engine SKODA OCTAVIA TOUR 2010 1.G / (1U) Columbus Navigation System Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 2010, Model line: OCTAVIA TOUR, Model: SKODA OCTAVIA TOUR 2010 1.G / (1U)Pages: 207, PDF Size: 12.63 MB

Page 153 of 207

Inspecting and replenishing

152For the sake of the environment

You must on no account pour oil into the ground or into the sewage system.

In view of the problems involved in prop erly disposing of old oil, the material,

equipment and the knowledge required for such work, we recommend that you have

the oil and oil filter change carried out by a specialist garage.Note

After your skin has come in contact with th e oil, you must thoroughly wash your skin.Power steeringThe reservoir for hydraulic oil of power steering is located in the front right of the

engine compartment page 149, fig. 145 .

Check hydraulic oil

The hydraulic system of the power steering is filled with the hydraulic oil designated in

the catalogue as G 002 000.

Perform the inspection of the hydraulic oil level when the engine is cold and not

running.

The hydraulic oil level must be be tween the “MIN” and “MAX” markings fig. 147 . If

the level drops below the marking “MIN”, it is necessary that the power steering is

checked by a specialist garage. It is not su fficient to solely refill with hydraulic oil.

Note

If the engine is not running (when towing) or if the V-ribbed belt is torn, the power

steering does not operate. The vehicle is fully steerable however. There is however

increased force required to turn the steering wheel.Cooling systemCoolant

The job of the coolant is to cool the engine.The cooling system does not require any maintenance under normal operating condi-

tions. The coolant consists of water with a concentration of coolant additive of 40 %.

This mixture not only provides antifreeze prot ection down to -25°C but also protects

the cooling and heating system from corrosion. It also prevents the formation of scale

and significantly increases the boiling point of the coolant.

You must therefore not reduce the concentration of antifreeze agent in the coolant by

adding water, also not during the summer mont hs or in countries with a warm climate.

The concentration of coolant additive in the coolant must be at least 40%.

You can increase the amount of antifreeze in the coolant if a higher concentration of

antifreeze is necessary for climatic reasons but only up to 60% (antifreeze protection

down to approx. -40°C). The antifreeze protection tails off above that concentration.

Vehicles exported to countries with a cold climate (e.g. Sweden, Norway, Finland) are

already factory-filled with a coolant which of fers antifreeze protection down to about

-35°C. In these countries the concentration of coolant additive should be at least 50%.

Coolant

The cooling system is factory- filled with coolant (purple in colour), which complies

with the specification TL-VW 774 G.

We recommend that you use the same coolan t additive - G13 (purple in colour) - for

topping up the system.

Please contact a specialist garage if you have any questions regarding the coolant or if

you wish to fill up with a different coolant.

A specialist garage can also supply yo u with the correct coolant additives.

Fig. 147 Hydraulic oil dipstick

s2rc.book Page 152 Thursday, April 22, 2010 10:58 AM

Page 154 of 207

Inspecting and replenishing153

Using the system

Safety

Driving Tips

General Maintenance

Breakdown assistance

Technical Data

Caution

Other coolant additives may cause operational problems which, in partic-

ular, involves significantly reducing the anticorrosion effect.

Any faults or problems resulting from corrosion may cause a loss of coolant

and, as a consequence of this, result in major engine damage.

Inspecting the coolant levelThe coolant expansion bottle is located in the engine compartment on the right.

– Switch the engine off.

– Open the bonnet in “Working in the engine compartment” on page 148.

– Check the level of coolant in the coolant expansion bottle fig. 148 . When the

engine is cold, the coolant level must lie between the and markings. When

the engine is warm, the level may also lie slightly above the hatched part.

If the coolant level in the reservoir is too lo w, this is indicated by the warning light in

the instrument cluster

page 28. We nevertheless recommend inspecting the

coolant level directly at the reservoir from time to time.

Loss of coolant

A loss of coolant is first and foremost an indication of a leak in the system. You should

not merely top up the coolant in the reservoir. It is also important to have the cooling

system inspected without delay by a specialist garage. Losses can only occur through the pressure

relief in the cap of the coolant expansion

bottle which is completely free of leaks if the coolant boils as a result of overheating

and is forced out of the cooling system.

WARNING

Read and observe the warning notes page 148, “Working in the engine

compartment” before working in the engine compartment.

Caution

One should contact a specialist garage as s oon as possible if the source of overheating

itself cannot be determined and removed, since there may be grave damage to the

engine.Replenishing the coolant– Switch the engine off.

– Allow the engine to cool down.

– Place a cloth over the cap of the coolant expansion reservoir fig. 148 and

unscrew the cap carefully by turning it to the left .

–Top up the coolant.

– Screw the cap tight until it is heard to lock.

The coolant which you use for replenishing th e system, must comply with one specific

specification page 152, “Coolant”. Do not use an al ternative additive if the coolant

additive G13 is not available in exceptional cases. Just top up the system with water

and as soon as possible arrange adjustment to correct the mixing ratio of water and

coolant additive again by a specialist garage.

Only use fresh coolant for topping up the system.

Do not top up the fluid above the hatched pa rt! Excess coolant which is heated up is

forced out of the cooling system through th e pressure relief valve in the cap of the

coolant compensation bottle.

Wait until the engine has cooled down for a system which has suffered a major loss of

coolant before pouring in coolant. This is necessary to avoid engine damage.

Fig. 148 Engine compartment:

Coolant expansion bottleAa

Ab

s2rc.book Page 153 Thursday, April 22, 2010 10:58 AM

Page 155 of 207

Inspecting and replenishing

154WARNING

The cooling system is pressurized! Do not open the cap of the coolant

expansion bottle if the engine is still hot - risk of scalding!

The coolant additive and thus all of the coolant is harmful to your health.

Avoid contact with the coolant. Coolant vapours are also harmful to the health.

It is important, therefore, to always safely store any coolant additive in its orig-

inal container out of the reach of children - risk of poisoning!

If any splashes of coolant get into yo ur eyes, rinse out your eyes immedi-

ately with clear water and contact a doctor as soon as possible.

You should also consult a doctor without delay if you have inadvertently

swallowed coolant.Caution

Do not continue your journey if for some reason it is not possible under the

conditions prevailing to top up with coolant. Switch the engine off and obtain

professional assistance from a specialist garage, otherwise it could lead to severe

engine damage.

For the sake of the environment

Do not re-use coolant if it is necessary to drain the coolant in the system. It should be

collected and disposed of in compliance with environmental protection regulations.Radiator fan

The radiator fan may switch on suddenly.The radiator fan is driven by an electric motor and controlled according to the coolant

temperature.

The radiator fan may continue running for up to 10 minutes after the engine has been

switched off - even if the ignition is also off. It may also switch on suddenly after a

certain time, if

the coolant temperature has risen beca use of an accumulation of heat or

the warm engine compartment is heated up additionally by strong sunlight.

WARNING

You must therefore be aware when working in the engine compartment that

the fan may switch on suddenly - risk of injury!Brake fluidInspecting the brake fluid levelThe brake fluid reservoir is located on the left of the engine compartment. The brake

fluid reservoir on right-hand steering models is positioned on the other side of the

engine compartment.

– Switch the engine off.

– Open the bonnet in “Working in the engine compartment” on page 148.

– Inspect the brake fluid level in the reservoir fig. 149 . The level must be between

the “MIN” and “MAX” markings.

A slight drop in the fluid level results when driving due to normal wear-and-tear and

automatic adjustment of the brak e pads, and is perfectly normal.

There may be an indication of a leak in th e brake system, however, if the fluid level

drops significantly within a short time or if it drops below the “MIN” marking. If the

brake fluid level is too low, this is indicated by the warning light

lighting up in the

Fig. 149 Engine compartment:

Brake fluid reservoir

s2rc.book Page 154 Thursday, April 22, 2010 10:58 AM

Page 156 of 207

Inspecting and replenishing155

Using the system

Safety

Driving Tips

General Maintenance

Breakdown assistance

Technical Data

instrument cluster

page 31. In this case stop immediately and do not drive any

further! Obtain professional assistance.

WARNING

Read and observe the warning notes page 148, “Working in the engine

compartment” before working in the engine compartment.

If the fluid level has dropped below the “MIN” marking, do not drive any

further - risk of accident! Obtain professional assistance.

Replacing brake fluidBrake fluid absorbs moisture. This causes the fluid to absorb moisture from the

surrounding air over a period of time. Excessive water in the brake fluid may be the

cause of corrosion in the brake system. The water content also lowers the boiling point

of the brake fluid.

One may only use new genuine brake fluid from Škoda Auto. The brake fluid must

comply with one of the following standards or specifications:

VW 50114

FMVSS 116 DOT4

DIN ISO 4925 CLASS 4

We recommend that you have the brake fluid replaced by an authorised Škoda

Service Partner as part of an Inspection Service.

WARNING

Using old brake fluid can result in severe stress on the brakes because of the

formation of vapour bubbles in the br ake system. This greatly impairs the

braking efficiency and thus also the safety of your vehicle.

Caution

Brake fluid damages the paintwork of the vehicle.

For the sake of the environment

In view of the problems involved with proper disposal of brake fluid, the special tools

and the professional knowledge required, you should have the brake fluid replaced by

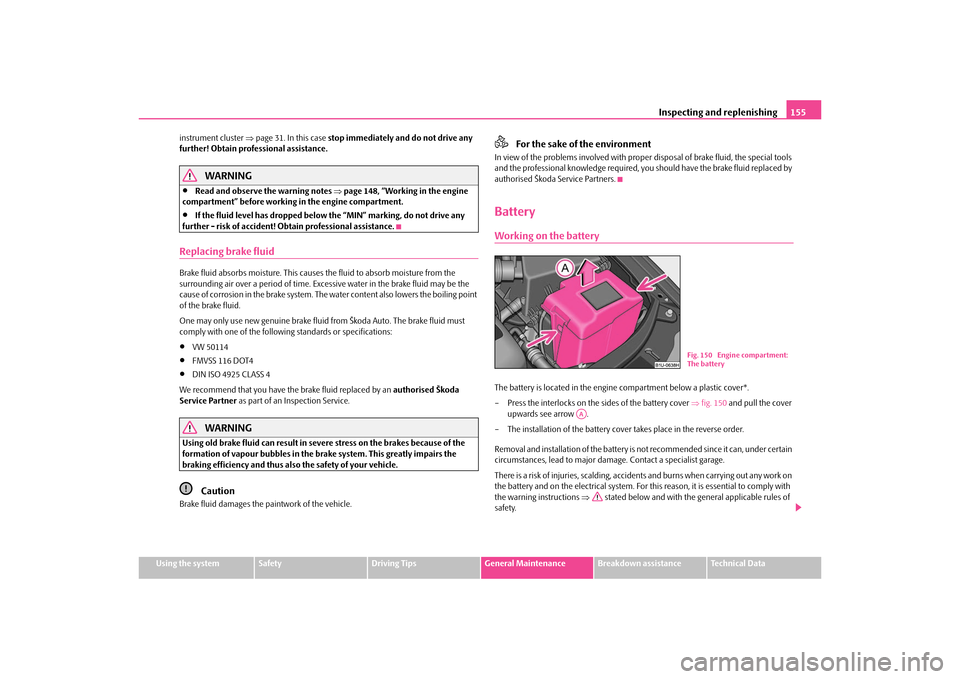

authorised Škoda Service Partners.BatteryWorking on the batteryThe battery is located in the engine compartment below a plastic cover*.

– Press the interlocks on the sides of the battery cover fig. 150 and pull the cover

upwards see arrow .

– The installation of the battery co ver takes place in the reverse order.

Removal and installation of the battery is not recommended since it can, under certain

circumstances, lead to major dama ge. Contact a specialist garage.

There is a risk of injuries, scalding, accidents and burns when carrying out any work on

the battery and on the electrical system. For th is reason, it is essential to comply with

the warning instructions stated below and with the general applicable rules of

safety.

Fig. 150 Engine compartment:

The battery

AA

s2rc.book Page 155 Thursday, April 22, 2010 10:58 AM

Page 157 of 207

Inspecting and replenishing

156WARNING

The battery acid is strongly corrosive and must, therefore, be handled with

the greatest of care. Always wear prot ective gloves, eye and skin protection

when handling batteries. Corrosive fumes in the air irritate the air passages and

lead to conjunctivitis and inflammation of the air passages in the lungs. Battery

acid corrodes dental enam el and creates deep wounds after contact with the

skin which take a long time to heal. Repeated contact with diluted acids causes

skin diseases (inflammations, ulcers, slin cracks). Acids coming into contact

with water are diluted accompanied by significant development of heat.

Do not tilt the battery otherwise battery electrolyte may flow out of the

battery vent openings. Protect the eyes with safety glas ses or a shield! There is

the danger of suffering blindness! If an y battery electrolyte gets into your eye,

rinse out your eye immediately with cl ear water for several minutes. Contact a

doctor without delay.

Splashes of acid on your skin or clothes should be neutralised as soon as

possible using soap suds and then rinsed with plenty of water. Contact a doctor

immediately if you swal low battery electrolyte.

Keep batteries out of the reach of children.

Hydrogen is released when you charge a battery and a highly explosive gas

mixture is produced. An explosion can be caused through sparkling over during

unclamping or loosening of the cable plug while the ignition is on.

Bridging of the poles will create a short circuit (e.g. through metal objects,

cables). Possible consequences of a short circuit: Melting of lead struts, explo-

sion and burning of the battery, jets of acid spurting out.

It is prohibited to work with a naked flame and light, to smoke or to carry out

any activities which produce sparks. Avoid creating sparks when working with

cables and electrical devices. Strong sparking represents a risk of injury.

Before carrying out any work on the el ectrical system, switch off the engine,

the ignition as well as all electrical components and disconnect the negative

cable (-) on the battery. If you wish to replace a bulb it is sufficient to switch off

the appropriate light.

Never charge a frozen or thawed batt ery - risk of explosion and caustic

burns! Replace a frozen battery.

Never use a battery which is damaged - risk of explosion! Immediately

replace a damaged battery.Caution

You must only disconnect the battery if th e ignition is switched off, otherwise the

electrical system (electronic components ) of the vehicle may be damaged. When

disconnecting the battery from the electrical system of the vehicle, first disconnect the

negative terminal (-) of the battery. Then disconnect the positive terminal (+).

When reconnecting the battery, first connect the positive terminal (+) and only

then the negative terminal (-) of the ba ttery. You must on no account connect the

cables wrongly - risk of a cable fire.

Ensure that battery acid does not come into contact with the vehicle body other-

wise damage could occur to the paintwork.

Do not place the battery in direct daylight in order to protect the battery housing

from the effects of ultra-violet light.For the sake of the environment

A removed battery is a special type of wa ste which is harmful to the environment -

contact your specialist garage regarding disposing of the battery.

Note

Please also refer to the guidelines page 158, “Disconnecting and reconnecting the

battery”, also after connecting the battery.

WARNING (continued)

s2rc.book Page 156 Thursday, April 22, 2010 10:58 AM

Page 159 of 207

Inspecting and replenishing

158

Charging the battery

A properly charged battery is essentia l for reliably starting the engine.– Read the warning notes in “Working on the battery” on page 155 and .

– Switch the ignition and all electrical components off.

– Only for “quick-charging”: Disconnect both battery cables (first of all “negative”,

then “positive”).

– Carefully attach the terminal clamps of the charger to the battery terminals (red =

“positive”, black = “negative”).

– You can now plug the mains cable of the charger into the power socket and switch on the charger.

– When charging is completed: switch the charger off and unplug the mains cable from the power socket.

– Only then should you disconnect the terminal clamps of the charger.

– Reconnect the cables to the battery (first of all “positive”, then “negative”).

It is not normally necessary to disconnect th e cables of the battery if you recharge the

battery using low amperages (as for example from a mini-charger). Please also refer

to the instructions from the charger manufacturer.

A charging current of 0.1 of the total battery capacity (or lower) is that which should be

used until full charging is achieved.

It is, however, necessary to disconnect both cables before charging the battery with

high amperages, so-called “ quick-charging”.

“Quick-charging” a battery is dangerous in “Working on the battery” on

page 155. It requires a special charger and appropriate knowledge. We therefore

recommend that you have your battery quick- charged only by your specialist garage.

A discharged battery may already freeze at temperatures just below 0°C . We

recommend that you no longer use a batter y which has thawed out because the casing

of the battery may be cracked through th e formation of ice and this would allow

battery electrolyte to flow out.

The vent plugs of the battery should not be opened for charging.

WARNING

Never charge a frozen or thawed battery - risk of explosion and caustic burns.

Replace a frozen battery.Disconnecting and reconnecting the batteryOn disconnecting and reconnecting the battery the following functions are initially

deactivated or are no longer able to operate fault-free.

We recommend having the vehicl e checked by a specialist garage to ensure full func-

tionality of all electrical systems.Replacing the batteryYou should only replace a battery with a new battery of the same capacity, voltage (12

V), amperage and of the same size. Specialist garages have a range of suitable batteries

available.

In view of the problems involved with its proper disposal, we recommend having the

battery replaced by a specialist garage.

For the sake of the environment

Batteries contain poisonous subs tances such as sulphuric acid and lead. They must be

disposed of in accordance with local envi ronmental protection regulations and on no

account as domestic waste.Operation

Operating measure

Electrical power window (operational faults)

page 43

Enter radio code number

see Radio Operating Instructions

Set hours

page 19

Data in the multi-functional indicator* are

deleted.

page 19

s2rc.book Page 158 Thursday, April 22, 2010 10:58 AM

Page 160 of 207

Inspecting and replenishing159

Using the system

Safety

Driving Tips

General Maintenance

Breakdown assistance

Technical Data

Windshield washer systemThe windshield washer reservoir contains the cleaning fluid for the windscreen or rear

window. The reservoir is located at the front right of the engine compartment

fig. 152 .

The filling level of the container is about 3 litres and about 5,5 litres on vehicles which

have a headlight washing system.

Clear water is not sufficient to intensively clean the windscreen and headlights. We

therefore recommend using clean washing water together with the screen cleaner

from Škoda genuine accessorie s (in winter additionally with antifreeze) which is

capable of removing stubborn dirt. Follow the instructions for use on the packaging

when using screen cleaning products.

You should always add antifreeze to the clea ning water in winter even if your vehicle

is fitted with heated windscreen washer nozzles*.

It is also possible in exceptional cases to use methylated spirits when no screen cleaner

with antifreeze is available. The concentratio n of methylated spirits must not be more

than 15 %. Please note, however, that the antifreeze protection at this concentration is

only adequate down to -5°C.

WARNING

Read and observe the warning notes page 148, “Working in the engine

compartment” before working in the engine compartment.

Caution

On no account should you add radiator an tifreeze or other additives to the wind-

screen washer fluid.

If the vehicle is fitted with a headlight cleaning system, you should only add

cleaning products which do not attack the polycarbonate coating of the headlights to

the windscreen washer fluid. Please contac t your specialist garage, who will tell you

which cleaning agent you can use.

Fig. 152 Engine compartment:

Windshield washer fluid reser-

voir

s2rc.book Page 159 Thursday, April 22, 2010 10:58 AM

Page 170 of 207

Breakdown assistance169

Using the system

Safety

Driving Tips

General Maintenance

Breakdown assistance

Technical Data

The spare wheel lies in a well under the floor covering of the luggage compartment

and is fixed in place using special screws

page 168, fig. 159 .

Before removing the spare wheel, you must take out the box with the vehicle tool kit

box page 167, fig. 157.

One should check the inflation pressure in the spare wheel (at best when generally

checking the tyre air pressures - see sign on the fuel filler flap page 160) to ensure

that the spare wheel is always ready to use.

Temporary spare wheel

A warning label displayed on the rim of the temporary spare wheel indicates that your

vehicle is equippe d with a temporary spare wheel.

Please observe the following notes when driving with a temporary spare wheel:

The warning label must not be covered after installing the wheel.

Do not drive faster than 80 km/h with this spare wheel and pay particular attention

while driving. Avoid accelerating at full throttle, sharp braking and fast cornering.

The inflation pressure for this spare wheel is identical to the inflation pressure of

the standard tyres.

Use this spare wheel only to reach the nearest specialist garage as it is not intended

for continuous use.

Changing a wheelPreliminary workThe following steps should be carried ou t before actually changing the wheel.

– If it is necessary to change a wheel, park the vehicle as far away as possible from

the traffic flow. The place you choose should be level.

–Have all the occupants get out. While changing a wheel, the occupants of the

vehicle should not stand on the road (e.g. behind a crash barrier).

– Apply the handbrake firmly.

– Shift up into the 1st gear . – If a trailer is coupled, uncouple it.

–Take the

vehicle tool kit page 167 and the spare wheel* page 168 out of the

luggage compartment.

WARNING

If you find yourself in flowing traffic switch on the hazard warning lights

system and place the warning triangle on the side of the road at the prescribed

distance from your vehicle while observin g all national legal provisions. In this

way you are protecting not only yourself but also other road users.

Never start the engine with the vehicle si tting on the raised jack - danger of

suffering injury.Caution

If you have to change a wheel on a slope fi rst block the opposite wheel with a stone or

similar object in order to secure the vehicle from unexpectedly rolling away.

Note

Comply with the national legal regulations.Changing a wheelAlways change a wheel on a level surface as far as possible.

– Take off the full wheel trim* page 170 or the caps page 171.

– In the case of light alloy wheels remove the wheel trim cap page 171.

– Slacken the wheel bolts page 171.

– Jack up the vehicle until the wheel to be changed is clear of the ground

page 172.

– Unscrew the wheel bolts and place them on a clean surface (cloth, paper etc.).

– Take off the wheel.

– Fit on the new spare wheel* and tighten the wheel bolts slightly.

– Lower the car.

s2rc.book Page 169 Thursday, April 22, 2010 10:58 AM

Page 174 of 207

Breakdown assistance173

Using the system

Safety

Driving Tips

General Maintenance

Breakdown assistance

Technical Data

– Have the

tightening torque checked with a torque wrench as soon as possible.

Steel and light alloy wheels must be tightened to a tightening torque of 120 Nm .

The safety wheel bolts on vehicles fitted wi th them (one safety wheel bolt per wheel)

can only be loosened or tighten up by using the adapter provided.

It is meaningful to note the code number hammered into the rear side of the adapter

or the rear side of the safety wheel bolts. You can obtain a replacement adapter from

a specialist garage, if necess ary, by quoting this number.

We recommend that you always carry the adapter for the wheel bolts with you in the

vehicle. It should be stow ed in the vehicle tool kit.

Caution

Damage can occur to the adapter and safety wh eel bolt if the safety wheel bolt is tight-

ened up too much.

Note

The set of safety wheel bolts can be obtained from a specialist garage.Jump-startingInitial stepsYou can use the battery of another vehicle for jump-starting yours if the engine does

not start because the battery on your vehicle is flat. You will require jump-start cables

for this purpose.

Both batteries must have a rated voltage of 12 V. The capacity (Ah) of the battery

supplying the power must not be significantly less than the capacity of the discharged

battery in your vehicle.

Jump-start cables

Only use jump-start cables which have an adequately large cross-section and insu-

lated terminal clamps. Plea se pay attention to the manufacturer's instructions.

Positive cable - colour coding in the majority of cases red. Negative cable -

colour coding in the majority of cases black.

WARNING

A discharged battery may already freeze at temperatures just below 0°C. In

case of frozen battery carry out no jump-starting - risk of explosion!

Please pay attention to the warning instructions relating to working in the

engine compartment page 148.Note

There must not be any contact between the two vehicles otherwise current may

flow as soon as the negati ve terminals are connected.

The discharged battery must be properly connected to the system of the vehicle.

Switch off any mobile phone, pay attention to the instructions for use of the mobile

phone in such a situation.

We recommend purchasing jump-start cabl es from Škoda Service Partners as a

Škoda original accessory or from retailers who sell branded batteries.

Start engineIt is important to connect the jump-start cables in the correct order.

Fig. 166 Jump-starting using

the battery from another vehicle:

A - flat vehicle battery, B -

battery providing current

s2rc.book Page 173 Thursday, April 22, 2010 10:58 AM

Page 175 of 207

Breakdown assistance

174

Connecting positive terminals

– Attach one end to the positive terminal page 173, fig. 166 of the discharged

battery .

– Attach the other end to the positive term inal of the battery supplying the power

.Connecting negative terminal and engine block– Attach one end to the negative termin al of the battery supplying the power .

– Attach the other end to a solid metal part which is connected firmly to the

engine block, or to the engine block itself.Starting the engine– Start the engine of the vehicle providing current and run the engine at idling speed.

– Now start the engine of the vehicle with the discharged battery.

– Interrupt the attempt at starting an engine after 10 seconds if it does not start right

away and wait for about 30 seconds before repeating the attempt.

– Disconnect the cables on the engine in exactly the reverse order they were

connected up.

WARNING

The non-insulated parts of the terminal clamps must never make contact

with each other. Furthermore, the cable connected to the positive terminal of

the battery must not come into contact with electrically conducting parts of the

vehicle - risk of a short circuit!

Do not affix the jump starting cables to the negative terminal of the

discharged battery. There is the risk of detonating gas seeping out the battery

being ignited by the strong spark which results from the engine being started.

Run the jump-start cables so that they cannot be caught by any rotating

parts in the engine compartment.

Do not bend over the batteries - risk of caustic burns!

The vent screws of the battery cells must be tightened firmly.

Keep any sources of ignition (naked flame, smouldering cigarettes etc.)

away from the battery - risk of an explosion!

Tow-starting and towing vehicleGeneralPlease pay attention to the following instru ctions if you are going to use a tow rope:Driver of the towing vehicle– Do not drive off until the tow rope is taught.

– Release the clutch particularly gently when starting off.Driver of the towed vehicle– Switch the ignition on so that the steering wheel is not blocked and you can also

operate the turn signal lights, the headlight flasher, the windscreen wipers and

windscreen washer system.

– Take the vehicle out of gear.

– Note that the brake servo unit and power steering only operate if the engine is running. You will require significantly greater physical force to depress the brake

pedal and to steer the vehicle if the engine is not running.

– Ensure that the tow rope is always kept taught.

Tow rope or tow bar

A tow bar is safest way of towing a vehicle and also minimizes any shocks. You can use

a tow rope only if a suitable tow bar is not available.

The tow rope must be elastic to protect the vehicle. Thus one should only use plastic

fibre rope or a rope made out of a similarly elastic material.

Only attach the tow rope to the towing eyes provided for this purpose page 175,

“Front towing eye”.

A1

AA

A2

AB

A3

AB

A4

WARNING (continued)

s2rc.book Page 174 Thursday, April 22, 2010 10:58 AM