SKODA RAPID 2012 1.G Owner's Manual

Manufacturer: SKODA, Model Year: 2012, Model line: RAPID, Model: SKODA RAPID 2012 1.GPages: 180, PDF Size: 4.36 MB

Page 141 of 180

Handling wheels and tyres

Fig. 106

Changing wheels around

First read and observe the introductory information and safety warn-

ings on page 137.

Changing wheels around

If significantly greater wear is present on the front tyres, we recommend chang-

ing the front wheels around with the rear wheels as shown in the dia-

gram » Fig. 106. You will then obtain approximately the same life for all the tyres.

We recommend that you change the wheels around every 10

000 km in order to

achieve even wear on all wheels and to obtain optimal tyre life.

Storing tyres

Mark wheels before removing them so that their previous direction of running can

be maintained when mounted them again.

Always store wheels or tyres which been removed in a cool, dry and, where possi-

ble, dark place. Tyres which are not fixed to a wheel trim should be stored up-

right. ÐNew wheels and tyres

First read and observe the introductory information and safety warn-

ings on page 137.

Only fit tyres of the same type, size (rolling circumference) and the same tread

pattern on one axle on all 4

wheels.

The tyre/wheel combinations which are approved for your vehicle are indicated in

your vehicle documents.

ä

ä Proper knowledge of the tyre data makes it easier for you to select the correct

type of tyre. Tyres, for example, have the following inscription on their walls.

195/55

R 15 85 H

What this means is:

195 Tyre width in mm

55 Height/width ratio in %

R Code letter for the type of tyre – Radial

15 Diameter of wheel in inches

85 Load index

H Speed symbol The following speed restrictions apply to tyres.

Speed symbol Permissible maximum speed

Q 160 km/h

R 170 km/h

S 180 km/h

T 190 km/h

U 200 km/h

H 210 km/h

V 240 km/h

W 270 km/h The date of manufacture

is also stated on the tyre wall (possibly only on the in-

side of wheel ): e.g.

DOT ... 27

12...

means, for example, that the tyre was manufactured in the 27th week of 2012.

The following must be observed if only one temporary spare wheel is availa-

ble » page 140. Ð

139

Wheels and Tyres

Page 142 of 180

Unidirectional tyres

First read and observe the introductory information and safety warn-

ings on page 137.

The direction of rotation of the tyres is marked by arrows on the wall of the tyre

.

The so specified running direction must absolutely be complied with. Only then

are the tyres able to provide the optimal properties in terms of grip, low noise,

wear-and-tear and aquaplaning.

If, in the event of a puncture, it is necessary to fit a spare wheel with a tyre with-

out a dedicated running direction or the opposite running direction, drive carefully

as the optimum characteristics of the tyre are no longer applicable in this situa-

tion. ÐSpare wheel

Fig. 107

Boot: Spare wheel

First read and observe the introductory information and safety warn-

ings on page 137.

The spare wheel is located in a well under the floor covering in the boot and is

fixed in place with a special bolt

» Fig. 107.

Before removing the spare wheel, the box containing the vehicle tool kit must be

removed.

It is important to check the inflation pressure in the spare wheel (preferably every

time the tyre air pressure is checked – see sticker on the fuel filler

flap » page 138) to ensure it is always ready to use. ä

ä If the dimensions or design of the spare wheel differ from the tyres fitted to the

vehicle (e.g. winter tyres or low-profile tyres), it must only be used briefly in the

event of a puncture and if an appropriately cautious style of driving is adop-

ted

» .

Replace it with a wheel having the appropriate mode and dimensions as soon as

possible

Temporary spare wheel

A warning label is displayed on the wheel rim of the spare wheel to indicate that

your vehicle is equipped with a temporary spare wheel.

Please observe the following when driving with a temporary spare wheel.

› The warning label must not be covered after installing the wheel.

› Do not drive faster than 80

km/h with the temporary spare wheel and pay par-

ticular attention while driving. Avoid accelerating at full throttle, sharp braking

and fast cornering.

› The inflation pressure for this spare wheel is identical to the maximum inflation

pressure of the standard tyres.

› Only use this temporary spare wheel to reach the nearest ŠKODA specialist ga-

rage as it is not intended for continuous use. WARNING

■ Never use the temporary spare wheel if it is damaged.

■ If the dimensions or design of the temporary spare wheel differ from the fit-

ted tyres, never drive faster than 80

km/h (or 50 mph). Avoid accelerating at

full throttle, sharp braking and fast cornering. CAUTION

Observe the instructions on the sticker on the temporary spare wheel. Note

The tyre pressure should be at the highest pressure specified for your vehicle at

all times. Ð

140 General Maintenance

Page 143 of 180

Full wheel trim

First read and observe the introductory information and safety warn-

ings on page 137.

Pulling off

›

Hook the clamp found in the vehicle tool kit into the reinforced edge of the

wheel trim.

› Push the wheel wrench through the clamp, support on the tyre and pull off the

wheel trim.

Install

› First press the full wheel trim onto the wheel rim at the valve opening provided.

Then press the full wheel trim into the wheel rim until its entire circumference

locks correctly in place. CAUTION

■ Use the pressure of your hand, do not knock the full wheel trim! Heavy knocks

mainly on the points where the full wheel trim has not been inserted into the

wheel, can result in damage to the guide and centring elements of the full wheel

trim.

■ First of all check that the theft-deterrent wheel bolt is located in the hole near

the valve before fitting the full wheel trim onto a steel wheel which is attached

with a theft-deterrent wheel bolt » page 149, Securing wheels against theft .

■ If wheel trims are retrofitted it must be ensured that an adequate flow of air is

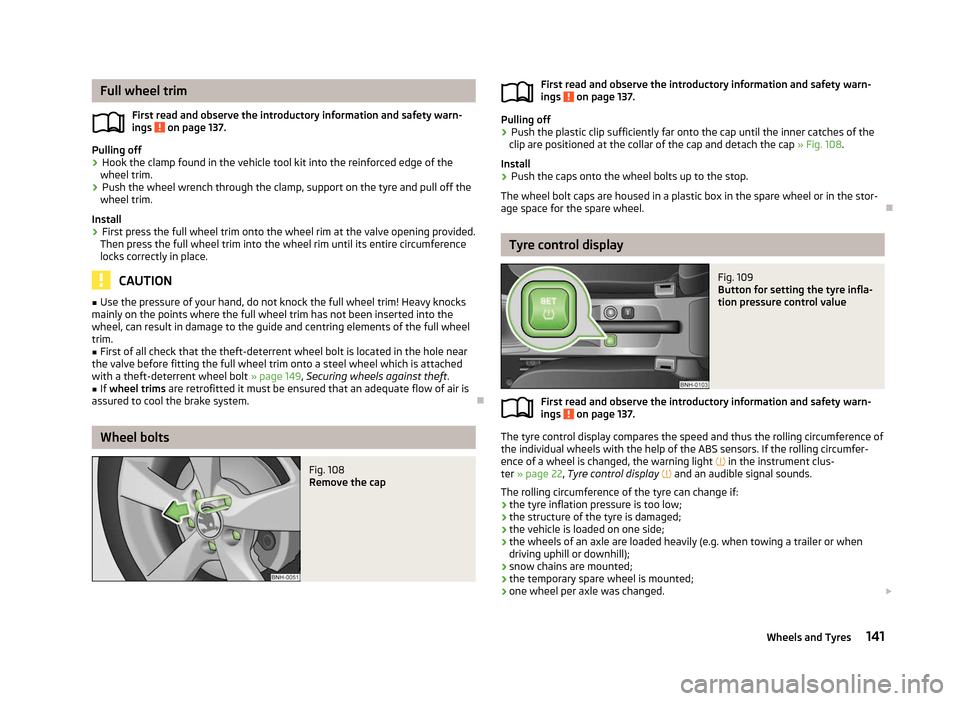

assured to cool the brake system. ÐWheel bolts

Fig. 108

Remove the cap

ä

First read and observe the introductory information and safety warn-

ings on page 137.

Pulling off

›

Push the plastic clip sufficiently far onto the cap until the inner catches of the

clip are positioned at the collar of the cap and detach the cap » Fig. 108.

Install

› Push the caps onto the wheel bolts up to the stop.

The wheel bolt caps are housed in a plastic box in the spare wheel or in the stor-

age space for the spare wheel. Ð Tyre control display

Fig. 109

Button for setting the tyre infla-

tion pressure control value

First read and observe the introductory information and safety warn-

ings on page 137.

The tyre control display compares the speed and thus the rolling circumference of

the individual wheels with the help of the ABS sensors. If the rolling circumfer-

ence of a wheel is changed, the warning light

in the instrument clus-

ter » page 22, Tyre control display and an audible signal sounds.

The rolling circumference of the tyre can change if: › the tyre inflation pressure is too low;

› the structure of the tyre is damaged;

› the vehicle is loaded on one side;

› the wheels of an axle are loaded heavily (e.g. when towing a trailer or when

driving uphill or downhill);

› snow chains are mounted;

› the temporary spare wheel is mounted;

› one wheel per axle was changed.

£

ä

ä 141

Wheels and Tyres

Page 144 of 180

Basic setting of the system

After changing the tyre inflation pressure, after changing one or several wheels,

the position of a wheel on the vehicle (e.g. exchanging the wheels between the

axles) or when the warning light lights up while driving, a basic setting of the sys-

tem must be carried out as follows:

› Inflate all of the tyres to the specified inflation pressure

» page 138, Service life

of tyres.

› Switch on the ignition.

› Press and hold the button

» Fig. 109

for longer than 2 seconds. While

pressing the button, the warning light illuminates. At the same time the sys-

tem memory is erased and the new calibration is started, which is confirmed

with an audible signal and then the warning light goes out.

› If the warning light

does not go out after the basic setting, this indicates a

system fault. Seek help from a ŠKODA specialist garage.

The warning light is lit

If the tyre inflation pressure of at least one wheel is insufficiently inflated in com-

parison to the stored basic value, the warning light » lights up.

The warning light flashes

If the warning light flashes, there is a system fault. Seek help from a

ŠKODA spe-

cialist garage to correct the fault. WARNING

■ When the warning light illuminates, immediately reduce the speed and

avoid sudden steering and brake manoeuvres. Stop the vehicle as soon as

possible and inspect the tyres and their inflation pressure.

■ Under certain circumstances (e.g. sporty style of driving, wintry or unpaved

roads) the warning light can be delayed or does not light up at all.

■ The tyre control display does not absolve the driver of the responsibility to

ensure the correct tyre inflation pressure. For this reason, the tyre inflation

pressure must be checked regularly. Note

■ The tyre control display does therefore not replace the regular tyre inflation

pressure control, as the system cannot detect an even loss of pressure. ■ The tyre control display cannot provide a warning in the event of very rapid tyre

inflation pressure loss, e.g. in the case of sudden tyre damage. In this case care-

fully bring the vehicle to a standstill without sudden steering movements or

sharp braking.

■ To ensure a proper functioning of the tyre control display, it is necessary to re-

peat the basic setting every 10 000 km or once a year. Ð Wheel bolts

First read and observe the introductory information and safety warn-

ings on page 137.

Wheels and

wheel bolts are matched to each other in terms of design. Each time

you fit other wheels, e.g. light alloy wheels or wheels with winter tyres, you must

therefore also use the matching wheel bolts of the correct length and shape of

spherical cap. This is essential to ensure that the wheels are tightly fitted and

that the brake system operates properly. Ð Winter tyres

First read and observe the introductory information and safety warn-

ings on page 137.

The handling of your vehicle will be significantly improved when driving on wintry

roads if you fit winter tyres. Summer tyres do not offer the same grip on ice, snow

and at temperatures below 7 °C because of their construction (width, rubber

blend, tread pattern). This particularly applies to vehicles which are equipped with

low-profile tyres

or high-speed tyres (code index H or V on wall of tyre).

To achieve the best possible handling properties, winter tyres must be fitted on

all 4 wheels, the minimum tread depth must be 4

mm and tyres must be no older

than 4 years.

Winter tyres of a lower speed category can be used provided that the permissible

maximum speed of these tyres is not exceeded even if the possible maximum

speed of the vehicle is higher. £

ä

ä

142 General Maintenance

Page 145 of 180

For the sake of the environment

Fit the summer tyres on again in good time as they provide better handling prop-

erties, a shorter braking distance, less tyre noise, and reduced tyre wear on roads

which are free of snow and ice as well as at temperatures above 7

°C. The fuel

consumption is also lower. ÐSnow chains

First read and observe the introductory information and safety warn-

ings on page 137.

Snow chains must only be mounted on the front wheels.

When driving on wintry roads, snow chains improve not only traction, but also the

braking performance.

For technical reasons, it is only permissible to fit snow chains with the following

wheel/tyre combinations.

Wheel size Depth (D)Tyre size

5J x 14 a)

35 mm 175/70

6J x 15 b)

38 mm 185/60

6J x 15 b)

38 mm 195/55a)

Only fit snow chains with links and locks not larger than 9 mm.

b) Only fit snow chains with links and locks not larger than 13 mm.

Remove the full wheel trims before installing the snow chains.

Observe the national legal regulations relating to the use of snow chains and the

maximum vehicle speed with snow chains. CAUTION

The chains must be removed when driving on roads which are free of snow. They

adversely affect the handling of your vehicle, damage the tyres and are rapidly

destroyed. Ðä

143

Wheels and Tyres

Page 146 of 180

Accessories, changes and replacement of

parts Introductory information

If you want to retrofit the vehicle with accessories, if a vehicle part is to be re-

placed with a new one, or when needing to make technical changes, the follow-

ing instructions must be observed.

› Always seek advice from a

ŠKODA Service Partner before purchasing any acces-

sories or parts and before making any technical changes » .

› The guidelines and instructions issued by

ŠKODA must be observed when mak-

ing technical changes.

Adhering to the prescribed procedures will prevent any kind of damage to the ve-

hicle, and its travelling and operating safety will be maintained. The vehicle also

complies with German road transport regulations (StVZO). More information is

available from a ŠKODA Service Partner who can also perform the necessary work

correctly.

Vehicles with special built-on types

Technical documents regarding changes carried out on the vehicle must be kept

by the vehicle user, in order to hand over later to the old car user. This ensures

the recycling in accordance with environmental regulations.

Interference on the electronic components and their software can lead to opera-

tional faults. This interference can also impair not directly affected systems be-

cause of the networking of the electronic components. In other words, the vehi-

cle's roadworthiness may be put at risk and increased wear on parts may arise.

Any damage caused by technical changes made without consent by ŠKODA is ex-

cluded from the warranty – see the warranty certificate. WARNING

■ Work or modifications on your vehicle, which have been carried out unpro-

fessionally, can cause operational faults – risk of accident!

■ We advise you, in your own interest, to only use ŠKODA Original Accessories

and ŠKODA

Original Parts which have been expressly approved for use on

your vehicle. Reliability, safety and suitability have been established for

ŠKODA Original Accessories and ŠKODA Original Parts.

■ Although we constantly monitor the market, we are not able to assess or

warrant the parts even though in some instances such parts may have a type

approval or may have been approved by a nationally recognised testing labo-

ratory. Note

ŠKODA Original Accessories and ŠKODA Original Parts can be purchased from

ŠKODA

Service Partners who will also professionally undertake the assembly of

the purchased parts. Ð Changes and impairments of the airbag system

Repairs and technical modifications must comply with

ŠKODA guidelines.

We recommend that any modifications and repairs to the front bumper, doors,

front seats, headliner or bodywork be carried out by a ŠKODA Service Partner.

These vehicle parts may include system components for the airbag system. WARNING

■ Airbag modules can not be repaired, but must be replaced.

■ Never install any airbag parts into the vehicle that have been removed from

old cars or have been recycled. ■ A modification to the suspension of the vehicle including the use of non-ap-

proved rim-tyre combinations can alter the functioning of the airbag and in-

crease the risk of serious or fatal injuries in an accident.

■ Parts of the airbag system may be damaged when working on the airbag

system or removing and installing system parts due to other repairs. This may

mean that the airbags will not deploy properly or not at all in the event of an

accident. Ð

144 General Maintenance

Page 147 of 180

Do-it-yourself

Do-it-yourself

First-aid kit and warning triangle

Fig. 110

Placing of the first-aid kit/placing of the warning triangle

The first aid kit A

» Fig. 110 is attached by a strap in the right-hand storage com-

partment in the luggage compartment.

A warning triangle B

with the maximum dimensions 436 x 45 x 32 mm can be

attached to the trim panel of the rear wall using the mountings. WARNING

The first-aid kit and warning triangle must always be secured safely so that

they do not come loose when making an emergency braking or in a vehicle

collision which could cause injuries to occupants. Note

■ Pay attention to the expiration date of the first-aid kit.

■ We recommend using a first-aid box from ŠKODA Original Accessories available

from a ŠKODA Service Partner. Ð Fire extinguisher

Please read carefully the instructions which are attached to the fire extinguish-

er.

The fire extinguisher must be checked by an authorised person on an annual ba-

sis (the national legal provisions must be observed). WARNING

The fire extinguisher must always be secured safely so that they do not come

loose when making an emergency braking or in a vehicle collision which could

cause injuries to occupants. Note

■ The fire extinguisher must comply with the relevant applicable national legal re-

quirements. ■ Pay attention to the expiration date of the fire extinguisher. If the fire extin-

guisher is used after the expiration date, its proper function is no longer assured. Ð Vehicle tool kit

Fig. 111

Vehicle tool kit £

145

Do-it-yourself

Page 148 of 180

The vehicle tool kit and the lifting jack with sticker are housed in a plastic box in

the spare wheel or in the storage space for the spare wheel. There is also space

here for the removable ball rod for the trailer towing device. The box is attached

with a strap on the spare wheel.

The vehicle tool kit contains the following parts (depending on equipment fitted):

Screwdriver

Adapter for anti-theft wheel bolts

Towing eye

Clamps for removing the wheel trims

Car jack

Wheel wrench

Extraction pliers for wheel bolt caps

Replacement bulb set

Before placing the lifting jack back into its storage area, screw in the arm of the

lifting jack fully. WARNING

■ The factory-supplied lifting jack is only intended for your model of vehicle.

Under no circumstances attempt to lift heavier vehicles or other loads – risk of

injury!

■ Ensure that the vehicle tool kit is safely secured in the boot. Note

Ensure that the box is always secured with the strap. ÐChanging a wheel

ä

Introduction

This chapter contains information on the following subjects:

Preliminary work 147

Changing a wheel 147

Subsequent steps 147

Loosening and tightening wheel bolts 1481

2

3

4

5

6

7

8 Raising the vehicle 148

Securing wheels against theft 149

WARNING

■ If you are in flowing traffic, switch on the hazard warning light system and

set up the warning triangle at the prescribed distance! The national legal re-

quirements must be observed. In this way you are not only protecting yourself

but other road users as well.

■ If the wheel is damaged or in the event of a puncture, park the vehicle as far

away as possible from the flow of traffic. Park on as flat and firm a surface as

possible. ■ If the wheel has to be changed on a slope, first of all block the opposite

wheel with a stone or similar object to prevent the vehicle from unexpectedly

rolling away.

■ If the vehicle is subsequently fitted with tyres which are different to those it

was fitted with at the works, follow these guidelines » page 139, New wheels

and tyres .

■ Always raise the vehicle with the doors closed.

■ Never position any body parts, such as arms or legs under the vehicle, while

the vehicle is raised with a lifting jack. ■ Secure the base plate of the lifting jack with suitable means to prevent pos-

sible moving. A soft and slippery ground under the base plate may move the

lifting jack, causing the vehicle to fall down. It is therefore always necessary to

place the lifting jack on a solid surface or use a wide and stable base. Use a

non-slip base (e.g. a rubber foot mat) if the surface is smooth, such as cobbled

stones, tiled floor, etc. ■ Never start the engine with the vehicle sitting on the raised jack – danger of

suffering injury.

■ Only attach the lifting jack to the attachment points provided for this pur-

pose. CAUTION

■ The prescribed tightening torque of the wheel bolts for steel and light alloy

wheels is 120

Nm.

■ If the anti-theft wheel bolt is fastened too tightly, it can cause damage to the

anti-theft wheel bolt and adapter. £

146 Do-it-yourself

Page 149 of 180

Note

■ The anti-theft wheel bolt set and adapter can be purchased from a ŠKODA Serv-

ice Partner. ■ The national legal requirements must be observed when changing a wheel. ÐPreliminary work

First read and observe the introductory information and safety warn-

ings on page 146.

The following steps must be carried out before actually changing the wheel:

›

In the event of a puncture, park the vehicle as far away as possible from the

flow of traffic. The place you choose should be level.

› Let all of the occupants get out.

While changing a tyre, the occupants of the

vehicle should not stand on the road (instead they should remain behind a crash

barrier).

› Switch off the engine and move the gearshift lever into

Neutral or move the

selector lever

for the automatic gearbox into position P .

› Firmly apply the

handbrake.

› If a trailer is connected, remove it.

› Remove the vehicle tool kit

» page 145 and the spare wheel » page 140, Spare

wheel from the boot. ÐChanging a wheel

First read and observe the introductory information and safety warn-

ings on page 146.

Always change a wheel on a level surface as far as possible.

›

Remove the full wheel trim

» page 141 or caps » page 141.

› First of all slacken the anti-theft wheel bolt and then the other wheel

bolts » page 148.

› Jack up the vehicle until the wheel that needs changing is clear of the

ground » page 148.

› Unscrew the wheel bolts and place them on a clean surface (cloth, paper, etc.).

› Remove the wheel.

› Attach the spare wheel and slightly screw on the wheel bolts.

› Lower the vehicle.

› Alternately tighten the wheel bolts opposite each other using the wheel

wrench (crosswise) and then tighten the anti-theft wheel bolt » page 148.

ä

ä

›

Replace the wheel trim or the caps. Note

■ All bolts must be clean and must turn easily.

■ Under no circumstances grease or oil the wheel bolts!

■ When fitting unidirectional tyres, ensure that the direction of rotation is cor-

rect »

page 140 , Unidirectional tyres . Ð Subsequent steps

First read and observe the introductory information and safety warn-

ings on page 146.

The following steps must also be performed after changing the wheel.

›

Stow and attach the replaced wheel in the spare wheel well using a special

screw » page 140, Spare wheel.

› Stow the vehicle tool kit in the space provided.

› Check

the tyre pressure

on the installed spare wheel as soon as possible.

› Have the

tightening torque of the wheel bolts checked with a torque wrench

as soon as possible.

› Change the damaged wheel or consult a ŠKODA specialist garage about repair

possibilities. Note

■ If it is determined that the wheel bolts are corroded and difficult to turn when

changing the wheel, the bolts must be replaced before checking the tightening

torque. ■ Drive cautiously and only at a moderate speed until the tightening torque has

been checked. Ð

ä

147

Do-it-yourself

Page 150 of 180

Loosening and tightening wheel bolts

Fig. 112

Changing a wheel: Loosening

the wheel bolts

First read and observe the introductory information and safety warn-

ings on page 146.

Loosening

›

Push the wheel wrench onto the wheel bolt up to the stop 1)

.

› Grasp the end of the wrench and turn the bolt about

one turn to the

left » Fig. 112 .

Tightening

› Push the wheel wrench onto the wheel bolt up to the stop 1)

.

› Grasp the end of the wrench and turn the bolt to the right until it is tight. WARNING

Undo the wheel bolts only a little (about one turn) as long as the vehicle has

not yet been jacked up – risk of an accident! Note

If it proves difficult to undo the bolts, carefully apply pressure to the end of the

wrench with your foodt. Keep hold of the vehicle when doing so, and make sure

you keep your footing. Ð

ä Raising the vehicle

Fig. 113

Changing a wheel: Jacking points

for positioning lifting jack Fig. 114

Attach lifting jack

First read and observe the introductory information and safety warn-

ings on page 146.

Position the lifting jack by selecting the jacking point that is closest to the faulty

wheel

» Fig. 113. The jacking point is located directly below the engraving in the

lower sill.

› Position the lifting jack below the jacking point and move it up until its claw is

positioned directly below the vertical web of the lower sill.

› Align the lifting jack so that its claw grasps the web

» Fig. 114 –

below the

embossing in the side surface of the lower sill.

› Ensure that the entire surface of the lifting jack base plate rests on level

ground and is located in a vertical position to the area » Fig. 114 where the claw

grasps the web. £

ä

1)

Use the appropriate adapter for undoing and tightening the anti-theft wheel bolts » page 149.

148 Do-it-yourself