SKODA FABIA 2003 1.G / 6Y Owner's Manual

Manufacturer: SKODA, Model Year: 2003, Model line: FABIA, Model: SKODA FABIA 2003 1.G / 6YPages: 233, PDF Size: 32.04 MB

Page 201 of 233

Breakdown assistance

200

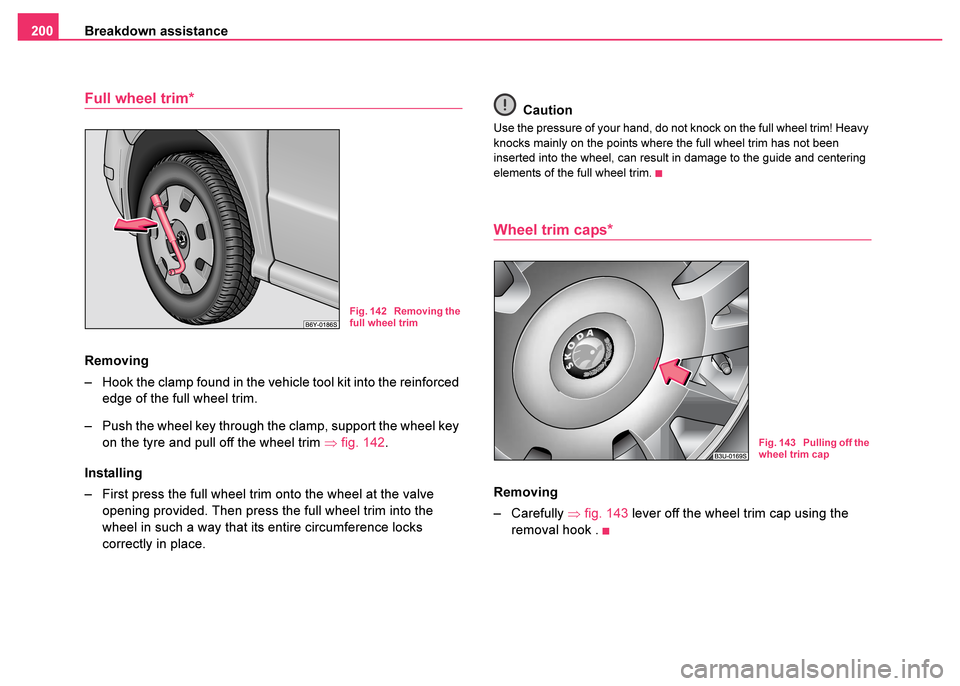

Full wheel trim*

Removing

– Hook the clamp found in the vehicle tool kit into the reinforced

edge of the full wheel trim.

– Push the wheel key through the clamp, support the wheel key on the tyre and pull off the wheel trim ⇒fig. 142 .

Installing

– First press the full wheel trim onto the wheel at the valve opening provided. Then press the full wheel trim into the

wheel in such a way that its entire circumference locks

correctly in place. Caution

Use the pressure of your hand, do not knock on the full wheel trim! Heavy

knocks mainly on the points where the full wheel trim has not been

inserted into the wheel, can result in damage to the guide and centering

elements of the full wheel trim.

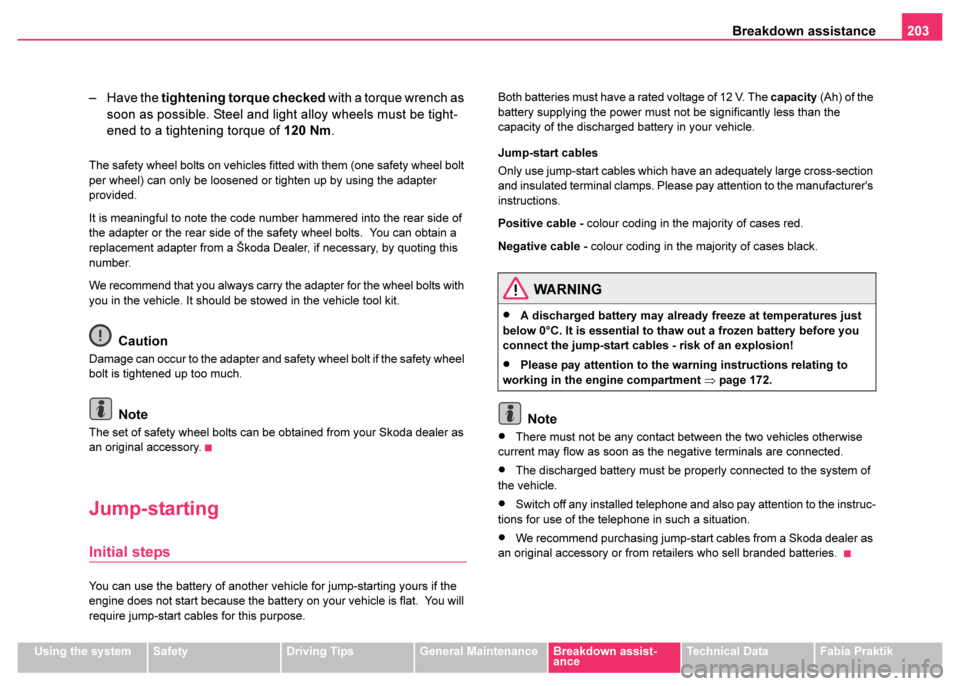

Wheel trim caps*

Removing

– Carefully

⇒fig. 143 lever off the wheel trim cap using the

removal hook .

Fig. 142 Removing the

full wheel trim

Fig. 143 Pulling off the

wheel trim cap

Page 202 of 233

Breakdown assistance201

Using the systemSafetyDriving TipsGeneral MaintenanceBreakdown assist-

anceTechnical DataFabia Praktik

Slackening and tightening wheel bolts

Slacken the wheel bolts before jacking up the vehicle.

Slackening wheel bolts

– Push the wheel wrench fully onto the wheel bolt

4).

– Grasp the end of the wrench and turn the bolt about one turn

to the left ⇒fig. 144 .

Tightening wheel bolts

– Push the wheel wrench fully onto the wheel bolt

4).

– Grasp the end of the wrench and turn the bolt to the right until it is tight. Note

Apply pressure carefully with your

foot to the end of the wheel wrench if

it proves difficult to slacken the wheel bolts. Hold tight on the vehicle when

doing this and ensure that you have a steady position.

Car jack

You have to raise the vehicle with a lifting jack in order to

be able to take off the wheel.

4)Use the appropriate adapter for slackening and tightening the safety wheel bolts

⇒ page 202.

Fig. 144 Changing a

wheel: Slackening

wheel bolts

WARNING

Slacken the wheel bolts only a little (about one turn) as long as the

vehicle has not yet been jacked up - risk of an accident!.

Fig. 145 Changing a

wheel: Points for posi-

tioning car jack

Page 203 of 233

Breakdown assistance

202

– Position the lifting jack by selecting the jacking point - lower sill - which is closest to the wheel to be removed ⇒page 201,

fig. 145 .

– Position the lifting jack below the jacking point and move it up until its claw is positioned directly below the vertical web of the

lower sill.

– Align the lifting jack so that its claw grasps the web of the lower sill and the moving base plate of the jack is resting flat

against firm ground.

– Turn the lifting jack up further until the wheel is just clear of the ground.

Ground below the lifting jack which is soft and slippery can cause the

vehicle to slip off the jack. It is therefore always necessary to place the

lifting jack on a solid surface or use a wide and stable base. Use a non-

slip base (e.g. a rubber foot mat) if the surface is smooth, such as

cobbled stones, a tiled floor,etc.

Securing wheels against being stolen*

You need a special adapter for slackening the safety

wheel bolts.

– Pull off the full wheel trim/cap from the wheel hub or cap from the safety wheel bolt.

– Push the adapter with its toothed side into the inner toothing of the safety wheel bolt right down in such a way

that only the outer hexagon is jutting out ⇒fig. 146 .

– Push the wheel wrench fully onto the adapter .

– Slacken the wheel bolt, or tighten it firmly ⇒page 201.

– Reinstall the full wheel trim/wheel cap after removing the adapter or place the cap onto the safety wheel bolt.

WARNING

•Take suitable measures to prevent the base of the lifting jack

from slipping off - risk of injury!

•Not positioning the lifting jack at the specified points can result

in damage to the vehicle. The jack can also slip off if it does not

have sufficient grip - risk of injury!.

•It is important to support the vehicle with suitable supporting

blocks if you wish to work under the lifted vehicle - risk of injury!

AAAB

Fig. 146 Safety wheel

bolt with adapter

AB

AA

AB

Page 204 of 233

Breakdown assistance203

Using the systemSafetyDriving TipsGeneral MaintenanceBreakdown assist-

anceTechnical DataFabia Praktik

– Have the tightening torque checked with a torque wrench as

soon as possible. Steel and light alloy wheels must be tight-

ened to a tightening torque of 120 Nm.

The safety wheel bolts on vehicles fitted with them (one safety wheel bolt

per wheel) can only be loosened or tighten up by using the adapter

provided.

It is meaningful to note the code number hammered into the rear side of

the adapter or the rear side of the safety wheel bolts. You can obtain a

replacement adapter from a Škoda Dealer, if necessary, by quoting this

number.

We recommend that you always carry the adapter for the wheel bolts with

you in the vehicle. It should be stowed in the vehicle tool kit.

Caution

Damage can occur to the adapter and safety wheel bolt if the safety wheel

bolt is tightened up too much.

Note

The set of safety wheel bolts can be obtained from your Skoda dealer as

an original accessory.

Jump-starting

Initial steps

You can use the battery of another vehicle for jump-starting yours if the

engine does not start because the battery on your vehicle is flat. You will

require jump-start cables for this purpose. Both batteries must have a rated voltage of 12 V. The

capacity (Ah) of the

battery supplying the power must not be significantly less than the

capacity of the discharged battery in your vehicle.

Jump-start cables

Only use jump-start cables which have an adequately large cross-section

and insulated terminal clamps. Please pay attention to the manufacturer's

instructions.

Positive cable - colour coding in the majority of cases red.

Negative cable - colour coding in the majority of cases black.

Note

•There must not be any contact between the two vehicles otherwise

current may flow as soon as the negative terminals are connected.

•The discharged battery must be properly connected to the system of

the vehicle.

•Switch off any installed telephone and also pay attention to the instruc-

tions for use of the telephone in such a situation.

•We recommend purchasing jump-start cables from a Skoda dealer as

an original accessory or from retailers who sell branded batteries.

WARNING

•A discharged battery may already freeze at temperatures just

below 0°C. It is essential to thaw out a frozen battery before you

connect the jump-start cables - risk of an explosion!

•Please pay attention to the warning instructions relating to

working in the engine compartment ⇒page 172.

Page 205 of 233

Breakdown assistance

204

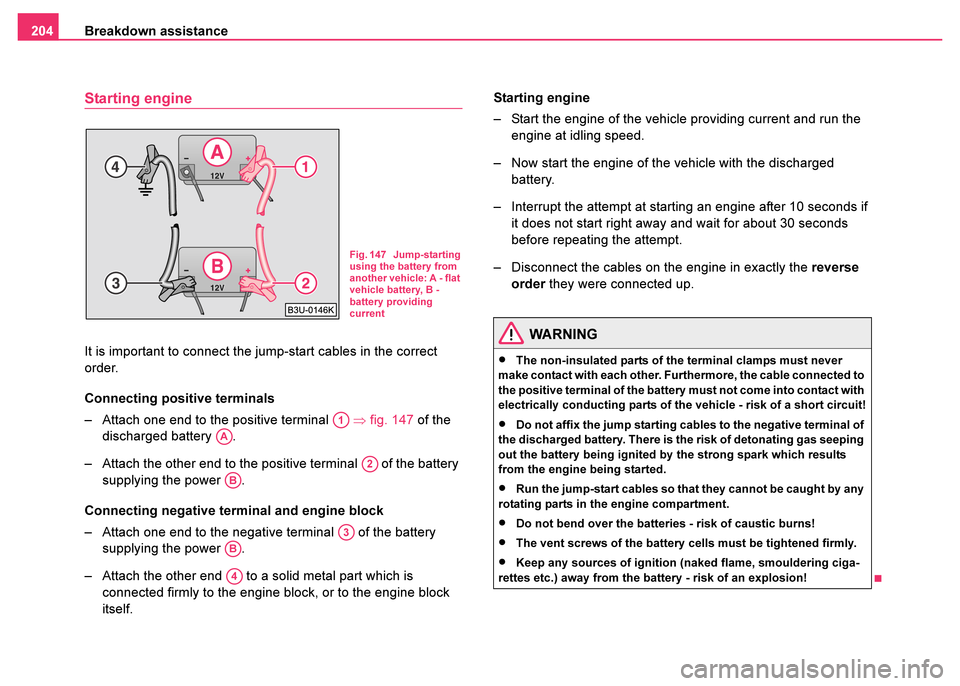

Starting engine

It is important to connect the jump-start cables in the correct

order.

Connecting positive terminals

– Attach one end to the positive terminal ⇒fig. 147 of the

discharged battery .

– Attach the other end to the positive terminal of the battery supplying the power .

Connecting negative terminal and engine block

– Attach one end to the negative terminal of the battery supplying the power .

– Attach the other end to a solid metal part which is connected firmly to the engine block, or to the engine block

itself. Starting engine

– Start the engine of the vehicle providing current and run the

engine at idling speed.

– Now start the engine of the vehicle with the discharged battery.

– Interrupt the attempt at starting an engine after 10 seconds if it does not start right away and wait for about 30 seconds

before repeating the attempt.

– Disconnect the cables on th e engine in exactly the reverse

order they were connected up.

Fig. 147 Jump-starting

using the battery from

another vehicle: A - flat

vehicle battery, B -

battery providing

current

A1

AA

A2

AB

A3

AB

A4

WARNING

•The non-insulated parts of the terminal clamps must never

make contact with each other. Furthermore, the cable connected to

the positive terminal of the battery must not come into contact with

electrically conducting parts of the vehicle - risk of a short circuit!

•Do not affix the jump starting cables to the negative terminal of

the discharged battery. There is the risk of detonating gas seeping

out the battery being ignited by the strong spark which results

from the engine being started.

•Run the jump-start cables so that they cannot be caught by any

rotating parts in the engine compartment.

•Do not bend over the batteries - risk of caustic burns!

•The vent screws of the battery cells must be tightened firmly.

•Keep any sources of ignition (naked flame, smouldering ciga-

rettes etc.) away from the battery - risk of an explosion!

Page 206 of 233

Breakdown assistance205

Using the systemSafetyDriving TipsGeneral MaintenanceBreakdown assist-

anceTechnical DataFabia Praktik

Tow-starting and towing vehicle

General

Please pay attention to the following instructions if you are going

to use a tow rope:

Driver of the towing vehicle

– Do not drive off until the tow rope is taught.

– Release the clutch particularly gently when starting off or

depress the accelerator particularly gently if your vehicle is

fitted with an automatic gearbox.

Driver of the towed vehicle

– Switch the ignition on so that the steering wheel is not blocked and you can also operate the turn signal lights, the headlight

flasher, the windscreen wipers and windscreen washer

system.

– Take the vehicle out of gear or move the selector lever into position N if your vehicle is fitted with an automatic gearbox.

– Note that the brake servo unit and power steering only operate if the engine is running. You will require significantly greater

physical force to depress the brake pedal and to steer the

vehicle if the engine is not running.

– Ensure that the tow rope is always kept taught.

Tow rope or tow bar

A tow bar is safest way of towing a vehicle and also minimizes any

shocks. You can use a tow rope only if a suitable tow bar is not available.

The tow rope must be elastic to protect the vehicle. Thus one should only

use plastic fibre rope or a rope made out of a similarly elastic material.

Only attach the tow rope to the towing eyes provided for this purpose

⇒ page 206, “Front towing eye” and ⇒page 207, “Rear towing eye”.

Driving style

Towing another vehicle requires a certain amount of practice. Both drivers

should be familiar with the particular points about towing a vehicle.

Unskilled drivers should not attempt to tow-start or tow in another vehicle.

One should be constantly vigilant not to allow impermissibly high towing

forces or jerky loadings. There is always a risk of excessive stresses and

damage resulting at the points to which you attach the tow rope or tow bar

when you attempt to tow a vehicle which is not standing on a paved road.

Caution

If the gearbox of your vehicle no longer contains any oil because of a

defect, your vehicle must only be towed in with the driven wheels raised

clear of the ground, or on a special vehicle transporter or trailer.

Note

•Please comply with any legal requirements particularly regarding the

switched on signal systems, when towing in or tow-starting another

vehicle.

•The tow rope must not be twisted as it may in certain circumstances

result in the front towing eye being unscrewed out of your vehicle.

Page 207 of 233

Breakdown assistance

206

Front towing eye

The towing eye is stored in the box for the vehicle tool kit.

Remove the protective grille carefully as follows: – Stick a screwdriver through the bore hole of the protective

grille (near the licence plate) ⇒fig. 148 and press downwards

thereby pressing off the spring clip on the protective grille.

Grab the edge of the protective grille by the hand at the same

time (arrow ) and loosen it.

– Hold the loosened protective grille in one hand. Push the screwdriver through the second bore hole, free up the protec-

tive grille completely and remove it.

– Screw in the towing eye anticlockwise down to the stop ⇒fig. 149 and tighten up using the wheel wrench (push the

wheel wrench through eye).

– Put the protective grille in place after screwing out the towing eye again and press into place. The protective grille must

engage firmly.

Fig. 148 Front

bumper: Protective

grille

Fig. 149 Front

bumper: Installing the

towing eye

AA

Page 208 of 233

Breakdown assistance207

Using the systemSafetyDriving TipsGeneral MaintenanceBreakdown assist-

anceTechnical DataFabia Praktik

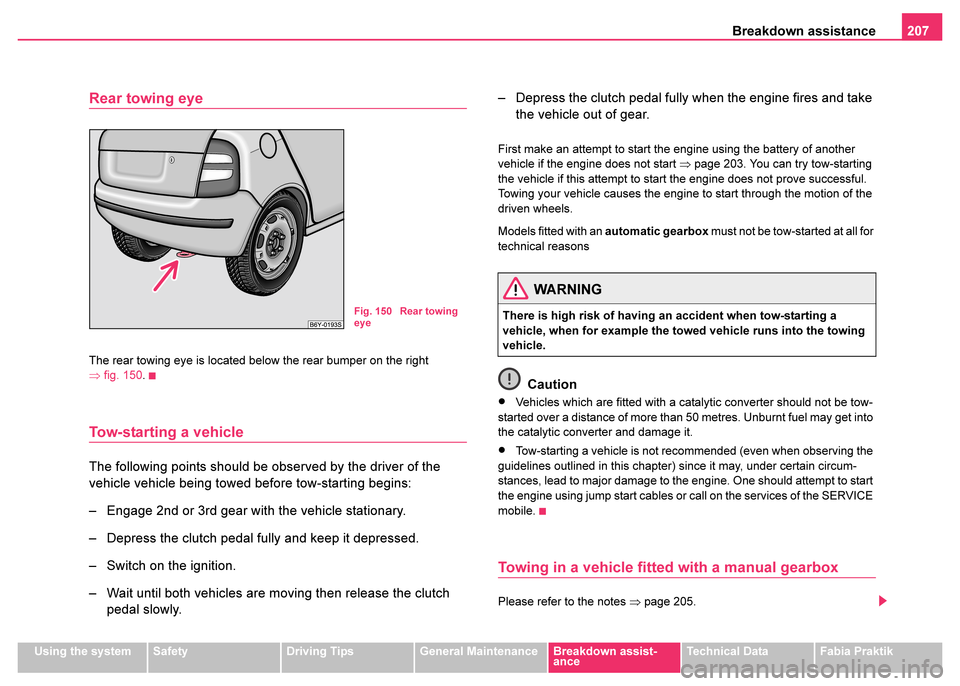

Rear towing eye

The rear towing eye is located below the rear bumper on the right

⇒fig. 150 .

Tow-starting a vehicle

The following points should be observed by the driver of the

vehicle vehicle being towed before tow-starting begins:

– Engage 2nd or 3rd gear with the vehicle stationary.

– Depress the clutch pedal fully and keep it depressed.

– Switch on the ignition.

– Wait until both vehicles are moving then release the clutch

pedal slowly. – Depress the clutch pedal fully when the engine fires and take

the vehicle out of gear.

First make an attempt to start the engine using the battery of another

vehicle if the engine does not start ⇒page 203. You can try tow-starting

the vehicle if this attempt to start the engine does not prove successful.

Towing your vehicle causes the engine to start through the motion of the

driven wheels.

Models fitted with an automatic gearbox must not be tow-started at all for

technical reasons

Caution

•Vehicles which are fitted with a catalytic converter should not be tow-

started over a distance of more than 50 metres. Unburnt fuel may get into

the catalytic converter and damage it.

•Tow-starting a vehicle is not recommended (even when observing the

guidelines outlined in this chapter) since it may, under certain circum-

stances, lead to major damage to the engine. One should attempt to start

the engine using jump start cables or call on the services of the SERVICE

mobile.

Towing in a vehicle fitted with a manual gearbox

Please refer to the notes ⇒page 205.

Fig. 150 Rear towing

eye

WARNING

There is high risk of having an accident when tow-starting a

vehicle, when for example the towed vehicle runs into the towing

vehicle.

Page 209 of 233

Breakdown assistance

208

The car can be towed in with a tow bar or a tow rope or with the front or

rear wheels raised. The maximum towing speed is 50 km/h.

Towing of a vehicle with an automatic gearbox

Please refer to the notes ⇒page 205.

The car can be towed in with a tow bar or a tow rope. Refer at the same

time to the following guidelines:

•Move selector lever into N .

•The maximum towing speed is 50 km/h.

•The maximum permissible towing distance is 50 km. The gear oil

pump does not operate when the engine is not running and the gear would

not be adequately lubricated at higher speeds and over longer towing

distance.

If the vehicle is towed in by a recovery vehicle, the vehicle should only be

towed in with the front wheels raised. The drive shafts drive the front

wheels. The drive shafts will rotate backwards when the vehicle is raised

at the rear - that is it runs backwards. Here the planetary gears in the auto-

matic gearbox will rotate at such a high speed that the gearbox will suffer

severe damage within a short time.

Note

The vehicle must be transported on a special vehicle or trailer if it is not

possible to tow in the vehicle in the way described or if the towing distance

is greater than 50 km.

Page 210 of 233

Fuses and light bulbs209

Using the systemSafetyDriving TipsGeneral MaintenanceBreakdown assist-

anceTechnical DataFabia Praktik

Fuses and light bulbs

Electric fuses

Replacing fuses

Defect fuses must be replaced.

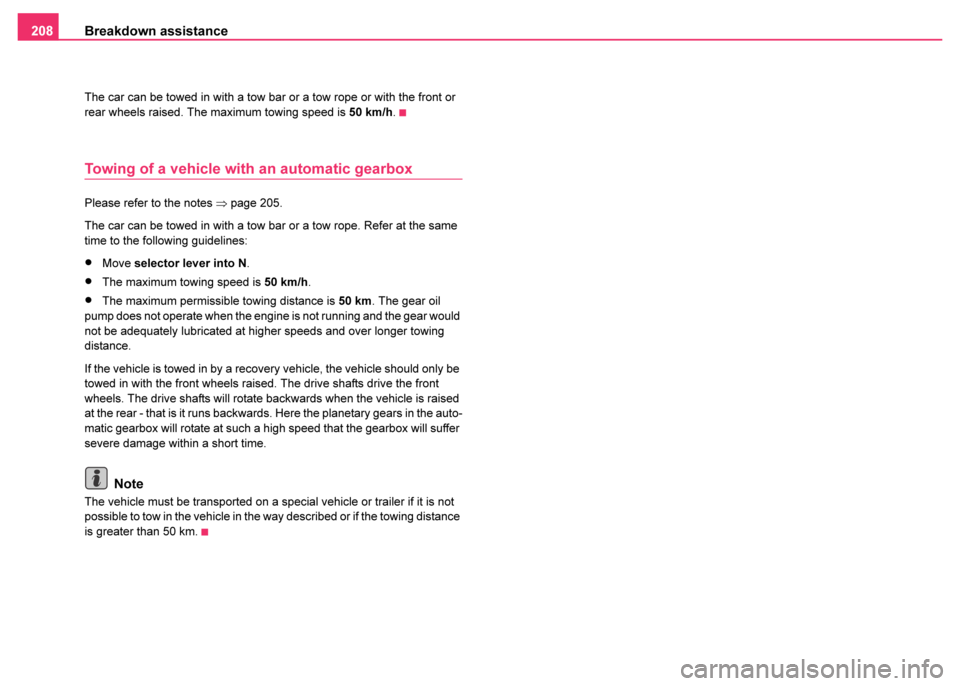

Individual electrical circuits are protected by fuses. The fuses are

located on the left side of the dash panel behind the safety cover.

– Switch the ignition off and also the electrical component

affected.

– Set the screwdriver under the safety cover (on the recess in the safety cover), lever it up carefully in the direction of the

arrow and take it out in the direction of the arrow

⇒fig. 151 . – Find out which fuse belongs to the component which is not

operating ⇒page 210, “Fuse assignment in the dash panel”.

– Defect fuses can be detected by their melted metal strips. Replace the defect fuse by a new fuse of the same ampere

number.

– First shift the safety cover into the dash panel in the direction of arrow then press the safety cover in the direction of the

arrow in such a way that the guide lug locks into the

opening of the dash panel.

There is a further box of fuses in the engine compartment on the battery.

We recommend that you have these fuses replaced by a Škoda dealer.

We recommend that you carry the box of replacement fuses with you

which was delivered in your vehicle. Replacement fuses

5) are available

at Škoda dealers.

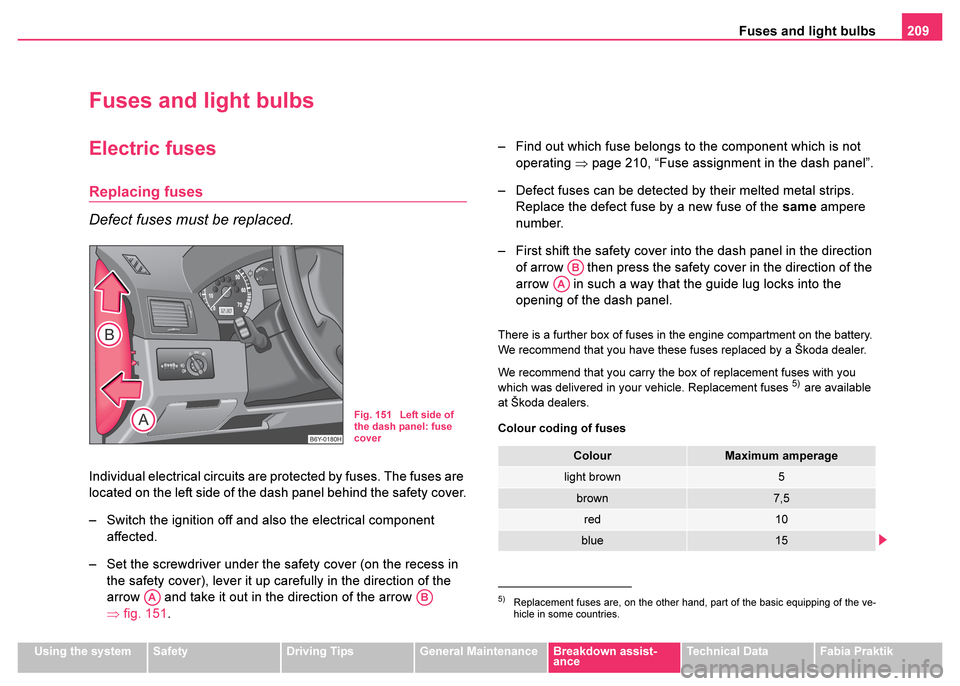

Colour coding of fuses

Fig. 151 Left side of

the dash panel: fuse

cover

AAAB5)Replacement fuses are, on the other hand, part of the basic equipping of the ve-

hicle in some countries.

ColourMaximum amperage

light brown5

brown7,5

red10

blue15

AB

AA