light switch SKODA OCTAVIA 2007 1.G / (1U) Owners Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 2007, Model line: OCTAVIA, Model: SKODA OCTAVIA 2007 1.G / (1U)Pages: 288, PDF Size: 15.19 MB

Page 217 of 288

Inspecting and Replenishing

216

Replenishing the coolant

– Switch the engine off.

– Allow the engine to cool down.

– Place a cloth over the cap of the coolant expansion reservoir

⇒page 215, fig. 199 and unscrew the cap carefully by turning it to the

left ⇒ .

– Top up the coolant.

– Screw the cap tight until it is heard to lock.

The coolant which you use for replenishing the system, must comply with one

specific specification ⇒page 214, “Coolant”. Do not use an alternative additive if

the coolant additive G12 PLUS is not availa ble in exceptional cases. Just top up the

system with water and as soon as possible arrange adjustment to correct the mixing

ratio of water and coolant additive again by a specialist garage.

Only use fresh coolant for topping up the system.

Do not fill up over the “MAX” marking! Exce ss coolant which is heated up is forced

out of the cooling system through the pressure relief valve in the cap of the coolant

compensation bottle.

Wait until the engine has cooled down for a system which has suffered a major loss

of coolant before pouring in coolant. Th is is necessary to avoid engine damage.

WARNING

•The cooling system is pressurized! Do not open the cap of the coolant

expansion bottle if the engine is still hot - risk of scalding!

•The coolant additive and thus all of the coolant is harmful to your health.

Avoid contact with the coolant. Coolant vapours are also harmful to the

health. It is important, therefore, to always safely store any coolant additive

in its original container out of the reach of children - risk of poisoning!

•If any splashes of coolant get into yo ur eyes, rinse out your eyes immedi-

ately with clear water and contact a doctor as soon as possible.

•You should also consult a doctor without delay if you have inadvertently

swallowed coolant.

Caution

Do not continue your journey if for some reason it is not possible under the

conditions prevailing to top up with coolant. Switch of the engine and contact

and obtain professional assistance from a specialist garage.

For the sake of the environment

Do not re-use coolant if it is necessary to drain the coolant in the system. It should

be collected and disposed of in comp liance with environmental protection

regulations.

Radiator fan

The radiator fan may switch on suddenly.

The radiator fan is driven by an electric motor and controlled according to the

coolant temperature.

The radiator fan may continue running for up to 10 mi nutes after the engine has

been switched off - even if the ignition is also off. It may also switch on suddenly

after a certain time, if

•the coolant temperature has risen because of an accumulation of heat or

•the warm engine compartment is heated up additionally by strong sunlight.

WARNING

You must therefore be aware when work ing in the engine compartment that

the fan may switch on suddenly - risk of injury!

WARNING (continued)

NKO A5 20 MR08.book Page 216 Wednesday, April 11, 2007 2:54 PM

Page 218 of 288

Inspecting and Replenishing217

Using the systemSafetyDriving TipsGeneral MaintenanceBreakdown assistanceTechnical Data

Brake fluid

Inspecting the brake fluid level

The brake fluid reservoir is located on the left of the engine compartment.

The brake fluid reservoir on right-hand steering models is positioned on

the other side of the engine compartment.

– Switch the engine off.

– Open the bonnet ⇒ in “Working in the engine compartment” on

page 210.

– Inspect the brake fluid level in the reservoir ⇒fig. 200 . The level must

be between the “MIN” and “MAX” markings.

A slight drop in the fluid level results when driving due to normal wear-and-tear

and automatic adjustment of the br ake pads, and is perfectly normal.

There may be an indication of a leak in the brake system, however, if the fluid level

drops significantly within a short time or if it drops below the “MIN” marking. A situ-

ation where the brake fluid level is too low is indicated by the warning light

lighting up in the instrument cluster ⇒page 32. In this case stop the car immedi-

ately and do not drive any further! Co ntact a Škoda Dealer to obtain profes-

sional assistance.

WARNING

•Read and observe the warning notes ⇒page 210, “Working in the engine

compartment” before working in the engine compartment.

•If the fluid level has dropped below the MIN marking, do not drive any

further - risk of accident! Contact a Škoda dealer to obtain professional

assistance.

Replacing brake fluid

Brake fluid absorbs moisture. This causes the fluid to absorb moisture from the

surrounding air over a period of time. Excessive water in the brake fluid may be the

cause of corrosion in the brake system. Th e water content also lowers the boiling

point of the brake fluid. This is why brake fluid must be replaced every two

years.

One may only use new genuine brake fluid from Škoda Auto a.s. The specification

for the brake fluid is “FMVSS 116 DOT 4”.

We recommend that you have the brake fluid replaced by a Škoda Service Partner

as part of an Inspection Service.

WARNING

•Using old brake fluid can result in seve re stress on the brakes because of

the formation of vapour bubbles in th e brake system. This greatly impairs

the braking efficiency and thus al so the safety of your vehicle.

•Brake fluid is toxic! It must therefor e be kept safely in closed original

containers and well away from children and unauthorized persons.

Caution

Brake fluid damages the paintwork of the vehicle.

Fig. 200 Engine

compartment: Brake

fluid reservoir

NKO A5 20 MR08.book Page 217 Wednesday, April 11, 2007 2:54 PM

Page 219 of 288

Inspecting and Replenishing

218

For the sake of the environment

In view of the problems involved with prop er disposal of brake fluid, the special

tools and the professional knowledge required, you should have the brake fluid

replaced by a Škoda Service Partner.

Battery

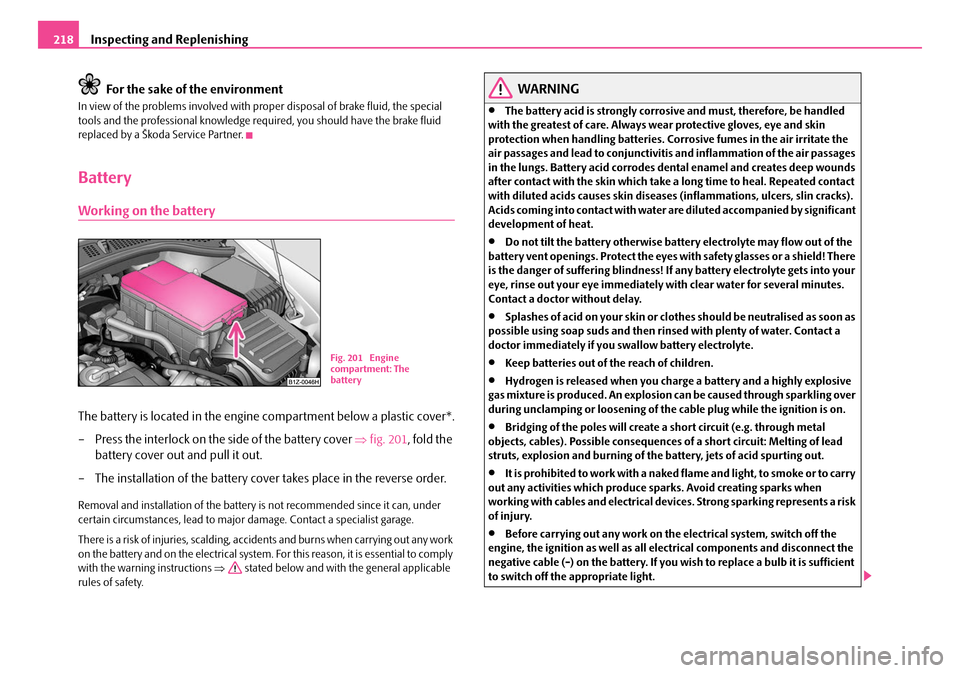

Working on the battery

The battery is located in the engine compartment below a plastic cover*.

– Press the interlock on the side of the battery cover ⇒fig. 201 , fold the

battery cover out and pull it out.

– The installation of the battery co ver takes place in the reverse order.

Removal and installation of the battery is not recommended since it can, under

certain circumstances, le ad to major damage. Contact a specialist garage.

There is a risk of injuries, scalding, acci dents and burns when carrying out any work

on the battery and on the electrical system. For this reason, it is essential to comply

with the warning instructions ⇒ stated below and with the general applicable

rules of safety.

WARNING

•The battery acid is strongly corros ive and must, therefore, be handled

with the greatest of care. Always we ar protective gloves, eye and skin

protection when handling batteries. Corrosive fumes in the air irritate the

air passages and lead to conjunctivitis and inflammation of the air passages

in the lungs. Battery acid corrodes de ntal enamel and creates deep wounds

after contact with the skin which take a long time to heal. Repeated contact

with diluted acids causes skin diseases (inflammations, ulcers, slin cracks).

Acids coming into contact with water are diluted accompanied by significant

development of heat.

•Do not tilt the battery otherwise battery electrolyte may flow out of the

battery vent openings. Protect the eyes with safety glasses or a shield! There

is the danger of suffering blindness! If any battery electrolyte gets into your

eye, rinse out your eye immediately with clear water for several minutes.

Contact a doctor without delay.

•Splashes of acid on your skin or clothes should be neutralised as soon as

possible using soap suds and then rinsed with plenty of water. Contact a

doctor immediately if you swallow battery electrolyte.

•Keep batteries out of the reach of children.

•Hydrogen is released when you char ge a battery and a highly explosive

gas mixture is produced. An explosion can be caused through sparkling over

during unclamping or loosening of the cable plug while the ignition is on.

•Bridging of the poles will create a short circuit (e.g. through metal

objects, cables). Possible consequences of a short circuit: Melting of lead

struts, explosion and burning of the battery, jets of acid spurting out.

•It is prohibited to work with a naked flame and light, to smoke or to carry

out any activities which produce sparks. Avoid creating sparks when

working with cables and electrical device s. Strong sparking represents a risk

of injury.

•Before carrying out any work on the electrical system, switch off the

engine, the ignition as well as all electrical components and disconnect the

negative cable (-) on the battery. If you wish to replace a bulb it is sufficient

to switch off the appropriate light.

Fig. 201 Engine

compartment: The

battery

NKO A5 20 MR08.book Page 218 Wednesday, April 11, 2007 2:54 PM

Page 220 of 288

Inspecting and Replenishing219

Using the systemSafetyDriving TipsGeneral MaintenanceBreakdown assistanceTechnical Data

•Never charge a frozen or thawed battery - risk of explosion and caustic

burns! Replace a frozen battery.

•Never use a battery which is damaged - risk of explosion! Immediately

replace a damaged battery.

Caution

•You must only disconnect the battery if the ignition is switched off, otherwise

the electrical system (electronic compon ents) of the vehicle may be damaged.

When disconnecting the battery from the electrical system of the vehicle, first

disconnect the negative terminal (-) of the battery. Then disconnect the positive

terminal (+).

•When reconnecting the battery, first conne ct the positive terminal (+) and only

then the negative terminal (-) of the ba ttery. You must on no account connect the

cables wrongly - risk of a cable fire.

•Ensure that battery acid does not come into contact with the vehicle body

otherwise damage could occur to the paintwork.

•Do not place the battery in direct dayl ight in order to protect the battery

housing from the effects of ultra-violet light.

For the sake of the environment

A removed battery is a special type of waste which is harmful to the environment -

contact your specialist garage regarding disposing of the battery.

Note

Please also refer to the guidelines ⇒page 221, “Disconnecting and reconnecting

the battery”, also after connecting the battery.

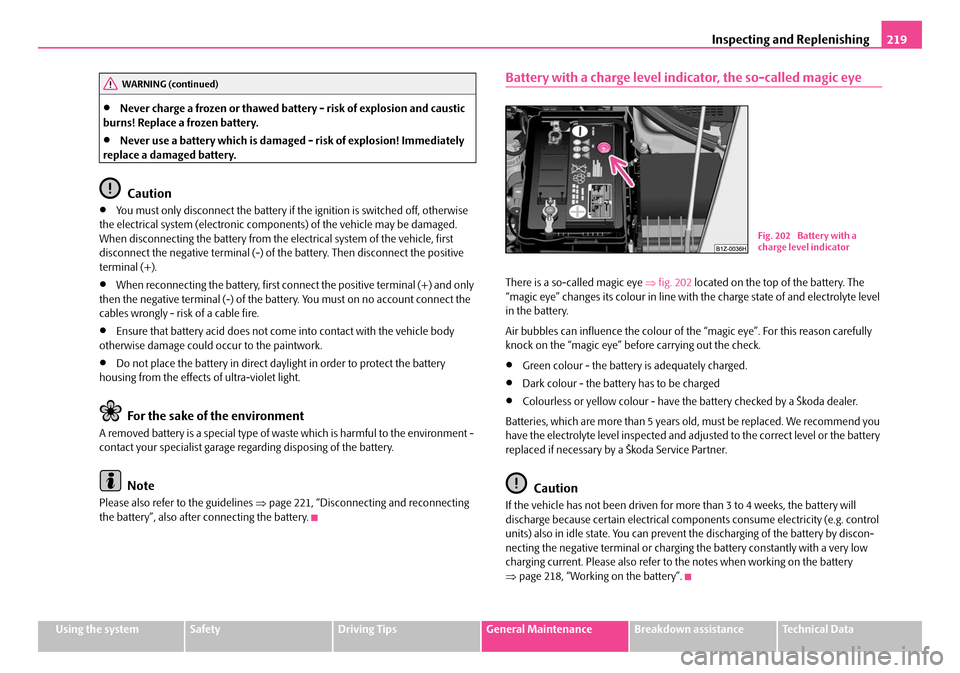

Battery with a charge level indicator, the so-called magic eye

There is a so-called magic eye ⇒fig. 202 located on the top of the battery. The

“magic eye” changes its colour in line with the charge state of and electrolyte level

in the battery.

Air bubbles can influence the colour of th e “magic eye”. For this reason carefully

knock on the “magic eye” before carrying out the check.

•Green colour - the battery is adequately charged.

•Dark colour - the battery has to be charged

•Colourless or yellow colour - have th e battery checked by a Škoda dealer.

Batteries, which are more than 5 years old, must be replaced. We recommend you

have the electrolyte level inspected and adju sted to the correct level or the battery

replaced if necessary by a Škoda Service Partner.

Caution

If the vehicle has not been driven for more than 3 to 4 weeks, the battery will

discharge because certain electrical components consume electricity (e.g. control

units) also in idle state. You can prevent the discharging of the battery by discon-

necting the negative terminal or charging the battery constantly with a very low

charging current. Please also refer to the notes when working on the battery

⇒ page 218, “Working on the battery”.

WARNING (continued)

Fig. 202 Battery with a

charge level indicator

NKO A5 20 MR08.book Page 219 Wednesday, April 11, 2007 2:54 PM

Page 235 of 288

Breakdown assistance

234

WARNING

•If you find yourself in flowing traffic switch on the hazard warning lights

system and place the warning triangle on the side of the road at the

prescribed distance from your vehicl e while observing all national legal

provisions. In this way you are protecting not only yourself but also other

road users.

•Never start the engine with the vehicle sitting on the raised jack - danger

of suffering injury!

Caution

If you have to change a wheel on a slope first block the opposite wheel with a stone

or similar object in order to secure th e vehicle from unexpectedly rolling away.

Note

Comply with the national legal regulations.

Changing a wheel

Always change a wheel on a level surface as far as possible.

– Take off the full wheel trim* ⇒page 235 or the caps ⇒page 235.

– In the case of light alloy wheels remove the wheel trim cap ⇒page 236.

– Slacken the wheel bolts ⇒page 236.

– Jack up the vehicle until the wheel to be changed is clear of the ground

⇒ page 237.

– Unscrew the wheel bolts and place them on a clean surface (cloth, paper etc.).

– Take off the wheel. – Fit on the spare wheel and tighten the wheel bolts slightly.

– Lower the car.

– Tighten the wheel bolts firmly, al

ternately and diagonally using the

wheel wrench ⇒page 236.

– Mount the full wheel trim/w heel trim cap or the caps.

Note

•All bolts must be clean and must turn easily.

•You must never grease or oil the wheel bolts!

•When fitting on unidirectional tyres, ensure that the tyres rotate in the correct

direction ⇒page 223.

Subsequent steps

After changing the wheel, you must perform the following steps.

– Stow and attach the replaced wheel in the spare wheel well.

– Stow the vehicle tool kit in the space provided.

– Check the tyre pressure on the spare wheel just mounted as soon as

possible.

– Have the tightening torque of the wheel bolts checked with a torque

wrench as soon as possible. Steel and light alloy wheels must be tight-

ened to a tightening torque of 120 Nm.

– Have the defective tyre repaired as soon as possible.

WARNING

It is necessary to observe the guidelines given on ⇒page 225, “New tyres

and wheels” if the vehicle is subseq uently fitted with tyres which are

different to those it was fitted with at the works.

NKO A5 20 MR08.book Page 234 Wednesday, April 11, 2007 2:54 PM

Page 239 of 288

Breakdown assistance

238

– Reinstall the full wheel trim/wheel cap after removing the adapter or place the cap onto the safety wheel bolt.

– Have the tightening torque checked w i t h a t o rq u e w re n c h a s s o o n a s

possible. Steel and light alloy wheels must be tightened to a tightening

torque of 120 Nm.

The safety wheel bolts on vehicles fitted with them (one safety wheel bolt per

wheel) can only be loosened or tigh ten up by using the adapter provided.

It is meaningful to note the code numbe r hammered into the rear side of the

adapter or the rear side of the safety wheel bolts. You can obtain a replacement

adapter from a Škoda Service Partner, if necessary, by quoting this number.

We recommend that you always carry the adapter for the wheel bolts with you in

the vehicle. It should be st owed in the vehicle tool kit.

Caution

Damage can occur to the adapter and safety wheel bolt if the safety wheel bolt is

tightened up too much.

Note

The set of safety wheel bolts can be obtained from a Škoda Service Partner.

Jump-starting

Initial steps

You can use the battery of another vehicl e for jump-starting yours if the engine

does not start because the battery on your vehicle is flat. You will require jump-start

cables for this purpose.

Both batteries must have a rated voltage of 12 V. The capacity (Ah) of the battery

supplying the power must not be significa ntly less than the capacity of the

discharged battery in your vehicle. Jump-start cables

Only use jump-start cables which have an

adequately large cross-section and insu-

lated terminal clamps. Please pay attent ion to the manufacturer's instructions.

Positive cable - colour coding in the majority of cases red.

Negative cable - colour coding in the majority of cases black.

WARNING

•A discharged battery may already freeze at temperatures just below 0°C.

In case of frozen battery carry out no jump-starting - risk of explosion!

•Please pay attention to the warning instructions relating to working in

the engine compartment ⇒page 210.

Note

•There must not be any contact between the two vehicles otherwise current may

flow as soon as the negative terminals are connected.

•The discharged battery must be properly connected to the system of the

vehicle.

•Switch off any mobile phone, pay attent ion to the instructions for use of the

mobile phone in such a situation.

•We recommend purchasing jump-start cabl es from Škoda Service Partners as a

Škoda original accessory or from retailers who sell branded batteries.

NKO A5 20 MR08.book Page 238 Wednesday, April 11, 2007 2:54 PM

Page 241 of 288

Breakdown assistance

240

– Release the clutch particularly gent ly when starting off or depress the

accelerator particularly gently if yo ur vehicle is fitted with an auto-

matic gearbox.

Driver of the towed vehicle

– Switch the ignition on so that the steering wheel is not blocked and you can also operate the turn signal lights, the headlight flasher, the

windscreen wipers and wi ndscreen washer system.

– Take the vehicle out of gear or move the selector lever into position N

if your vehicle is fitted with an automatic gearbox.

– Note that the brake servo unit and power steering only operate if the engine is running. You will require si gnificantly greater physical force

to depress the brake pedal and to steer the vehicle if the engine is not

running.

– Ensure that the tow rope is always kept taught.

Tow rope or tow bar

A tow bar is safest way of towing a vehicle and also minimizes any shocks. You can

use a tow rope only if a suitable tow bar is not available.

The tow rope must be elastic to protect the vehicle. Thus one should only use

plastic fibre rope or a rope made out of a similarly elastic material.

Only attach the tow rope to the towing eyes provided for this purpose ⇒page 241,

“Front towing eye” and ⇒page 241, “Rear towing eye”.

Driving style

Towing another vehicle requires a certain amount of practice. Both drivers should

be familiar with the particular points about towing a vehicle. Unskilled drivers

should not attempt to tow in another vehicle or to be towed in.

One should be constantly vigilant not to allow impermissibly high towing forces or

jerky loadings. There is always a risk of excessive stresses and damage resulting at

the points to which you attach the tow ro pe or tow bar when you attempt to tow a

vehicle which is not standing on a paved road.

Caution

If the gearbox of your vehicle no longer contains any oil because of a defect, your

vehicle must only be towed in with the driven wheels raised clear of the ground, or

on a special vehicle transporter or trailer.

Note

•Please comply with any legal requirements particularly regarding the switched

on signal systems, when towing in or tow-starting another vehicle.

•The tow rope must not be twisted as it may in certain circumstances result in the

front towing eye being unscrewed out of your vehicle.

NKO A5 20 MR08.book Page 240 Wednesday, April 11, 2007 2:54 PM

Page 244 of 288

Fuses and light bulbs243

Using the systemSafetyDriving TipsGeneral MaintenanceBreakdown assistanceTechnical Data

Fuses and light bulbs

Electric fuses

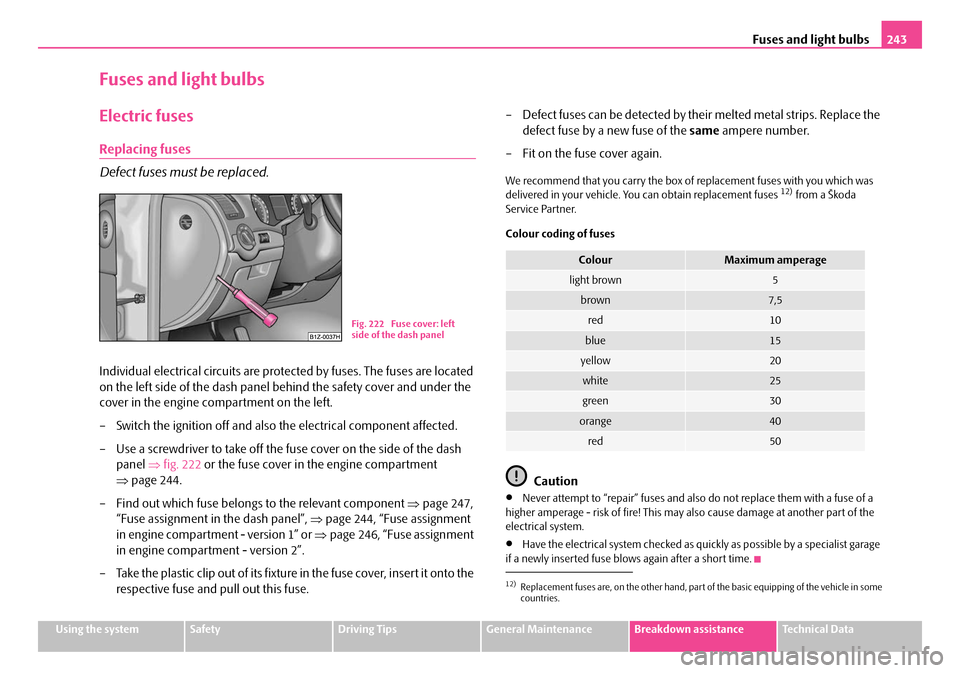

Replacing fuses

Defect fuses must be replaced.

Individual electrical circuits are protected by fuses. The fuses are located

on the left side of the dash panel behind the safety cover and under the

cover in the engine compartment on the left.

– Switch the ignition off and also the electrical component affected.

– Use a screwdriver to take off the fuse cover on the side of the dash panel ⇒fig. 222 or the fuse cover in the engine compartment

⇒ page 244.

– Find out which fuse belongs to the relevant component ⇒page 247,

“Fuse assignment in the dash panel”, ⇒page 244, “Fuse assignment

in engine compartment - version 1” or ⇒page 246, “Fuse assignment

in engine compartment - version 2”.

– Take the plastic clip out of its fixture in the fuse cover, insert it onto the respective fuse and pull out this fuse. – Defect fuses can be detected by their melted metal strips. Replace the

defect fuse by a new fuse of the same ampere number.

– Fit on the fuse cover again.

We recommend that you carry the box of replacement fuses with you which was

delivered in your vehicle. You can obtain replacement fuses 12) from a Škoda

Service Partner.

Colour coding of fuses

Caution

•Never attempt to “repair” fuses and also do not replace them with a fuse of a

higher amperage - risk of fire! This may also cause damage at another part of the

electrical system.

•Have the electrical system checked as quickly as possible by a specialist garage

if a newly inserted fuse blows again after a short time.

Fig. 222 Fuse cover: left

side of the dash panel

12)Replacement fuses are, on the other hand, part of the basic equipping of the vehicle in some

countries.

ColourMaximum amperage

light brown5

brown7,5

red10

blue15

yellow20

white25

green30

orange40

red50

NKO A5 20 MR08.book Page 243 Wednesday, April 11, 2007 2:54 PM

Page 246 of 288

Fuses and light bulbs245

Using the systemSafetyDriving TipsGeneral MaintenanceBreakdown assistanceTechnical Data

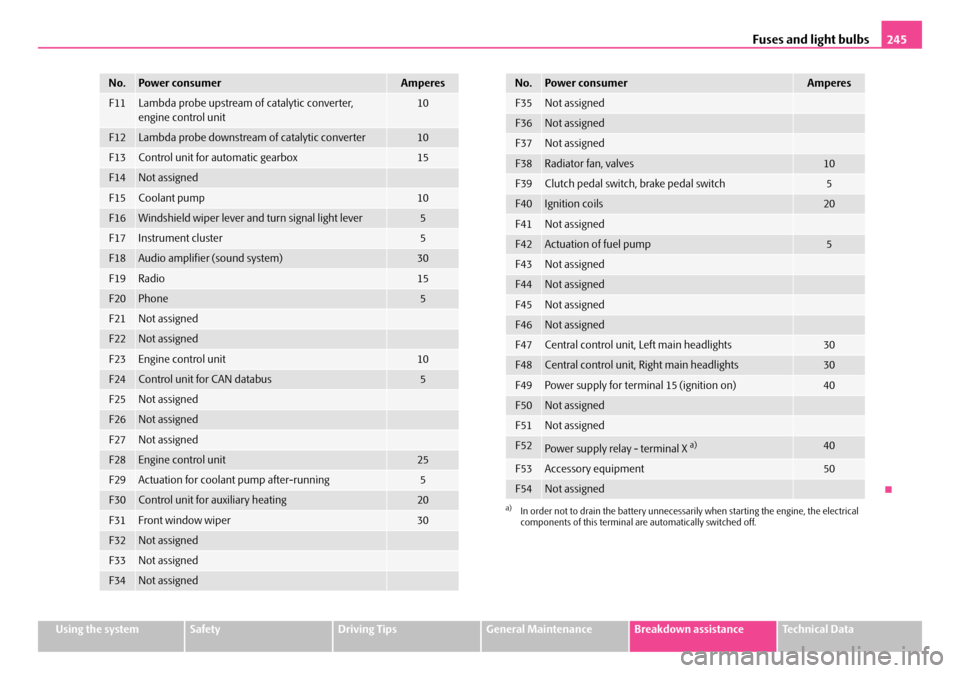

F11Lambda probe upstream of catalytic converter,

engine control unit10

F12Lambda probe downstream of catalytic converter10

F13Control unit for automatic gearbox15

F14Not assigned

F15Coolant pump10

F16Windshield wiper lever and turn signal light lever5

F17Instrument cluster5

F18Audio amplifier (sound system)30

F19Radio15

F20Phone5

F21Not assigned

F22Not assigned

F23Engine control unit10

F24Control unit for CAN databus5

F25Not assigned

F26Not assigned

F27Not assigned

F28Engine control unit25

F29Actuation for coolant pump after-running5

F30Control unit for auxiliary heating20

F31Front window wiper30

F32Not assigned

F33Not assigned

F34Not assigned

No.Power consumerAmperes

F35Not assigned

F36Not assigned

F37Not assigned

F38Radiator fan, valves10

F39Clutch pedal switch, brake pedal switch5

F40Ignition coils20

F41Not assigned

F42Actuation of fuel pump5

F43Not assigned

F44Not assigned

F45Not assigned

F46Not assigned

F47Central control unit, Left main headlights30

F48Central control unit, Right main headlights30

F49Power supply for terminal 15 (ignition on)40

F50Not assigned

F51Not assigned

F52Power supply relay - terminal X a)40

F53Accessory equipment50

F54Not assigned

a)In order not to drain the battery unnecessarily when starting the engine, the electrical

components of this terminal are automatically switched off.

No.Power consumerAmperes

NKO A5 20 MR08.book Page 245 Wednesday, April 11, 2007 2:54 PM

Page 247 of 288

Fuses and light bulbs

246

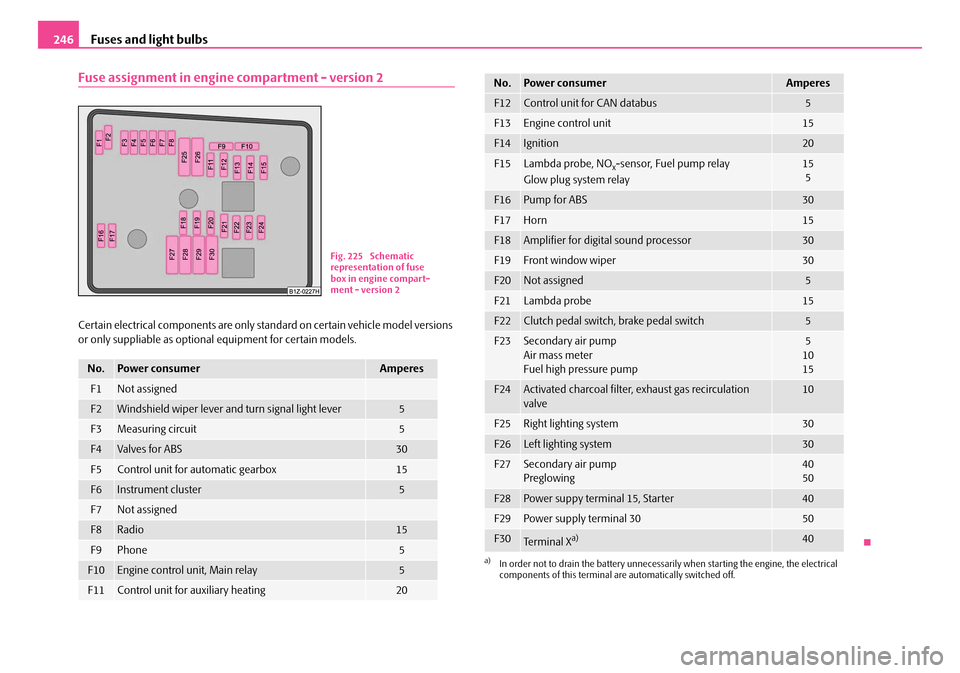

Fuse assignment in engine compartment - version 2

Certain electrical components are only st andard on certain vehicle model versions

or only suppliable as optional equipment for certain models.

No.Power consumerAmperes

F1Not assigned

F2Windshield wiper lever and turn signal light lever5

F3Measuring circuit5

F4Valves for ABS30

F5Control unit for automatic gearbox15

F6Instrument cluster5

F7Not assigned

F8Radio15

F9Phone5

F10Engine control unit, Main relay5

F11Control unit for auxiliary heating20

Fig. 225 Schematic

representation of fuse

box in engine compart-

ment - version 2

F12Control unit for CAN databus5

F13Engine control unit15

F14Ignition20

F15Lambda probe, NOx-sensor, Fuel pump relay

Glow plug system relay15 5

F16Pump for ABS30

F17Horn15

F18Amplifier for digital sound processor30

F19Front window wiper30

F20Not assigned5

F21Lambda probe15

F22Clutch pedal switch, brake pedal switch5

F23Secondary air pump

Air mass meter

Fuel high pressure pump5

10

15

F24Activated charcoal filter, exhaust gas recirculation

valve10

F25Right lighting system30

F26Left lighting system30

F27Secondary air pump

Preglowing40

50

F28Power suppy terminal 15, Starter40

F29Power supply terminal 3050

F30Te r m i n a l Xa)40

a)In order not to drain the battery unnecessarily when starting the engine, the electrical

components of this terminal are automatically switched off.

No.Power consumerAmperes

NKO A5 20 MR08.book Page 246 Wednesday, April 11, 2007 2:54 PM