tow bar SKODA FABIA 2016 3.G / NJ Owner's Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 2016, Model line: FABIA, Model: SKODA FABIA 2016 3.G / NJPages: 196, PDF Size: 31.86 MB

Page 85 of 196

Fig. 106

Install crossmember: Tighten the

screws

Read and observe and on page 82 first.

›

To install complete detach the

A

screws in the direction of arrows

1

and

pull out partially. The brackets

B

are unlocked » Fig. 105.

›

Set the crossbar so that the screws

A

are pointing forward.

›

Place the crossmember with the fixed part

C

onto the left lashing eyelet in

the direction of arrow

2

.

›

Pull out part

D

of the cross member and place onto the right lashing eyelet

in arrow direction

3

.

›

Push the mounts

B

in the direction of arrows

4

until they click » Fig. 106.

›

Turn the screws

A

in the direction of arrow

5

up tothe latch.

›

Check how well the crossmember is fastened by pulling on it.

Removing is carried out in the reverse order.

Fitting/removing the bike rackFig. 107

Fitting the bike rack

Read and observe

and on page 82 first.

›

To install , loosen screw

A

on the bicycle rack (hereinafter only referred to as

"carrier") in direction of arrow

1

» Fig. 107 .

›

Place the carrier of the crossmember in the direction of arrow

2

.

›

Hold part

B

of the carrier firmly and press on part

C

of the support in the

direction of arrow

3

.

›

Remove screw

A

in the direction of arrow

4

.

›

Screw out screw

D

in the direction of arrow

5

and remove.

›

Place part

E

in the direction of arrow

6

, depending on bike size, in one of

the possible positions » .

›

Insert screw

D

and tighten in the direction of arrow

7

.

Removing is carried out in the reverse order.

CAUTION

The bike stowed in the rack must not touch either the boot lid or other vehicle

parts - there is a risk of damage to the vehicle occurring.83Transport of cargo

Page 86 of 196

Place bicycle into the carrierFig. 108

Insert the front fork of the bicycle into the carrier / mounting ex-

ample of the front wheel

Read and observe

and on page 82 first.

›

Remove the front wheel from the bike.

›

Release the quick release

A

» Fig. 108 on the carrier and adjust according to

the bicycle fork width.

›

Place the bicycle fork on the fixing axle and tighten with the quick release

A

.

›

Set the left bicycle pedal towards the vehicle front to secure the front wheel

more easily.

›

If you want to transport two bicycles, loosen screw

A

» Fig. 107 on page 83

on the carrier and move the carrier along with attached bike to the left.

The handlebar must not touch the side window of the luggage compartment.

›

Tighten screw

A

» Fig. 107 on page 83 on the support.

›

Guide the boot lid gently downwards and check while doing this that there is

no contact between the handlebar and the rear window.

›

If necessary, the position of the sliding part

E

» Fig. 107 on page 83 can be

adjusted.

›

The dismantled front wheel can best be stowed between the left crank and

the bicycle frame.

›

Attach the front wheel with belt

B

to the front fork » Fig. 108 or to the bicy-

cle frame.

›

The second carrier is installed and the bicycle is secured in a similar way.

Ensure the stability of the bicycles with a beltFig. 109

Ensure the stability of the bicycles with a belt

Read and observe

and on page 82 first.

›

In order to loosen the rubber part of the clamp, push both parts against each

other and open the clamp.

›

Position the clamp with the rubber part in the direction of travel as low down

on the saddle support as possible and close it.

›

When transporting two bicycles, stretch the belt » Fig. 109 -

between the

saddles by moving the bicycles apart.

›

Hook the carabiners on the ends of the belt into the lower lashing eyelets

behind the rear seats » Fig. 109 -

.

›

Pull the belt through the tensioning clasps on both sides in turn.

If necessary, you can correct the position of the bicycles in the vehicle after-

wards.

Transportation on the roof rack

Fig. 110

Attachment points

84Operation

Page 121 of 196

Towing device and trailer

Hitch

Introduction

This chapter contains information on the following subjects:

Description

119

Adjusting the ready position

120

Check the setting of the standby position

120

Assembling the bar ball - Step 1

120

Assembling the bar ball - Step 2

121

Check proper fitting

121

Removing the bar ball - Step 1

122

Removing the bar ball - Step 2

122

Vertical load with mounted accessories

123

The maximum trailer nose weight when towing a trailer is 50 kg. Other data

(e.g. shown onthe nameplate of the hitch) on provides information about the

test values of the device .

WARNING■ Check that the ball head is seated correctly and is secured in the mount-

ing recess before starting any journey.■

When the knee-joint bar is not used and properly secured in the receiving

shaft, it is damaged or incomplete, this must not be used - there is a risk of

an accident.

■

Do not modify or adapt the towing equipment in any way.

■

Keep the mounting recess of the towing equipment clean at all times.

Such dirt prevents the ball head from being attached securely.

DescriptionFig. 150

Carrier for the towing device / tow bar

Read and observe

on page 119 first.

The knee-joint bar is detachable and is located in the storage compartment for

the spare / emergency wheel.

Support for the towing device and tow bar » Fig. 150

Cover for the mounting recess

Mounting recess

Dust cap

Ball head

Operating lever

Lock cap

Release pin

Key

Locking ball

123456789119Towing device and trailer

Page 122 of 196

Adjusting the ready positionFig. 151

Remove cap from the lock / insert key into the lock

Fig. 152

Lock unlock / press release bolt and lever and push

Read and observe

on page 119 first.

The tow bar must be set prior to installation to the standby position

» page 120 , Check the setting of the standby position .

›

Grip the tow bar below the protective cap.

›

Remove the cover

A

from the lock in the direction of the arrow

1

» Fig. 151 .

›

Insert the key

B

into the lock in the direction of arrow

2

, so that its green

marker points upward.

›

Turn the key

B

in the direction of arrow

3

so that the red marking points

upwards » Fig. 152.

›

Push in the release bolt

C

in the direction of arrow

4

until it stops and si-

multaneously press the operating lever

D

in the direction of arrow

5

until it

stops.

The operating lever

D

remains locked in this position.

Check the setting of the standby positionFig. 153

Ready position

Read and observe on page 119 first.

Correctly adjusted standby position » Fig. 153

The operating lever

A

is locked in the lower position.

The release bolts

B

can be moved.

The red mark on the key

C

is pointing upwards.

In the ready position, the key cannot be removed or turned into a different po-

sition.

Assembling the bar ball - Step 1

Fig. 154

Removing cap: on the rear bumper / for the receiving shaft

120Driving

Page 123 of 196

Fig. 155

Insert ball rod / trigger bolt in the extended state

Read and observe

on page 119 first.

The tow bar must be set to the standby position » page 120.

Preparing installation

›

Remove the cover cap

A

in the direction of arrow

1

» Fig. 154 using the on-

board tool clamp for pulling off the wheel trims.

›

Remove cover cap

B

in the direction of arrow

2

» .

Fitting

›

Grip the tow bar from underneath » Fig. 155 and insert into the mounting re-

cess in arrow direction

3

until you hear it click into place » .

The operating lever

C

automatically turns upwards in the direction of arrow

4

and the release pin

D

pops out (both its red and green parts are visible)

» .

If the operating lever

C

does not turn automatically, or if the release pin

D

does not pop out, remove the tow bar from the mounting recess by turning the

operating lever

C

downwards as far as it can go. Clean the contact surfaces

on the tow bar and the mounting recess.

WARNING■ Carefully remove the cap for the mounting recess B - there is a risk of

hand injury.■

Keep your hands outside the operating lever's range of motion when at-

taching the ball head – there is a risk of finger injury.

■

Never attempt to pull the operating lever upwards forcibly to turn the

key. Doing so would mean the ball head is not attached correctly.

Assembling the bar ball - Step 2Fig. 156

Secure the lock and remove key / place cap on lock

Read and observe

on page 119 first.

›

Turn the key

A

in the direction of arrow

1

so that the green marking points

upwards » Fig. 156 .

›

Remove the key in the direction of the arrow

2

.

›

Fit and press in the cap

B

on the hand-wheel lock in the direction of the ar-

row

3

.

›

Check the ball head for secure mounting » page 121, Check proper fitting .

Check proper fitting

Fig. 157

Correctly secured ball head

Read and observe on page 119 first.

Correctly secured ball rod » Fig. 157

The ball head does not come out of the mounting recess even after heavy

“shaking”.

Operating lever

A

is located as far up as possible.

121Towing device and trailer

Page 124 of 196

The release pin B is completely exposed (both its red and green parts are

visible).

The key is removed and the cap C

attached to the lock.

Removing the bar ball - Step 1

Fig. 158

Remove the cap from the lock

Fig. 159

Insert the key into the lock / unlock the lock

Read and observe

on page 119 first.

No trailer or other accessory is connected to the tow bar. We recommend put- ting the protective cover onto the ball head before removing the tow bar.

›

Remove the cover

A

from the lock in the direction of the arrow

1

» Fig. 158 .

›

Insert the key

B

into the lock in the direction of arrow

2

, so that its green

marker points upward » Fig. 159.

›

Turn the key in the direction of arrow

3

so that the red marking points up-

wards.

Removing the bar ball - Step 2Fig. 160

Release tow bar

Read and observe on page 119 first.

Removing

›

Grasp the ball head from underneath » Fig. 160 .

›

Push in the release bolt

A

in the direction of arrow

1

until it stops and si-

multaneously press the operating lever

B

in the direction of arrow

2

until it

stops.

The ball head is released in this position and falls freely into the hand. If it

does not fall freely into the hand, use your other hand to push it upwards.

Subsequent steps

›

Insert the cover

B

» Fig. 154 on page 120 in the opposite direction to arrow

2

.

›

Fix the cap

A

» Fig. 154 on page 120 aligning it with “check mark” in the low-

er bumper area.

›

Push the cap in first on the left and right and then at the top.

If the operating lever

B

is held firm and not pushed downwards as far as it

can go, it will go back up after the ball head is removed and will not latch into

the ready position. The knee-joint bar will then need to be brought into this

position before the next time it is installed » page 120, Adjusting the ready po-

sition .

The knee-joint bar must be cleaned before storing in the box with the vehicle

tool always.

WARNINGNever allow the ball head to remain unsecured in the boot. This could

cause damage to the boot upon sudden braking, and could put the safety

of the occupants at risk! 122Driving

Page 125 of 196

CAUTION■Place the tow bar in the standby position, with the key upwards, and store in

the box - otherwise there is a risk of damage to the key!■

Do not use excessive force when handling the operating lever (e.g. do not

step on it).

Vertical load with mounted accessories

Fig. 161

Representation of the maximum

length of the mounted accesso-

ries and the permissible total

weight of the accessory depend-

ing on the load centre of gravity

Read and observe on page 119 first.

When using the accessories (e.g. bicycle carrier), the maximum length and the

permissible total weight including load must be considered.

The maximum length of the mounted accessories (from the ball of the towing

device) is 70 cm » Fig. 161 .

The total permitted weight of the accessories including load changes with in-

creasing distance of the load centre of gravity from the ball head of the towing

device.

Distance of the load centre of gravity from the ball headPermissible total weight of the ac-cessories, including load0 cm50 kg30 cm50 kg60 cm25 kg70 cm0 kg

CAUTION

Never exceed the permissible total weight of the accessories incl. load and

maximum length of the accessories - risk of damage to the towing device.NoteWe recommend that you use the accessories from ŠKODA Original Accessories.

Using hitch

Trailer (accessory) connect and disconnect

Fig. 162

Housing of the 13 pin socket,

safety eyelet

Connect and disconnect

›

Install the ball bar and the remove the protective cap

3

» Fig. 150 on page 119

lose weight.

›

Place the trailer (the accessory) onto the tow ball.

›

Plug the trailer cable into 13-pin socket

A

» Fig. 162 . (If the trailer / accesso-

ries have a 7-pin connector, use a corresponding reduction piece from the

ŠKODA Original Accessories).

›

Suspend the breakaway cable of the trailer at the safety eyelet

B

(the

breakaway cable must sag in all trailer settings in view of the vehicle).

Uncoupling takes place in reverse order.

Exterior mirrors

You should have additional exterior mirrors fitted if you are not able to see the

traffic behind the trailer using the standard rear-view mirrors.

Headlights

The front of the vehicle may lift up when a trailer (accessory) is being towed

and the headlights may dazzle other road users. Set the range of the head-

lights » page 53 , Operating the lights .

Power supply of the trailer / accessory power system

In the electrical connection between the vehicle and trailer (accessory), the

trailer (accessories) is supplied with power from the vehicle (with ignition

switched on and off).

123Towing device and trailer

Page 153 of 196

CAUTIONScrew the jack back to its starting position prior to putting it back in its box -

risk of damage to the box.

Note

The declaration of conformity is included with the jack or the log folder.

Changing a wheel

Preliminary work

For safety's sake, the following instructions must be observed before

changing a wheel on the road.

›

Park the vehicle as far as possible away from the traffic flow - choose a place

with a flat and firm surface.

›

Switch off the engine.

›

For vehicles with manual transmission select1, gear .

›

For vehicles with automatic transmission , place the selector lever in the P

position.

›

Firmly apply the handbrake.

›

Switch on the hazard warning lights and set up the warning triangle at the

prescribed distance.

›

Have all the occupants get out . The passengers should not stand on the

road while the wheel is being changed (they should remain behind a crash

barrier, for instance).

›

Uncouple any trailers.

Changing a wheel

›

Take out the emergency or spare wheel » page 152.

›

Remove the full wheel trim » page 152or caps» page 152 .

›

Loosen the wheel bolts » page 153 » .

›

Jack up the vehicle » page 153 until the wheel that needs changing is clear of

the ground.

›

Unscrew the wheel bolts and place them on a clean surface (cloth, paper,

etc.).

›

Remove the wheel carefully.

›

Attach the spare wheel and slightly screw on the wheel bolts.

›

Lower the vehicle.

›

Tighten the wheel bolts opposite each other using the wheel wrench (“pull- ing crossways”) » page 153.

›Replace the wheel trim

» page 152and caps» page 152 .

When fitting unidirectional tyres, ensure that the direction of rotation is cor-

rect » page 145 .

All bolts must be clean and must turn easily. If screws are corroded and diffi-

cult to move, these must be replaced.WARNING■ Undo the wheel bolts just a little (about one turn), provided the vehicle

has not yet been jacked up. Otherwise the wheel could come loose and fall

off – risk of injury.■

Under no circumstances must the bolts be greased or oiled - cause an ac-

cident.

Subsequent steps

After changing the wheel, the following work should be carried out.

›

Stow the replaced wheel in the well under the floor covering of the luggage

compartment and secure it with a nut.

›

Stow the tool kit in the space provided and secure using the strap.

›

Check tyre pressure on the mounted wheel and adjust if necessary and, with

vehicles with tyre pressure monitoring, save the tyre pressure values in the

system » page 117 .

›

Have the tightening torque of the wheel bolts checked as soon as possible.

The prescribed tightening torque is 120 Nm.

Change the damaged wheel or consult a specialist garage about repair possi-

bilities.

WARNINGTightening torque which is too high can damage the threads and this can

result in permanent deformation of the contact surfaces on the rim. Where

tightening torque is too low, the wheels may become loose while driving -

risk of accident. Therefore drive cautiously and only at a moderate speed

until the tightening torque has been checked.151Emergency equipment, and self-help

Page 159 of 196

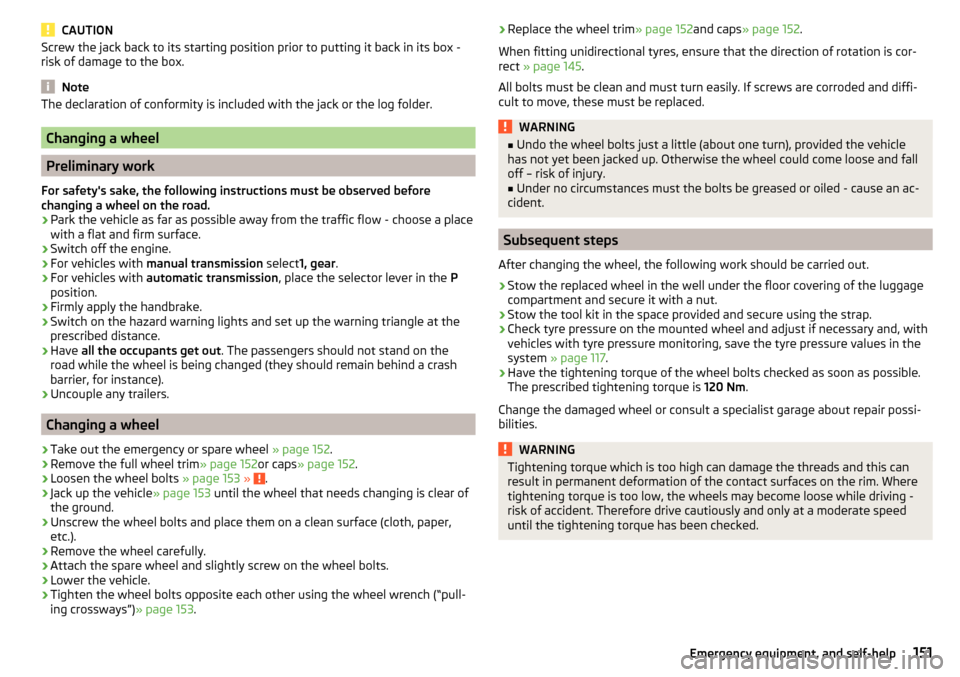

Jump-starting using the battery from another vehicleFig. 188

Jump-starting:

- Discharged battery,

- power-supplying bat-

tery / ground point of the engine for the START-STOP system

Read and observe

on page 156 first.

If, because of a discharged battery, it is not possible to start the engine, the

battery of another vehicle can be used to start the engine. To do this, jump-

start cables are required which have a sufficiently large cross-section and in-

sulated terminal clamps.

The rated voltage of the two batteries must be 12 V. The capacity (Ah) of the

power-supplying battery must not be significantly lower than the capacity of

the discharged battery.

The jump-start cables must be attached in the following sequence.

›

Attach clamp

1

to the positive terminal of the discharged battery.

›

Attach clamp

2

to the positive terminal of the power-supplying battery.

›

Attach clamp

3

to the negative terminal of the power-supplying battery.

›

For vehicles with the START-STOPsystem, attach clamp

4

to the ground

point of the engine

A

» Fig. 188 .

›

For vehicles without the START-STOPsystem, attach clamp

4

to a solid

metal part firmly attached to the engine block or directly to the engine block.

Starting engine

›

Start the engine on the vehicle providing the power and allow it to idle.

›

Initiate the starting process in the vehicle with the discharged battery.

›

If the engine does not start within 10 s, then cancel the starting procedure

and repeat after half a minute.

›

Detach the jumper cables in the exact reverse order that they were attached.

WARNING■

Never clamp the jump cable to the negative terminal of the discharged

battery - risk of explosion.■

The non-insulated parts of the terminal clamps must never touch each

other – risk of short circuit.

■

The jump-start cable connected to the positive terminal of the battery

must not come into contact with electrically conducting parts of the vehicle

– risk of short circuit.

■

Position the jump cables so that they cannot be caught in rotating parts

in the engine compartment - danger of injuries and the risk of vehicle dam-

age.

Towing the vehicle

Information about the towing process

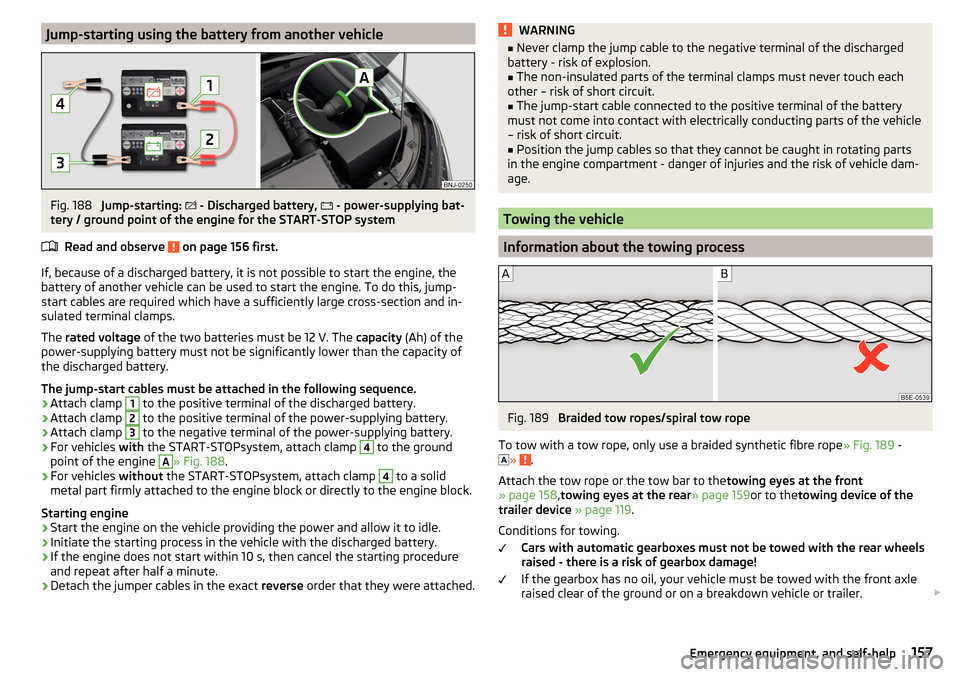

Fig. 189

Braided tow ropes/spiral tow rope

To tow with a tow rope, only use a braided synthetic fibre rope » Fig. 189 -

»

.

Attach the tow rope or the tow bar to the towing eyes at the front

» page 158 ,towing eyes at the rear » page 159or to thetowing device of the

trailer device » page 119 .

Conditions for towing. Cars with automatic gearboxes must not be towed with the rear wheels

raised - there is a risk of gearbox damage!

If the gearbox has no oil, your vehicle must be towed with the front axle

raised clear of the ground or on a breakdown vehicle or trailer.

157Emergency equipment, and self-help

Page 161 of 196

Towing eye rearFig. 191

Rear towing eye

The rear towing eye is located below the rear bumper on the right » Fig. 191.

Vehicles with a trailer device

For vehicles with a factory-fitted towing device, the pre-installed detachable

tow-bar may be used » page 119, Hitch .

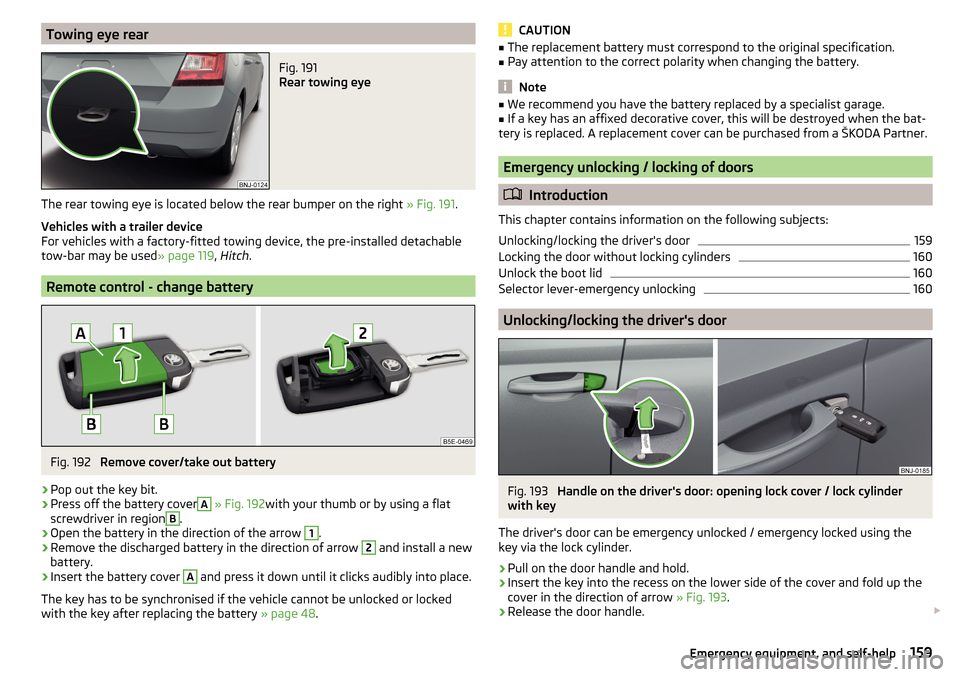

Remote control - change battery

Fig. 192

Remove cover/take out battery

›

Pop out the key bit.

›

Press off the battery cover

A

» Fig. 192 with your thumb or by using a flat

screwdriver in region

B

.

›

Open the battery in the direction of the arrow

1

.

›

Remove the discharged battery in the direction of arrow

2

and install a new

battery.

›

Insert the battery cover

A

and press it down until it clicks audibly into place.

The key has to be synchronised if the vehicle cannot be unlocked or locked

with the key after replacing the battery » page 48.

CAUTION■

The replacement battery must correspond to the original specification.■Pay attention to the correct polarity when changing the battery.

Note

■We recommend you have the battery replaced by a specialist garage.■If a key has an affixed decorative cover, this will be destroyed when the bat-

tery is replaced. A replacement cover can be purchased from a ŠKODA Partner.

Emergency unlocking / locking of doors

Introduction

This chapter contains information on the following subjects:

Unlocking/locking the driver's door

159

Locking the door without locking cylinders

160

Unlock the boot lid

160

Selector lever-emergency unlocking

160

Unlocking/locking the driver's door

Fig. 193

Handle on the driver's door: opening lock cover / lock cylinder

with key

The driver's door can be emergency unlocked / emergency locked using the key via the lock cylinder.

›

Pull on the door handle and hold.

›

Insert the key into the recess on the lower side of the cover and fold up the

cover in the direction of arrow » Fig. 193.

›

Release the door handle.

159Emergency equipment, and self-help