headlight SKODA FABIA 2000 1.G / 6Y Workshop Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 2000, Model line: FABIA, Model: SKODA FABIA 2000 1.G / 6YPages: 86, PDF Size: 3.58 MB

Page 6 of 86

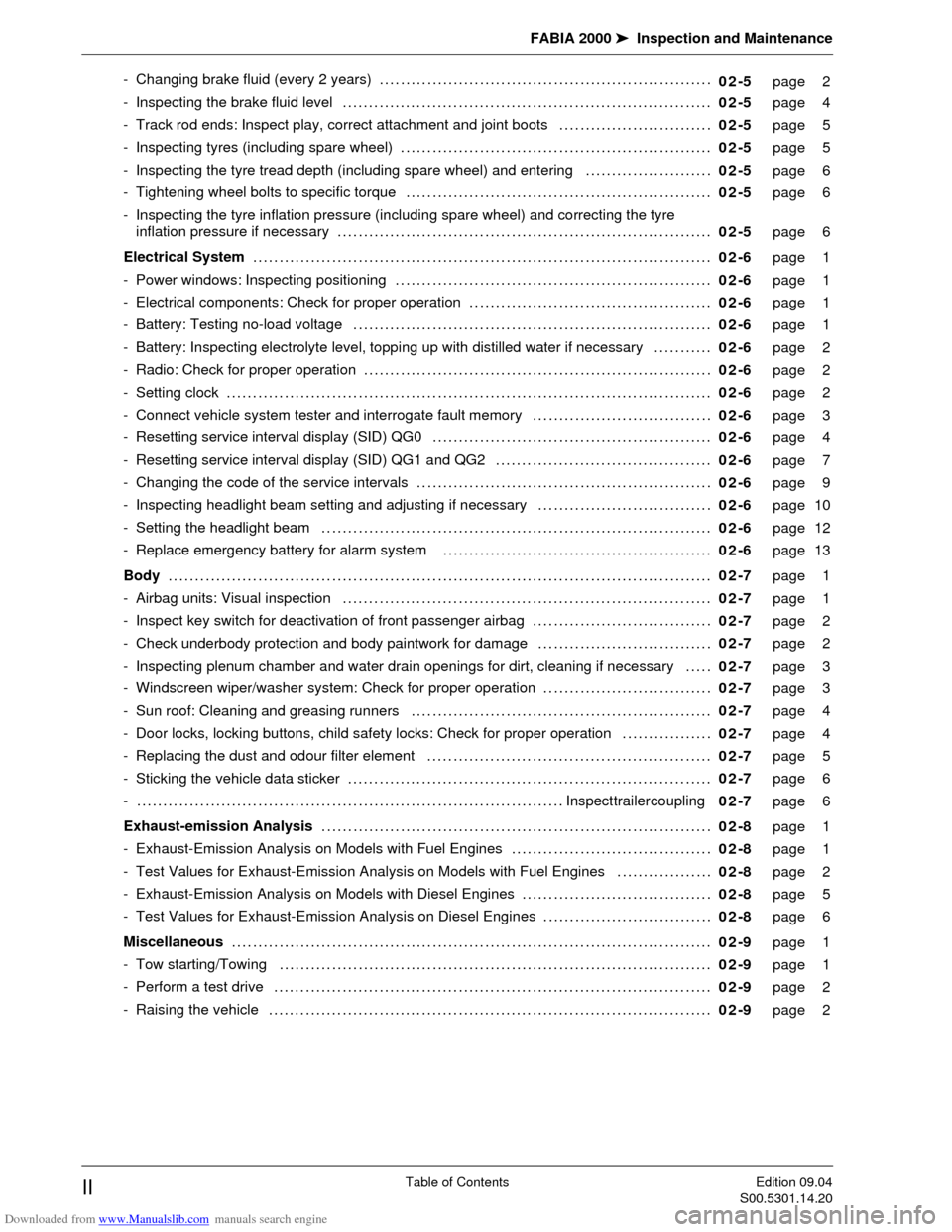

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

Table of ContentsEdition 09.04

S00.5301.14.20II

- Changing brake fluid (every 2 years)...............................................................

- Inspecting the brake fluid level ......................................................................

- Track rod ends: Inspect play, correct attachment and joint boots .............................

- Inspecting tyres (including spare wheel) ...........................................................

- Inspecting the tyre tread depth (including spare wheel) and entering ........................

- Tightening wheel bolts to specific torque ..........................................................

- Inspecting the tyre inflation pressure (including spare wheel) and correcting the tyre

inflation pressure if necessary .......................................................................

Electrical System.......................................................................................

- Power windows: Inspecting positioning ............................................................

- Electrical components: Check for proper operation ..............................................

- Battery: Testing no-load voltage ....................................................................

- Battery: Inspecting electrolyte level, topping up with distilled water if necessary ...........

- Radio: Check for proper operation..................................................................

- Setting clock ............................................................................................

- Connect vehicle system tester and interrogate fault memory..................................

- Resetting service interval display (SID) QG0 .....................................................

- Resetting service interval display (SID) QG1 and QG2 .........................................

- Changing the code of the service intervals ........................................................

- Inspecting headlight beam setting and adjusting if necessary .................................

- Setting the headlight beam ..........................................................................

- Replace emergency battery for alarm system ...................................................

Body.......................................................................................................

- Airbag units: Visual inspection ......................................................................

- Inspect key switch for deactivation of front passenger airbag ..................................

- Check underbody protection and body paintwork for damage .................................

- Inspecting plenum chamber and water drain openings for dirt, cleaning if necessary .....

- Windscreen wiper/washer system: Check for proper operation ................................

- Sun roof: Cleaning and greasing runners .........................................................

- Door locks, locking buttons, child safety locks: Check for proper operation .................

- Replacing the dust and odour filter element ......................................................

- Sticking the vehicle data sticker .....................................................................

- ................................................................................. Inspect trailer coupling

Exhaust-emission Analysis..........................................................................

- Exhaust-Emission Analysis on Models with Fuel Engines ......................................

- Test Values for Exhaust-Emission Analysis on Models with Fuel Engines..................

- Exhaust-Emission Analysis on Models with Diesel Engines ....................................

- Test Values for Exhaust-Emission Analysis on Diesel Engines................................

Miscellaneous...........................................................................................

- Tow starting/Towing ..................................................................................

- Perform a test drive ...................................................................................

- Raising the vehicle ....................................................................................02-5page 2

02-5page 4

02-5page 5

02-5page 5

02-5page 6

02-5page 6

02-5page 6

02-6page 1

02-6page 1

02-6page 1

02-6page 1

02-6page 2

02-6page 2

02-6page 2

02-6page 3

02-6page 4

02-6page 7

02-6page 9

02-6page 10

02-6page 12

02-6page 13

02-7page 1

02-7page 1

02-7page 2

02-7page 2

02-7page 3

02-7page 3

02-7page 4

02-7page 4

02-7page 5

02-7page 6

02-7page 6

02-8page 1

02-8page 1

02-8page 2

02-8page 5

02-8page 6

02-9page 1

02-9page 1

02-9page 2

02-9page 2

Page 16 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

InspectionEdition 09.04

S00.5301.14.2002-2 page 6 02

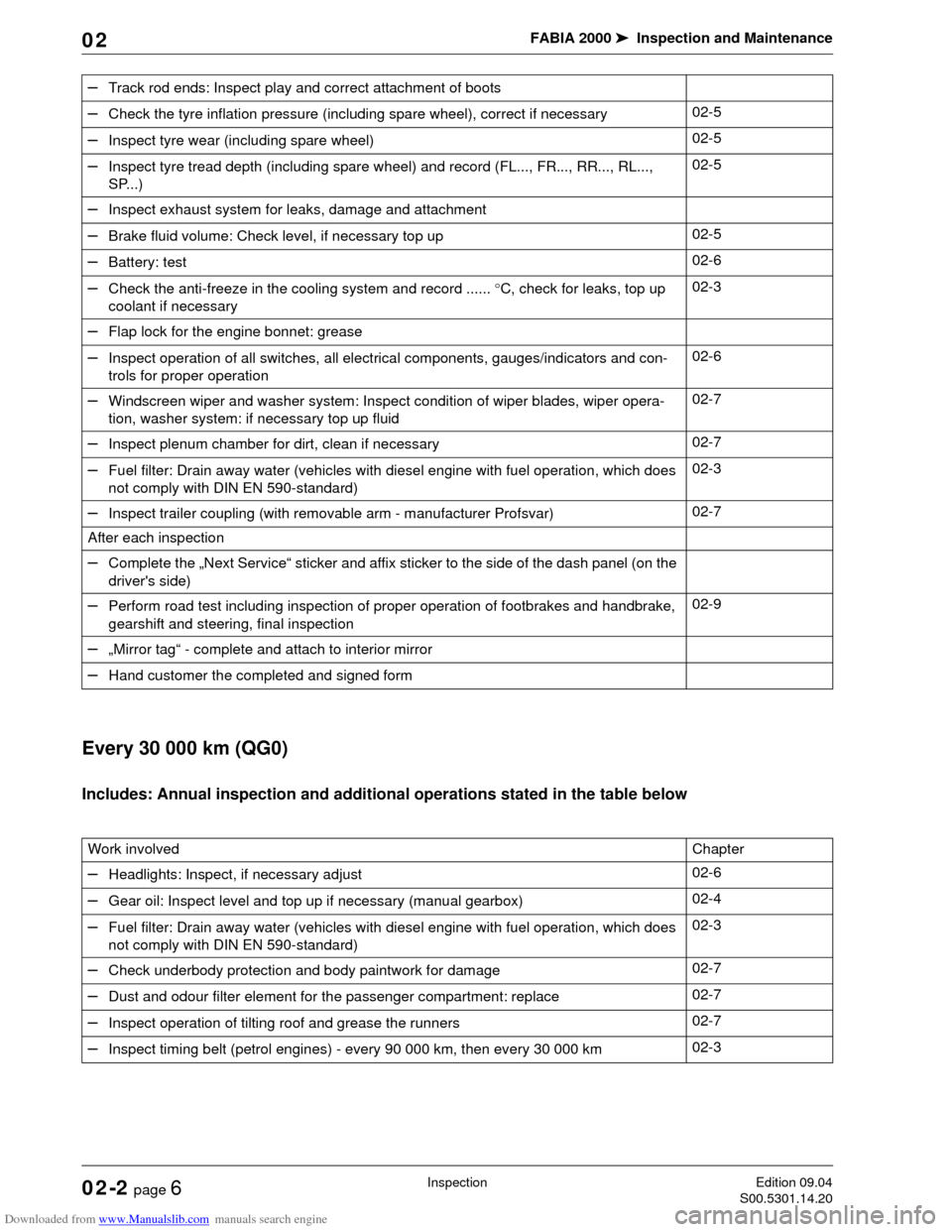

Every 30 000 km (QG0)

Includes: Annual inspection and additional operations stated in the table below

–Track rod ends: Inspect play and correct attachment of boots

–Check the tyre inflation pressure (including spare wheel), correct if necessary02-5

–Inspect tyre wear (including spare wheel)02-5

–Inspect tyre tread depth (including spare wheel) and record (FL..., FR..., RR..., RL...,

SP...)02-5

–Inspect exhaust system for leaks, damage and attachment

–Brake fluid volume: Check level, if necessary top up02-5

–Battery: test02-6

–Check the anti-freeze in the cooling system and record ...... °C, check for leaks, top up

coolant if necessary02-3

–Flap lock for the engine bonnet: grease

–Inspect operation of all switches, all electrical components, gauges/indicators and con-

trols for proper operation02-6

–Windscreen wiper and washer system: Inspect condition of wiper blades, wiper opera-

tion, washer system: if necessary top up fluid02-7

–Inspect plenum chamber for dirt, clean if necessary02-7

–Fuel filter: Drain away water (vehicles with diesel engine with fuel operation, which does

not comply with DIN EN 590-standard)02-3

–Inspect trailer coupling (with removable arm - manufacturer Profsvar)02-7

After each inspection

–Complete the „Next Service“ sticker and affix sticker to the side of the dash panel (on the

driver's side)

–Perform road test including inspection of proper operation of footbrakes and handbrake,

gearshift and steering, final inspection02-9

–„Mirror tag“ - complete and attach to interior mirror

–Hand customer the completed and signed form

Work involvedChapter

–Headlights: Inspect, if necessary adjust02-6

–Gear oil: Inspect level and top up if necessary (manual gearbox)02-4

–Fuel filter: Drain away water (vehicles with diesel engine with fuel operation, which does

not comply with DIN EN 590-standard)02-3

–Check underbody protection and body paintwork for damage02-7

–Dust and odour filter element for the passenger compartment: replace02-7

–Inspect operation of tilting roof and grease the runners02-7

–Inspect timing belt (petrol engines) - every 90 000 km, then every 30 000 km02-3

Page 19 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

InspectionEdition 09.04

S00.5301.14.2002-2 page 9 02

–Check the tyre inflation pressure (including spare wheel), correct if necessary02-5

–Inspect tyre wear (including spare wheel)02-5

–Inspect tyre tread depth (including spare wheel) and record (FL..., FR..., RR..., RL...,

SP...)02-5

–Inspect exhaust system for leaks, damage and attachment

–Brake fluid volume: Check level, if necessary top up02-5

–Battery: test02-6

–Check the anti-freeze in the cooling system and record ...... °C, check for leaks, top up

coolant if necessary02-3

–Flap lock for the engine bonnet: grease

–Inspect operation of all switches, all electrical components, gauges/indicators and con-

trols for proper operation02-6

–Windscreen wiper and washer system: Inspect condition of wiper blades, wiper operation,

washer system: if necessary top up fluid02-7

–Inspect plenum chamber for dirt, clean if necessary02-7

–Inspect operation of tilting roof and grease the runners02-7

–Headlights: Inspect, if necessary adjust02-6

–Gear oil: Inspect level and top up if necessary (manual gearbox)02-4

–Draining the fuel filter (diesel engine)

–Inspect trailer coupling (with removable arm - manufacturer Profsvar)02-7

–Check underbody protection and body paintwork for damage02-7

–Dust and odour filter element for the passenger compartment: replace02-7

–Air filter: Clean the housing, replace the insert every 4 years or 60.000 km.02-3

–Replace the fuel filter (diesel engine with fuel operation, which does not comply with DIN

EN 590-standard)

–Ribbed V-belt: Inspect condition and for vehicles without tensioning pulley also the ten-

sion - every 60.000 km02-3

–Replace the fuel filter (diesel engine) - every 60.000 km

–Spark plugs: replace - every 60.000 km.02-3

–Automatic gearbox: Check the ATF level, and top up if necessary, every 60.000 km

–Check the timing belt for the camshaft on a 4-cylinder petrol engine at 90.000 km and

then every 30.000 km after that

–Replace the emergency battery for the alarm system - every five years02-6

After each inspection

–Complete the „Next Service“ sticker and affix sticker to the side of the dash panel (on the

driver's side)

–Perform road test including inspection of proper operation of footbrakes and handbrake,

gearshift and steering, final inspection02-9

–„Mirror tag“ - complete and attach to interior mirror

–Hand customer the completed and signed form Work involvedChapter

Page 55 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

Electrical SystemEdition 09.04

S00.5301.14.2002-6 page 1 02

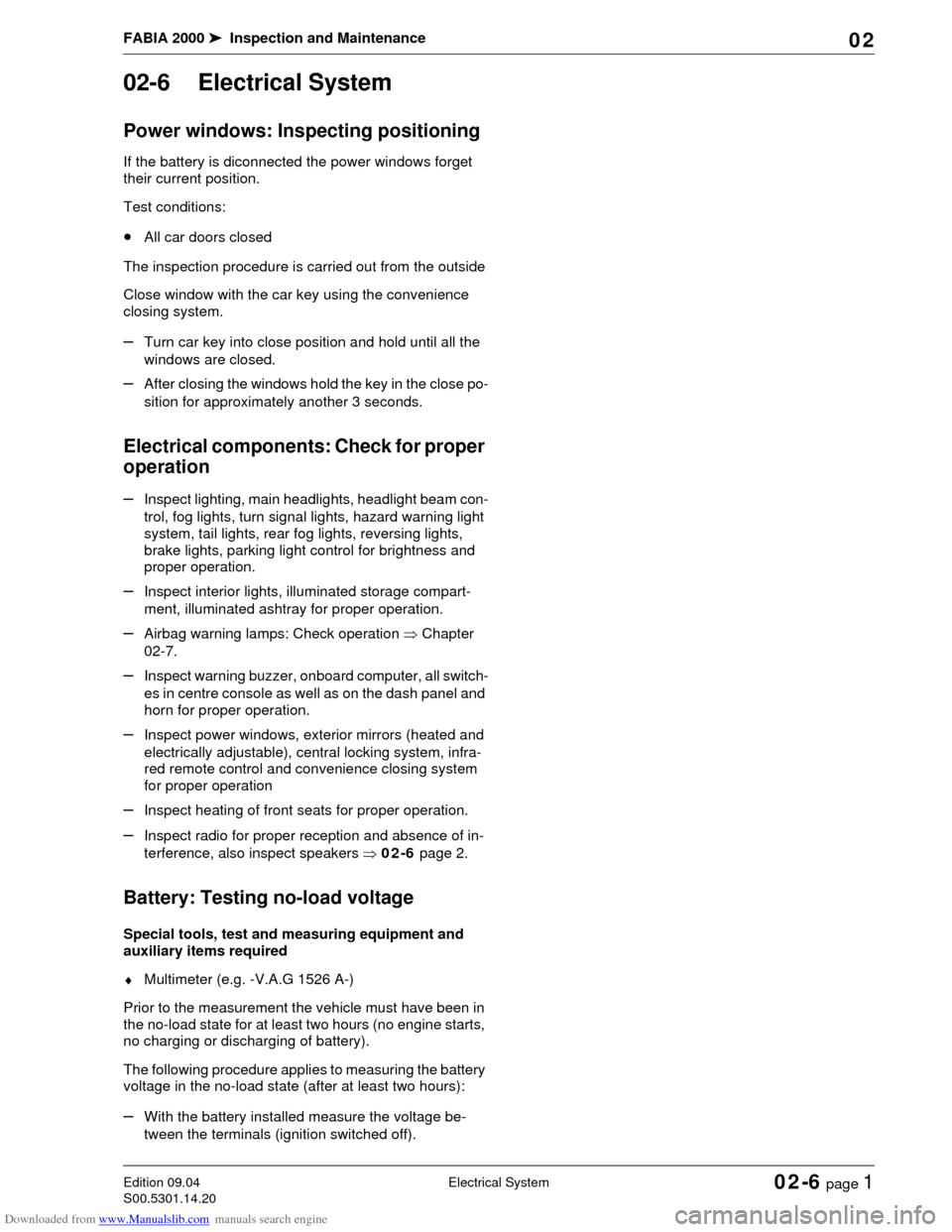

02-6 Electrical System

Power windows: Inspecting positioning

If the battery is diconnected the power windows forget

their current position.

Test conditions:

•All car doors closed

The inspection procedure is carried out from the outside

Close window with the car key using the convenience

closing system.

–Turn car key into close position and hold until all the

windows are closed.

–After closing the windows hold the key in the close po-

sition for approximately another 3 seconds.

Electrical components: Check for proper

operation

–Inspect lighting, main headlights, headlight beam con-

trol, fog lights, turn signal lights, hazard warning light

system, tail lights, rear fog lights, reversing lights,

brake lights, parking light control for brightness and

proper operation.

–Inspect interior lights, illuminated storage compart-

ment, illuminated ashtray for proper operation.

–Airbag warning lamps: Check operation ⇒Chapter

02-7.

–Inspect warning buzzer, onboard computer, all switch-

es in centre console as well as on the dash panel and

horn for proper operation.

–Inspect power windows, exterior mirrors (heated and

electrically adjustable), central locking system, infra-

red remote control and convenience closing system

for proper operation

–Inspect heating of front seats for proper operation.

–Inspect radio for proper reception and absence of in-

terference, also inspect speakers ⇒02-6 page 2.

Battery: Testing no-load voltage

Special tools, test and measuring equipment and

auxiliary items required

♦Multimeter (e.g. -V.A.G 1526 A-)

Prior to the measurement the vehicle must have been in

the no-load state for at least two hours (no engine starts,

no charging or discharging of battery).

The following procedure applies to measuring the battery

voltage in the no-load state (after at least two hours):

–With the battery installed measure the voltage be-

tween the terminals (ignition switched off).

Page 64 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

Electrical SystemEdition 09.04

S00.5301.14.2002-6 page 10 02

–Connect -V.A.G 1552-.

–Switch on ignition.

–Enter address word 17 „Dash Panel Insert“ and con-

firm with .

Readout on display (e.g.):

–Note the dash panel insert coding.

–Press key.

Readout on display (e.g.):

–Press key.

Readout on display:

–Enter function 07 „Code control unit“ and confirm with

key.

Readout on display:

–Enter dash panel insert coding which is identical to the

original coding. The value on the fourth position must,

however, be altered from 1 to 2.

XXX1X - QG1

XXX2X - QG2

Readout on display (e.g.):

–Confirm the entry with key .

Readout on display (e.g.):

–Press key.

Readout on display (e.g.):

–Press key.

Readout on display:

–Enter 06 for „End output“.

Readout on display:

–Confirm the entry with key .

–Switch off ignition.

–Switch off -V.A.G 1552-.

Inspecting headlight beam setting and

adjusting if necessary

Special tools, test and measuring equipment and

auxiliary items required

♦Headlight beam setting device

In principle the following inspection and setting descrip-

tion applies for all countries. However, comply with na-

tional guidelines and legislation of the relevant country.

⇒Operating instructions for the headlight beam setting

device

Q

6Y1919870B COMBIINSTRUMENT VDO X09 ->

Coding 03111 WSC 12345

TMBMC46Y0Y7000001 SKZ7Z0W0204038 ->

Vehicle system test HELP

Select function XX

Q

Coding control unit

Enter code number XXXXX (0-32767)

Coding control unit

Enter code number 03121 (0-32767)

Q

6Y1919870B COMBIINSTRUMENT VDO X09 ->

Coding 03121 WSC 12345

TMBMC46Y0Y7000001 SKZ7Z0W0204038 ->

Vehicle system test HELP

Select function XX

Vehicle system test HELP

06 End output

Q

Page 65 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

Electrical SystemEdition 09.04

S00.5301.14.2002-6 page 11 02

Test and setting conditions

•Tyre inflation pressure O.K.

•Lenses must neither be damaged nor soiled.

•Reflectors and bulbs O.K.

•Vehicle load must be achieved.

Load: With an individual or 75 kg on the driver's seat in an

otherwise unladen vehicle (dead weight).

The unladen weight is the weight of the vehicle with full

fuel tank (at least 90 %) including the weight of all the op-

erational equipment elements (e.g. spare wheel, tool kit,

jack etc.).

The vehicle must have rolled a few metres or have been

depressed a few times at the front and rear to allow the

springs to settle.

•Both the vehicel and headlight beam setting device

must be on a level flat surface.

•Align the vehicle and headlight beam setting device in

accordance with the device manufaturer's indications.

•Check the control system of vehicles equipped with

headlight beam control by repeatedly turning the

thumbwheel in the dash panel. Then turn the thum-

bwheel to basic position.

•Set the inclination value.

Inclination value:

The inclination value is marked in „%“ at the top of the

headlight housing. The main headlights must be set to

this value. The percentage value applies up to 10 metres

projection distance. This will be 12 cm for an inclination

value of e.g. 1.2 %.

Inspecting headlight beam setting and adjusting

if necessary

Main headlights:

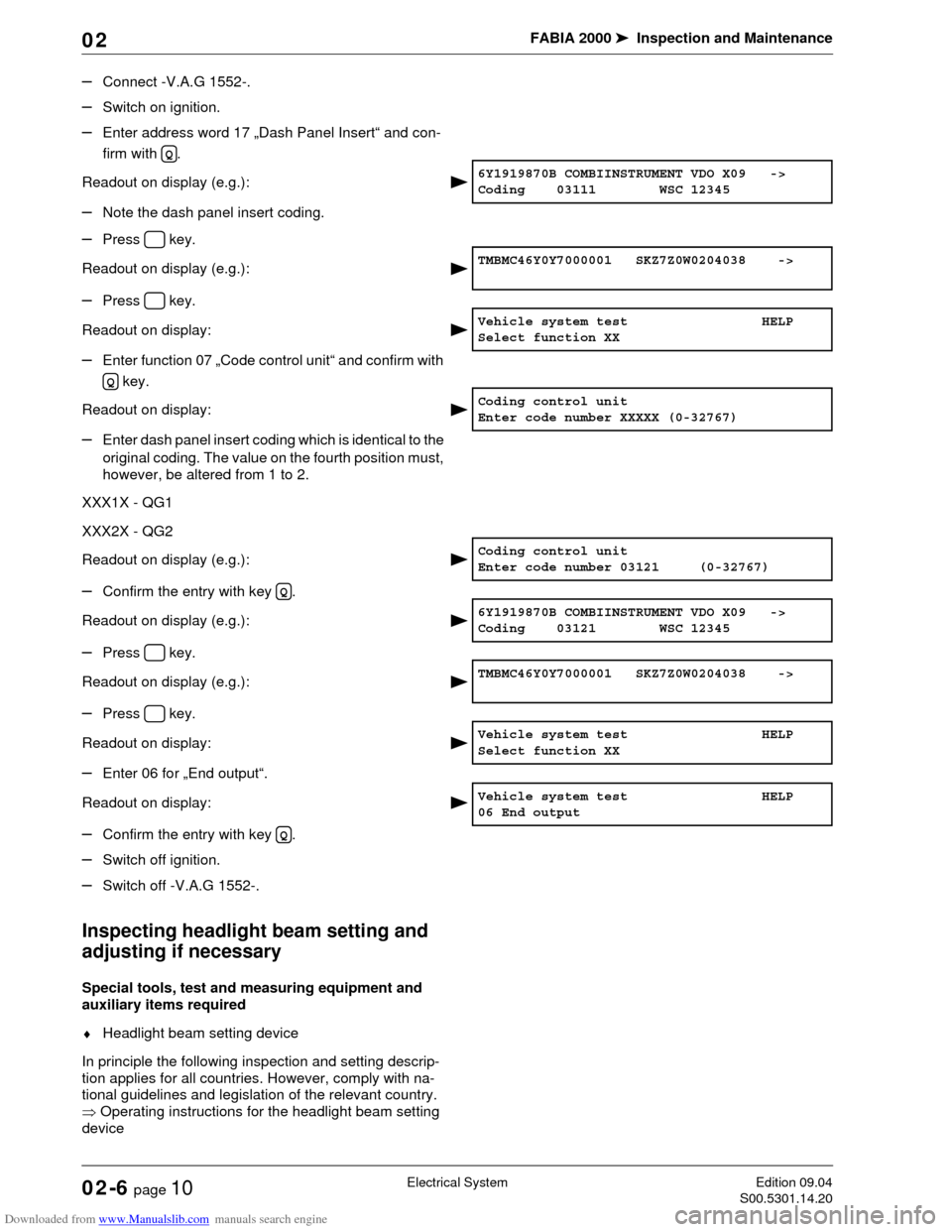

–Check whether the horizontal light/dark limit touches

the separation mark -1- on the test surface when the

low beam light is on .

–Check whether the kink -2- between the left horizontal

part and the ascending right part of the light/dark limit

intersects with the central mark -3- on the vertical line.

The light core of the light beam must be located to the

right of the vertical line.132

S02-0091

Page 66 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

Electrical SystemEdition 09.04

S00.5301.14.2002-6 page 12 02

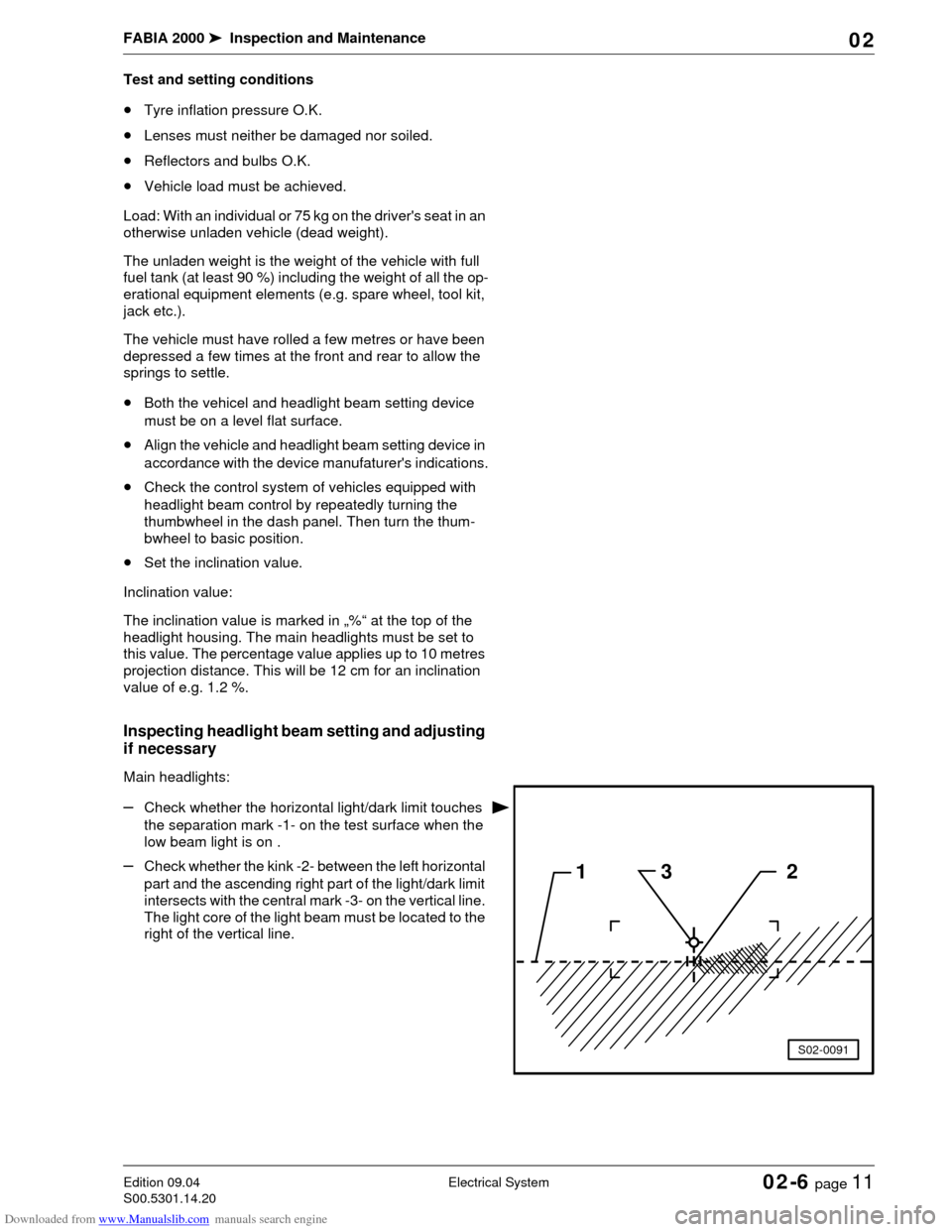

♦To easily determine the kink -2-, alternately cover and

uncover the left half of the headlight (in the driving di-

rection) a few times. After this, check the low beam

once again.

♦Once the low beam light has been correctly set the

centre of the light beam of the main beam must be po-

sitioned on the central mark -3-.

♦The adjustment foreseen for the new control screen

also applies for the previous one, which has a 15 ad-

justing line. To avoid incorrect settings disregard the

15 adjusting line.

Other additional headlights:

Additionally fitted headlights must be inspected or set in

compliance with the relevant applicable directives.

Setting the headlight beam

Setting the main beam

The headlight adjusting device is used to set up the head-

light. Nominal values ⇒02-6 page 10.

Left headlight (right headlight in mirror image)

1 - Vertical adjustment

2 - Lateral adjustment

–Adjust with corresponding thumbwheel.

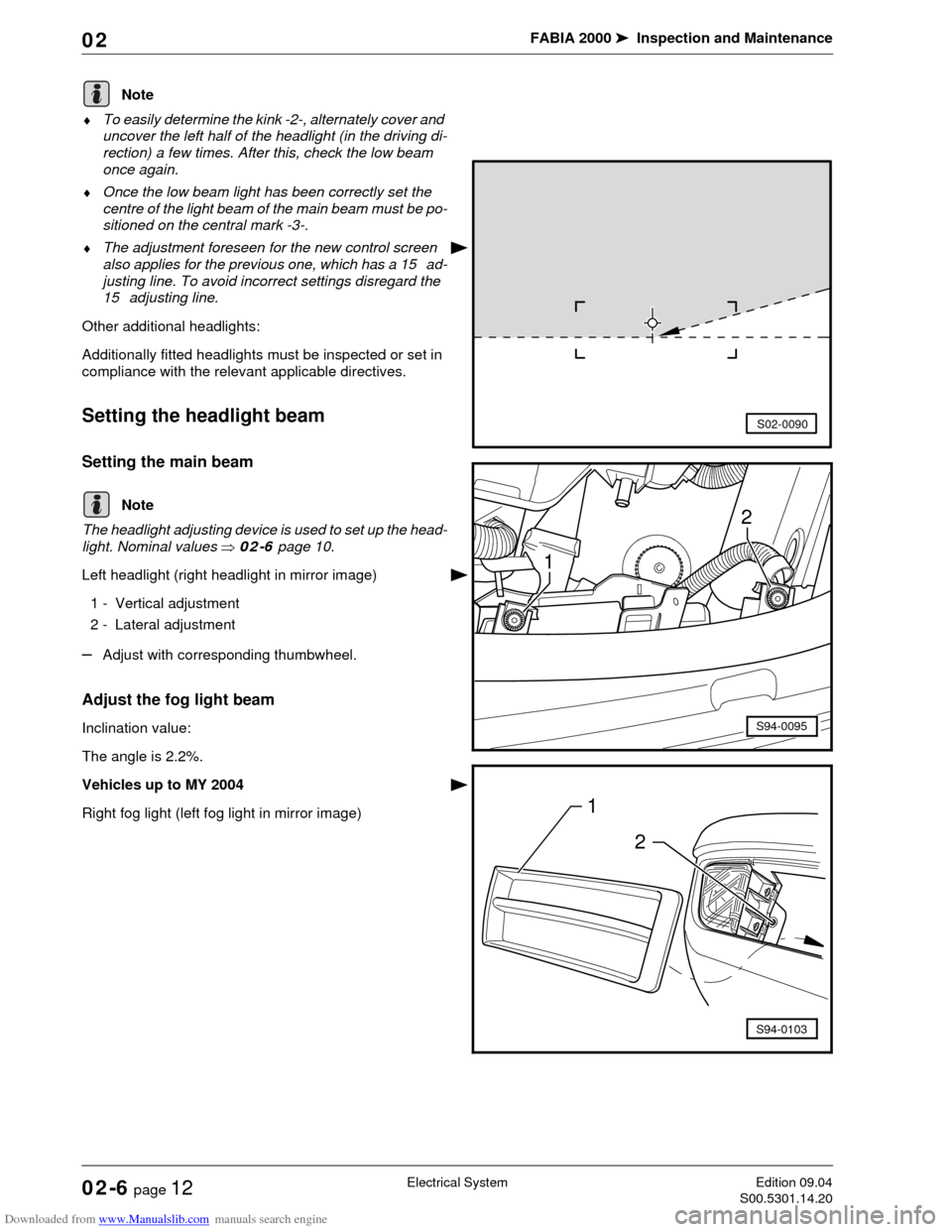

Adjust the fog light beam

Inclination value:

The angle is 2.2%.

Vehicles up to MY 2004

Right fog light (left fog light in mirror image)

Note

S02-0090

Note2

1

S94-0095

1

2

S94-0103

Page 71 of 86

Downloaded from www.Manualslib.com manuals search engine FABIA 2000➤Inspection and Maintenance

BodyEdition 09.04

S00.5301.14.2002-7 page 3 02

The materials and the corresponding work instructions

are listed in the ⇒Technical Service Handbook, Part 6 -

Technology of paint repairs, chemical materials.

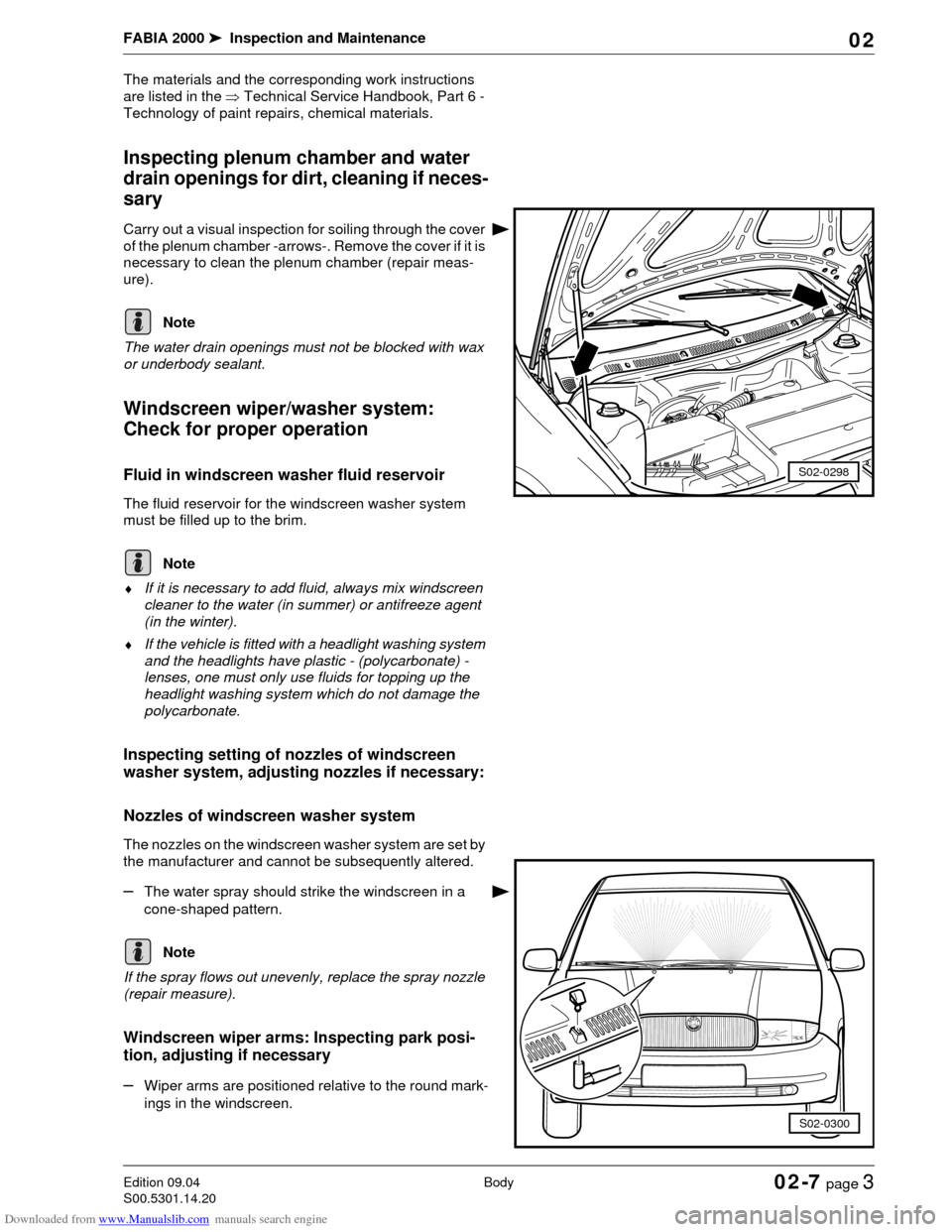

Inspecting plenum chamber and water

drain openings for dirt, cleaning if neces-

sary

Carry out a visual inspection for soiling through the cover

of the plenum chamber -arrows-. Remove the cover if it is

necessary to clean the plenum chamber (repair meas-

ure).

The water drain openings must not be blocked with wax

or underbody sealant.

Windscreen wiper/washer system:

Check for proper operation

Fluid in windscreen washer fluid reservoir

The fluid reservoir for the windscreen washer system

must be filled up to the brim.

♦If it is necessary to add fluid, always mix windscreen

cleaner to the water (in summer) or antifreeze agent

(in the winter).

♦If the vehicle is fitted with a headlight washing system

and the headlights have plastic - (polycarbonate) -

lenses, one must only use fluids for topping up the

headlight washing system which do not damage the

polycarbonate.

Inspecting setting of nozzles of windscreen

washer system, adjusting nozzles if necessary:

Nozzles of windscreen washer system

The nozzles on the windscreen washer system are set by

the manufacturer and cannot be subsequently altered.

–The water spray should strike the windscreen in a

cone-shaped pattern.

If the spray flows out unevenly, replace the spray nozzle

(repair measure).

Windscreen wiper arms: Inspecting park posi-

tion, adjusting if necessary

–Wiper arms are positioned relative to the round mark-

ings in the windscreen.

S02-0298

Note

Note

S02-0300

Note