ECU SKODA RAPID 2015 1.G Owner's Guide

[x] Cancel search | Manufacturer: SKODA, Model Year: 2015, Model line: RAPID, Model: SKODA RAPID 2015 1.GPages: 204, PDF Size: 27.52 MB

Page 122 of 204

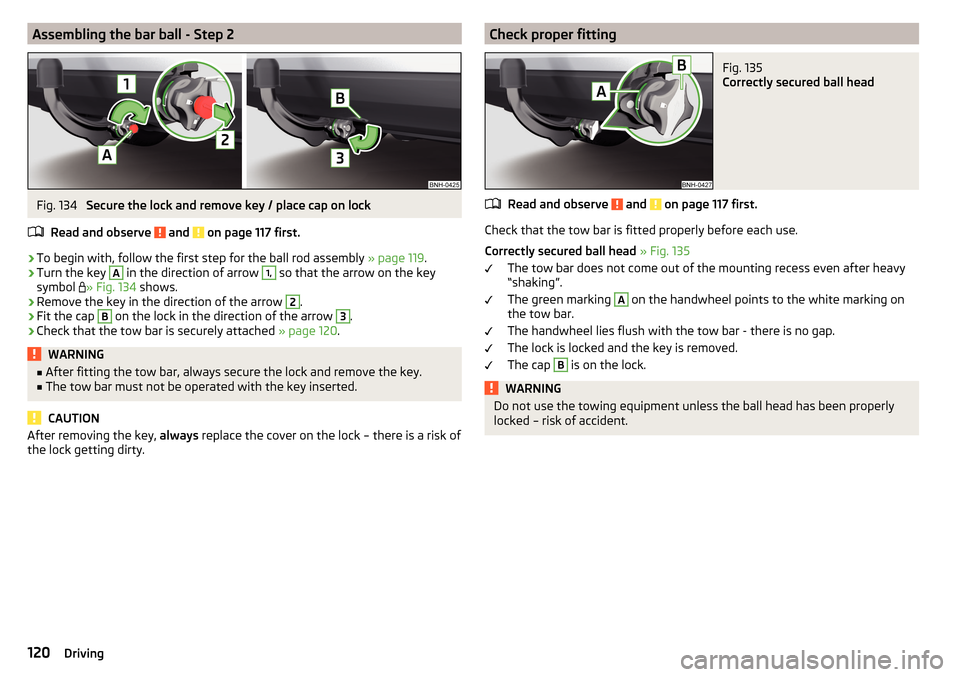

Assembling the bar ball - Step 2Fig. 134

Secure the lock and remove key / place cap on lock

Read and observe

and on page 117 first.

›

To begin with, follow the first step for the ball rod assembly » page 119.

›

Turn the key

A

in the direction of arrow

1,

so that the arrow on the key

symbol » Fig. 134

shows.

›

Remove the key in the direction of the arrow

2

.

›

Fit the cap

B

on the lock in the direction of the arrow

3

.

›

Check that the tow bar is securely attached » page 120.

WARNING■

After fitting the tow bar, always secure the lock and remove the key.■The tow bar must not be operated with the key inserted.

CAUTION

After removing the key, always replace the cover on the lock – there is a risk of

the lock getting dirty.Check proper fittingFig. 135

Correctly secured ball head

Read and observe and on page 117 first.

Check that the tow bar is fitted properly before each use.

Correctly secured ball head » Fig. 135

The tow bar does not come out of the mounting recess even after heavy

“shaking”.

The green marking

A

on the handwheel points to the white marking on

the tow bar.

The handwheel lies flush with the tow bar - there is no gap.

The lock is locked and the key is removed.

The cap

B

is on the lock.

WARNINGDo not use the towing equipment unless the ball head has been properly

locked – risk of accident.120Driving

Page 123 of 204

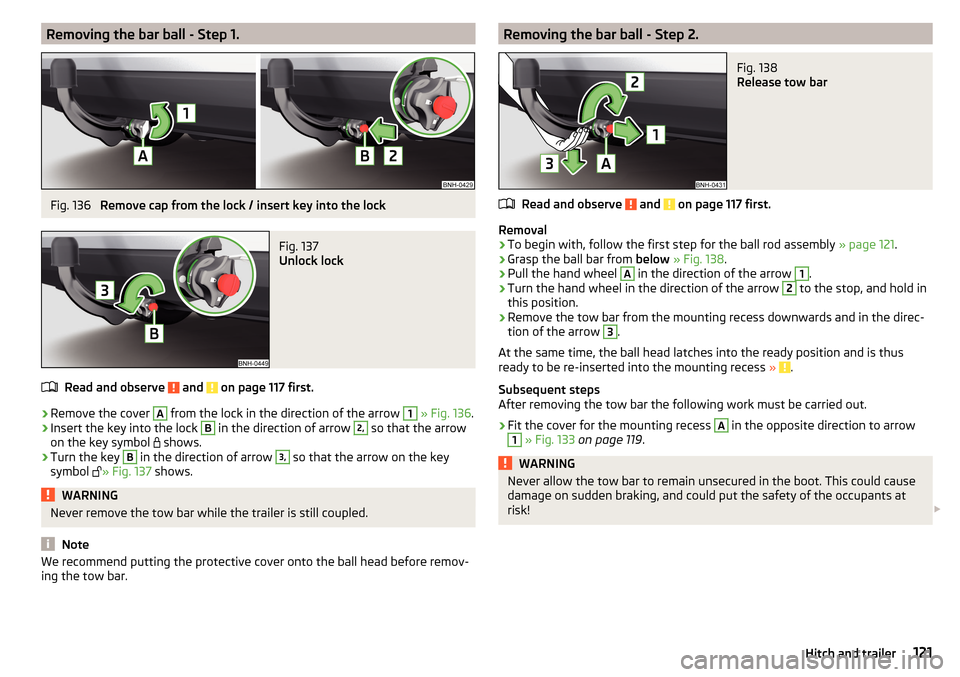

Removing the bar ball - Step 1.Fig. 136

Remove cap from the lock / insert key into the lock

Fig. 137

Unlock lock

Read and observe and on page 117 first.

›

Remove the cover

A

from the lock in the direction of the arrow

1

» Fig. 136 .

›

Insert the key into the lock

B

in the direction of arrow

2,

so that the arrow

on the key symbol shows.

›

Turn the key

B

in the direction of arrow

3,

so that the arrow on the key

symbol » Fig. 137

shows.

WARNINGNever remove the tow bar while the trailer is still coupled.

Note

We recommend putting the protective cover onto the ball head before remov-

ing the tow bar.Removing the bar ball - Step 2.Fig. 138

Release tow bar

Read and observe and on page 117 first.

Removal

›

To begin with, follow the first step for the ball rod assembly » page 121.

›

Grasp the ball bar from below » Fig. 138 .

›

Pull the hand wheel

A

in the direction of the arrow

1

.

›

Turn the hand wheel in the direction of the arrow

2

to the stop, and hold in

this position.

›

Remove the tow bar from the mounting recess downwards and in the direc-

tion of the arrow

3

.

At the same time, the ball head latches into the ready position and is thus

ready to be re-inserted into the mounting recess »

.

Subsequent steps

After removing the tow bar the following work must be carried out.

›

Fit the cover for the mounting recess

A

in the opposite direction to arrow

1

» Fig. 133 on page 119 .

WARNINGNever allow the tow bar to remain unsecured in the boot. This could cause

damage on sudden braking, and could put the safety of the occupants at

risk! 121Hitch and trailer

Page 125 of 204

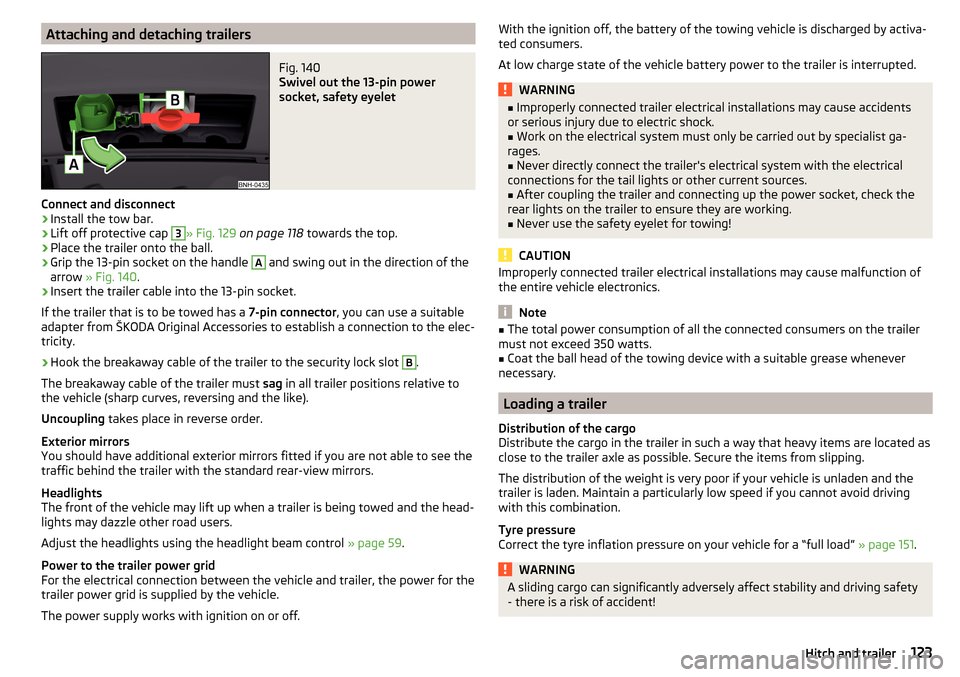

Attaching and detaching trailersFig. 140

Swivel out the 13-pin power

socket, safety eyelet

Connect and disconnect

›

Install the tow bar.

›

Lift off protective cap

3

» Fig. 129 on page 118 towards the top.

›

Place the trailer onto the ball.

›

Grip the 13-pin socket on the handle

A

and swing out in the direction of the

arrow » Fig. 140 .

›

Insert the trailer cable into the 13-pin socket.

If the trailer that is to be towed has a 7-pin connector, you can use a suitable

adapter from ŠKODA Original Accessories to establish a connection to the elec-

tricity.

›

Hook the breakaway cable of the trailer to the security lock slot

B

.

The breakaway cable of the trailer must sag in all trailer positions relative to

the vehicle (sharp curves, reversing and the like).

Uncoupling takes place in reverse order.

Exterior mirrors

You should have additional exterior mirrors fitted if you are not able to see the

traffic behind the trailer with the standard rear-view mirrors.

Headlights

The front of the vehicle may lift up when a trailer is being towed and the head-

lights may dazzle other road users.

Adjust the headlights using the headlight beam control » page 59.

Power to the trailer power grid

For the electrical connection between the vehicle and trailer, the power for the

trailer power grid is supplied by the vehicle.

The power supply works with ignition on or off.

With the ignition off, the battery of the towing vehicle is discharged by activa- ted consumers.

At low charge state of the vehicle battery power to the trailer is interrupted.WARNING■ Improperly connected trailer electrical installations may cause accidents

or serious injury due to electric shock.■

Work on the electrical system must only be carried out by specialist ga-

rages.

■

Never directly connect the trailer's electrical system with the electrical

connections for the tail lights or other current sources.

■

After coupling the trailer and connecting up the power socket, check the

rear lights on the trailer to ensure they are working.

■

Never use the safety eyelet for towing!

CAUTION

Improperly connected trailer electrical installations may cause malfunction of

the entire vehicle electronics.

Note

■ The total power consumption of all the connected consumers on the trailer

must not exceed 350 watts.■

Coat the ball head of the towing device with a suitable grease whenever

necessary.

Loading a trailer

Distribution of the cargo

Distribute the cargo in the trailer in such a way that heavy items are located as

close to the trailer axle as possible. Secure the items from slipping.

The distribution of the weight is very poor if your vehicle is unladen and the

trailer is laden. Maintain a particularly low speed if you cannot avoid driving

with this combination.

Tyre pressure

Correct the tyre inflation pressure on your vehicle for a “full load” » page 151.

WARNINGA sliding cargo can significantly adversely affect stability and driving safety

- there is a risk of accident!123Hitch and trailer

Page 133 of 204

NoteDue to the special tools and knowledge required, and to avoid any potential

problems with the cleaning and care of your vehicle's exterior, we recommend

that the cleaning and care of your vehicle be carried out by a ŠKODA Service

Partner.

Vehicle paint work

Read and observe

and on page 130 first.

Preserving the vehicle paintwork

A thorough wax treatment provides the vehicle's paintwork with highly effec-

tive protection against harmful environmental influences.

The vehicle must be treated with a high-quality hard wax polish at the latest, when no more drops form on the clean paintwork.

A new layer of a high-quality hard wax polish can be applied to the clean body- work after it has dried thoroughly.

Even if you use a wax preserver regularly we still recommend that you treat

the paintwork of the vehicle at least twice a year with hard wax.

Polishing

Polishing is necessary if the vehicle's paintwork has become unattractive and

if it is no longer possible to achieve a gloss with wax preservatives.

If the polish does not contain any preserving elements, the paint must be trea- ted with a preservative afterwards.

CAUTION

■ Paint damage is to be repaired immediately.■Never apply wax to the windows.■

Mat painted or plastic parts must not be treated with polishing products or

hard waxes.

■

Do not polish the paintwork in a dusty environment - risk of paint scratches.

■

Do not apply any paint care products to door seals or window guides.

■

If possible, do not apply any paint care products to parts of the bodywork

that come into contact with door seals or window guides.

Films

Read and observe

and on page 130 first.

Cleaning

Films (e.g. Roof, decorative, protective films, etc.) must be cleaned more care-

fully than the vehicle paint.

The films may not be washed with a high-pressure cleaner.

Only wash the films with a soft cloth, mild soap solution and clean, warm wa-

ter.

Service life

Environmental influences (e.g. sunlight, humidity, air pollution, rockfall) affect

the life of the films.

Sunlight may also affect the strength of the film colour.

Films will age and become brittle – this is entirely normal; this is not a fault.

CAUTION

■ Never use aggressive cleaning agents or chemical solvents for the glued sur-

faces with films - there is a danger of film damage.■

Never use dirty cloths or chemical solvents for the glued surfaces with films -

there is a danger of damaging the film.

■

In the winter months, do not use an ice scraper to remove ice and snow from

the areas with films. Do not use any other objects to remove frozen layers of

snow or ice – risk of film damage.

■

Do not polish the films - risk of damage!

■

When transporting a load on the roof rack (e.g. roof box or similar), there is

an increased risk of film damage (e.g. of chipping from the secured load).

Plastic parts

Read and observe

and on page 130 first.

Clean plastic parts with a damp cloth.

If this method does not completely clean the plastic parts, use cleaning prod-

ucts specially designed for this purpose.

CAUTION

Do not use paint care products on plastic parts.131Care and maintenance

Page 142 of 204

WARNINGInformation for working on the fuel system or the electrical system■Always disconnect the vehicle battery from the electrical system.■

Do not smoke.

■

Never work near open flames.

■

Always have a functioning fire extinguisher nearby.

WARNING■Read and observe the information and warning instructions on the fluid

containers.■

Keep the working fluids in sealed original containers and safe from peo-

ple who are not completely independent, e.g. children.

■

Never spill operating fluids over the hot engine - risk of fire.

■

If you intend to work underneath the vehicle, you must secure the vehicle

from rolling away and support it with suitable supporting blocks; the car

jack is not sufficient – risk of injury!

CAUTION

Always top up using the correct specification of fluids. This may result in major

operating problems and also vehicle damage!

For the sake of the environment

In view of the requirements for the environmentally friendly disposal of fluids and the special tools and knowledge required for such work, we recommend

that fluids be changed by a specialist garage.

Note

■ Please consult a specialist garage for any questions relating to fluids.■Fluids with the proper specifications can be purchased from the ŠKODA Origi-

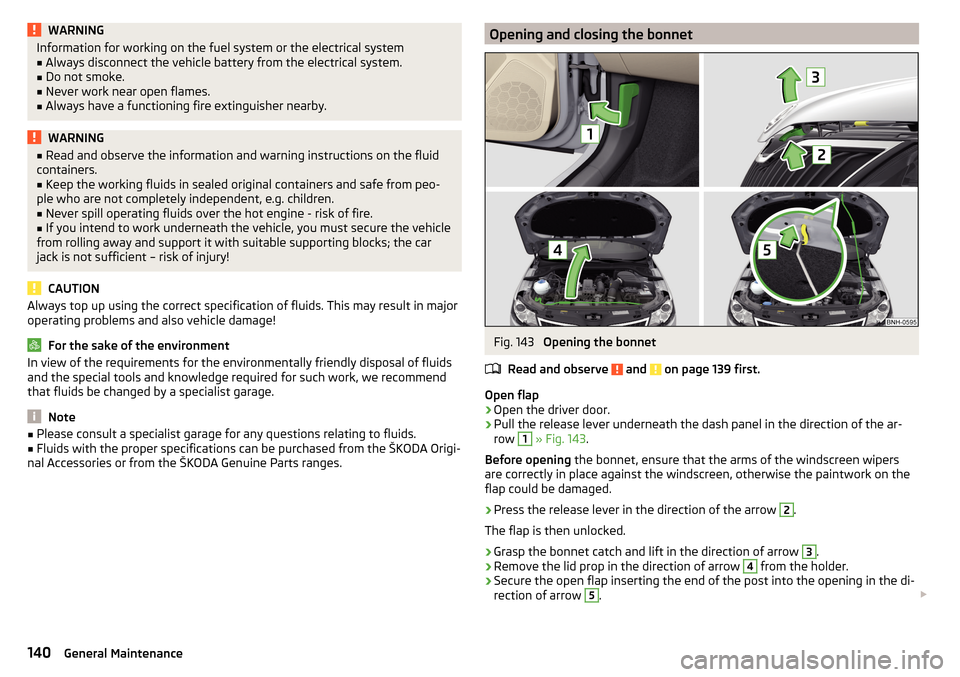

nal Accessories or from the ŠKODA Genuine Parts ranges.Opening and closing the bonnetFig. 143

Opening the bonnet

Read and observe

and on page 139 first.

Open flap

›

Open the driver door.

›

Pull the release lever underneath the dash panel in the direction of the ar-

row

1

» Fig. 143 .

Before opening the bonnet, ensure that the arms of the windscreen wipers

are correctly in place against the windscreen, otherwise the paintwork on the

flap could be damaged.

›

Press the release lever in the direction of the arrow

2

.

The flap is then unlocked.

›

Grasp the bonnet catch and lift in the direction of arrow

3

.

›

Remove the lid prop in the direction of arrow

4

from the holder.

›

Secure the open flap inserting the end of the post into the opening in the di-

rection of arrow

5

.

140General Maintenance

Page 150 of 204

Checking the battery electrolyte levelFig. 150

Vehicle battery: Electrolyte level

indicator

Read and observe and on page 147 first.

On vehicles with a vehicle battery fitted with a colour indicator, the electrolyte

level can be determined by looking at the change in colour of this display.

Air bubbles can influence the colour of the indicator. For this reason carefully

knock on the indicator before carrying out the check.

Check

Black colour – electrolyte level is correct.

Colourless or light yellow colour – electrolyte level too low, the battery must

be replaced.

For technical reasons, on vehicles with the description “AGM”, the electrolyte

level cannot be checked.

Vehicles with the START-STOPsystem are fitted with a battery control unit for

checking the energy level for recurring engine starts.

We recommend that you have the acid level checked regularly by a specialist

garage, especially in the following cases. ▶ High external temperatures.

▶ Longer day trips.

▶ After each charge.

Winter time

The vehicle battery only has a proportion of the starting power in lower tem- peratures. A discharged vehicle battery may already freeze at temperatures

just below 0 °C .

We therefore recommend that you have the battery checked and, if necessary,

recharged by a specialist garage before the start of the winter.

NoteThe battery acid level is also checked regularly by a specialist garage as part of

the inspection service.

Charging

Read and observe

and on page 147 first.

A properly charged vehicle battery is essential for reliably starting the engine.

A charging operation can be performed if the following conditions are satis-

fied.

The engine is turned off.

The ignition is switched off.

All consumers are turned off.

The bonnet is open.

“Fast charging” with high currents

›

Disconnect both battery cables (first of all “negative”, then “positive”).

›

Attach the terminal clamps of the charger to the battery terminals (red =

“positive”, black = “negative”).

›

Plug the mains cable of the charger into the power socket and switch on the

device.

›

After charging has been successful: Switch off the charger and remove the

mains cable from the power socket.

›

Only then disconnect the charger's terminal clamps.

›

Reconnect the cables to the battery (first “positive”, then “negative”).

Charging with low voltages

It is not necessary to disconnect the cables from the battery if you recharge

the vehicle battery, for example from a mini-charger.

Refer to the instructions of the charger manufacturer .

A charging current of 0.1 multiple of the total vehicle battery capacity (or low-

er) must be used until full charging is achieved.

The vent plugs of the vehicle battery should not be opened for charging.

148General Maintenance

Page 158 of 204

Do-it-yourself

Emergency equipment and self-help

Emergency equipment

Introduction

This chapter contains information on the following subjects:

First aid kit and warning triangle

156

reflective vest

156

fire extinguisher

156

Vehicle tool kit

157

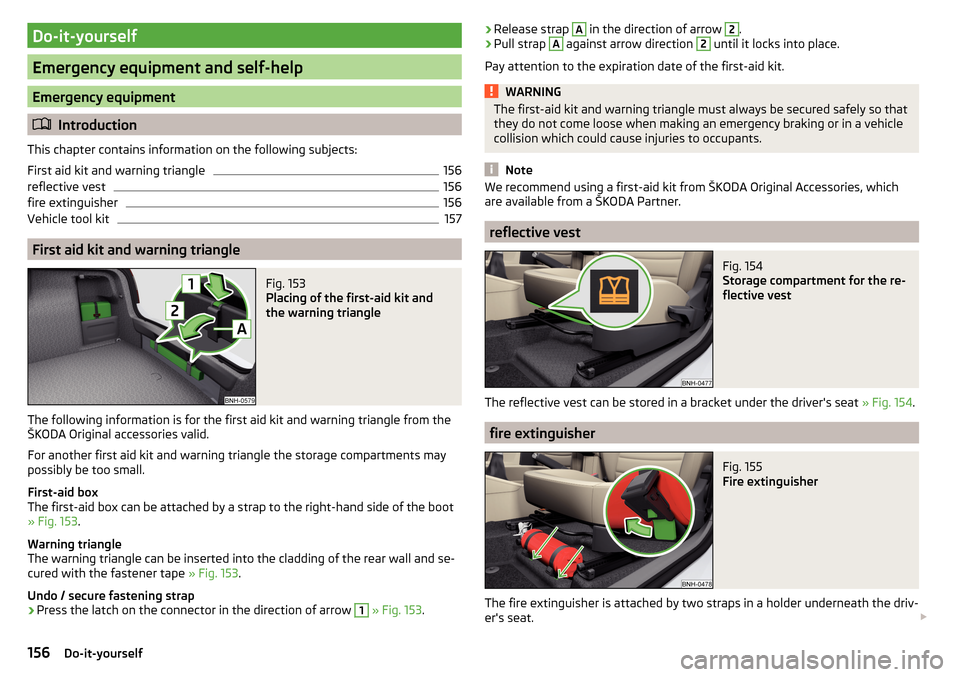

First aid kit and warning triangle

Fig. 153

Placing of the first-aid kit and

the warning triangle

The following information is for the first aid kit and warning triangle from the

ŠKODA Original accessories valid.

For another first aid kit and warning triangle the storage compartments may

possibly be too small.

First-aid box

The first-aid box can be attached by a strap to the right-hand side of the boot

» Fig. 153 .

Warning triangle

The warning triangle can be inserted into the cladding of the rear wall and se-

cured with the fastener tape » Fig. 153.

Undo / secure fastening strap

›

Press the latch on the connector in the direction of arrow

1

» Fig. 153 .

›Release strap A in the direction of arrow 2.›Pull strap A against arrow direction 2 until it locks into place.

Pay attention to the expiration date of the first-aid kit.WARNINGThe first-aid kit and warning triangle must always be secured safely so that

they do not come loose when making an emergency braking or in a vehicle

collision which could cause injuries to occupants.

Note

We recommend using a first-aid kit from ŠKODA Original Accessories, which

are available from a ŠKODA Partner.

reflective vest

Fig. 154

Storage compartment for the re-

flective vest

The reflective vest can be stored in a bracket under the driver's seat » Fig. 154.

fire extinguisher

Fig. 155

Fire extinguisher

The fire extinguisher is attached by two straps in a holder underneath the driv-

er's seat.

156Do-it-yourself

Page 159 of 204

Removing/attaching›Loosen the two straps by pulling the buckles in the direction of the arrow

» Fig. 155 .›

Remove the fire extinguisher.

›

For mounting, fit the fire extinguisher back into the holder and secure it with

straps.

Please read the instructions which are attached to the fire extinguisher.

Pay attention to the expiration date of the fire extinguisher. Proper function-

ing of the fire extinguisher is not assured once it has passed its expiry date.

WARNINGThe fire extinguisher must always be secured safely so that they do not

come loose when making an emergency braking or in a vehicle collision

which could cause injuries to occupants.

Note

The fire extinguisher is part of the scope of delivery in certain countries only.

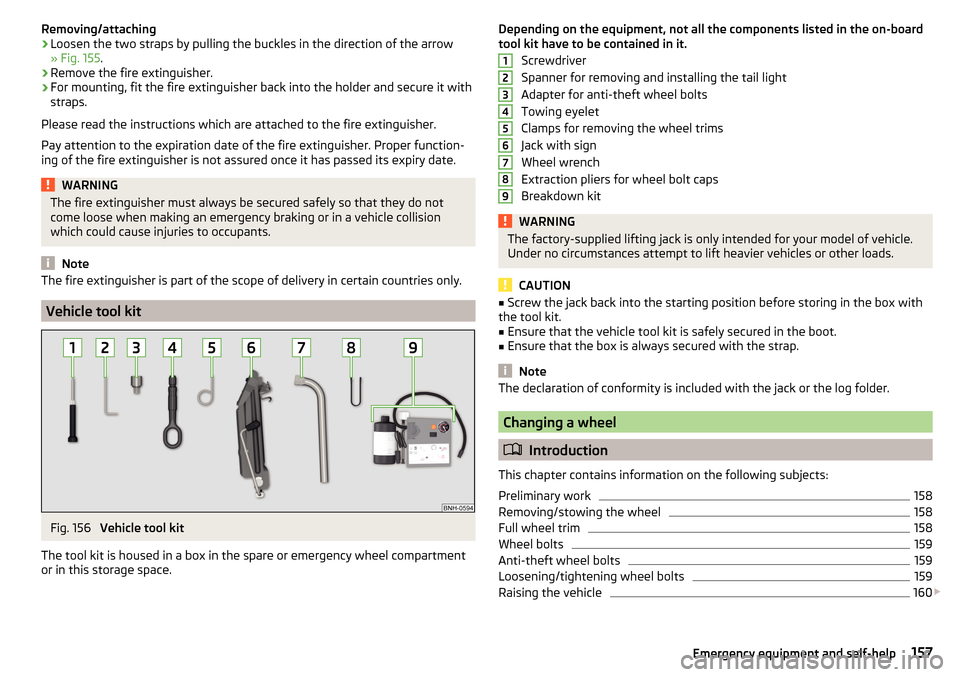

Vehicle tool kit

Fig. 156

Vehicle tool kit

The tool kit is housed in a box in the spare or emergency wheel compartment

or in this storage space.

Depending on the equipment, not all the components listed in the on-board

tool kit have to be contained in it.

Screwdriver

Spanner for removing and installing the tail light

Adapter for anti-theft wheel bolts

Towing eyelet

Clamps for removing the wheel trims

Jack with sign

Wheel wrench

Extraction pliers for wheel bolt caps

Breakdown kitWARNINGThe factory-supplied lifting jack is only intended for your model of vehicle.

Under no circumstances attempt to lift heavier vehicles or other loads.

CAUTION

■ Screw the jack back into the starting position before storing in the box with

the tool kit.■

Ensure that the vehicle tool kit is safely secured in the boot.

■

Ensure that the box is always secured with the strap.

Note

The declaration of conformity is included with the jack or the log folder.

Changing a wheel

Introduction

This chapter contains information on the following subjects:

Preliminary work

158

Removing/stowing the wheel

158

Full wheel trim

158

Wheel bolts

159

Anti-theft wheel bolts

159

Loosening/tightening wheel bolts

159

Raising the vehicle

160

123456789157Emergency equipment and self-help

Page 160 of 204

Remove the wheel / fix161Follow-up work161

For your own safety and the safety of the passengers, the following instruc-

tions must be observed before changing a wheel on the road.

Switch on the hazard warning lights system.

Place the warning triangle at the prescribed distance.

Park the vehicle as far away as possible from the flowing traffic.

Choose a location with a flat, solid surface.

Have all the occupants get out. The passengers should not stand on the

road (instead they should remain behind a crash barrier, for instance) while

the wheel is being changed.

Preliminary work

Before changing the wheel, the following work must be carried out.

›

Switch off the engine.

›

For vehicles with manual transmission select 1st gear.

›

On vehicles with automatic transmission , place the selector lever in the P

position.

›

Firmly apply the handbrake.

›

Uncouple trailer, if attached.

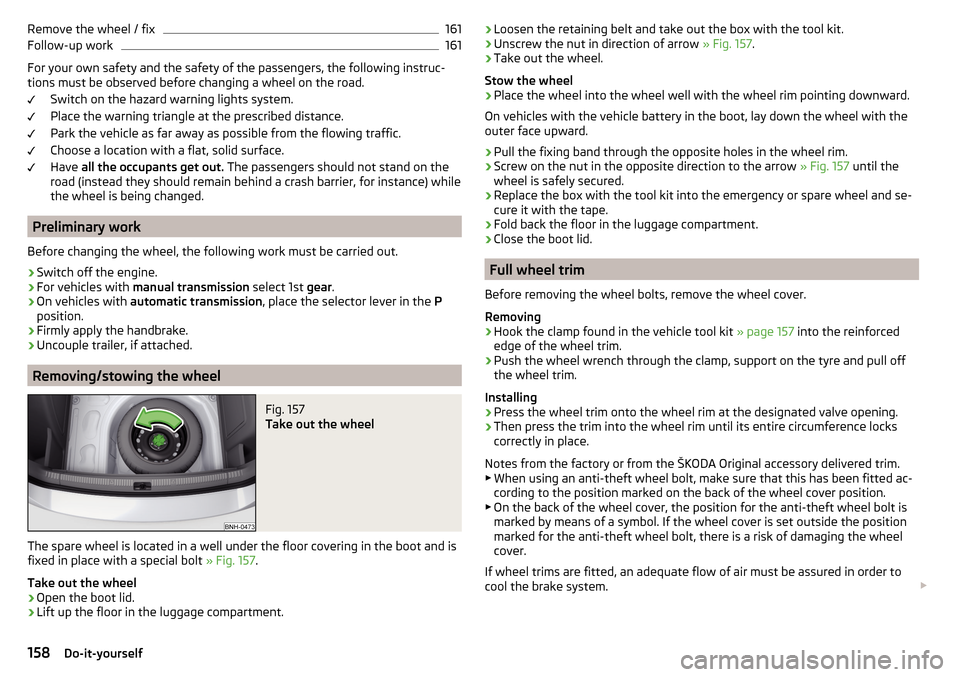

Removing/stowing the wheel

Fig. 157

Take out the wheel

The spare wheel is located in a well under the floor covering in the boot and is

fixed in place with a special bolt » Fig. 157.

Take out the wheel

›

Open the boot lid.

›

Lift up the floor in the luggage compartment.

› Loosen the retaining belt and take out the box with the tool kit.›Unscrew the nut in direction of arrow

» Fig. 157.›

Take out the wheel.

Stow the wheel

›

Place the wheel into the wheel well with the wheel rim pointing downward.

On vehicles with the vehicle battery in the boot, lay down the wheel with the

outer face upward.

›

Pull the fixing band through the opposite holes in the wheel rim.

›

Screw on the nut in the opposite direction to the arrow » Fig. 157 until the

wheel is safely secured.

›

Replace the box with the tool kit into the emergency or spare wheel and se-

cure it with the tape.

›

Fold back the floor in the luggage compartment.

›

Close the boot lid.

Full wheel trim

Before removing the wheel bolts, remove the wheel cover.

Removing

›

Hook the clamp found in the vehicle tool kit » page 157 into the reinforced

edge of the wheel trim.

›

Push the wheel wrench through the clamp, support on the tyre and pull off

the wheel trim.

Installing

›

Press the wheel trim onto the wheel rim at the designated valve opening.

›

Then press the trim into the wheel rim until its entire circumference locks

correctly in place.

Notes from the factory or from the ŠKODA Original accessory delivered trim.

▶ When using an anti-theft wheel bolt, make sure that this has been fitted ac-

cording to the position marked on the back of the wheel cover position.

▶ On the back of the wheel cover, the position for the anti-theft wheel bolt is

marked by means of a symbol. If the wheel cover is set outside the position

marked for the anti-theft wheel bolt, there is a risk of damaging the wheel

cover.

If wheel trims are fitted, an adequate flow of air must be assured in order to

cool the brake system.

158Do-it-yourself

Page 162 of 204

Release›Push the wheel wrench onto the wheel bolt to the stop.

Use the appropriate adapter for undoing the anti-theft wheel bolts » page 159.›

Grasp the end of the wrench and turn the bolt about one turn in the direction

of the arrow » Fig. 160.

Tightening

›

Push the wheel wrench onto the wheel bolt to the stop.

Use the appropriate adapter for tightening the anti-theft wheel bolts

» page 159 .

›

Grasp the end of the wrench and turn the bolt against the direction of the

arrow » Fig. 160 until it is tight.

After tightening the wheel bolts, the covering caps must be replaced.

WARNINGIf it proves difficult to undo the bolts, carefully apply pressure to the end of

the wrench with your foot. Keep hold of the vehicle when doing so, and

make sure you keep your footing.

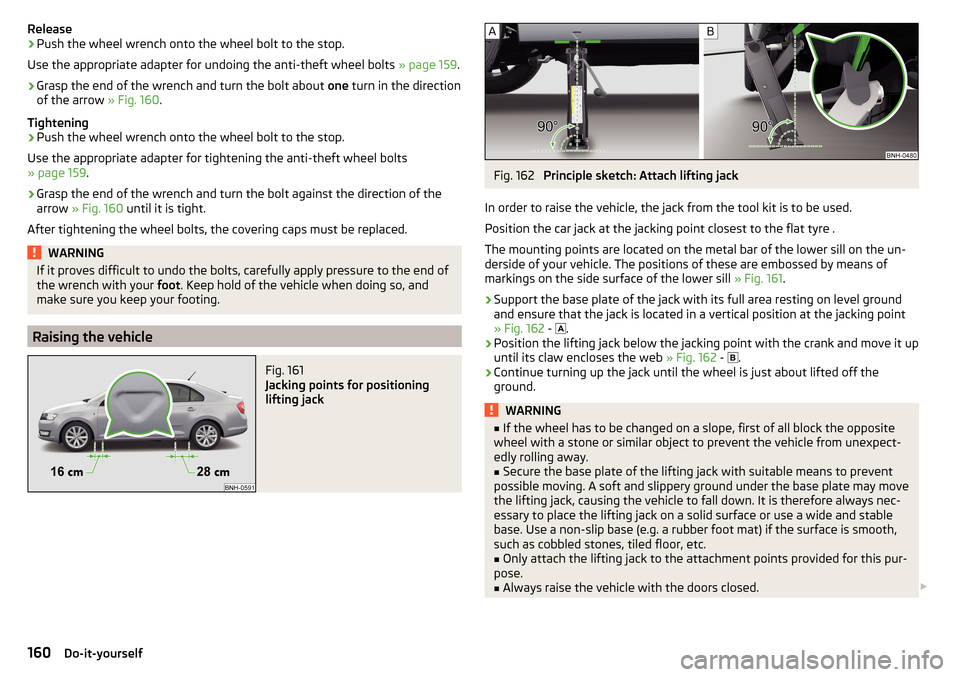

Raising the vehicle

Fig. 161

Jacking points for positioning

lifting jack

Fig. 162

Principle sketch: Attach lifting jack

In order to raise the vehicle, the jack from the tool kit is to be used.

Position the car jack at the jacking point closest to the flat tyre .

The mounting points are located on the metal bar of the lower sill on the un- derside of your vehicle. The positions of these are embossed by means of

markings on the side surface of the lower sill » Fig. 161.

›

Support the base plate of the jack with its full area resting on level ground

and ensure that the jack is located in a vertical position at the jacking point

» Fig. 162 -

.

›

Position the lifting jack below the jacking point with the crank and move it up

until its claw encloses the web » Fig. 162 -

.

›

Continue turning up the jack until the wheel is just about lifted off the

ground.

WARNING■ If the wheel has to be changed on a slope, first of all block the opposite

wheel with a stone or similar object to prevent the vehicle from unexpect-

edly rolling away.■

Secure the base plate of the lifting jack with suitable means to prevent

possible moving. A soft and slippery ground under the base plate may move

the lifting jack, causing the vehicle to fall down. It is therefore always nec-

essary to place the lifting jack on a solid surface or use a wide and stable

base. Use a non-slip base (e.g. a rubber foot mat) if the surface is smooth,

such as cobbled stones, tiled floor, etc.

■

Only attach the lifting jack to the attachment points provided for this pur-

pose.

■

Always raise the vehicle with the doors closed.

160Do-it-yourself