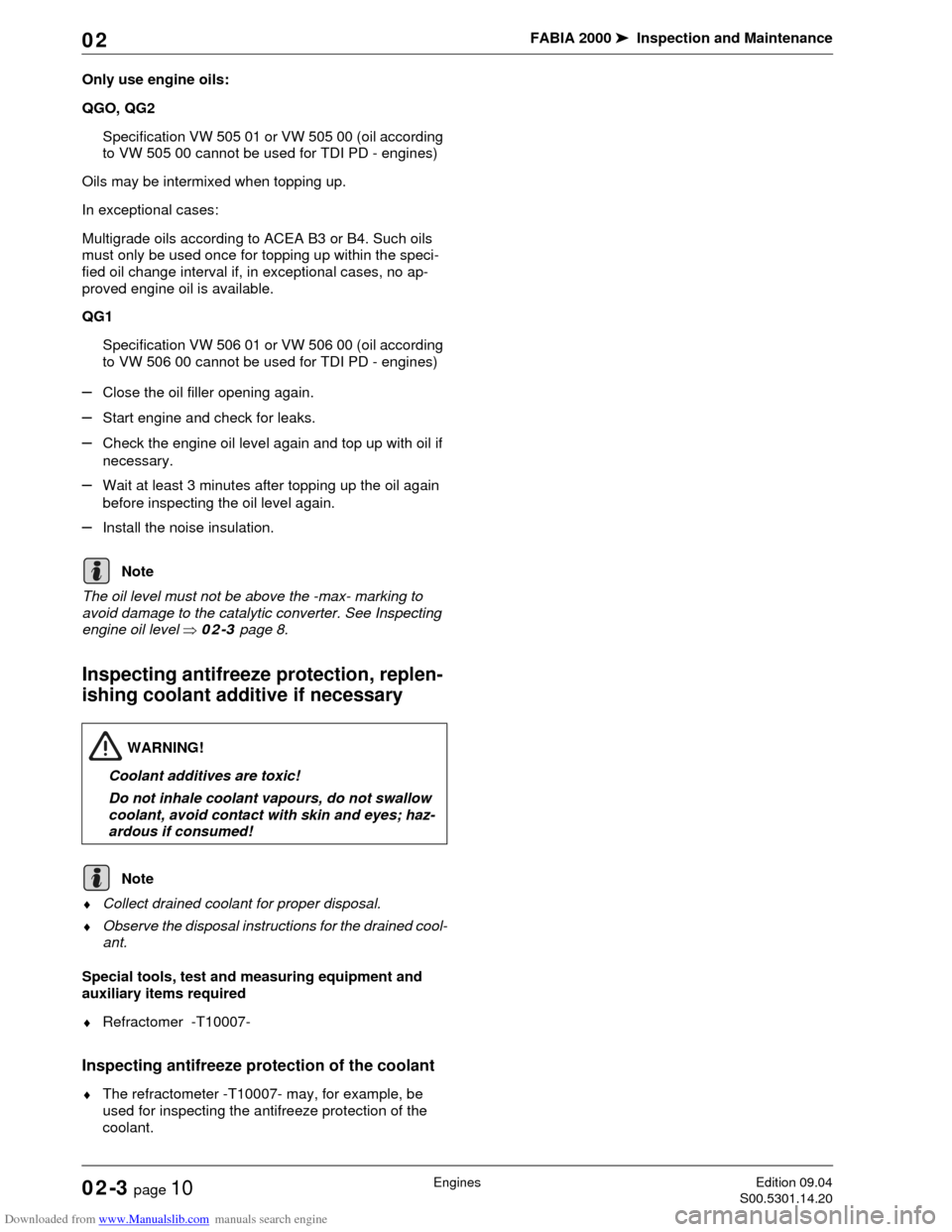

Inspecting timing belt for camshaft drive

for wear and running (petrol engine)

Check timing belt for:

♦Tears or splits -A-, cross-sectional fractures

♦Lateral catches -B-

♦Fraying or chunking -C-

♦Crack in the base tooth -D-

♦Separation of layers (timing belt housing, cords)

♦Traces of oil and grease

S02-0339

2

1

4

3

Page 30 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

EnginesEdition 09.04

S00.5301.14.2002-3 page 10 02

Only use engine oils:

QGO, QG2

Specification VW 505 01 or VW 505 00 (oil according

to VW 505 00 cannot be used for TDI PD - engines)

Oils may be intermixed when topping up.

In exceptional cases:

Multigrade oils according to ACEA B3 or B4. Such oils

must only be used once for topping up within the speci-

fied oil change interval if, in exceptional cases, no ap-

proved engine oil is available.

QG1

Specification VW 506 01 or VW 506 00 (oil according

to VW 506 00 cannot be used for TDI PD - engines)

–Close the oil filler opening again.

–Start engine and check for leaks.

–Check the engine oil level again and top up with oil if

necessary.

–Wait at least 3 minutes after topping up the oil again

before inspecting the oil level again.

–Install the noise insulation.

The oil level must not be above the -max- marking to

avoid damage to the catalytic converter. See Inspecting

engine oil level ⇒02-3 page 8.

Inspecting antifreeze protection, replen-

ishing coolant additive if necessary

♦Collect drained coolant for proper disposal.

♦Observe the disposal instructions for the drained cool-

ant.

Special tools, test and measuring equipment and

auxiliary items required

♦Refractomer -T10007-

Inspecting antifreeze protection of the coolant

♦The refractometer -T10007- may, for example, be

used for inspecting the antifreeze protection of the

coolant.

Note

WARNING!

Coolant additives are toxic!

Do not inhale coolant vapours, do not swallow

coolant, avoid contact with skin and eyes; haz-

ardous if consumed!

Note

Page 32 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

EnginesEdition 09.04

S00.5301.14.2002-3 page 12 02

–Perform a test drive and again check the coolant anti-

freeze protection.

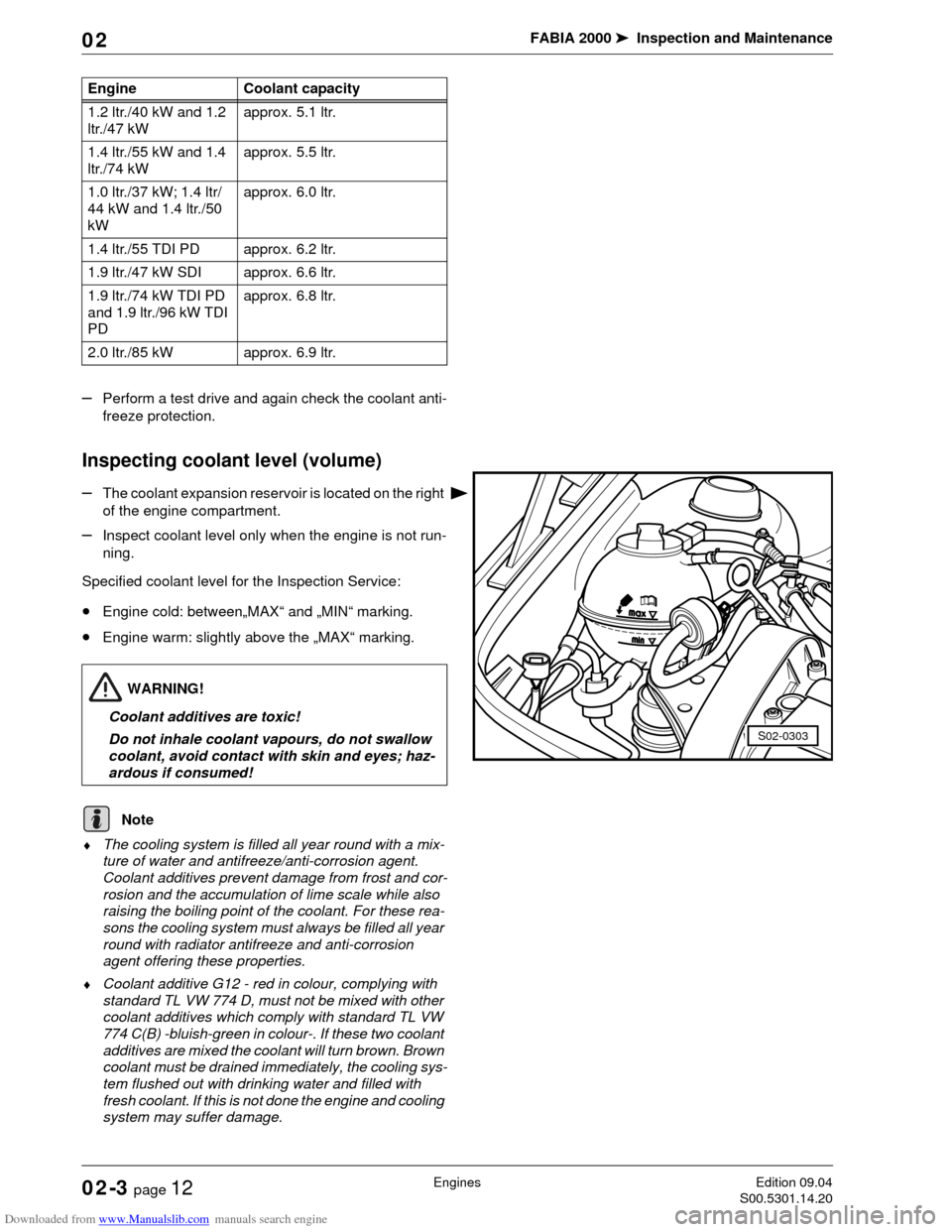

Inspecting coolant level (volume)

–The coolant expansion reservoir is located on the right

of the engine compartment.

–Inspect coolant level only when the engine is not run-

ning.

Specified coolant level for the Inspection Service:

•Engine cold: between„MAX“ and „MIN“ marking.

•Engine warm: slightly above the „MAX“ marking.

♦The cooling system is filled all year round with a mix-

ture of water and antifreeze/anti-corrosion agent.

Coolant additives prevent damage from frost and cor-

rosion and the accumulation of lime scale while also

raising the boiling point of the coolant. For these rea-

sons the cooling system must always be filled all year

round with radiator antifreeze and anti-corrosion

agent offering these properties.

♦Coolant additive G12 - red in colour, complying with

standard TL VW 774 D, must not be mixed with other

coolant additives which comply with standard TL VW

774 C(B) -bluish-green in colour-. If these two coolant

additives are mixed the coolant will turn brown. Brown

coolant must be drained immediately, the cooling sys-

tem flushed out with drinking water and filled with

fresh coolant. If this is not done the engine and cooling

system may suffer damage. Engine Coolant capacity

1.2 ltr./40 kW and 1.2

ltr./47 kWapprox. 5.1 ltr.

1.4 ltr./55 kW and 1.4

ltr./74 kWapprox. 5.5 ltr.

1.0 ltr./37 kW; 1.4 ltr/

44 kW and 1.4 ltr./50

kWapprox. 6.0 ltr.

1.4 ltr./55 TDI PD approx. 6.2 ltr.

1.9 ltr./47 kW SDI approx. 6.6 ltr.

1.9 ltr./74 kW TDI PD

and 1.9 ltr./96 kW TDI

PDapprox. 6.8 ltr.

2.0 ltr./85 kW approx. 6.9 ltr.

S02-0303

WARNING!

Coolant additives are toxic!

Do not inhale coolant vapours, do not swallow

coolant, avoid contact with skin and eyes; haz-

ardous if consumed!

Note

Page 34 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

EnginesEdition 09.04

S00.5301.14.2002-3 page 14 02

The listed G12 PLUS coolant additives may be inter-

mixed.

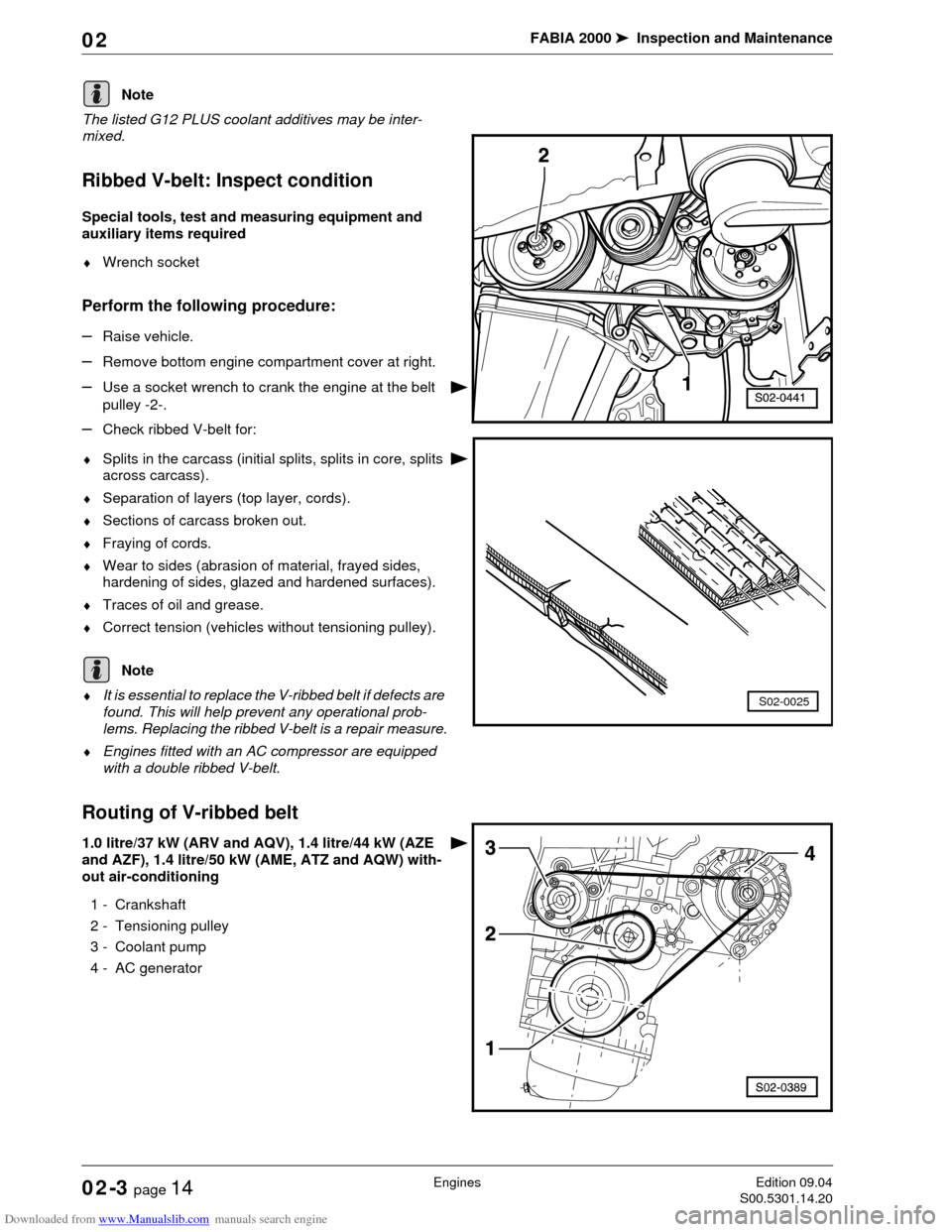

Ribbed V-belt: Inspect condition

Special tools, test and measuring equipment and

auxiliary items required

♦Wrench socket

Perform the following procedure:

–Raise vehicle.

–Remove bottom engine compartment cover at right.

–Use a socket wrench to crank the engine at the belt

pulley -2-.

–Check ribbed V-belt for:

♦Splits in the carcass (initial splits, splits in core, splits

across carcass).

♦Separation of layers (top layer, cords).

♦Sections of carcass broken out.

♦Fraying of cords.

♦Wear to sides (abrasion of material, frayed sides,

hardening of sides, glazed and hardened surfaces).

♦Traces of oil and grease.

♦Correct tension (vehicles without tensioning pulley).

♦It is essential to replace the V-ribbed belt if defects are

found. This will help prevent any operational prob-

lems. Replacing the ribbed V-belt is a repair measure.

♦Engines fitted with an AC compressor are equipped

with a double ribbed V-belt.

Routing of V-ribbed belt

1.0 litre/37 kW (ARV and AQV), 1.4 litre/44 kW (AZE

and AZF), 1.4 litre/50 kW (AME, ATZ and AQW) with-

out air-conditioning

1 - Crankshaft

2 - Tensioning pulley

3 - Coolant pump

4 - AC generator

Note

S02-0025

Note

Page 38 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

EnginesEdition 09.04

S00.5301.14.2002-3 page 18 02

Replace air filter element

–Open the filter housing.

–Replace the filter element and clean the filter housing.

–Close filter housing and check correct fitting.

Replacing the fuel filter (diesel engine)

♦Make sure no diesel fuel comes into contact with the

coolant hoses. If necessary clean the hoses immedi-

ately!

♦It is absolutely necessary to observe the oil disposal

instructions!

♦Observe the disposal instructions!

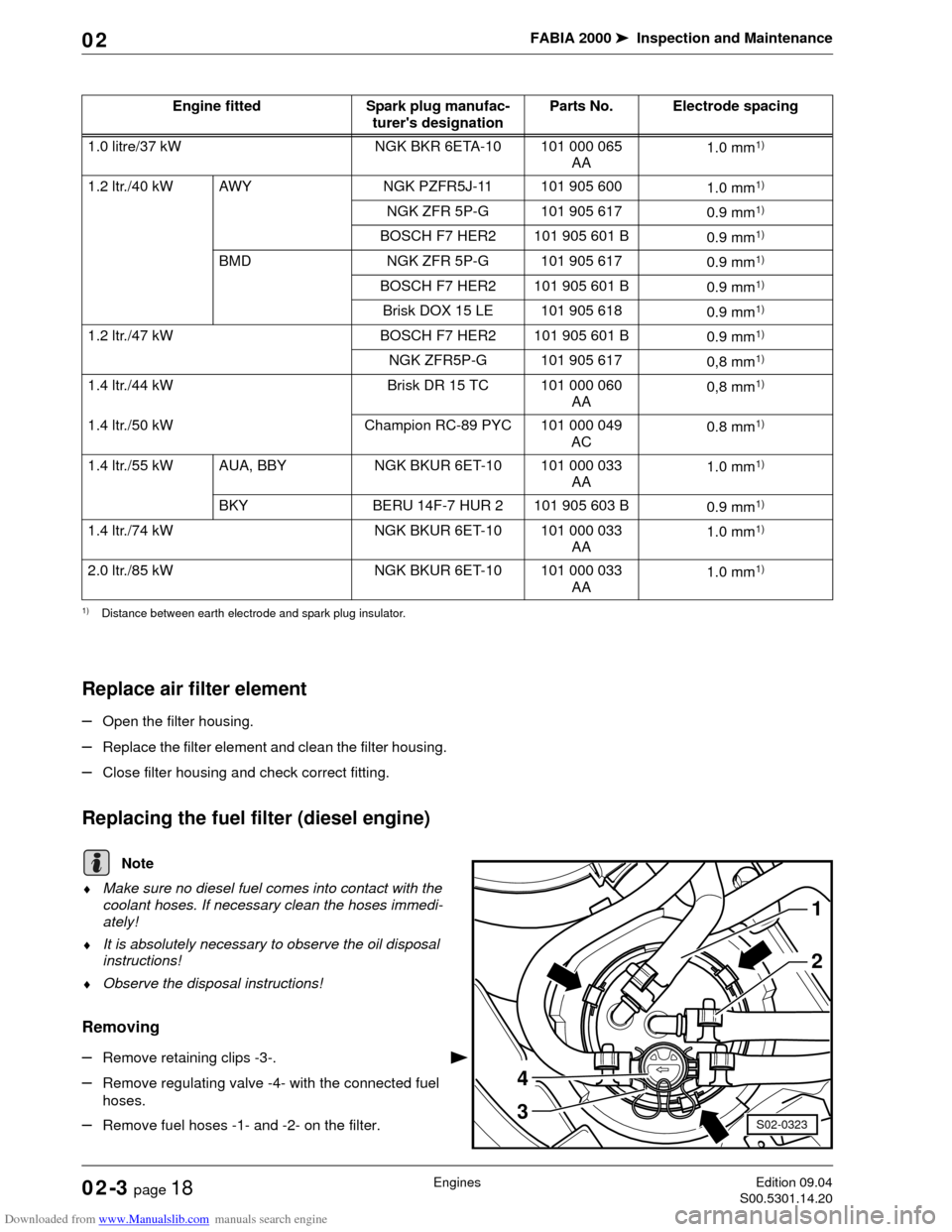

Removing

–Remove retaining clips -3-.

–Remove regulating valve -4- with the connected fuel

hoses.

–Remove fuel hoses -1- and -2- on the filter.Engine fitted Spark plug manufac-

turer's designationParts No. Electrode spacing

1.0 litre/37 kW NGK BKR 6ETA-10 101 000 065

AA1.0 mm

1)

1) Distance between earth electrode and spark plug insulator.

1.2 ltr./40 kW AWY NGK PZFR5J-11 101 905 600

1.0 mm1)

NGK ZFR 5P-G 101 905 617

0.9 mm1)

BOSCH F7 HER2 101 905 601 B

0.9 mm1)

BMD NGK ZFR 5P-G 101 905 617

0.9 mm1)

BOSCH F7 HER2 101 905 601 B

0.9 mm1)

Brisk DOX 15 LE 101 905 618

0.9 mm1)

1.2 ltr./47 kW BOSCH F7 HER2 101 905 601 B

0.9 mm1)

NGK ZFR5P-G 101 905 617

0,8 mm1)

1.4 ltr./44 kW Brisk DR 15 TC 101 000 060

AA0,8 mm1)

1.4 ltr./50 kW Champion RC-89 PYC 101 000 049

AC0.8 mm1)

1.4 ltr./55 kW AUA, BBY NGK BKUR 6ET-10 101 000 033

AA1.0 mm1)

BKY BERU 14F-7 HUR 2 101 905 603 B

0.9 mm1)

1.4 ltr./74 kW NGK BKUR 6ET-10 101 000 033

AA1.0 mm1)

2.0 ltr./85 kW NGK BKUR 6ET-10 101 000 033

AA1.0 mm1)

Note

1

2

3

4

S02-0323

Page 41 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

GearboxEdition 07.03

S00.5301.12.2002-4 page 1 02

02-4 Gearbox

Gearbox/Final drive: Check the oil level

and top it if necessary

5 speed gearbox 002

Gearbox oil specification: G50 SAE 75W90 (synthetic oil)

–Unscrew plug for inspecting gear oil -arrow-.

The oil is at the correct level if the gear is filled up to the

lower edge of the oil filler hole.

–Tighten plug -arrow-, 25 Nm.

When topping up, pay attention to the following

points:

–Unscrew plug for inspecting gear oil -arrow-.

–Pour in gear oil up to lower edge of the filler hole.

–Screw in plug -arrow-.

–Start engine, engage a gear and allow gearbox to ro-

tate for about 2 minutes.

–Switch off engine, unscrew plug -arrow- and top up

gear oil to lower edge of the filler hole.

–Tighten plug -arrow-, 25 Nm.

5 speed gearbox 02R

Gearbox oil specification: G50 SAE 75W90 (synthetic oil)

–Remove noise insulation panel -arrows-.

–Unscrew plug for inspecting gear oil -arrow-.

The oil is at the correct level if the gear is filled up to the

lower edge of the oil filler hole.

–Tighten plug -arrow-, 30 Nm.

When topping up, pay attention to the following

points:

–Unscrew plug for inspecting gear oil -arrow-.

–Pour in gear oil up to lower edge of the filler hole.

–Screw in plug -arrow-.

–Start engine, engage a gear and allow gearbox to ro-

tate for about 2 minutes.

–Switch off engine, unscrew plug -arrow- and top up

gear oil to lower edge of the filler hole.

–Tighten plug -arrow-, 30 Nm.

5 speed gearbox 02T

Special tools, test and measuring equipment and

auxiliary items required

♦Socket wrench insert -T30023 (3357)-

S34-0408

S10-0101

S34-0498

Page 51 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

ChassisEdition 02.04

S00.5301.13.2002-5 page 5 02

Track rod ends: Inspect play, correct at-

tachment and joint boots

–Raise vehicle (wheel clear of the ground) and inspect

play by moving the track rods and wheels. Clearance:

There must not be any play present.

–Inspect attachment.

–Inspect seals for damage and correct installation.

Inspecting tyres (including spare wheel)

Only tyres of the same type may be fitted to the vehicle.

Tyres of the same brand and tread pattern must always

be fitted to wheels on the same axle!

Delivery Inspection:

–Inspect the tyre tread and side wall for damage, if nec-

essary remove any foreign bodies from the tyres, such

as nails or glass splinters.

Inspection Service:

–Inspect the tyre tread and side wall for damage, if nec-

essary remove any foreign bodies from the tyres, such

as nails or glass splinters.

–Inspect tyres for scrubbing, tread worn down on one

side, porous side walls, cuts and punctures. Any de-

fects found must be advised to the customer and the

customer's attention must be drawn to any necessary

repair measures!

Inspecting tyre wear

–The wear pattern on the front tyres makes it possible

to assess whether it is necessary to inspect the wheel

toe and camber:

♦The formation of ridges on the tyre tread is an indica-

tion of wheel toe errors.

♦Tread worn on one side is usually attributable to cam-

ber errors.

–If such signs of wear are found, determine the cause

by checking the chassis alignment (repair measure).

Note

WARNING!

Tyres that are more than 6 years old must only be

used in case of emergency and while driving very

carefully.

Page 55 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

Electrical SystemEdition 09.04

S00.5301.14.2002-6 page 1 02

02-6 Electrical System

Power windows: Inspecting positioning

If the battery is diconnected the power windows forget

their current position.

Test conditions:

•All car doors closed

The inspection procedure is carried out from the outside

Close window with the car key using the convenience

closing system.

–Turn car key into close position and hold until all the

windows are closed.

–After closing the windows hold the key in the close po-

sition for approximately another 3 seconds.

Electrical components: Check for proper

operation

–Inspect lighting, main headlights, headlight beam con-

trol, fog lights, turn signal lights, hazard warning light

system, tail lights, rear fog lights, reversing lights,

brake lights, parking light control for brightness and

proper operation.

–Inspect interior lights, illuminated storage compart-

ment, illuminated ashtray for proper operation.

–Airbag warning lamps: Check operation ⇒Chapter

02-7.

–Inspect warning buzzer, onboard computer, all switch-

es in centre console as well as on the dash panel and

horn for proper operation.

–Inspect power windows, exterior mirrors (heated and

electrically adjustable), central locking system, infra-

red remote control and convenience closing system

for proper operation

–Inspect heating of front seats for proper operation.

–Inspect radio for proper reception and absence of in-

terference, also inspect speakers ⇒02-6 page 2.

Battery: Testing no-load voltage

Special tools, test and measuring equipment and

auxiliary items required

♦Multimeter (e.g. -V.A.G 1526 A-)

Prior to the measurement the vehicle must have been in

the no-load state for at least two hours (no engine starts,

no charging or discharging of battery).

The following procedure applies to measuring the battery

voltage in the no-load state (after at least two hours):

–With the battery installed measure the voltage be-

tween the terminals (ignition switched off).

Page 56 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

Electrical SystemEdition 09.04

S00.5301.14.2002-6 page 2 02

If the tester indicates a voltage of 12.5 Volts or more, the

battery is O.K.

If the voltage is less than 12.5 Volts determine the cause

(repair measure).

Battery: Inspecting electrolyte level, top-

ping up with distilled water if necessary

This procedure is not valid for batteries with the sign

„Magic eye“. Test procedure for these batteries

⇒Electrical System; Rep. Gr. 27.

–Inspect electrolyte level:

–The electrolyte level must be between the „MIN“ and

„MAX“ markings.

–Top up the battery with distilled water up to the „MAX“

marking if necessary.

Before disconnecting the battery determine the code of

radio sets fitted with anti-theft coding.

Radio: Check for proper operation

Precise information on how to operate the radio should

be obtained from the operating instructions before in-

specting proper operation of the radio set.

–Switch radio set on and off.

–Operate the volume control.

–Carry out station programming1).

–Inspect station search1).

–Inspect cassette player (insert cassette and play) 1).

–Inspect activation of the anti-theft code of the radio 1).

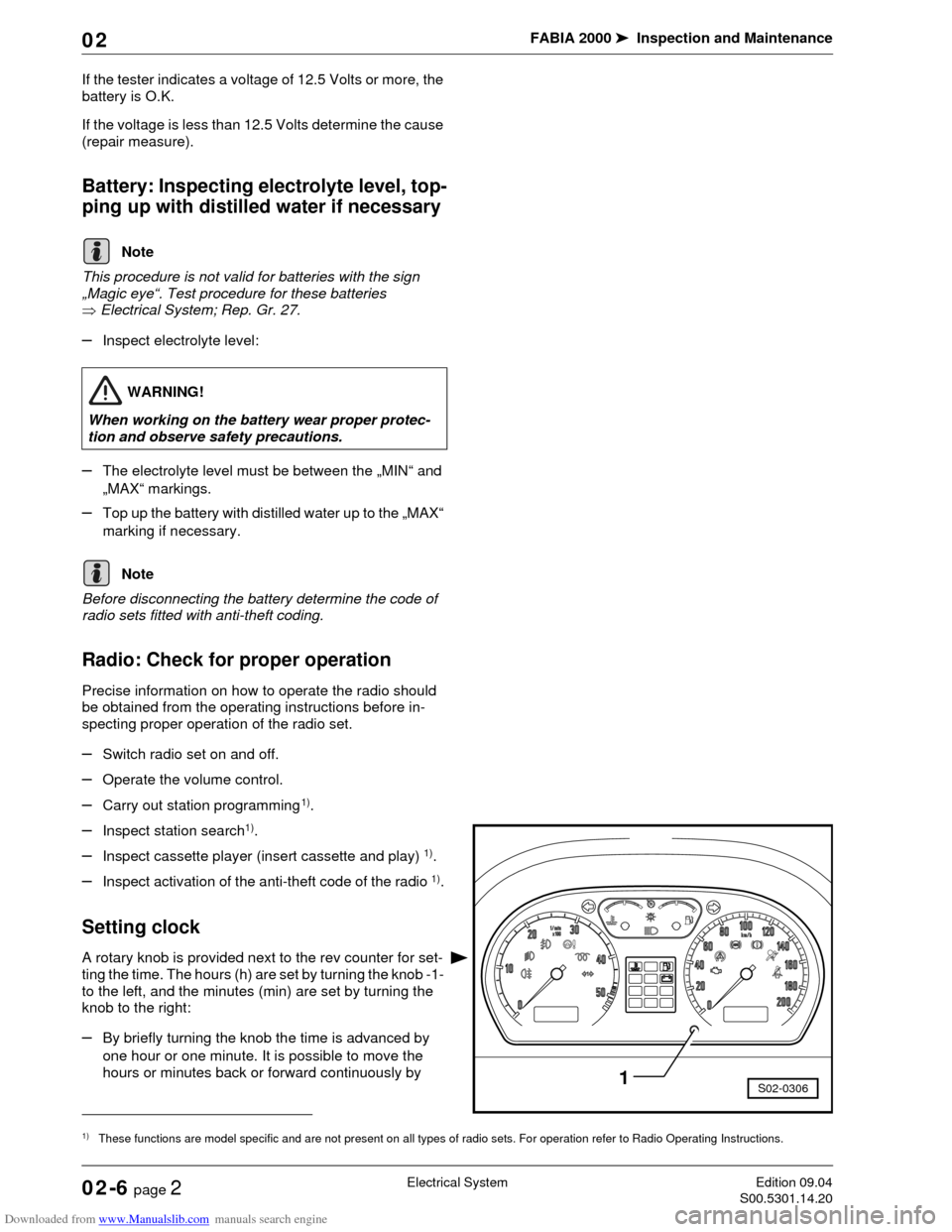

Setting clock

A rotary knob is provided next to the rev counter for set-

ting the time. The hours (h) are set by turning the knob -1-

to the left, and the minutes (min) are set by turning the

knob to the right:

–By briefly turning the knob the time is advanced by

one hour or one minute. It is possible to move the

hours or minutes back or forward continuously by

Note

WARNING!

When working on the battery wear proper protec-

tion and observe safety precautions.

1)These functions are model specific and are not present on all types of radio sets. For operation refer to Radio Operating Instructions.

Note

S02-03061

Page 65 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

Electrical SystemEdition 09.04

S00.5301.14.2002-6 page 11 02

Test and setting conditions

•Tyre inflation pressure O.K.

•Lenses must neither be damaged nor soiled.

•Reflectors and bulbs O.K.

•Vehicle load must be achieved.

Load: With an individual or 75 kg on the driver's seat in an

otherwise unladen vehicle (dead weight).

The unladen weight is the weight of the vehicle with full

fuel tank (at least 90 %) including the weight of all the op-

erational equipment elements (e.g. spare wheel, tool kit,

jack etc.).

The vehicle must have rolled a few metres or have been

depressed a few times at the front and rear to allow the

springs to settle.

•Both the vehicel and headlight beam setting device

must be on a level flat surface.

•Align the vehicle and headlight beam setting device in

accordance with the device manufaturer's indications.

•Check the control system of vehicles equipped with

headlight beam control by repeatedly turning the

thumbwheel in the dash panel. Then turn the thum-

bwheel to basic position.

•Set the inclination value.

Inclination value:

The inclination value is marked in „%“ at the top of the

headlight housing. The main headlights must be set to

this value. The percentage value applies up to 10 metres

projection distance. This will be 12 cm for an inclination

value of e.g. 1.2 %.

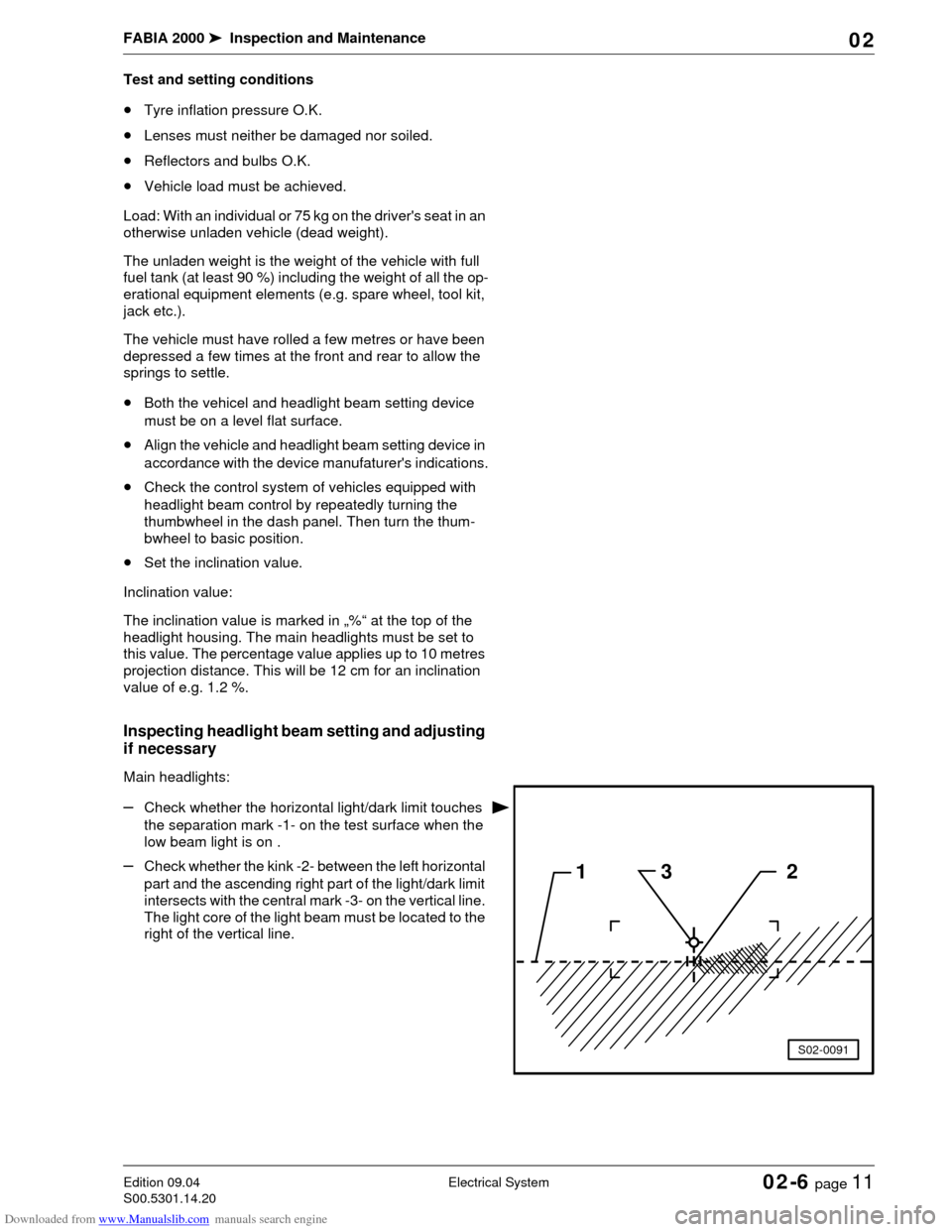

Inspecting headlight beam setting and adjusting

if necessary

Main headlights:

–Check whether the horizontal light/dark limit touches

the separation mark -1- on the test surface when the

low beam light is on .

–Check whether the kink -2- between the left horizontal

part and the ascending right part of the light/dark limit

intersects with the central mark -3- on the vertical line.

The light core of the light beam must be located to the

right of the vertical line.132

S02-0091