air filter SKODA FABIA 2000 1.G / 6Y Workshop Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 2000, Model line: FABIA, Model: SKODA FABIA 2000 1.G / 6YPages: 86, PDF Size: 3.58 MB

Page 5 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

Table of ContentsEdition 09.04

S00.5301.14.20I Table of Contents

02 – Inspection and Maintenance

General points..........................................................................................

- Vehicle identification data ............................................................................

- Storage of ŠKODA new vehicles ....................................................................

- Vehicle handover from stock ........................................................................

- Additional customer information regarding inspection and maintenance .....................

Inspection................................................................................................

- Pre-Delivery Inspection -PDI- (Export) .............................................................

- Pre-sales Inspection - (the Czech Republic) ......................................................

- Delivery Inspection (Export) .........................................................................

- Oil Change Service every 15.000 km

1) (QG0) ....................................................

- Annual Inspection (every 12 months) (QG0) ......................................................

- Every 30 000 km (QG0) ..............................................................................

- Every 60 000 km (QG0) ..............................................................................

- Every 90 000 km (QG0) ..............................................................................

- Every 120 000 km (QG0) .............................................................................

- Every 150.000 km (QG0) .............................................................................

- Every 240 000 km (QG0) .............................................................................

- Inspection Service (QG1, QG2) .....................................................................

- Oil change (QG1, QG2)..............................................................................

Engines...................................................................................................

- Engine overview .......................................................................................

- Engine fitted ............................................................................................

- Visual inspection: Engine for leaks and damage .................................................

- Replace engine oil filter ...............................................................................

- Replacing timing belt and tensioning pulley for camshaft drive (1.9 TDI engines) ..........

- Replacing timing belt and tensioning pulley for camshaft drive (1.4 TDI engines) ..........

- Inspecting timing belt for camshaft drive for wear and running (petrol engine) ..............

- Replacing toothed belt and guide pulley for camshaft drive (1.9 SDI engines) ..............

- Inspecting engine oil level ............................................................................

- Change engine oil .....................................................................................

- Inspecting antifreeze protection, replenishing coolant additive if necessary .................

- Inspecting coolant level (volume) ...................................................................

- Ribbed V-belt: Inspect condition....................................................................

- Routing of V-ribbed belt ..............................................................................

- Replace spark plugs ..................................................................................

- Replace air filter element .............................................................................

- Replacing the fuel filter (diesel engine) ............................................................

- Draining the fuel filter (diesel engine) ..............................................................

Gearbox...................................................................................................

- Gearbox/Final drive: Check the oil level and top it if necessary ................................

- Inspecting ATF level, if necessary topping up ....................................................

Chassis...................................................................................................

- Inspecting thickness of front and rear brake pads/linings .......................................

- Inspecting brake system for leaks and damage ..................................................

02-1page 1

02-1page 1

02-1page 3

02-1page 3

02-1page 3

02-2page 1

02-2page 1

02-2page 2

02-2page 3

02-2page 5

02-2page 5

02-2page 6

02-2page 7

02-2page 7

02-2page 7

02-2page 7

02-2page 8

02-2page 8

02-2page 10

02-3page 1

02-3page 1

02-3page 4

02-3page 6

02-3page 7

02-3page 7

02-3page 7

02-3page 7

02-3page 8

02-3page 8

02-3page 8

02-3page 10

02-3page 12

02-3page 14

02-3page 14

02-3page 17

02-3page 18

02-3page 18

02-3page 19

02-4page 1

02-4page 1

02-4page 2

02-5page 1

02-5page 1

02-5page 2

Page 6 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

Table of ContentsEdition 09.04

S00.5301.14.20II

- Changing brake fluid (every 2 years)...............................................................

- Inspecting the brake fluid level ......................................................................

- Track rod ends: Inspect play, correct attachment and joint boots .............................

- Inspecting tyres (including spare wheel) ...........................................................

- Inspecting the tyre tread depth (including spare wheel) and entering ........................

- Tightening wheel bolts to specific torque ..........................................................

- Inspecting the tyre inflation pressure (including spare wheel) and correcting the tyre

inflation pressure if necessary .......................................................................

Electrical System.......................................................................................

- Power windows: Inspecting positioning ............................................................

- Electrical components: Check for proper operation ..............................................

- Battery: Testing no-load voltage ....................................................................

- Battery: Inspecting electrolyte level, topping up with distilled water if necessary ...........

- Radio: Check for proper operation..................................................................

- Setting clock ............................................................................................

- Connect vehicle system tester and interrogate fault memory..................................

- Resetting service interval display (SID) QG0 .....................................................

- Resetting service interval display (SID) QG1 and QG2 .........................................

- Changing the code of the service intervals ........................................................

- Inspecting headlight beam setting and adjusting if necessary .................................

- Setting the headlight beam ..........................................................................

- Replace emergency battery for alarm system ...................................................

Body.......................................................................................................

- Airbag units: Visual inspection ......................................................................

- Inspect key switch for deactivation of front passenger airbag ..................................

- Check underbody protection and body paintwork for damage .................................

- Inspecting plenum chamber and water drain openings for dirt, cleaning if necessary .....

- Windscreen wiper/washer system: Check for proper operation ................................

- Sun roof: Cleaning and greasing runners .........................................................

- Door locks, locking buttons, child safety locks: Check for proper operation .................

- Replacing the dust and odour filter element ......................................................

- Sticking the vehicle data sticker .....................................................................

- ................................................................................. Inspect trailer coupling

Exhaust-emission Analysis..........................................................................

- Exhaust-Emission Analysis on Models with Fuel Engines ......................................

- Test Values for Exhaust-Emission Analysis on Models with Fuel Engines..................

- Exhaust-Emission Analysis on Models with Diesel Engines ....................................

- Test Values for Exhaust-Emission Analysis on Diesel Engines................................

Miscellaneous...........................................................................................

- Tow starting/Towing ..................................................................................

- Perform a test drive ...................................................................................

- Raising the vehicle ....................................................................................02-5page 2

02-5page 4

02-5page 5

02-5page 5

02-5page 6

02-5page 6

02-5page 6

02-6page 1

02-6page 1

02-6page 1

02-6page 1

02-6page 2

02-6page 2

02-6page 2

02-6page 3

02-6page 4

02-6page 7

02-6page 9

02-6page 10

02-6page 12

02-6page 13

02-7page 1

02-7page 1

02-7page 2

02-7page 2

02-7page 3

02-7page 3

02-7page 4

02-7page 4

02-7page 5

02-7page 6

02-7page 6

02-8page 1

02-8page 1

02-8page 2

02-8page 5

02-8page 6

02-9page 1

02-9page 1

02-9page 2

02-9page 2

Page 9 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

General pointsEdition 09.04

S00.5301.14.2002-1 page 3 02

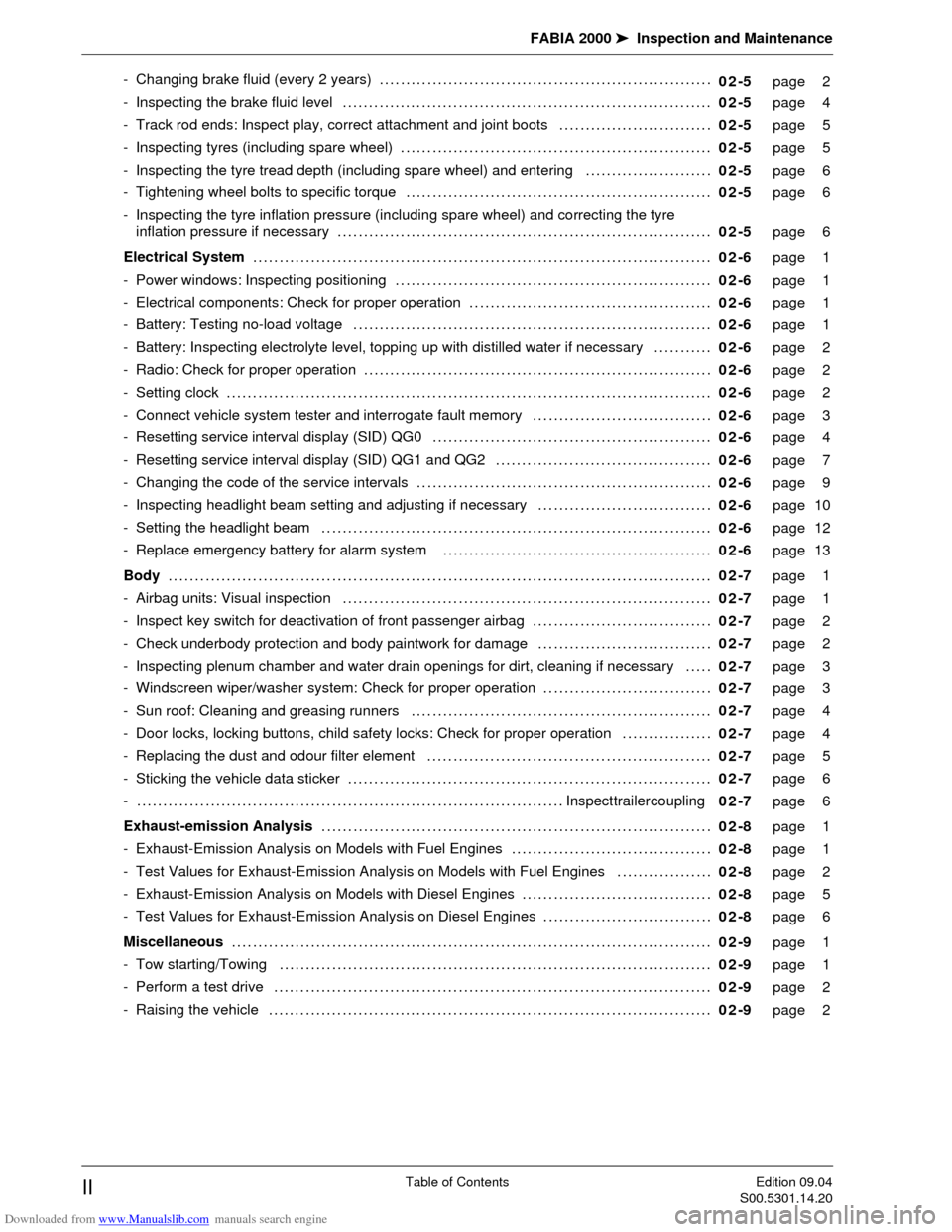

Vehicle data sticker

The vehicle data sticker is located at the rear left on the

floor of the boot.

Storage of ŠKODA new vehicles

Notes on storage of new vehicles ⇒Technical Service

Handbook.

Vehicle handover from stock

–Before starting a stock vehicle, carry out a Pre-sales

Inspection.

–If the vehicle has been in stock for more than 6

months, replace the brake fluid.

–Inspect the electrolyte level of the battery and top up,

if necessary.

–Before the vehicle is sold, the recharging table must

be removed from the battery.

–If the battery is more than 52 weeks old or has been

recharged more than twice, it must be replaced with

a new battery.

Additional customer information regard-

ing inspection and maintenance

Information regarding the use of vehicles under

„severe conditions“:

–The service advisor should always point out to the

customer that the inspection intervals are based on

normal operating conditions.

–Under „severe conditions“ the inspection intervals

must be shortened.

„Severe conditions“ exist, for instance, if the vehicle is op-

erated continuously in one or several of the conditions

stated below:

♦Towing a trailer or when fitted with a roof rack.

♦Operated on dusty, poor, muddy roads or roads treat-

ed with road salt.

♦Driven for short distances and at ambient tempera-

tures below freezing point.

–If one or several of these „severe conditions“ exists,

please advise your customer whether it is necessary

to have work carried out between the normal service

intervals, such as:

♦Changing the engine oil before the normal specified

interval.

♦Cleaning or replacing the air filter element in the air fil-

ter housing.

Page 15 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

InspectionEdition 09.04

S00.5301.14.2002-2 page 5 02

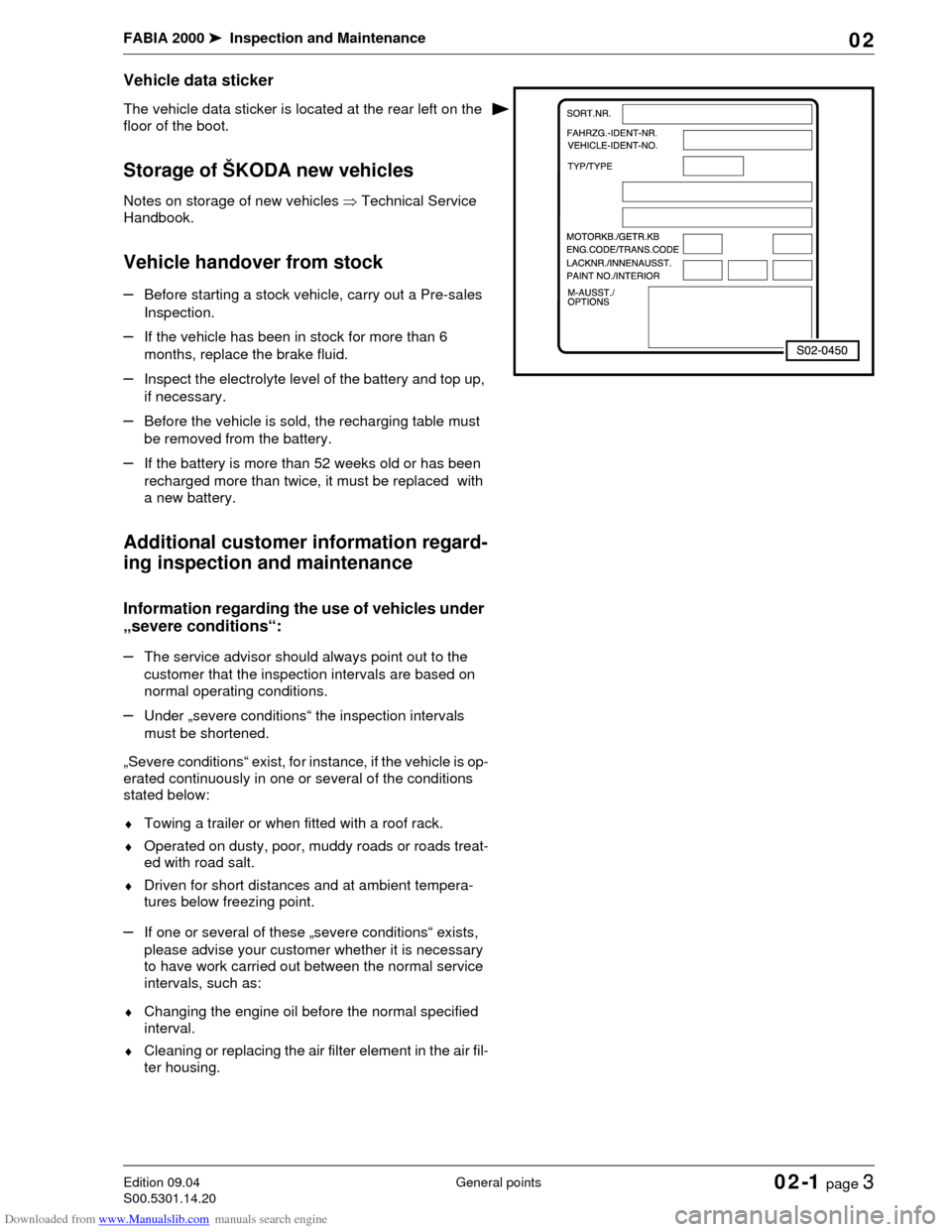

Oil Change Service every 15.000 km1) (QG0)

An Oil Change Service need only be carried out if the vehicle has covered 15 000 km before one year has

elapsed1). If the Oil Change Service is due only a few months prior to the Annual Inspection, it is recommend-

ed to carry out the Annual Inspection at the same time.

Annual Inspection (every 12 months) (QG0)

1)The 7500 km interval applies for diesel operation with high sulphur content - it does not apply for the Czech Republic (for further information

refer to Technical Service Handbook)

Work involvedChapter

–Change engine oil

–Replace engine oil filter02-3

–Disc brake pads: Inspect thickness02-5

–Reset service interval display02-6

–Drain away water from the fuel filter (diesel engine with fuel operation, which does not

comply with DIN EN 590-standard)

After each oil change

–Complete „Next service date“ sticker (max. 1 year or 15 000 km) and affix sticker to the

side of the dash panel (on the driver's side)

–Complete and attach service mirror tag to the interior rear-view mirror

–Hand customer the completed and signed form

Chapter

♦For vehicles with a high mileage carry out an Oil Change Service no later than after 15

000 km1). Carry out Annual Inspection after 30 000 km prior to the scheduled date02-3

♦Every 2 years - in addition change brake fluid 02-5

♦Every 4 years - in addition, change air filter element and clean air filter housing - vehicles

driven less than 60 000 km within 4 years - replace contents set for tyre repair 02-3

♦Every 5 years - replace the emergency battery for the alarm 02-6

♦Exhaust-emission analysis (EEA): Expiry date - see EEA tag on the vehicle identification

plate (only valid for some countries)

♦Recommendation: Replace windscreen wiper blades every 2 years

♦At each inspection - check the 'use by date' of the first aid kit

Work involved

–Interrogate fault memory of all systems, if necessary erase02-6

–Inspect engine and components in the engine compartment for leaks and damage02-3

–Change engine oil

–Replace engine oil filter02-3

–Airbag units: Perform visual inspection for external damage02-7

–Reset service interval display02-6

–Inspecting brake system for leaks and damage02-5

–Check the thickness of the brake pads on all wheels02-5

–Check gearbox, final drive, drive shafts and joint boots for leaks and damage

–Axle joints: Inspect boots for leaks and damage

Page 17 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

InspectionEdition 09.04

S00.5301.14.2002-2 page 7 02

Every 60 000 km (QG0)

Includes: Inspection every 30 000 km and additional operations stated in the table below

Every 90 000 km (QG0)

Includes: Inspection every 30 000 km and additional operations stated in the table below

Every 120 000 km (QG0)

Includes: Inspection every 60 000 km and additional operations stated in the table below

Every 150.000 km (QG0)

Includes: Inspection every 60 000 km and additional operations stated in the table below

Work involvedChapter

–Air filter: Clean housing, replace filter element02-3

–Fuel filter: replace (vehicles with diesel engine)02-3

–Ribbed V-belt: Inspect condition and for vehicles without tensioning pulley also the ten-

sion02-3

–Spark plugs: replace02-3

–Automatic gearbox: Inspect ATF1) level, if necessary top up

1)Automatic transmission fluid for the automatic gearbox

02-4

Work involvedChapter

–Timing belt for camshaft drive: replace (ASY diesel engines up to 04.2001)02-3

–Timing belt and tensioning pulley for camshaft drive: replace (PD diesel engine up to

07.03)02-3

–Timing belt for camshaft drive: inspect (petrol engines) - every 90 000 km, then every 30

000 km02-3

Work involvedChapter

–Timing belt and tensioning pulley (038 109 244 H)1) for camshaft drive: replace (diesel en-

gines other than the PD engine) - vehicles as of 05.2001 to 04.2002

1)When the tensioning pulley Spare Part No. 038 109 244 M is mounted after 120 000 km. on vehicles with a diesel engine during replacement of

the timing belt and the tensioning pulley the change interval of the timing belt should be altered from 120 000 km to 150 000 km. The customer

should be informed about the new service interval when the tensioning pulley is first replaced by a new tensioning pulley Spare Part No. 038

109 244 M by making an entry in the service plan, in the section „Workshop entries“. Only the timing belt will be replaced at each next service

interval at 150 000 km.

02-3

–Timing belt for camshaft drive: replace (PD diesel engine as of 08.03)02-3

Work involvedChapter

–Timing belt: replace (diesel engines other than the PD engine) - vehicles as of 05.200202-3

Page 18 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

InspectionEdition 09.04

S00.5301.14.2002-2 page 8 02

Every 240 000 km (QG0)

Includes: Inspection every 120 000 km and additional operations stated in the table below

Inspection Service (QG1, QG2)

♦Vehicles with WIV (QG1) must be filled with oils which conform to the VW standard 503 00 (petrol engines) VW

506 00 (SDI, TDI diesel engines) or VW 506 01 (TDI PD diesel engines), possibility of damage when using other

oils.

♦Vehicles with WIV which have been filled with oils which do not conform to the VW standard 503 00 or VW 506 00

or VW 506 01, must be coded in the WIV with a fixed oil change limitation (QG2) ⇒Chapter 02-6. Work involvedChapter

–Replace tensioning pulley (PD diesel engine as of 08.03)02-3

♦Every 2 years - in addition change brake fluid

♦Every 4 years - replace contents set for tyre repair

♦Every 90 000 km - replace the guide pulley and the tensioning pulley (PD diesel engine up to 07.03)

♦Every 120 000 km - replace the timing belt and the guide pulley (038 109 244 H) (diesel engines as of 05.01 to

04.02 except the PD engine)

♦Every 120 000 km - Replace the timing belt (PD Diesel engine as of 08.03)

♦Every 150 000 km - replace the timing belt (diesel engines as of 05.02 and with the guide pulleyr 038 109 244

M) - except on the TDI PD engine

♦Every 240 000 km - Replace the tensioning pulley (PD Diesel engine as of 08.03)

♦Exhaust-emission analysis (EEA). Expiry date - see EEA tag on the vehicle identification plate (only valid for

some countries)

♦At each inspection - check the 'use by date' of the first aid kit

♦Recommendation: Replace windscreen wiper blades every 2 years

Note

Work involvedChapter

–Interrogate fault memory of all systems, if necessary erase02-6

–Visual inspection: Engine and components in the engine compartment for leaks and dam-

age02-3

–Change the engine oil, replace the oil filter02-3

–Conduct a visual inspection of the airbag units for external damage02-7

–Reset service interval display02-6

–Inspecting brake system for leaks and damage02-5

–Check the thickness of the brake pads on all wheels02-5

–Check gearbox, final drive, drive shafts and joint boots for leaks and damage

–Axle joints: Inspect boots for leaks and damage

–Track rod ends: Inspect play and correct attachment of boots

Page 19 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

InspectionEdition 09.04

S00.5301.14.2002-2 page 9 02

–Check the tyre inflation pressure (including spare wheel), correct if necessary02-5

–Inspect tyre wear (including spare wheel)02-5

–Inspect tyre tread depth (including spare wheel) and record (FL..., FR..., RR..., RL...,

SP...)02-5

–Inspect exhaust system for leaks, damage and attachment

–Brake fluid volume: Check level, if necessary top up02-5

–Battery: test02-6

–Check the anti-freeze in the cooling system and record ...... °C, check for leaks, top up

coolant if necessary02-3

–Flap lock for the engine bonnet: grease

–Inspect operation of all switches, all electrical components, gauges/indicators and con-

trols for proper operation02-6

–Windscreen wiper and washer system: Inspect condition of wiper blades, wiper operation,

washer system: if necessary top up fluid02-7

–Inspect plenum chamber for dirt, clean if necessary02-7

–Inspect operation of tilting roof and grease the runners02-7

–Headlights: Inspect, if necessary adjust02-6

–Gear oil: Inspect level and top up if necessary (manual gearbox)02-4

–Draining the fuel filter (diesel engine)

–Inspect trailer coupling (with removable arm - manufacturer Profsvar)02-7

–Check underbody protection and body paintwork for damage02-7

–Dust and odour filter element for the passenger compartment: replace02-7

–Air filter: Clean the housing, replace the insert every 4 years or 60.000 km.02-3

–Replace the fuel filter (diesel engine with fuel operation, which does not comply with DIN

EN 590-standard)

–Ribbed V-belt: Inspect condition and for vehicles without tensioning pulley also the ten-

sion - every 60.000 km02-3

–Replace the fuel filter (diesel engine) - every 60.000 km

–Spark plugs: replace - every 60.000 km.02-3

–Automatic gearbox: Check the ATF level, and top up if necessary, every 60.000 km

–Check the timing belt for the camshaft on a 4-cylinder petrol engine at 90.000 km and

then every 30.000 km after that

–Replace the emergency battery for the alarm system - every five years02-6

After each inspection

–Complete the „Next Service“ sticker and affix sticker to the side of the dash panel (on the

driver's side)

–Perform road test including inspection of proper operation of footbrakes and handbrake,

gearshift and steering, final inspection02-9

–„Mirror tag“ - complete and attach to interior mirror

–Hand customer the completed and signed form Work involvedChapter

Page 38 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

EnginesEdition 09.04

S00.5301.14.2002-3 page 18 02

Replace air filter element

–Open the filter housing.

–Replace the filter element and clean the filter housing.

–Close filter housing and check correct fitting.

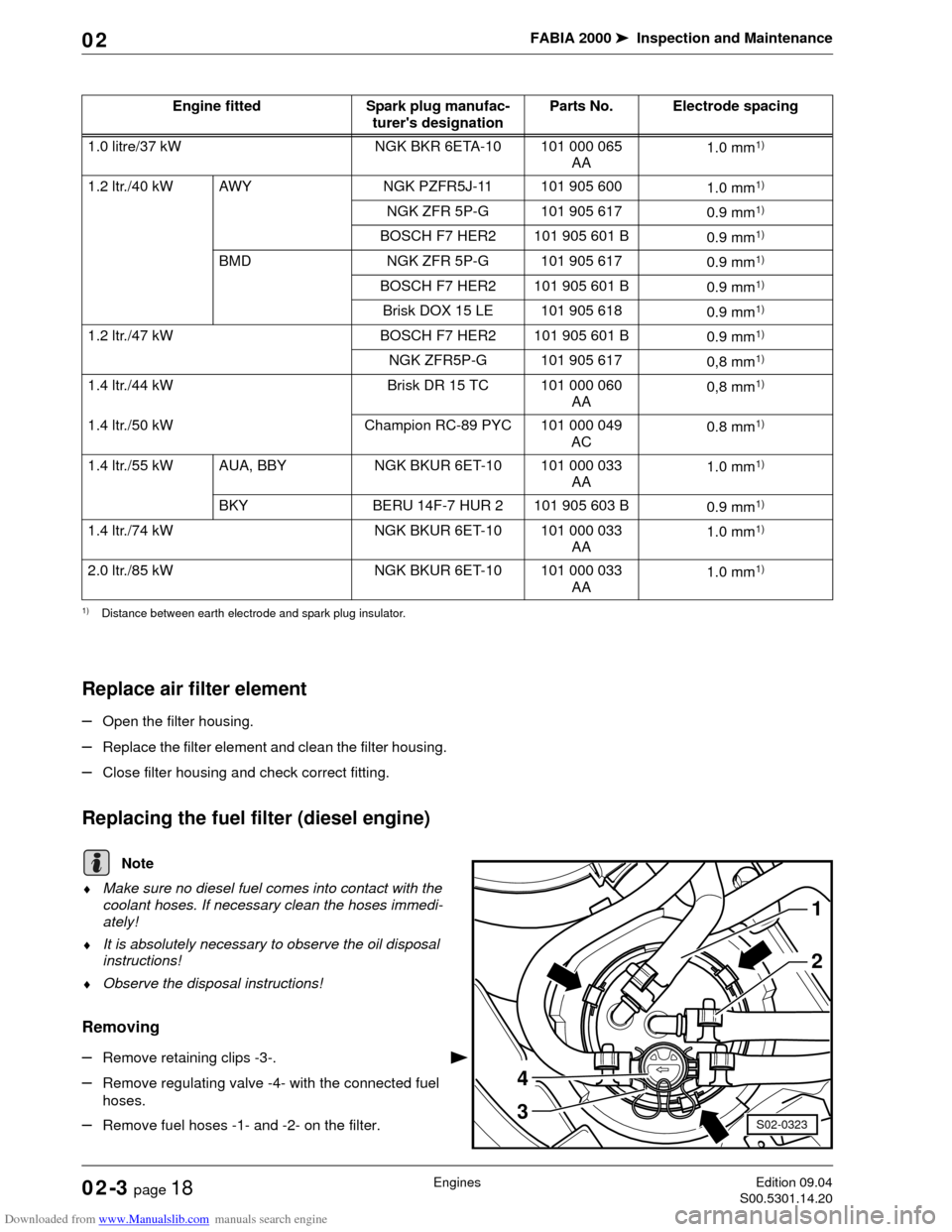

Replacing the fuel filter (diesel engine)

♦Make sure no diesel fuel comes into contact with the

coolant hoses. If necessary clean the hoses immedi-

ately!

♦It is absolutely necessary to observe the oil disposal

instructions!

♦Observe the disposal instructions!

Removing

–Remove retaining clips -3-.

–Remove regulating valve -4- with the connected fuel

hoses.

–Remove fuel hoses -1- and -2- on the filter.Engine fitted Spark plug manufac-

turer's designationParts No. Electrode spacing

1.0 litre/37 kW NGK BKR 6ETA-10 101 000 065

AA1.0 mm

1)

1) Distance between earth electrode and spark plug insulator.

1.2 ltr./40 kW AWY NGK PZFR5J-11 101 905 600

1.0 mm1)

NGK ZFR 5P-G 101 905 617

0.9 mm1)

BOSCH F7 HER2 101 905 601 B

0.9 mm1)

BMD NGK ZFR 5P-G 101 905 617

0.9 mm1)

BOSCH F7 HER2 101 905 601 B

0.9 mm1)

Brisk DOX 15 LE 101 905 618

0.9 mm1)

1.2 ltr./47 kW BOSCH F7 HER2 101 905 601 B

0.9 mm1)

NGK ZFR5P-G 101 905 617

0,8 mm1)

1.4 ltr./44 kW Brisk DR 15 TC 101 000 060

AA0,8 mm1)

1.4 ltr./50 kW Champion RC-89 PYC 101 000 049

AC0.8 mm1)

1.4 ltr./55 kW AUA, BBY NGK BKUR 6ET-10 101 000 033

AA1.0 mm1)

BKY BERU 14F-7 HUR 2 101 905 603 B

0.9 mm1)

1.4 ltr./74 kW NGK BKUR 6ET-10 101 000 033

AA1.0 mm1)

2.0 ltr./85 kW NGK BKUR 6ET-10 101 000 033

AA1.0 mm1)

Note

1

2

3

4

S02-0323

Page 74 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

BodyEdition 09.04

S00.5301.14.2002-7 page 6 02

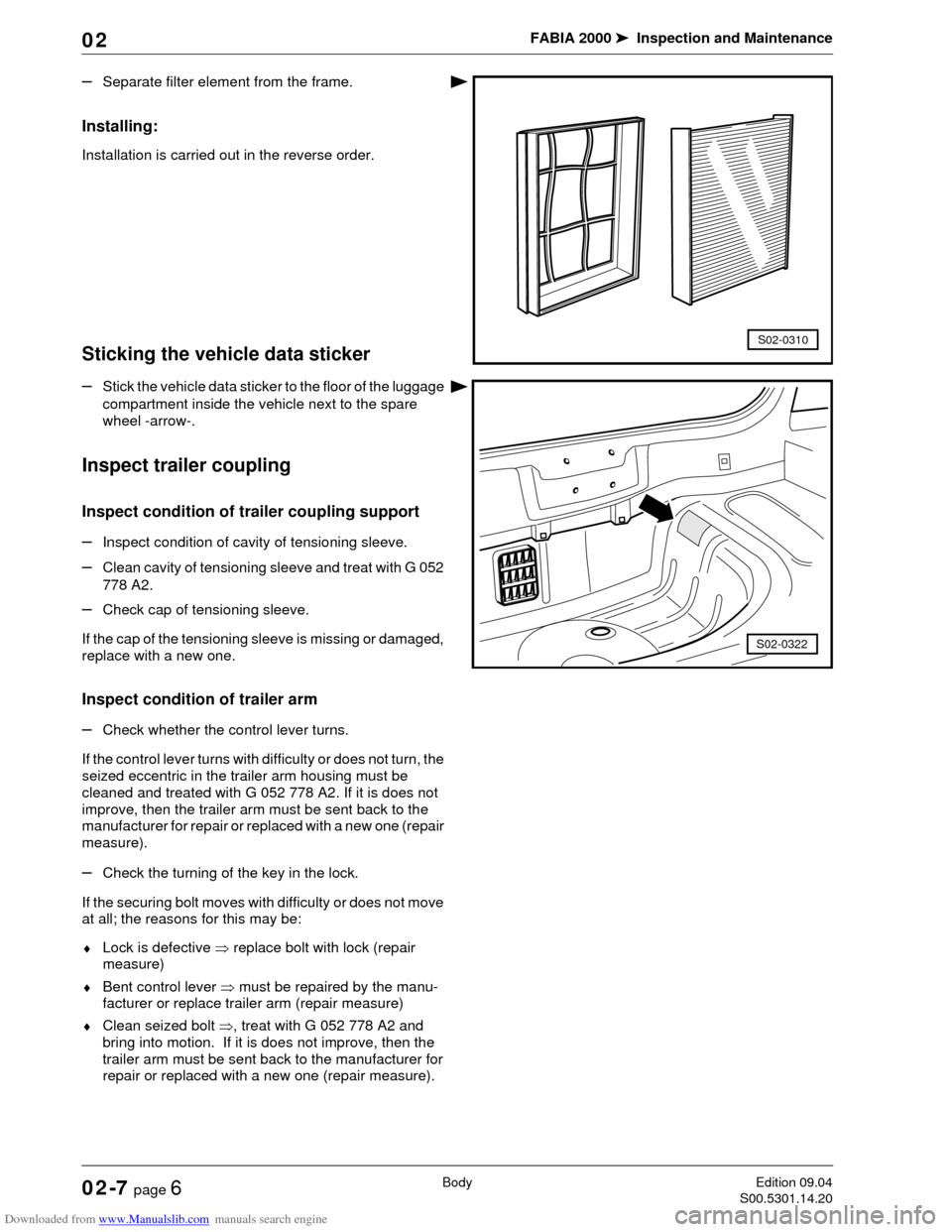

–Separate filter element from the frame.

Installing:

Installation is carried out in the reverse order.

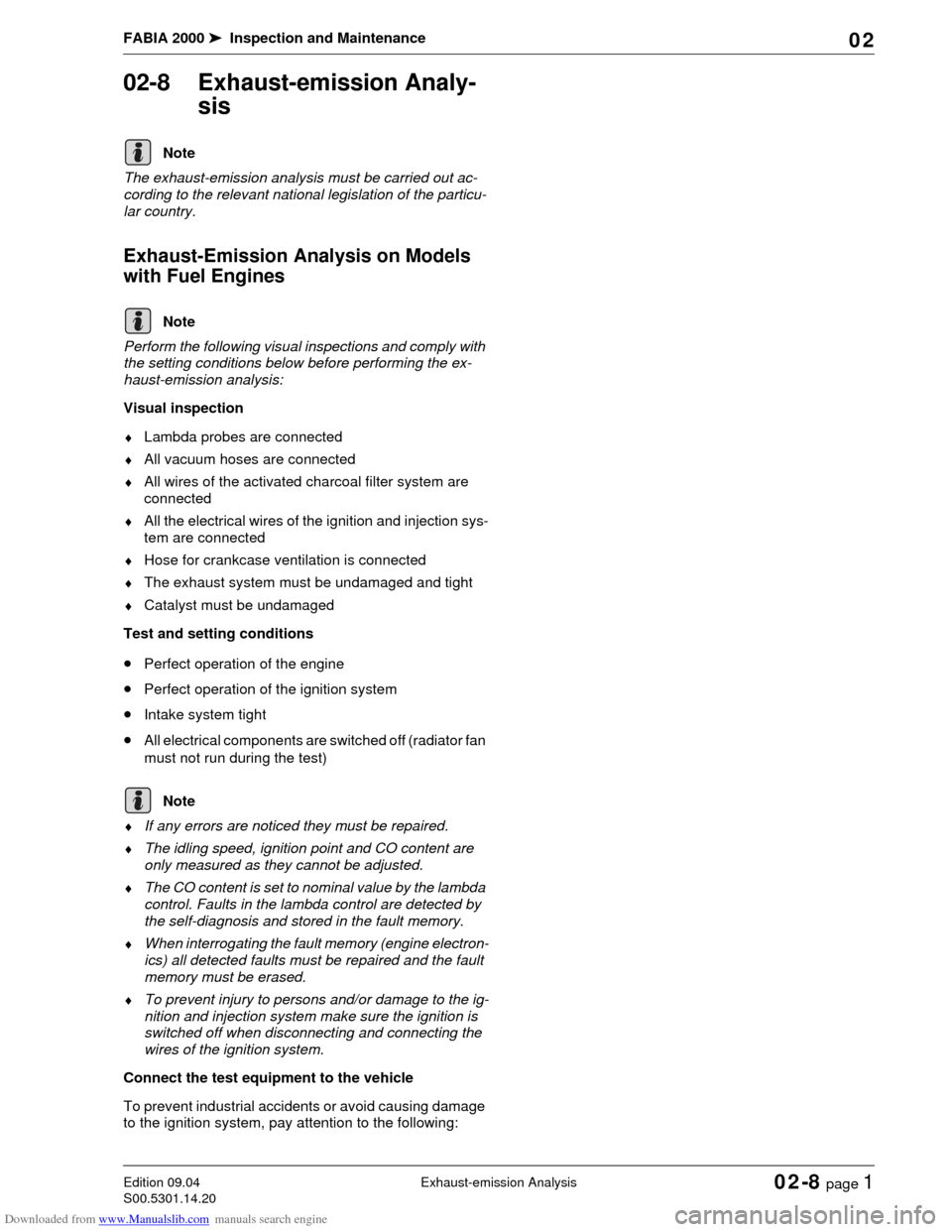

Sticking the vehicle data sticker

–Stick the vehicle data sticker to the floor of the luggage

compartment inside the vehicle next to the spare

wheel -arrow-.

Inspect trailer coupling

Inspect condition of trailer coupling support

–Inspect condition of cavity of tensioning sleeve.

–Clean cavity of tensioning sleeve and treat with G 052

778 A2.

–Check cap of tensioning sleeve.

If the cap of the tensioning sleeve is missing or damaged,

replace with a new one.

Inspect condition of trailer arm

–Check whether the control lever turns.

If the control lever turns with difficulty or does not turn, the

seized eccentric in the trailer arm housing must be

cleaned and treated with G 052 778 A2. If it is does not

improve, then the trailer arm must be sent back to the

manufacturer for repair or replaced with a new one (repair

measure).

–Check the turning of the key in the lock.

If the securing bolt moves with difficulty or does not move

at all; the reasons for this may be:

♦Lock is defective ⇒ replace bolt with lock (repair

measure)

♦Bent control lever ⇒ must be repaired by the manu-

facturer or replace trailer arm (repair measure)

♦Clean seized bolt ⇒, treat with G 052 778 A2 and

bring into motion. If it is does not improve, then the

trailer arm must be sent back to the manufacturer for

repair or replaced with a new one (repair measure).

S02-0310

S02-0322

Page 77 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

Exhaust-emission AnalysisEdition 09.04

S00.5301.14.2002-8 page 1 02

02-8 Exhaust-emission Analy-

sis

The exhaust-emission analysis must be carried out ac-

cording to the relevant national legislation of the particu-

lar country.

Exhaust-Emission Analysis on Models

with Fuel Engines

Perform the following visual inspections and comply with

the setting conditions below before performing the ex-

haust-emission analysis:

Visual inspection

♦Lambda probes are connected

♦All vacuum hoses are connected

♦All wires of the activated charcoal filter system are

connected

♦All the electrical wires of the ignition and injection sys-

tem are connected

♦Hose for crankcase ventilation is connected

♦The exhaust system must be undamaged and tight

♦Catalyst must be undamaged

Test and setting conditions

•Perfect operation of the engine

•Perfect operation of the ignition system

•Intake system tight

•All electrical components are switched off (radiator fan

must not run during the test)

♦If any errors are noticed they must be repaired.

♦The idling speed, ignition point and CO content are

only measured as they cannot be adjusted.

♦The CO content is set to nominal value by the lambda

control. Faults in the lambda control are detected by

the self-diagnosis and stored in the fault memory.

♦When interrogating the fault memory (engine electron-

ics) all detected faults must be repaired and the fault

memory must be erased.

♦To prevent injury to persons and/or damage to the ig-

nition and injection system make sure the ignition is

switched off when disconnecting and connecting the

wires of the ignition system.

Connect the test equipment to the vehicle

To prevent industrial accidents or avoid causing damage

to the ignition system, pay attention to the following:

Note

Note

Note