AUX SKODA FABIA 2000 1.G / 6Y Workshop Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 2000, Model line: FABIA, Model: SKODA FABIA 2000 1.G / 6YPages: 86, PDF Size: 3.58 MB

Page 27 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

EnginesEdition 09.04

S00.5301.14.2002-3 page 7 02

Replace engine oil filter

Vehicles with petrol engine

Special tools, test and measuring equipment and

auxiliary items required

♦Oil filter wrench

–Release oil filter (e.g. Würth, Hazet) and remove.

–Clean sealing surface at engine.

–Oil rubber seal slightly.

–Screw in new filter and tighten by hand.

–After filling with oil, run engine until it is at operating

temperature and inspect for leaks.

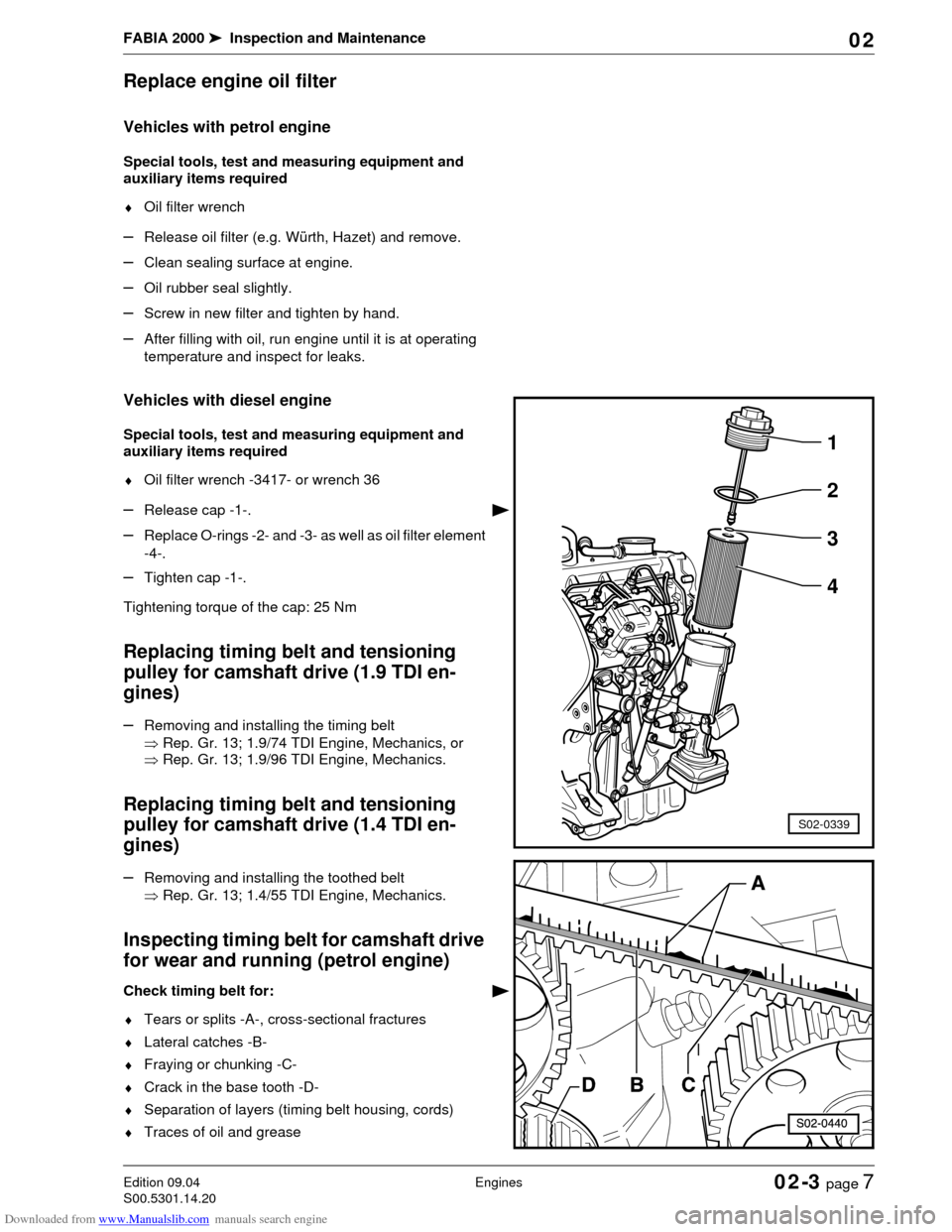

Vehicles with diesel engine

Special tools, test and measuring equipment and

auxiliary items required

♦Oil filter wrench -3417- or wrench 36

–Release cap -1-.

–Replace O-rings -2- and -3- as well as oil filter element

-4-.

–Tighten cap -1-.

Tightening torque of the cap: 25 Nm

Replacing timing belt and tensioning

pulley for camshaft drive (1.9 TDI en-

gines)

–Removing and installing the timing belt

⇒Rep. Gr. 13; 1.9/74 TDI Engine, Mechanics, or

⇒Rep. Gr. 13; 1.9/96 TDI Engine, Mechanics.

Replacing timing belt and tensioning

pulley for camshaft drive (1.4 TDI en-

gines)

–Removing and installing the toothed belt

⇒Rep. Gr. 13; 1.4/55 TDI Engine, Mechanics.

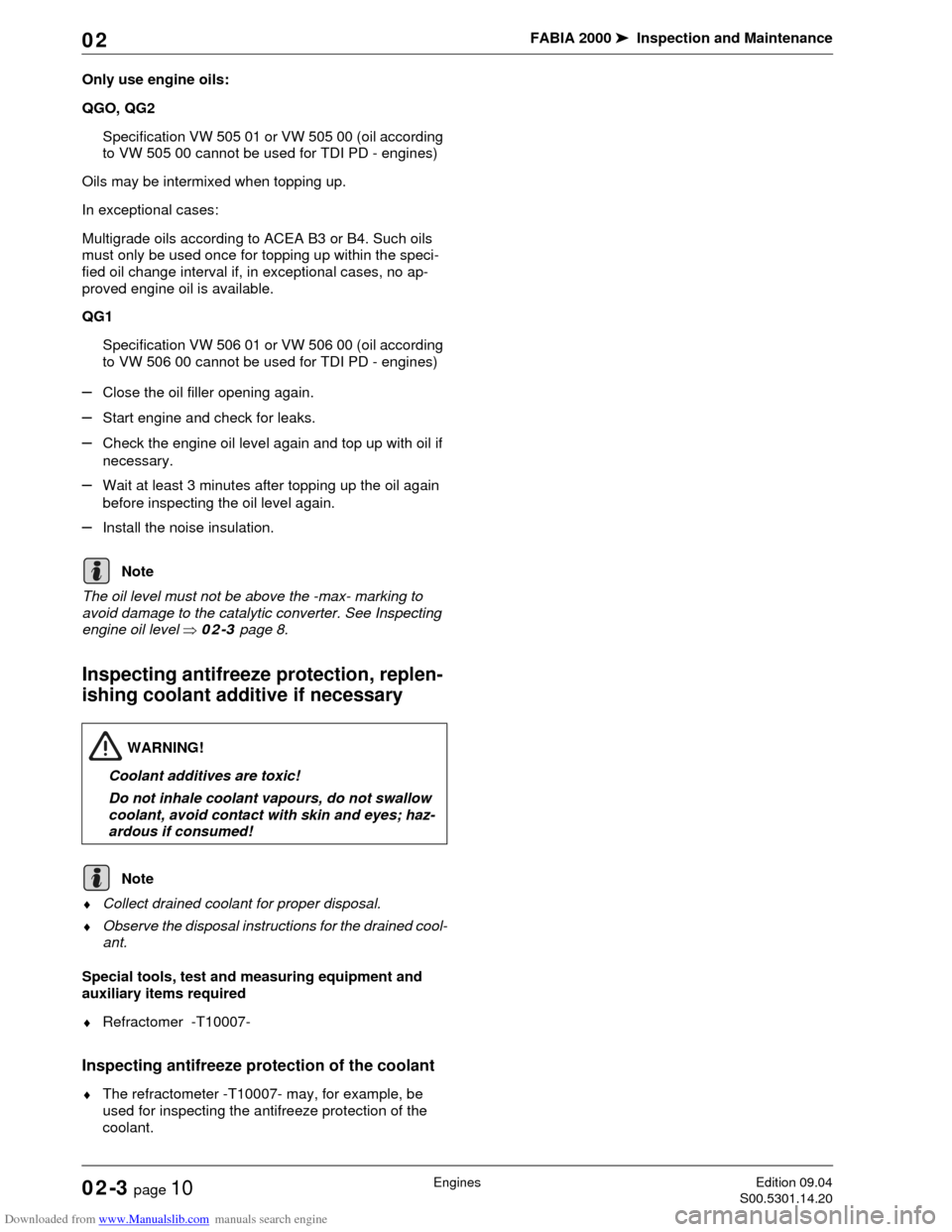

Inspecting timing belt for camshaft drive

for wear and running (petrol engine)

Check timing belt for:

♦Tears or splits -A-, cross-sectional fractures

♦Lateral catches -B-

♦Fraying or chunking -C-

♦Crack in the base tooth -D-

♦Separation of layers (timing belt housing, cords)

♦Traces of oil and grease

S02-0339

2

1

4

3

Page 30 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

EnginesEdition 09.04

S00.5301.14.2002-3 page 10 02

Only use engine oils:

QGO, QG2

Specification VW 505 01 or VW 505 00 (oil according

to VW 505 00 cannot be used for TDI PD - engines)

Oils may be intermixed when topping up.

In exceptional cases:

Multigrade oils according to ACEA B3 or B4. Such oils

must only be used once for topping up within the speci-

fied oil change interval if, in exceptional cases, no ap-

proved engine oil is available.

QG1

Specification VW 506 01 or VW 506 00 (oil according

to VW 506 00 cannot be used for TDI PD - engines)

–Close the oil filler opening again.

–Start engine and check for leaks.

–Check the engine oil level again and top up with oil if

necessary.

–Wait at least 3 minutes after topping up the oil again

before inspecting the oil level again.

–Install the noise insulation.

The oil level must not be above the -max- marking to

avoid damage to the catalytic converter. See Inspecting

engine oil level ⇒02-3 page 8.

Inspecting antifreeze protection, replen-

ishing coolant additive if necessary

♦Collect drained coolant for proper disposal.

♦Observe the disposal instructions for the drained cool-

ant.

Special tools, test and measuring equipment and

auxiliary items required

♦Refractomer -T10007-

Inspecting antifreeze protection of the coolant

♦The refractometer -T10007- may, for example, be

used for inspecting the antifreeze protection of the

coolant.

Note

WARNING!

Coolant additives are toxic!

Do not inhale coolant vapours, do not swallow

coolant, avoid contact with skin and eyes; haz-

ardous if consumed!

Note

Page 34 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

EnginesEdition 09.04

S00.5301.14.2002-3 page 14 02

The listed G12 PLUS coolant additives may be inter-

mixed.

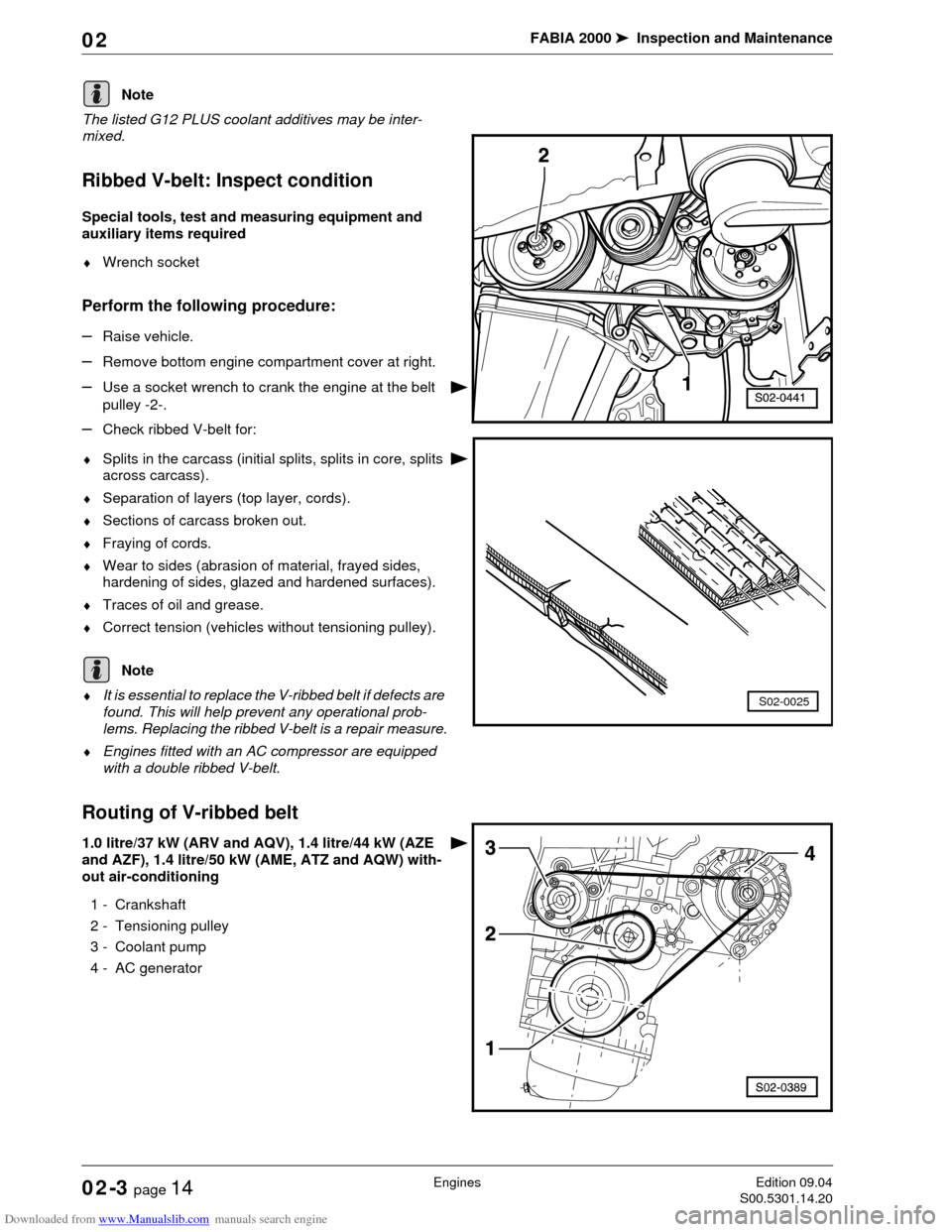

Ribbed V-belt: Inspect condition

Special tools, test and measuring equipment and

auxiliary items required

♦Wrench socket

Perform the following procedure:

–Raise vehicle.

–Remove bottom engine compartment cover at right.

–Use a socket wrench to crank the engine at the belt

pulley -2-.

–Check ribbed V-belt for:

♦Splits in the carcass (initial splits, splits in core, splits

across carcass).

♦Separation of layers (top layer, cords).

♦Sections of carcass broken out.

♦Fraying of cords.

♦Wear to sides (abrasion of material, frayed sides,

hardening of sides, glazed and hardened surfaces).

♦Traces of oil and grease.

♦Correct tension (vehicles without tensioning pulley).

♦It is essential to replace the V-ribbed belt if defects are

found. This will help prevent any operational prob-

lems. Replacing the ribbed V-belt is a repair measure.

♦Engines fitted with an AC compressor are equipped

with a double ribbed V-belt.

Routing of V-ribbed belt

1.0 litre/37 kW (ARV and AQV), 1.4 litre/44 kW (AZE

and AZF), 1.4 litre/50 kW (AME, ATZ and AQW) with-

out air-conditioning

1 - Crankshaft

2 - Tensioning pulley

3 - Coolant pump

4 - AC generator

Note

S02-0025

Note

Page 41 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

GearboxEdition 07.03

S00.5301.12.2002-4 page 1 02

02-4 Gearbox

Gearbox/Final drive: Check the oil level

and top it if necessary

5 speed gearbox 002

Gearbox oil specification: G50 SAE 75W90 (synthetic oil)

–Unscrew plug for inspecting gear oil -arrow-.

The oil is at the correct level if the gear is filled up to the

lower edge of the oil filler hole.

–Tighten plug -arrow-, 25 Nm.

When topping up, pay attention to the following

points:

–Unscrew plug for inspecting gear oil -arrow-.

–Pour in gear oil up to lower edge of the filler hole.

–Screw in plug -arrow-.

–Start engine, engage a gear and allow gearbox to ro-

tate for about 2 minutes.

–Switch off engine, unscrew plug -arrow- and top up

gear oil to lower edge of the filler hole.

–Tighten plug -arrow-, 25 Nm.

5 speed gearbox 02R

Gearbox oil specification: G50 SAE 75W90 (synthetic oil)

–Remove noise insulation panel -arrows-.

–Unscrew plug for inspecting gear oil -arrow-.

The oil is at the correct level if the gear is filled up to the

lower edge of the oil filler hole.

–Tighten plug -arrow-, 30 Nm.

When topping up, pay attention to the following

points:

–Unscrew plug for inspecting gear oil -arrow-.

–Pour in gear oil up to lower edge of the filler hole.

–Screw in plug -arrow-.

–Start engine, engage a gear and allow gearbox to ro-

tate for about 2 minutes.

–Switch off engine, unscrew plug -arrow- and top up

gear oil to lower edge of the filler hole.

–Tighten plug -arrow-, 30 Nm.

5 speed gearbox 02T

Special tools, test and measuring equipment and

auxiliary items required

♦Socket wrench insert -T30023 (3357)-

S34-0408

S10-0101

S34-0498

Page 42 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

GearboxEdition 07.03

S00.5301.12.2002-4 page 2 02

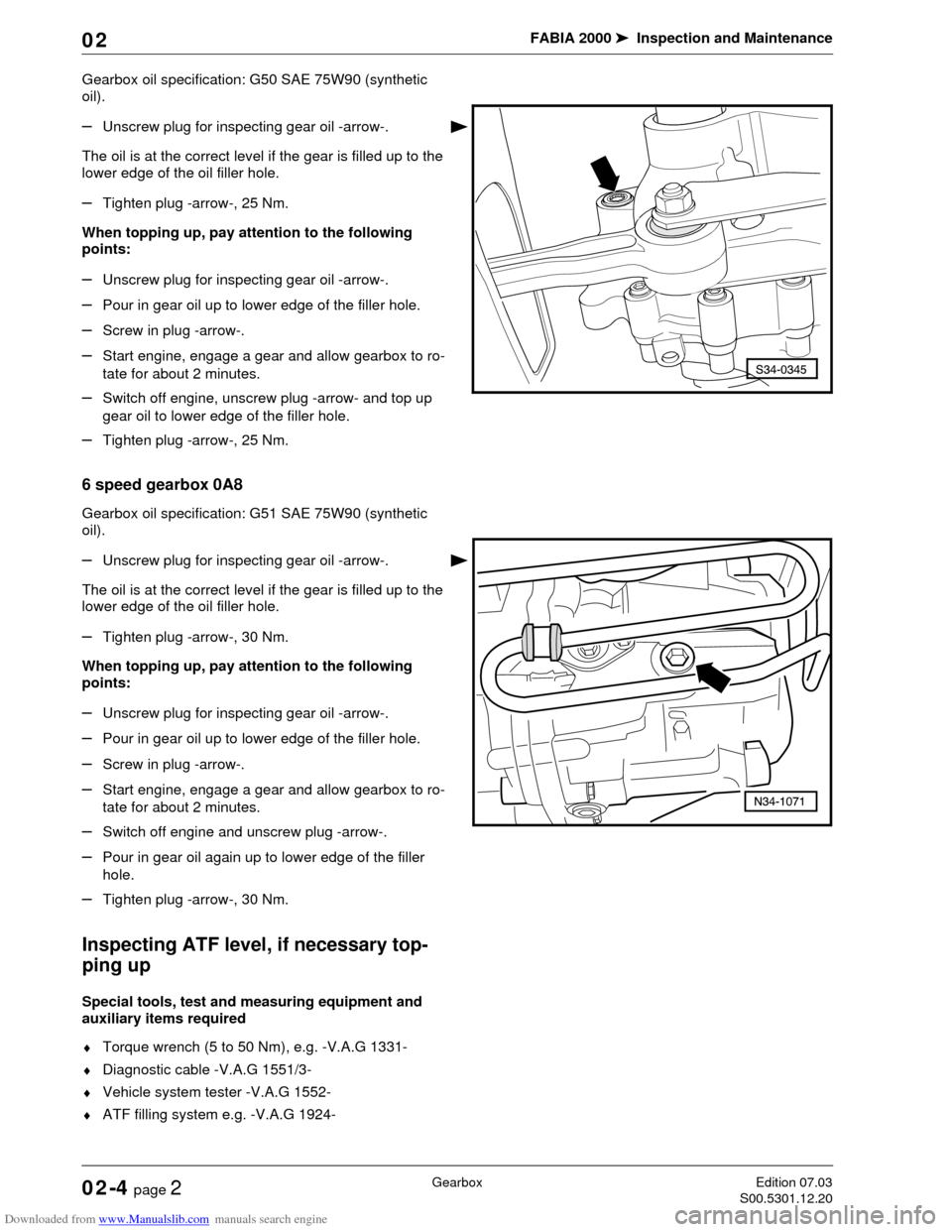

Gearbox oil specification: G50 SAE 75W90 (synthetic

oil).

–Unscrew plug for inspecting gear oil -arrow-.

The oil is at the correct level if the gear is filled up to the

lower edge of the oil filler hole.

–Tighten plug -arrow-, 25 Nm.

When topping up, pay attention to the following

points:

–Unscrew plug for inspecting gear oil -arrow-.

–Pour in gear oil up to lower edge of the filler hole.

–Screw in plug -arrow-.

–Start engine, engage a gear and allow gearbox to ro-

tate for about 2 minutes.

–Switch off engine, unscrew plug -arrow- and top up

gear oil to lower edge of the filler hole.

–Tighten plug -arrow-, 25 Nm.

6 speed gearbox 0A8

Gearbox oil specification: G51 SAE 75W90 (synthetic

oil).

–Unscrew plug for inspecting gear oil -arrow-.

The oil is at the correct level if the gear is filled up to the

lower edge of the oil filler hole.

–Tighten plug -arrow-, 30 Nm.

When topping up, pay attention to the following

points:

–Unscrew plug for inspecting gear oil -arrow-.

–Pour in gear oil up to lower edge of the filler hole.

–Screw in plug -arrow-.

–Start engine, engage a gear and allow gearbox to ro-

tate for about 2 minutes.

–Switch off engine and unscrew plug -arrow-.

–Pour in gear oil again up to lower edge of the filler

hole.

–Tighten plug -arrow-, 30 Nm.

Inspecting ATF level, if necessary top-

ping up

Special tools, test and measuring equipment and

auxiliary items required

♦Torque wrench (5 to 50 Nm), e.g. -V.A.G 1331-

♦Diagnostic cable -V.A.G 1551/3-

♦Vehicle system tester -V.A.G 1552-

♦ATF filling system e.g. -V.A.G 1924-

Page 48 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

ChassisEdition 02.04

S00.5301.13.2002-5 page 2 02

ways replace the brake linings on both sides (repair

measure).

Avoid soiling from brake fluid or grease flowing out.

Inspecting brake system for leaks and

damage

–Inspect master brake cylinder, brake servo unit (for

ABS: hydraulic unit), brake pressure regulator, brake

calipers for leaks and damage.

–Inspect brake hoses for twisting.

–Ensure that the brake hoses do not touch any parts of

the vehicle when the steering is turned to full left or full

right lock.

–Inspect the brake hoses for porous and brittle points.

Inspect the brake hoses and brake lines for chafing

points.

–Inspect the brake connections and attachments to en-

sure they are correctly fitted, free of leaks and corro-

sion.

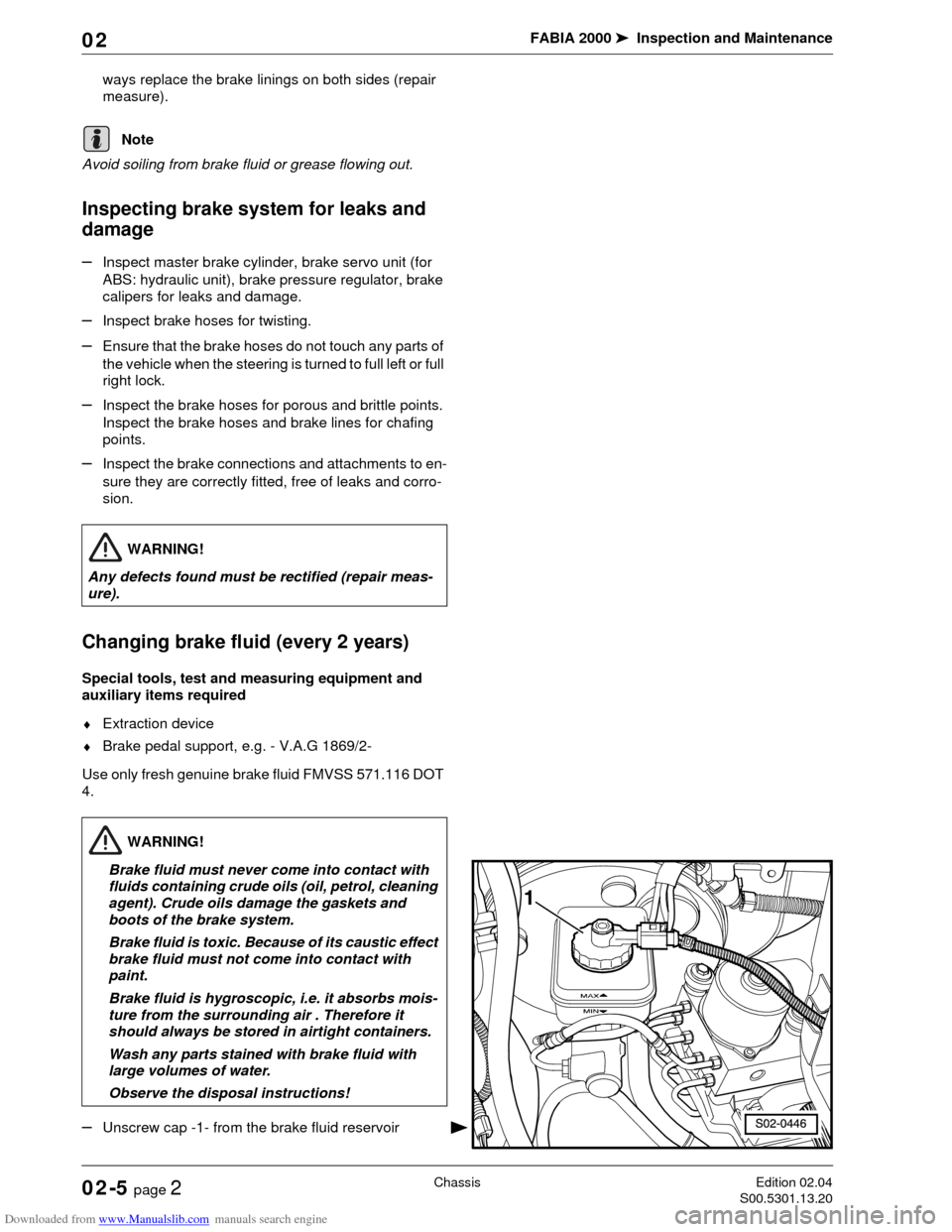

Changing brake fluid (every 2 years)

Special tools, test and measuring equipment and

auxiliary items required

♦Extraction device

♦Brake pedal support, e.g. - V.A.G 1869/2-

Use only fresh genuine brake fluid FMVSS 571.116 DOT

4.

–Unscrew cap -1- from the brake fluid reservoir

Note

WARNING!

Any defects found must be rectified (repair meas-

ure).

WARNING!

Brake fluid must never come into contact with

fluids containing crude oils (oil, petrol, cleaning

agent). Crude oils damage the gaskets and

boots of the brake system.

Brake fluid is toxic. Because of its caustic effect

brake fluid must not come into contact with

paint.

Brake fluid is hygroscopic, i.e. it absorbs mois-

ture from the surrounding air . Therefore it

should always be stored in airtight containers.

Wash any parts stained with brake fluid with

large volumes of water.

Observe the disposal instructions!

Page 52 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

ChassisEdition 02.04

S00.5301.13.2002-5 page 6 02

Inspecting the tyre tread depth (includ-

ing spare wheel) and entering

This value may differ in individual countries as a result of

differing statutory requirements.

If the tyre tread depth is close to the legal minimum, in

other words if no further tread exists at the points around

the circumference of the tyre at which the 1.6 mm high

wear indicators are positioned, the customer should be

informed of the necessary repair measures.

Tightening wheel bolts to specific torque

Special tools, test and measuring equipment and

auxiliary items required

♦Torque wrench

Tightening torque for steel and light alloy wheels 120 Nm.

Inspecting the tyre inflation pressure (in-

cluding spare wheel) and correcting the

tyre inflation pressure if necessary

Special tools, test and measuring equipment and

auxiliary items required

♦Tyre inflation pressure tester

♦The tyre inflation pressures are indicated on a stick-

er,which is affixed to the inside of the fuel filler flap.

♦The tyre inflation pressures indicated on the sticker

apply only to the tyres when cold. Do not reduce the

higher inflation pressure of warm tyres.

♦If winter tyres are fitted, the relevant tyre inflation pres-

sure should be increased by 0.2 bar/20 kPa.

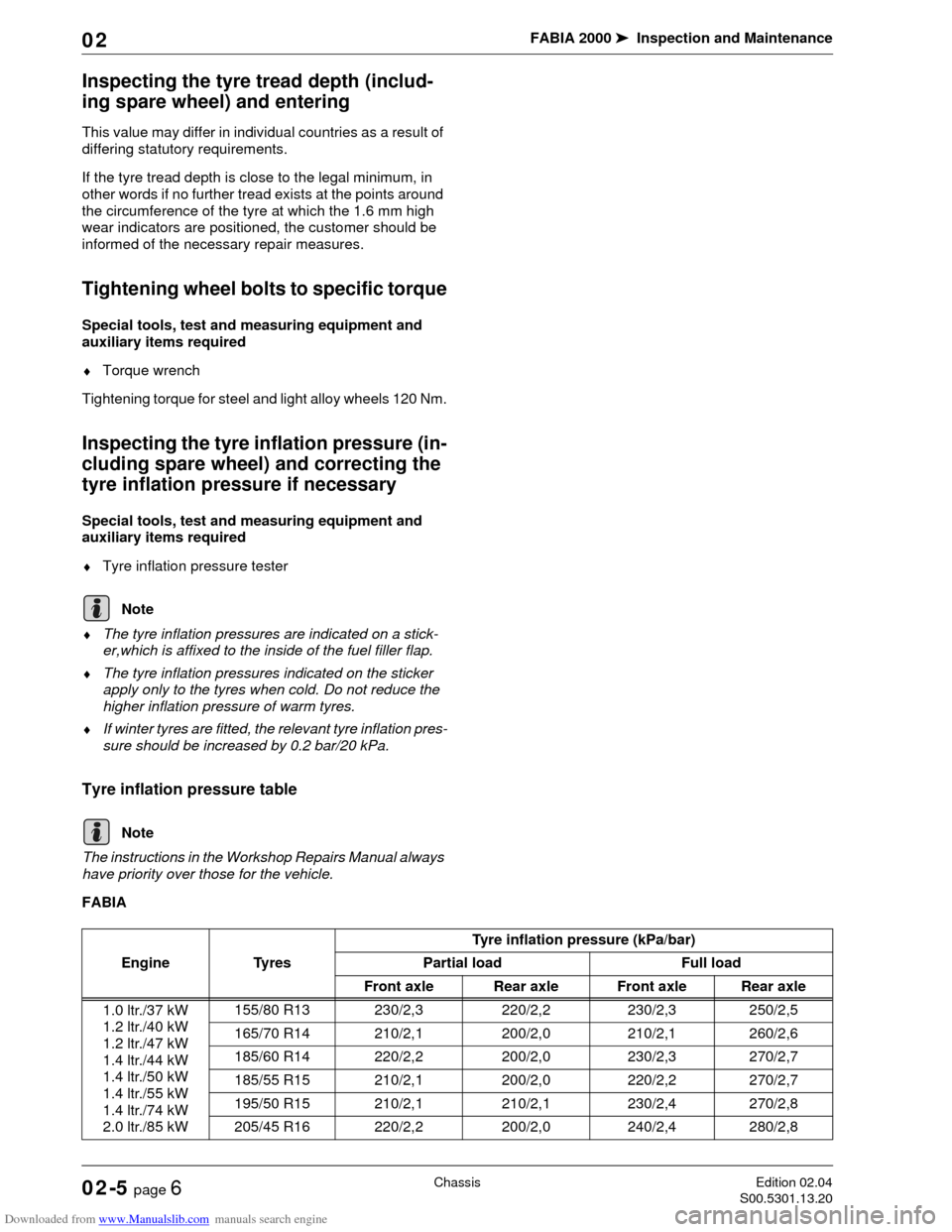

Tyre inflation pressure table

The instructions in the Workshop Repairs Manual always

have priority over those for the vehicle.

FABIA

Note

Note

Engine TyresTyre inflation pressure (kPa/bar)

Partial load Full load

Front axle Rear axle Front axle Rear axle

1.0 ltr./37 kW

1.2 ltr./40 kW

1.2 ltr./47 kW

1.4 ltr./44 kW

1.4 ltr./50 kW

1.4 ltr./55 kW

1.4 ltr./74 kW

2.0 ltr./85 kW155/80 R13 230/2,3 220/2,2 230/2,3 250/2,5

165/70 R14 210/2,1 200/2,0 210/2,1 260/2,6

185/60 R14 220/2,2 200/2,0 230/2,3 270/2,7

185/55 R15 210/2,1 200/2,0 220/2,2 270/2,7

195/50 R15 210/2,1 210/2,1 230/2,4 270/2,8

205/45 R16 220/2,2 200/2,0 240/2,4 280/2,8

Page 55 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

Electrical SystemEdition 09.04

S00.5301.14.2002-6 page 1 02

02-6 Electrical System

Power windows: Inspecting positioning

If the battery is diconnected the power windows forget

their current position.

Test conditions:

•All car doors closed

The inspection procedure is carried out from the outside

Close window with the car key using the convenience

closing system.

–Turn car key into close position and hold until all the

windows are closed.

–After closing the windows hold the key in the close po-

sition for approximately another 3 seconds.

Electrical components: Check for proper

operation

–Inspect lighting, main headlights, headlight beam con-

trol, fog lights, turn signal lights, hazard warning light

system, tail lights, rear fog lights, reversing lights,

brake lights, parking light control for brightness and

proper operation.

–Inspect interior lights, illuminated storage compart-

ment, illuminated ashtray for proper operation.

–Airbag warning lamps: Check operation ⇒Chapter

02-7.

–Inspect warning buzzer, onboard computer, all switch-

es in centre console as well as on the dash panel and

horn for proper operation.

–Inspect power windows, exterior mirrors (heated and

electrically adjustable), central locking system, infra-

red remote control and convenience closing system

for proper operation

–Inspect heating of front seats for proper operation.

–Inspect radio for proper reception and absence of in-

terference, also inspect speakers ⇒02-6 page 2.

Battery: Testing no-load voltage

Special tools, test and measuring equipment and

auxiliary items required

♦Multimeter (e.g. -V.A.G 1526 A-)

Prior to the measurement the vehicle must have been in

the no-load state for at least two hours (no engine starts,

no charging or discharging of battery).

The following procedure applies to measuring the battery

voltage in the no-load state (after at least two hours):

–With the battery installed measure the voltage be-

tween the terminals (ignition switched off).

Page 57 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

Electrical SystemEdition 09.04

S00.5301.14.2002-6 page 3 02

holding the knob in the left or right position respective-

ly.

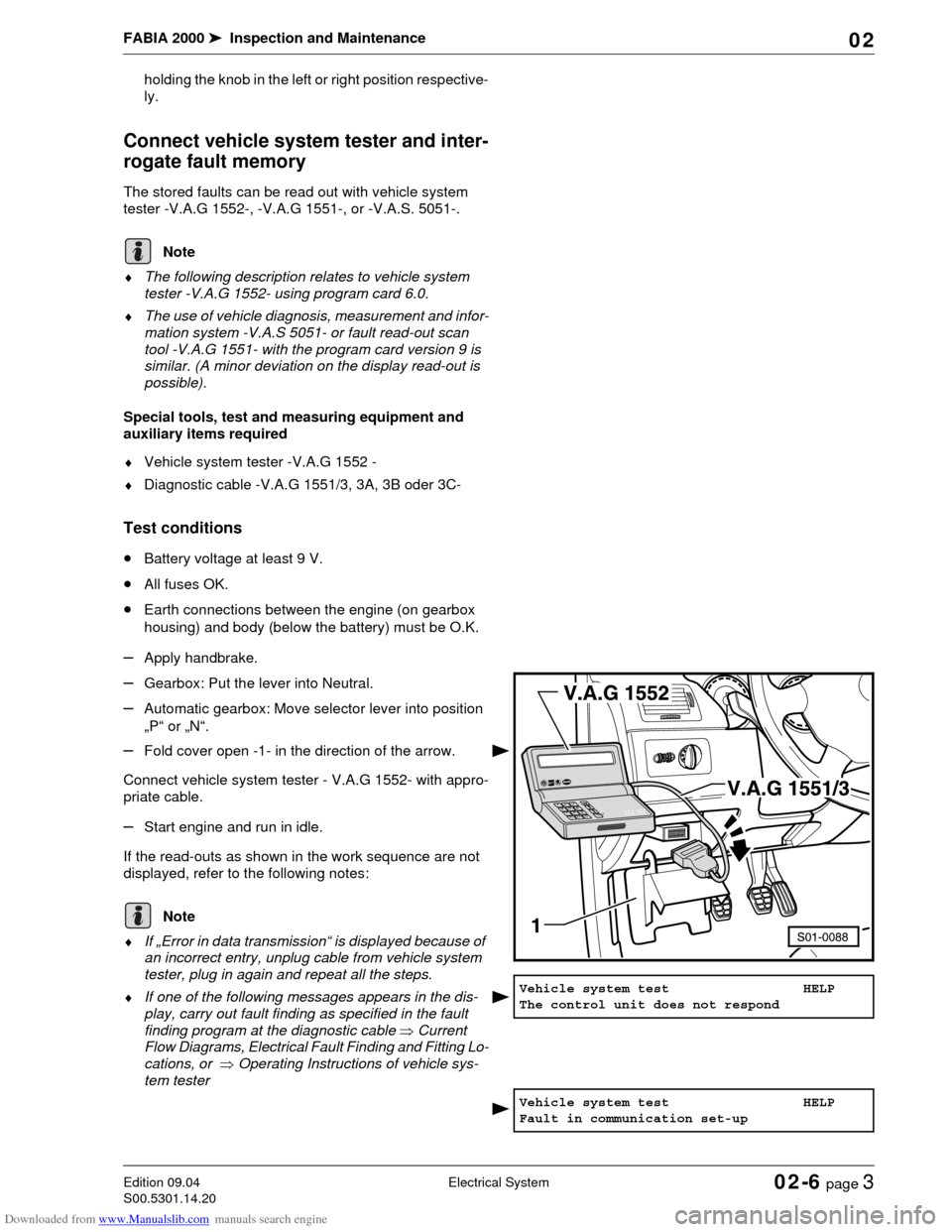

Connect vehicle system tester and inter-

rogate fault memory

The stored faults can be read out with vehicle system

tester -V.A.G 1552-, -V.A.G 1551-, or -V.A.S. 5051-.

♦The following description relates to vehicle system

tester -V.A.G 1552- using program card 6.0.

♦The use of vehicle diagnosis, measurement and infor-

mation system -V.A.S 5051- or fault read-out scan

tool -V.A.G 1551- with the program card version 9 is

similar. (A minor deviation on the display read-out is

possible).

Special tools, test and measuring equipment and

auxiliary items required

♦Vehicle system tester -V.A.G 1552 -

♦Diagnostic cable -V.A.G 1551/3, 3A, 3B oder 3C-

Test conditions

•Battery voltage at least 9 V.

•All fuses OK.

•Earth connections between the engine (on gearbox

housing) and body (below the battery) must be O.K.

–Apply handbrake.

–Gearbox: Put the lever into Neutral.

–Automatic gearbox: Move selector lever into position

„P“ or „N“.

–Fold cover open -1- in the direction of the arrow.

Connect vehicle system tester - V.A.G 1552- with appro-

priate cable.

–Start engine and run in idle.

If the read-outs as shown in the work sequence are not

displayed, refer to the following notes:

♦If „Error in data transmission“ is displayed because of

an incorrect entry, unplug cable from vehicle system

tester, plug in again and repeat all the steps.

♦If one of the following messages appears in the dis-

play, carry out fault finding as specified in the fault

finding program at the diagnostic cable ⇒Current

Flow Diagrams, Electrical Fault Finding and Fitting Lo-

cations, or ⇒Operating Instructions of vehicle sys-

tem tester

Note

1552V.A.

G

.H

E

LPQ O C9 8 76 5 43 2 1

Note

Vehicle system test HELP

The control unit does not respond

Vehicle system test HELP

Fault in communication set-up

Page 64 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

Electrical SystemEdition 09.04

S00.5301.14.2002-6 page 10 02

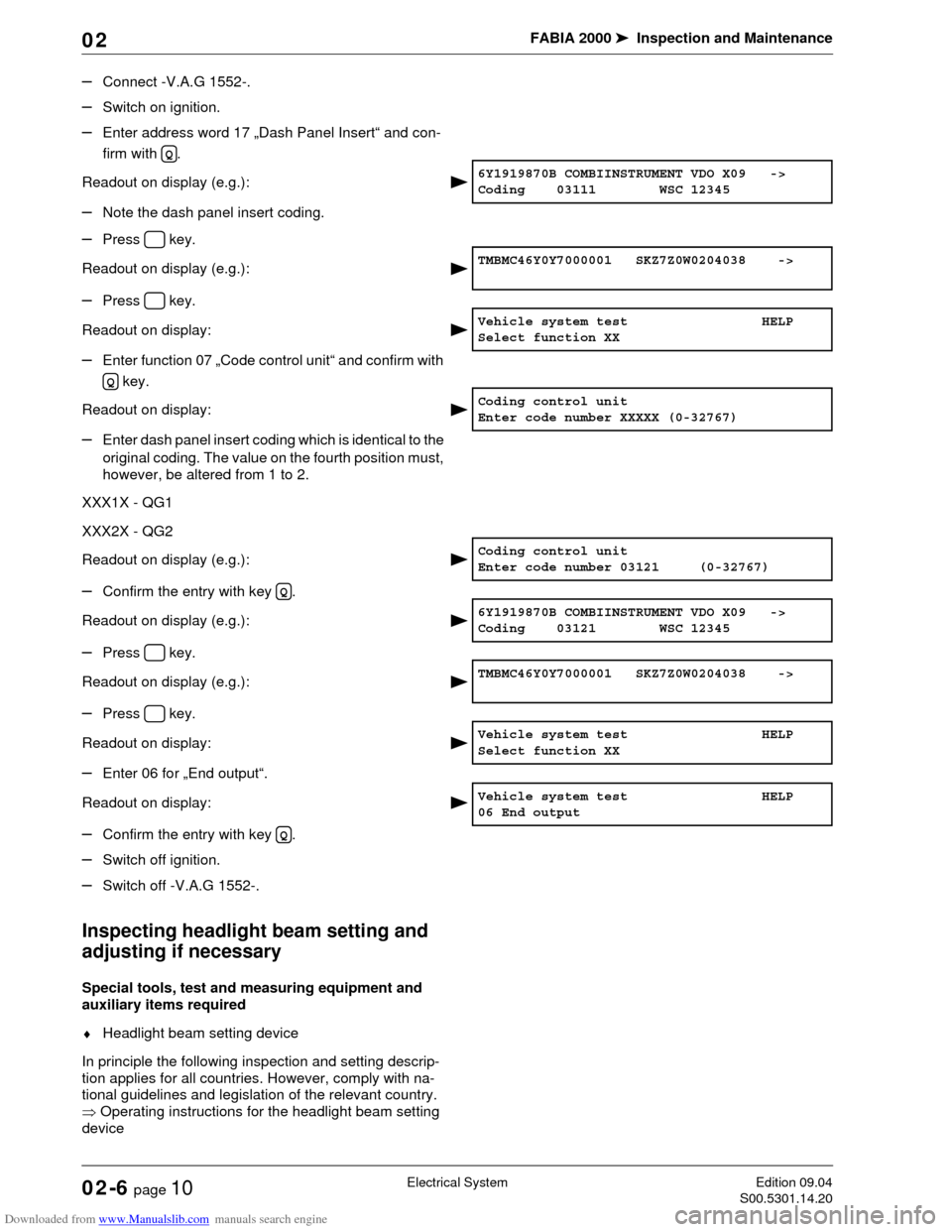

–Connect -V.A.G 1552-.

–Switch on ignition.

–Enter address word 17 „Dash Panel Insert“ and con-

firm with .

Readout on display (e.g.):

–Note the dash panel insert coding.

–Press key.

Readout on display (e.g.):

–Press key.

Readout on display:

–Enter function 07 „Code control unit“ and confirm with

key.

Readout on display:

–Enter dash panel insert coding which is identical to the

original coding. The value on the fourth position must,

however, be altered from 1 to 2.

XXX1X - QG1

XXX2X - QG2

Readout on display (e.g.):

–Confirm the entry with key .

Readout on display (e.g.):

–Press key.

Readout on display (e.g.):

–Press key.

Readout on display:

–Enter 06 for „End output“.

Readout on display:

–Confirm the entry with key .

–Switch off ignition.

–Switch off -V.A.G 1552-.

Inspecting headlight beam setting and

adjusting if necessary

Special tools, test and measuring equipment and

auxiliary items required

♦Headlight beam setting device

In principle the following inspection and setting descrip-

tion applies for all countries. However, comply with na-

tional guidelines and legislation of the relevant country.

⇒Operating instructions for the headlight beam setting

device

Q

6Y1919870B COMBIINSTRUMENT VDO X09 ->

Coding 03111 WSC 12345

TMBMC46Y0Y7000001 SKZ7Z0W0204038 ->

Vehicle system test HELP

Select function XX

Q

Coding control unit

Enter code number XXXXX (0-32767)

Coding control unit

Enter code number 03121 (0-32767)

Q

6Y1919870B COMBIINSTRUMENT VDO X09 ->

Coding 03121 WSC 12345

TMBMC46Y0Y7000001 SKZ7Z0W0204038 ->

Vehicle system test HELP

Select function XX

Vehicle system test HELP

06 End output

Q