display SKODA FABIA 2000 1.G / 6Y Workshop Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 2000, Model line: FABIA, Model: SKODA FABIA 2000 1.G / 6YPages: 86, PDF Size: 3.58 MB

Page 6 of 86

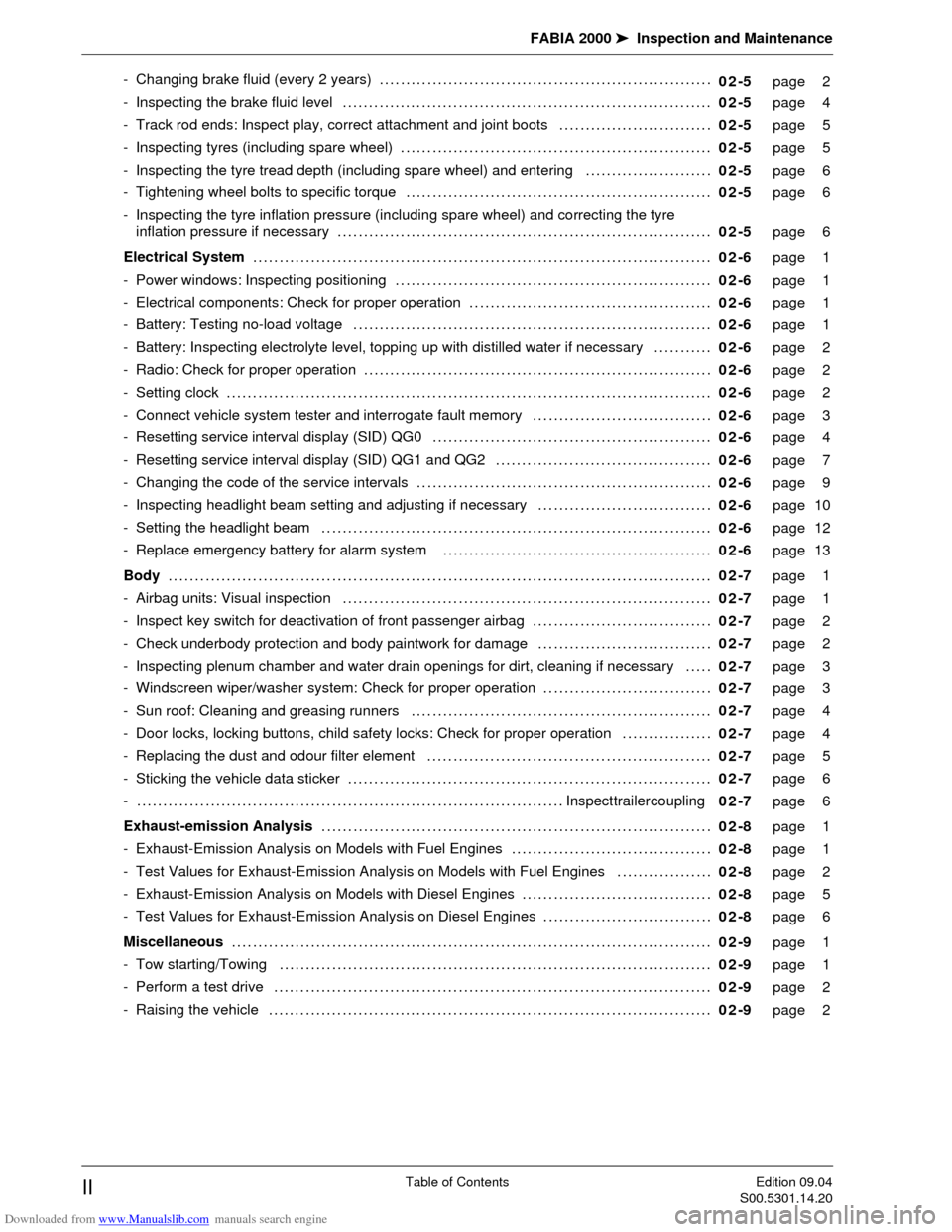

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

Table of ContentsEdition 09.04

S00.5301.14.20II

- Changing brake fluid (every 2 years)...............................................................

- Inspecting the brake fluid level ......................................................................

- Track rod ends: Inspect play, correct attachment and joint boots .............................

- Inspecting tyres (including spare wheel) ...........................................................

- Inspecting the tyre tread depth (including spare wheel) and entering ........................

- Tightening wheel bolts to specific torque ..........................................................

- Inspecting the tyre inflation pressure (including spare wheel) and correcting the tyre

inflation pressure if necessary .......................................................................

Electrical System.......................................................................................

- Power windows: Inspecting positioning ............................................................

- Electrical components: Check for proper operation ..............................................

- Battery: Testing no-load voltage ....................................................................

- Battery: Inspecting electrolyte level, topping up with distilled water if necessary ...........

- Radio: Check for proper operation..................................................................

- Setting clock ............................................................................................

- Connect vehicle system tester and interrogate fault memory..................................

- Resetting service interval display (SID) QG0 .....................................................

- Resetting service interval display (SID) QG1 and QG2 .........................................

- Changing the code of the service intervals ........................................................

- Inspecting headlight beam setting and adjusting if necessary .................................

- Setting the headlight beam ..........................................................................

- Replace emergency battery for alarm system ...................................................

Body.......................................................................................................

- Airbag units: Visual inspection ......................................................................

- Inspect key switch for deactivation of front passenger airbag ..................................

- Check underbody protection and body paintwork for damage .................................

- Inspecting plenum chamber and water drain openings for dirt, cleaning if necessary .....

- Windscreen wiper/washer system: Check for proper operation ................................

- Sun roof: Cleaning and greasing runners .........................................................

- Door locks, locking buttons, child safety locks: Check for proper operation .................

- Replacing the dust and odour filter element ......................................................

- Sticking the vehicle data sticker .....................................................................

- ................................................................................. Inspect trailer coupling

Exhaust-emission Analysis..........................................................................

- Exhaust-Emission Analysis on Models with Fuel Engines ......................................

- Test Values for Exhaust-Emission Analysis on Models with Fuel Engines..................

- Exhaust-Emission Analysis on Models with Diesel Engines ....................................

- Test Values for Exhaust-Emission Analysis on Diesel Engines................................

Miscellaneous...........................................................................................

- Tow starting/Towing ..................................................................................

- Perform a test drive ...................................................................................

- Raising the vehicle ....................................................................................02-5page 2

02-5page 4

02-5page 5

02-5page 5

02-5page 6

02-5page 6

02-5page 6

02-6page 1

02-6page 1

02-6page 1

02-6page 1

02-6page 2

02-6page 2

02-6page 2

02-6page 3

02-6page 4

02-6page 7

02-6page 9

02-6page 10

02-6page 12

02-6page 13

02-7page 1

02-7page 1

02-7page 2

02-7page 2

02-7page 3

02-7page 3

02-7page 4

02-7page 4

02-7page 5

02-7page 6

02-7page 6

02-8page 1

02-8page 1

02-8page 2

02-8page 5

02-8page 6

02-9page 1

02-9page 1

02-9page 2

02-9page 2

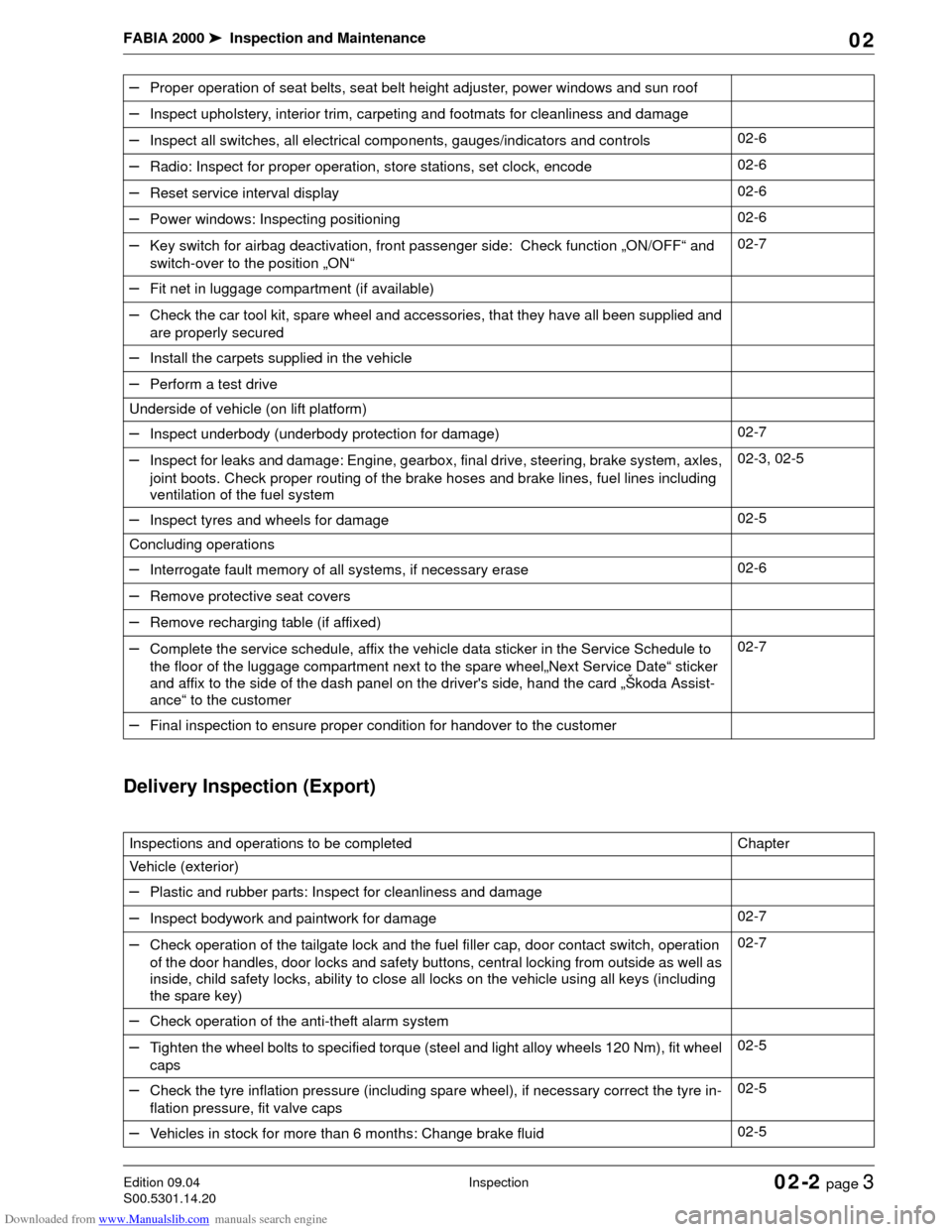

Page 13 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

InspectionEdition 09.04

S00.5301.14.2002-2 page 3 02

Delivery Inspection (Export)

–Proper operation of seat belts, seat belt height adjuster, power windows and sun roof

–Inspect upholstery, interior trim, carpeting and footmats for cleanliness and damage

–Inspect all switches, all electrical components, gauges/indicators and controls02-6

–Radio: Inspect for proper operation, store stations, set clock, encode02-6

–Reset service interval display02-6

–Power windows: Inspecting positioning02-6

–Key switch for airbag deactivation, front passenger side: Check function „ON/OFF“ and

switch-over to the position „ON“02-7

–Fit net in luggage compartment (if available)

–Check the car tool kit, spare wheel and accessories, that they have all been supplied and

are properly secured

–Install the carpets supplied in the vehicle

–Perform a test drive

Underside of vehicle (on lift platform)

–Inspect underbody (underbody protection for damage)02-7

–Inspect for leaks and damage: Engine, gearbox, final drive, steering, brake system, axles,

joint boots. Check proper routing of the brake hoses and brake lines, fuel lines including

ventilation of the fuel system02-3, 02-5

–Inspect tyres and wheels for damage02-5

Concluding operations

–Interrogate fault memory of all systems, if necessary erase02-6

–Remove protective seat covers

–Remove recharging table (if affixed)

–Complete the service schedule, affix the vehicle data sticker in the Service Schedule to

the floor of the luggage compartment next to the spare wheel„Next Service Date“ sticker

and affix to the side of the dash panel on the driver's side, hand the card „Škoda Assist-

ance“ to the customer02-7

–Final inspection to ensure proper condition for handover to the customer

Inspections and operations to be completed Chapter

Vehicle (exterior)

–Plastic and rubber parts: Inspect for cleanliness and damage

–Inspect bodywork and paintwork for damage02-7

–Check operation of the tailgate lock and the fuel filler cap, door contact switch, operation

of the door handles, door locks and safety buttons, central locking from outside as well as

inside, child safety locks, ability to close all locks on the vehicle using all keys (including

the spare key)02-7

–Check operation of the anti-theft alarm system

–Tighten the wheel bolts to specified torque (steel and light alloy wheels 120 Nm), fit wheel

caps02-5

–Check the tyre inflation pressure (including spare wheel), if necessary correct the tyre in-

flation pressure, fit valve caps02-5

–Vehicles in stock for more than 6 months: Change brake fluid02-5

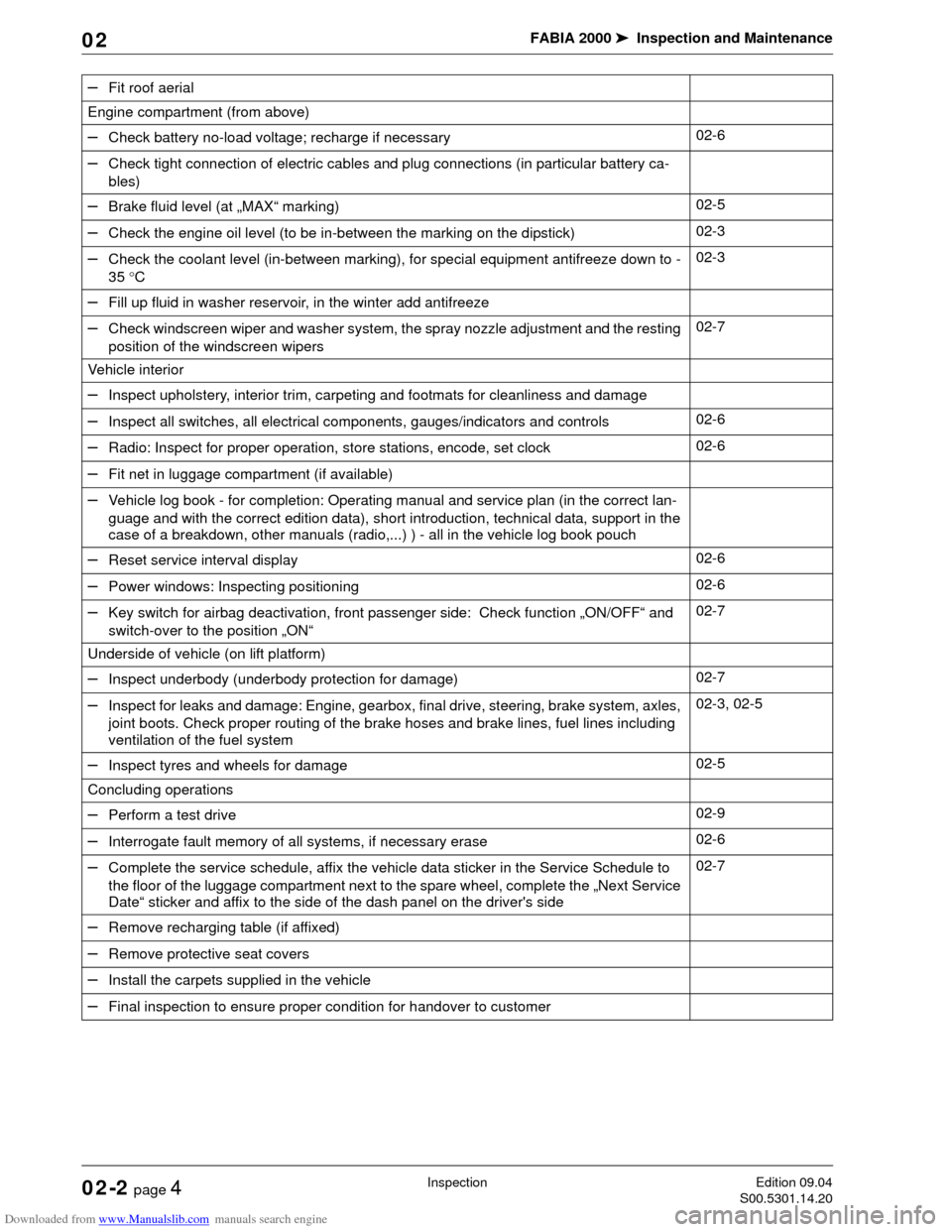

Page 14 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

InspectionEdition 09.04

S00.5301.14.2002-2 page 4 02

–Fit roof aerial

Engine compartment (from above)

–Check battery no-load voltage; recharge if necessary02-6

–Check tight connection of electric cables and plug connections (in particular battery ca-

bles)

–Brake fluid level (at „MAX“ marking)02-5

–Check the engine oil level (to be in-between the marking on the dipstick)02-3

–Check the coolant level (in-between marking), for special equipment antifreeze down to -

35 °C02-3

–Fill up fluid in washer reservoir, in the winter add antifreeze

–Check windscreen wiper and washer system, the spray nozzle adjustment and the resting

position of the windscreen wipers02-7

Vehicle interior

–Inspect upholstery, interior trim, carpeting and footmats for cleanliness and damage

–Inspect all switches, all electrical components, gauges/indicators and controls02-6

–Radio: Inspect for proper operation, store stations, encode, set clock02-6

–Fit net in luggage compartment (if available)

–Vehicle log book - for completion: Operating manual and service plan (in the correct lan-

guage and with the correct edition data), short introduction, technical data, support in the

case of a breakdown, other manuals (radio,...) ) - all in the vehicle log book pouch

–Reset service interval display02-6

–Power windows: Inspecting positioning02-6

–Key switch for airbag deactivation, front passenger side: Check function „ON/OFF“ and

switch-over to the position „ON“02-7

Underside of vehicle (on lift platform)

–Inspect underbody (underbody protection for damage)02-7

–Inspect for leaks and damage: Engine, gearbox, final drive, steering, brake system, axles,

joint boots. Check proper routing of the brake hoses and brake lines, fuel lines including

ventilation of the fuel system02-3, 02-5

–Inspect tyres and wheels for damage02-5

Concluding operations

–Perform a test drive02-9

–Interrogate fault memory of all systems, if necessary erase02-6

–Complete the service schedule, affix the vehicle data sticker in the Service Schedule to

the floor of the luggage compartment next to the spare wheel, complete the „Next Service

Date“ sticker and affix to the side of the dash panel on the driver's side02-7

–Remove recharging table (if affixed)

–Remove protective seat covers

–Install the carpets supplied in the vehicle

–Final inspection to ensure proper condition for handover to customer

Page 15 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

InspectionEdition 09.04

S00.5301.14.2002-2 page 5 02

Oil Change Service every 15.000 km1) (QG0)

An Oil Change Service need only be carried out if the vehicle has covered 15 000 km before one year has

elapsed1). If the Oil Change Service is due only a few months prior to the Annual Inspection, it is recommend-

ed to carry out the Annual Inspection at the same time.

Annual Inspection (every 12 months) (QG0)

1)The 7500 km interval applies for diesel operation with high sulphur content - it does not apply for the Czech Republic (for further information

refer to Technical Service Handbook)

Work involvedChapter

–Change engine oil

–Replace engine oil filter02-3

–Disc brake pads: Inspect thickness02-5

–Reset service interval display02-6

–Drain away water from the fuel filter (diesel engine with fuel operation, which does not

comply with DIN EN 590-standard)

After each oil change

–Complete „Next service date“ sticker (max. 1 year or 15 000 km) and affix sticker to the

side of the dash panel (on the driver's side)

–Complete and attach service mirror tag to the interior rear-view mirror

–Hand customer the completed and signed form

Chapter

♦For vehicles with a high mileage carry out an Oil Change Service no later than after 15

000 km1). Carry out Annual Inspection after 30 000 km prior to the scheduled date02-3

♦Every 2 years - in addition change brake fluid 02-5

♦Every 4 years - in addition, change air filter element and clean air filter housing - vehicles

driven less than 60 000 km within 4 years - replace contents set for tyre repair 02-3

♦Every 5 years - replace the emergency battery for the alarm 02-6

♦Exhaust-emission analysis (EEA): Expiry date - see EEA tag on the vehicle identification

plate (only valid for some countries)

♦Recommendation: Replace windscreen wiper blades every 2 years

♦At each inspection - check the 'use by date' of the first aid kit

Work involved

–Interrogate fault memory of all systems, if necessary erase02-6

–Inspect engine and components in the engine compartment for leaks and damage02-3

–Change engine oil

–Replace engine oil filter02-3

–Airbag units: Perform visual inspection for external damage02-7

–Reset service interval display02-6

–Inspecting brake system for leaks and damage02-5

–Check the thickness of the brake pads on all wheels02-5

–Check gearbox, final drive, drive shafts and joint boots for leaks and damage

–Axle joints: Inspect boots for leaks and damage

Page 18 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

InspectionEdition 09.04

S00.5301.14.2002-2 page 8 02

Every 240 000 km (QG0)

Includes: Inspection every 120 000 km and additional operations stated in the table below

Inspection Service (QG1, QG2)

♦Vehicles with WIV (QG1) must be filled with oils which conform to the VW standard 503 00 (petrol engines) VW

506 00 (SDI, TDI diesel engines) or VW 506 01 (TDI PD diesel engines), possibility of damage when using other

oils.

♦Vehicles with WIV which have been filled with oils which do not conform to the VW standard 503 00 or VW 506 00

or VW 506 01, must be coded in the WIV with a fixed oil change limitation (QG2) ⇒Chapter 02-6. Work involvedChapter

–Replace tensioning pulley (PD diesel engine as of 08.03)02-3

♦Every 2 years - in addition change brake fluid

♦Every 4 years - replace contents set for tyre repair

♦Every 90 000 km - replace the guide pulley and the tensioning pulley (PD diesel engine up to 07.03)

♦Every 120 000 km - replace the timing belt and the guide pulley (038 109 244 H) (diesel engines as of 05.01 to

04.02 except the PD engine)

♦Every 120 000 km - Replace the timing belt (PD Diesel engine as of 08.03)

♦Every 150 000 km - replace the timing belt (diesel engines as of 05.02 and with the guide pulleyr 038 109 244

M) - except on the TDI PD engine

♦Every 240 000 km - Replace the tensioning pulley (PD Diesel engine as of 08.03)

♦Exhaust-emission analysis (EEA). Expiry date - see EEA tag on the vehicle identification plate (only valid for

some countries)

♦At each inspection - check the 'use by date' of the first aid kit

♦Recommendation: Replace windscreen wiper blades every 2 years

Note

Work involvedChapter

–Interrogate fault memory of all systems, if necessary erase02-6

–Visual inspection: Engine and components in the engine compartment for leaks and dam-

age02-3

–Change the engine oil, replace the oil filter02-3

–Conduct a visual inspection of the airbag units for external damage02-7

–Reset service interval display02-6

–Inspecting brake system for leaks and damage02-5

–Check the thickness of the brake pads on all wheels02-5

–Check gearbox, final drive, drive shafts and joint boots for leaks and damage

–Axle joints: Inspect boots for leaks and damage

–Track rod ends: Inspect play and correct attachment of boots

Page 20 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

InspectionEdition 09.04

S00.5301.14.2002-2 page 10 02

Oil change (QG1, QG2)

Work involvedChapter

–Change engine oil

–Replace engine oil filter02-3

–Disc brake pads: Inspect thickness02-5

–Reset service interval display02-6

–Drain away water from the fuel filter (diesel engine with fuel operation, which does not

comply with DIN EN 590-standard)

After each oil change

–Enter the next service date on the „Next Service“ sticker and affix sticker to the side of

the dash panel on the driver's side, that is according to the indicator or the kilometer

schedule (also the date for changing the brake fluid)

–Complete and attach service mirror tag to the interior rear-view mirror

–Hand customer the completed and signed form

Page 43 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

GearboxEdition 07.03

S00.5301.12.2002-4 page 3 02

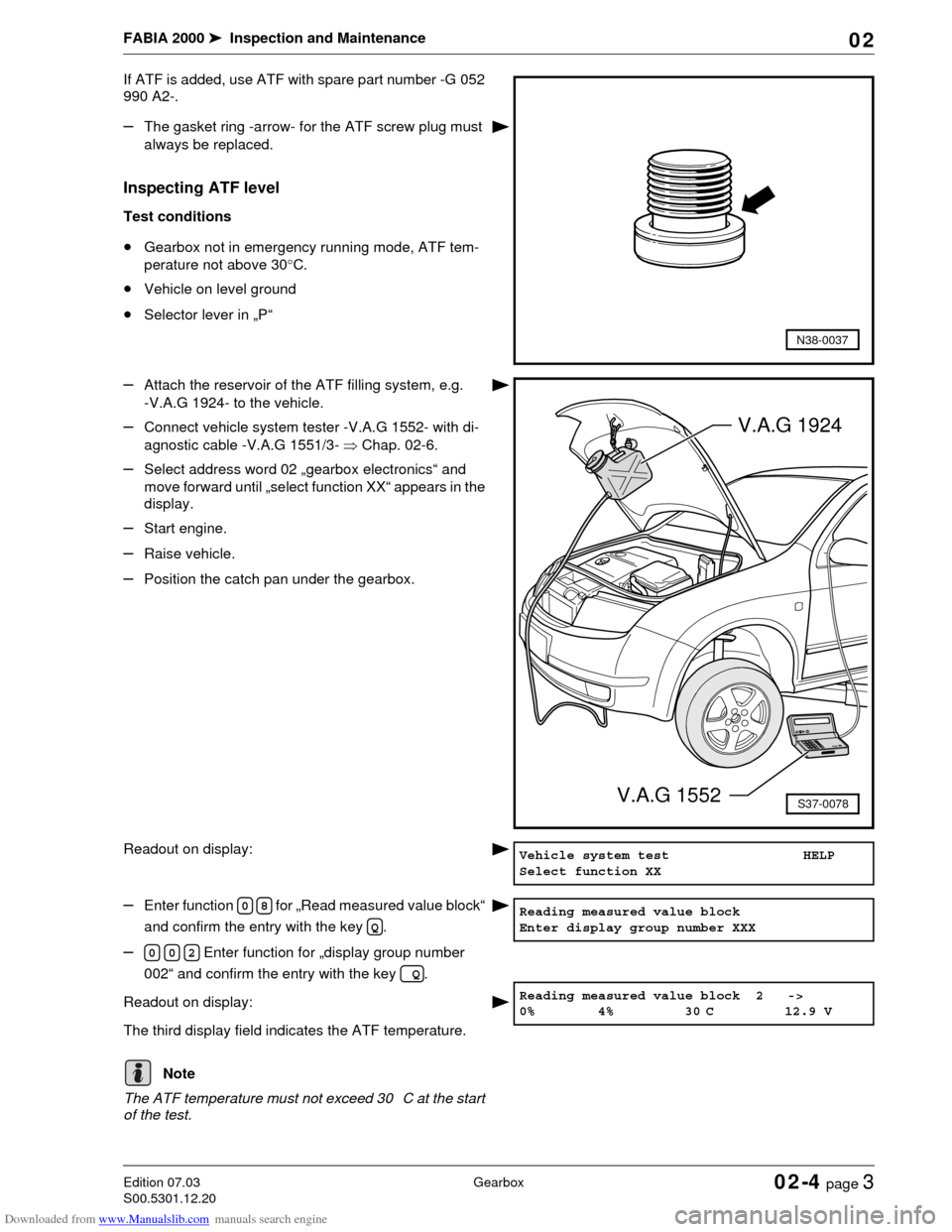

If ATF is added, use ATF with spare part number -G 052

990 A2-.

–The gasket ring -arrow- for the ATF screw plug must

always be replaced.

Inspecting ATF level

Test conditions

•Gearbox not in emergency running mode, ATF tem-

perature not above 30°C.

•Vehicle on level ground

•Selector lever in „P“

–Attach the reservoir of the ATF filling system, e.g.

-V.A.G 1924- to the vehicle.

–Connect vehicle system tester -V.A.G 1552- with di-

agnostic cable -V.A.G 1551/3- ⇒Chap. 02-6.

–Select address word 02 „gearbox electronics“ and

move forward until „select function XX“ appears in the

display.

–Start engine.

–Raise vehicle.

–Position the catch pan under the gearbox.

Readout on display:

–Enter function for „Read measured value block“

and confirm the entry with the key .

– Enter function for „display group number

002“ and confirm the entry with the key .

Readout on display:

The third display field indicates the ATF temperature.

The ATF temperature must not exceed 30 C at the start

of the test.

N38-0037

S37-0078

V.A.G 1924

V.A.G 1552

Vehicle system test HELP

Select function XX

Reading measured value block

Enter display group number XXX 08

Q

002

Q

Reading measured value block 2 ->

0% 4% 30 C 12.9 V

Note

Page 57 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

Electrical SystemEdition 09.04

S00.5301.14.2002-6 page 3 02

holding the knob in the left or right position respective-

ly.

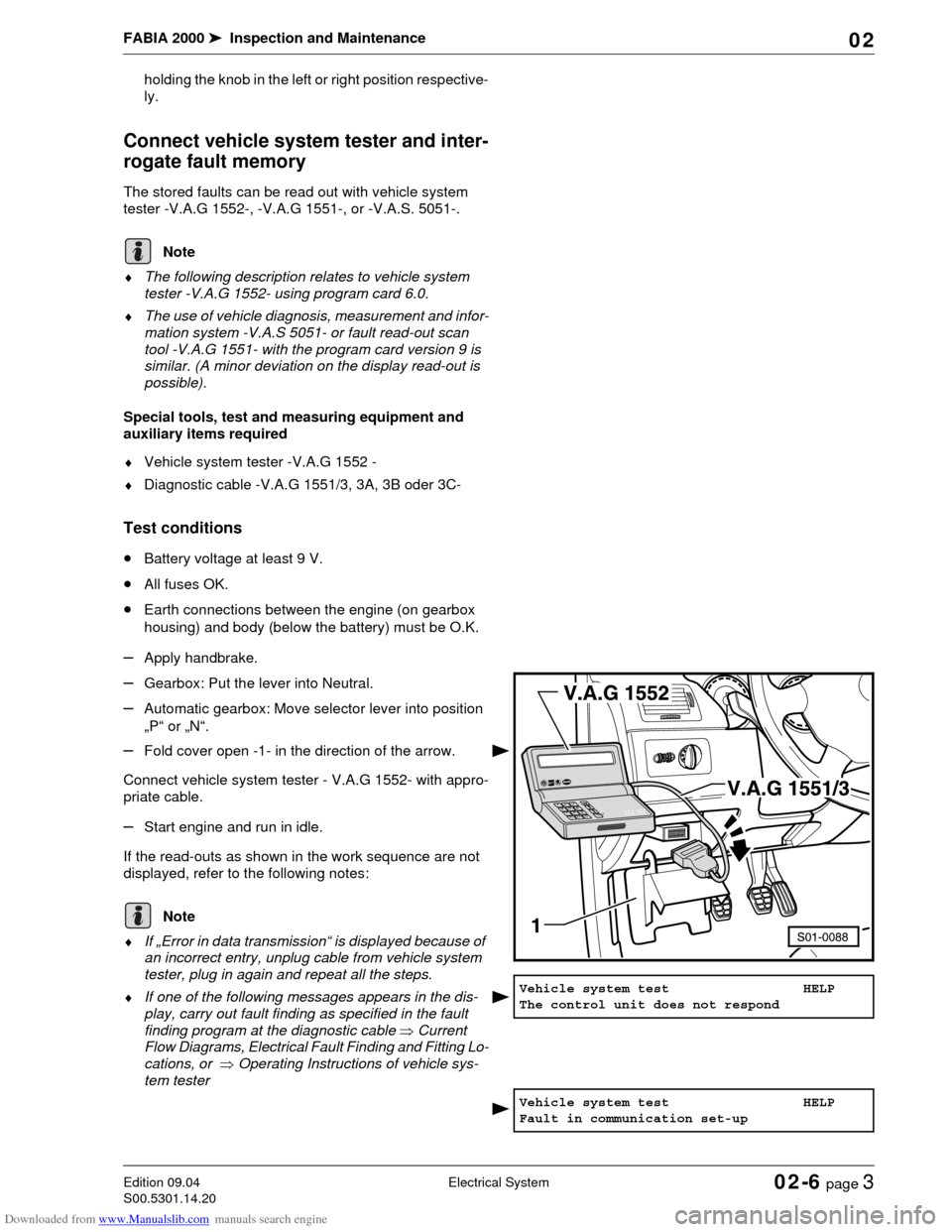

Connect vehicle system tester and inter-

rogate fault memory

The stored faults can be read out with vehicle system

tester -V.A.G 1552-, -V.A.G 1551-, or -V.A.S. 5051-.

♦The following description relates to vehicle system

tester -V.A.G 1552- using program card 6.0.

♦The use of vehicle diagnosis, measurement and infor-

mation system -V.A.S 5051- or fault read-out scan

tool -V.A.G 1551- with the program card version 9 is

similar. (A minor deviation on the display read-out is

possible).

Special tools, test and measuring equipment and

auxiliary items required

♦Vehicle system tester -V.A.G 1552 -

♦Diagnostic cable -V.A.G 1551/3, 3A, 3B oder 3C-

Test conditions

•Battery voltage at least 9 V.

•All fuses OK.

•Earth connections between the engine (on gearbox

housing) and body (below the battery) must be O.K.

–Apply handbrake.

–Gearbox: Put the lever into Neutral.

–Automatic gearbox: Move selector lever into position

„P“ or „N“.

–Fold cover open -1- in the direction of the arrow.

Connect vehicle system tester - V.A.G 1552- with appro-

priate cable.

–Start engine and run in idle.

If the read-outs as shown in the work sequence are not

displayed, refer to the following notes:

♦If „Error in data transmission“ is displayed because of

an incorrect entry, unplug cable from vehicle system

tester, plug in again and repeat all the steps.

♦If one of the following messages appears in the dis-

play, carry out fault finding as specified in the fault

finding program at the diagnostic cable ⇒Current

Flow Diagrams, Electrical Fault Finding and Fitting Lo-

cations, or ⇒Operating Instructions of vehicle sys-

tem tester

Note

1552V.A.

G

.H

E

LPQ O C9 8 76 5 43 2 1

Note

Vehicle system test HELP

The control unit does not respond

Vehicle system test HELP

Fault in communication set-up

Page 58 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

Electrical SystemEdition 09.04

S00.5301.14.2002-6 page 4 02

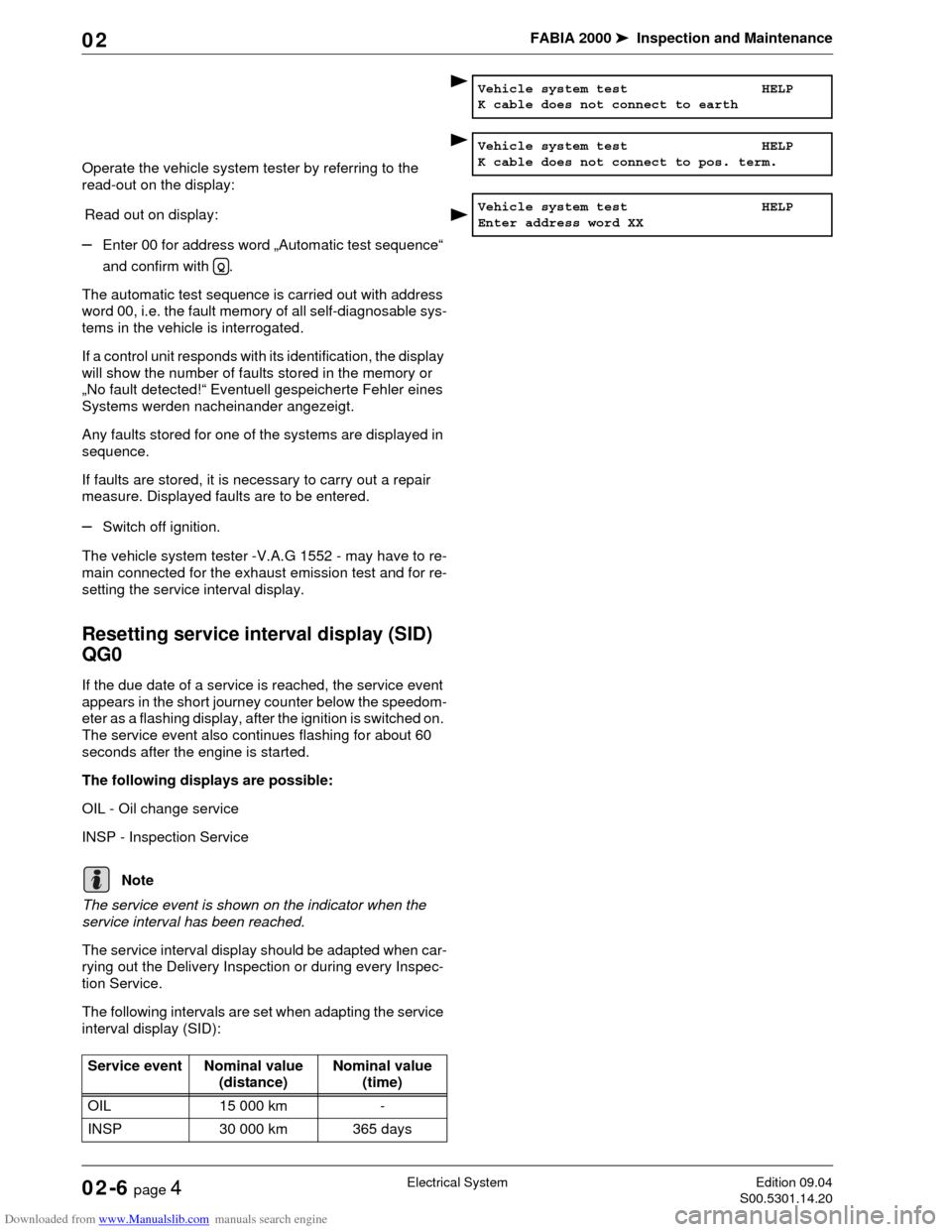

Operate the vehicle system tester by referring to the

read-out on the display:

Read out on display:

–Enter 00 for address word „Automatic test sequence“

and confirm with .

The automatic test sequence is carried out with address

word 00, i.e. the fault memory of all self-diagnosable sys-

tems in the vehicle is interrogated.

If a control unit responds with its identification, the display

will show the number of faults stored in the memory or

„No fault detected!“ Eventuell gespeicherte Fehler eines

Systems werden nacheinander angezeigt.

Any faults stored for one of the systems are displayed in

sequence.

If faults are stored, it is necessary to carry out a repair

measure. Displayed faults are to be entered.

–Switch off ignition.

The vehicle system tester -V.A.G 1552 - may have to re-

main connected for the exhaust emission test and for re-

setting the service interval display.

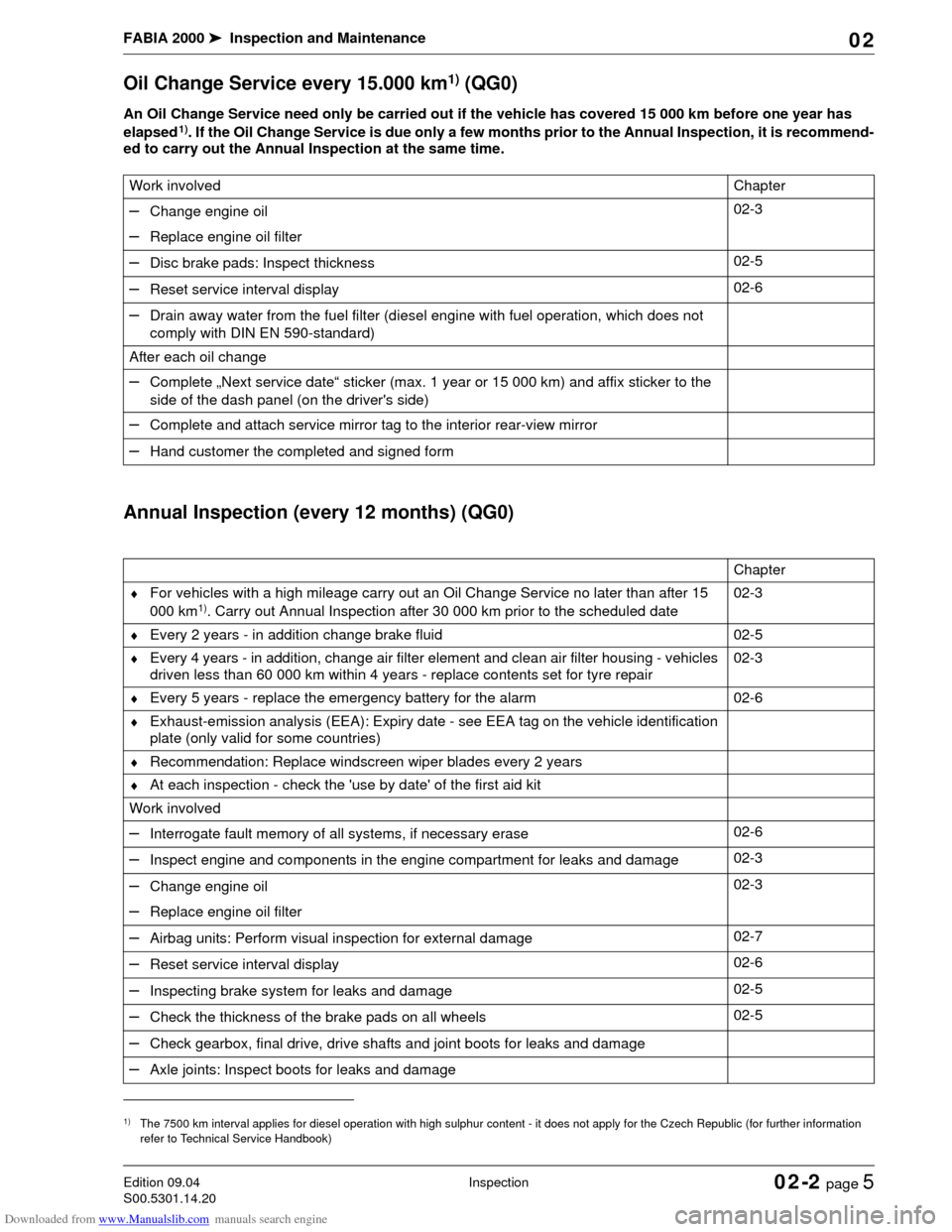

Resetting service interval display (SID)

QG0

If the due date of a service is reached, the service event

appears in the short journey counter below the speedom-

eter as a flashing display, after the ignition is switched on.

The service event also continues flashing for about 60

seconds after the engine is started.

The following displays are possible:

OIL - Oil change service

INSP - Inspection Service

The service event is shown on the indicator when the

service interval has been reached.

The service interval display should be adapted when car-

rying out the Delivery Inspection or during every Inspec-

tion Service.

The following intervals are set when adapting the service

interval display (SID):

Vehicle system test HELP

K cable does not connect to earth

Vehicle system test HELP

K cable does not connect to pos. term.

Vehicle system test HELP

Enter address word XX

Q

Note

Service event Nominal value

(distance)Nominal value

(time)

OIL 15 000 km -

INSP 30 000 km 365 days

Page 59 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

Electrical SystemEdition 09.04

S00.5301.14.2002-6 page 5 02

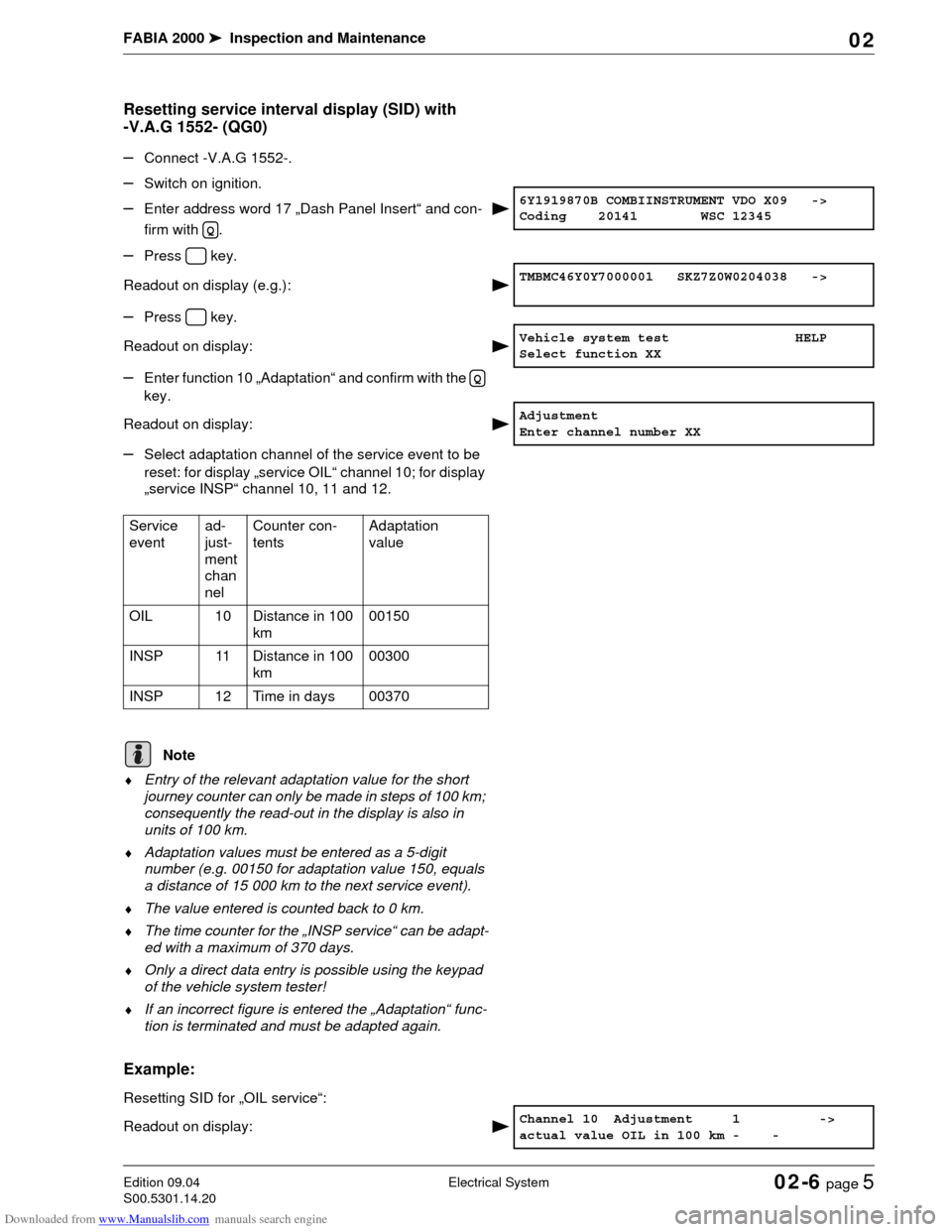

Resetting service interval display (SID) with

-V.A.G 1552- (QG0)

–Connect -V.A.G 1552-.

–Switch on ignition.

–Enter address word 17 „Dash Panel Insert“ and con-

firm with .

–Press key.

Readout on display (e.g.):

–Press key.

Readout on display:

–Enter function 10 „Adaptation“ and confirm with the

key.

Readout on display:

–Select adaptation channel of the service event to be

reset: for display „service OIL“ channel 10; for display

„service INSP“ channel 10, 11 and 12.

♦Entry of the relevant adaptation value for the short

journey counter can only be made in steps of 100 km;

consequently the read-out in the display is also in

units of 100 km.

♦Adaptation values must be entered as a 5-digit

number (e.g. 00150 for adaptation value 150, equals

a distance of 15 000 km to the next service event).

♦The value entered is counted back to 0 km.

♦The time counter for the „INSP service“ can be adapt-

ed with a maximum of 370 days.

♦Only a direct data entry is possible using the keypad

of the vehicle system tester!

♦If an incorrect figure is entered the „Adaptation“ func-

tion is terminated and must be adapted again.

Example:

Resetting SID for „OIL service“:

Readout on display:

6Y1919870B COMBIINSTRUMENT VDO X09 ->

Coding 20141 WSC 12345

Q

TMBMC46Y0Y7000001 SKZ7Z0W0204038 ->

Vehicle system test HELP

Select function XX

Q

Adjustment

Enter channel number XX

Service

eventad-

just-

ment

chan

nelCounter con-

tentsAdaptation

value

OIL 10 Distance in 100

km00150

INSP 11 Distance in 100

km00300

INSP 12 Time in days 00370

Note

Channel 10 Adjustment 1 ->

actual value OIL in 100 km - -