trailer SKODA RAPID SPACEBACK 2013 1.G User Guide

[x] Cancel search | Manufacturer: SKODA, Model Year: 2013, Model line: RAPID SPACEBACK, Model: SKODA RAPID SPACEBACK 2013 1.GPages: 193, PDF Size: 14.8 MB

Page 118 of 193

Trailer

Introduction

This chapter contains information on the following subjects:

Loading a trailer

116

Driving with a trailer

116

Anti-theft alarm system

117WARNINGAlways drive particularly carefully with the trailer.

Loading a trailer

Read and observe

on page 116 first.

The vehicle/trailer combination must be balanced. Whereby the maximum per-missible draw bar load must be utilised. If the draw bar load is too low, it jeop-

ardises the performance of the vehicle/trailer combination.

Distribution of the load

Distribute the load in the trailer in such a way that heavy items are located as

close to the axle as possible. Secure the items from slipping.

The distribution of the weight is very poor if your vehicle is unladen and the

trailer is laden. Maintain a particularly low speed if you cannot avoid driving

with this combination.

Tyre pressure

Correct the tyre inflation pressure on your vehicle for a “full load” » page 143,

Service life of tyres .

Towing capacity and trailer weight

The permissible trailer load must not be exceeded under any circumstan-

ces » page 172 , Technical data .

The details given in the vehicle's technical documentation always take prece-

dence over the details in the Owner's Manual.

The trailer loads specified apply only to altitudes up to 1,000 metres above

mean sea level.

The engine output falls as altitude increases, as does the vehicle's climbing

power. Therefore, for every additional 1,000 m in height (or part), the maximum

permissible towed weight must be reduced by 10%.

The towed weight is made up of the actual weights of the loaded towing vehi-

cle and the loaded trailer.

The trailer and draw bar load information on the type plate of the towing de-

vice is merely a test value for the towing device. The vehicle-specific values

are detailed in the vehicle documents.WARNING■ Do not exceed the maximum permissible axle and draw bar load and the

maximum permissible total or towed weight of the vehicle and the trailer -

risk of accident and serious injuries!■

A sliding cargo can adversely affect stability and driving safety significant-

ly - there is a risk of accident!

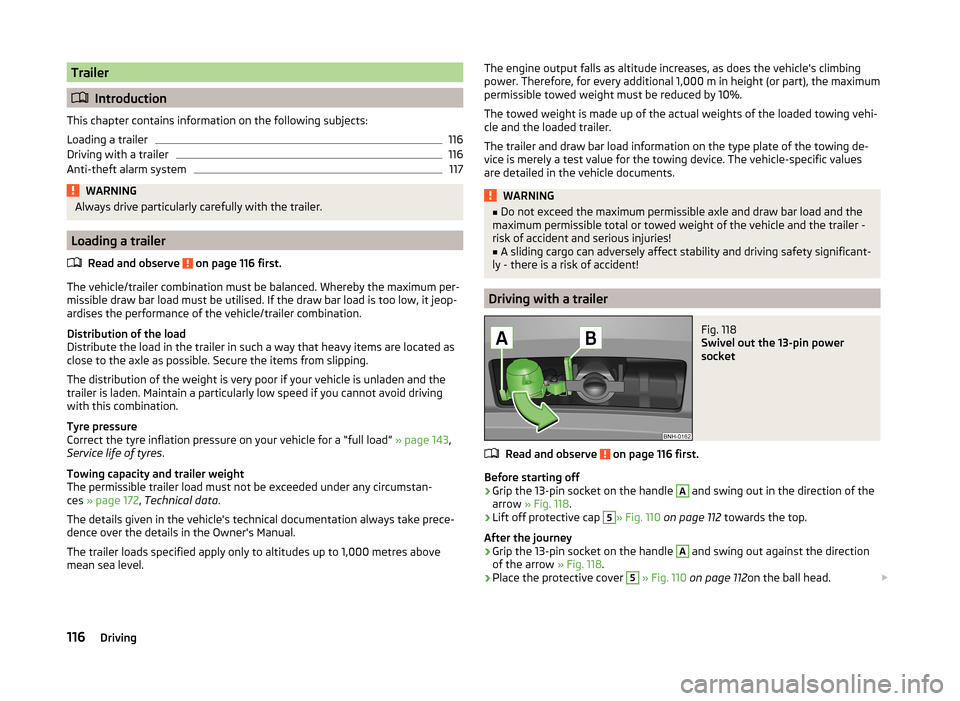

Driving with a trailer

Fig. 118

Swivel out the 13-pin power

socket

Read and observe on page 116 first.

Before starting off

›

Grip the 13-pin socket on the handle

A

and swing out in the direction of the

arrow » Fig. 118 .

›

Lift off protective cap

5

» Fig. 110 on page 112 towards the top.

After the journey

›

Grip the 13-pin socket on the handle

A

and swing out against the direction

of the arrow » Fig. 118.

›

Place the protective cover

5

» Fig. 110 on page 112 on the ball head.

116Driving

Page 119 of 193

Safety eyelet

The safety eyelet B» Fig. 118 serves to attach the breakaway cable of the

trailer.

When attaching the breakaway cable to the safety eyelet, it must sag freely

against the vehicle in all trailer positions (sharp bends, in reverse etc.) sag .

Exterior mirrors

You can have additional exterior mirrors fitted if you are not able to see the

traffic behind the trailer with the standard rear-view mirrors. The national legal

requirements must be observed.

Headlights

The front of the vehicle may lift up when a trailer is being towed and the head- lights may dazzle other road users.

Adjust the headlights using the headlight beam control » page 54.

Driving speed

For safety reasons, do not drive faster than 80 km/h when towing a trailer.

Immediately reduce your speed as soon as even the slightest swaying of the

trailer is detected. Never attempt to stop the trailer from “swaying” by acceler-

ating.

Brakes

Apply the brakes in good time! If the trailer is fitted with a trailer brake, apply

the brakes gently at first, then brake firmly. This will avoid brake jolts resulting

from the trailer wheels locking.

On downhill sections shift down a gear in good time to also use the engine as

a brake.

Engine overheating

If the needle for the coolant temperature gauge moves into the right-hand

area or the red area of the scale, the speed must be reduced immediately.

Stop and switch off the engine if the warning light lights up and/or starts to

blink in the instrument » page 32cluster. Wait a few minutes and check the

level of coolant » page 137.

The following guidelines must be observed » page 32.

The coolant temperature level can be reduced by switching on the heating.WARNING■ Never use the safety eyelet for towing!■Adapt your speed to the conditions of the road surface and to the traffic

situation.■

Improper or incorrectly connected electrical installations can energise the

trailer and cause functional faults to the vehicle's entire electrical system

as well as accidents and severe injuries.

■

Works on the electrical system must only be carried out by specialist ga-

rages.

■

Never directly connect the trailer's electrical system with the electrical

connections for the tail lights or other current sources.

■

After coupling the trailer and connecting the power socket, check that

the rear lights on the trailer are working correctly.

Note

■ If there is an error in the trailer lighting, check the fuses in the fuse box in

the dash panel » page 164.■

Contact between the breakaway cable and the safety eyelet can result in

mechanical wear on the surface protection of the eyelet. Such wear does not

impair the functioning of the safety eyelet and does not constitute a fault. It is

excluded from the warranty coverage.

■

If you tow a trailer frequently, you should also have your vehicle inspected

between service intervals.

■

The handbrake on the towing vehicle must be applied when coupling and un-

coupling the trailer.

Anti-theft alarm system

Read and observe

on page 116 first.

When the vehicle is locked, the alarm is activated when the electrical connec-tion to the trailer is interrupted.

Always switch off the anti-theft alarm system before a trailer is coupled or un-

coupled » page 49 .

Conditions for including a trailer in the anti-theft alarm system. The vehicle is factory-fitted with an anti-theft alarm system and towing

device.

The trailer is electrically connected to the towing vehicle via the trailer

socket.

117Hitch and trailer

Page 120 of 193

The electrical system of the vehicle and trailer is functional.

The vehicle is locked with the vehicle key and the anti-theft alarm system

is activated.

CAUTION

For technical reasons, trailers with rear LED lights cannot be connected to the

anti-theft alarm system.118Driving

Page 148 of 193

SettingFig. 132

Button for setting the tyre infla-

tion pressure control value

Read and observe and on page 145 first.

›

Inflate all of the tyres to the specified inflation pressure » page 143.

›

Switch on the ignition.

›

Press the symbol button

» Fig. 132 for longer than 2 seconds.

If the warning light in the instrument cluster lights up and does not go out

after the system configuration, this indicates a system fault.

If there is a blinking light in the instrument cluster, then there is a system

fault.

Display

Read and observe

and on page 145 first.

The control light in the instrument cluster lights up when any of the follow-

ing conditions are met.

› The tyre inflation pressure is low.

› The structure of the tyre is damaged.

› The vehicle is loaded on one side.

› The wheels of one axle are loaded more heavily (e.g. when towing a trailer or

when driving uphill or downhill).

› Snow chains are mounted.

› The spare wheel is mounted.

› One wheel per axle was changed.

WARNING■

When illuminated control lights light up in the instrument cluster lights,

immediately reduce speed and avoid violent steering and brake manoeu-

vres. Stop the vehicle as soon as possible and inspect the tyres and their

inflation pressure.■

Under certain circumstances (e.g. sporty style of driving, wintry or un-

paved roads) the warning light

in the instrument cluster may be delayed

or not light up at all.

Reserve and temporary spare wheel

Introduction

This chapter contains information on the following subjects:

Change

147

Spare wheel

147

Fit a wheel in the appropriate dimensions and design as soon as possible.

WARNING■ If, in the event of a puncture, it is necessary to fit a spare wheel with a

tyre without a dedicated running direction or with the opposite direction of

rotation, drive carefully as the optimal characteristics of the tyre are no lon-

ger applicable in this situation.■

If the dimensions or design of the spare wheel differ from the tyres fitted

to the vehicle (e.g. winter tyres or low-profile tyres), it must only be used

briefly in the event of a puncture and if an appropriately cautious style of

driving is adopted.

146General Maintenance

Page 152 of 193

fire extinguisherFig. 136

Fire extinguisher

The fire extinguisher is attached by two straps in a holder underneath the driv-

er's seat.

Removing/attaching

›

Loosen the two straps by pulling the buckles in the direction of the ar-

row » Fig. 136 .

›

Remove the fire extinguisher.

Follow these steps in the reverse order for attachment.

Please read carefully the instructions which are attached to the fire extin-

guisher.

The fire extinguisher must be checked by an authorised person once a year.

The national legal requirements must be observed.

WARNINGThe fire extinguisher must always be secured safely so that they do not

come loose when making an emergency braking or in a vehicle collision

which could cause injuries to occupants.

Note

■ The fire extinguisher must comply with national legal requirements.■Pay attention to the expiration date of the fire extinguisher. Proper function-

ing of the fire extinguisher is not assured once it has passed its expiry date.■

The fire extinguisher is part of the scope of delivery in certain countries only.

Vehicle tool kitFig. 137

Vehicle tool kit

The vehicle tool kit and the jack with sticker are housed in a plastic box in the

spare wheel or in the storage space for the spare wheel. There is also space

here for the removable ball rod for the trailer towing device. The box is attach-

ed with a strap on the spare wheel.

Depending on the equipment, not all the components listed in the on-board

tool kit have to be contained in it.

Possible components of the on-board tool kit » Fig. 137

Screwdriver

Spanner for removing and installing the tail light

Adapter for anti-theft wheel bolts

Towing eyelet

Clamps for removing the wheel trims

Car jack

Wheel wrench

Extraction pliers for wheel bolt caps

Replacement bulb set

Screw the car jack back into its initial position after use in order to store it back

in the box with the vehicle tool kit.

123456789150Do-it-yourself

Page 154 of 193

›Move the gear shift lever into

Neutral or move the selector lever for the au-

tomatic gearbox into position P.›

Firmly apply the handbrake.

›

Uncouple any trailers.

›

Remove the vehicle tool kit » page 150 and the spare wheel » page 146 from

the boot.

Full wheel trim

Read and observe

on page 151 first.

Removing

›

Hook the clamp found in the vehicle tool kit » page 150into the reinforced

edge of the wheel trim.

›

Push the wheel wrench through the clamp, support on the tyre and pull off

the wheel trim.

Installing

›

Press the wheel trim onto the wheel rim at the designated valve open-

ing » .

›

Then press the trim into the wheel rim until its entire circumference locks

correctly in place.

CAUTION

■ Use the pressure of your hand only, do not strike the full wheel trim! The

cover could be damaged.■

When using the anti-theft wheel bolt, ensure that it is in the hole in the

valve area.

■

If wheel trims are fitted, it must be ensured that an adequate flow of air is

assured to cool the brake system. We recommend that you use child seats

from ŠKODA Original Accessories.

Wheel boltsFig. 138

Remove the cap

Read and observe on page 151 first.

Removing

›

Push the extraction pliers » page 150sufficiently far onto the cap until the in-

ner catches of the pliers are positioned at the collar of the cap.

›

Remove the cap in the direction of the arrow » Fig. 138.

Installing

›

Push the cap onto the wheel bolt up to the stop.

The wheel bolt caps are housed in a plastic box in the spare wheel or in the

storage space for the spare wheel.

Changing a wheel

Read and observe

on page 151 first.

›

Remove the full wheel trim or the caps of the wheel bolts.

›

First of all slacken the anti-theft wheel bolt and then the other wheel bolts.

›

Jack up the vehicle until the wheel that needs changing is clear of the

ground.

›

Unscrew the wheel bolts and place them on a clean surface (cloth, paper, etc.).

›

Remove the wheel carefully.

›

Attach the spare wheel and slightly screw on the wheel bolts.

›

Lower the vehicle.

›

Alternately tighten wheel bolts opposite (diagonally) with the wheel wrench.

Tighten the anti-theft wheel bolt last.

›

Replace the wheel trim or the caps.

152Do-it-yourself

Page 158 of 193

Inflation hose with plug

Air compressor

Button for releasing the tyre pressure

12 volt cable connector

Tyre inflation hose

Tyre inflation pressure indicator

ON and OFF switch

Tyre inflater bottle with sealing agent

Replacement valve core

The valve remover 2

has a slot at its lower end which fits into the valve core.

Preparations for using the breakdown kit

Read and observe

on page 155 first.

Always change a wheel on a level surface as far as possible.

The following preparatory work must be carried out before using the break-

down kit.

›

Have all of the occupants get out of the vehicle. While changing a tyre, the

occupants of the vehicle should not stand on the road (they should instead

remain behind a crash barrier).

›

Switch off the engine.

›

Move the gear shift lever into Neutral or move the selector lever for the au-

tomatic gearbox into position P.

›

Firmly apply the handbrake.

›

Check that you can carry out the repairs with the breakdown kit » page 155.

›

Uncouple any trailers.

›

Remove the breakdown kit from the boot.

›

Stick the sticker

1

» Fig. 143 on page 155 on the dashboard in the driver's

field of view.

›

Do not remove the foreign body, e.g. screw or nail, from the tyre.

›

Unscrew the valve cap.

›

Use the valve remover

2

to unscrew the valve core and place it on a clean

surface (rag, paper, etc.).

34567891011Sealing and inflating the tyre

Read and observe

on page 155 first.

Sealing

›

Forcefully shake the tyre inflater bottle

10

» Fig. 143 on page 155 back and

forth several times.

›

Firmly screw the inflation hose

3

onto the tyre inflater bottle

10

in a clock-

wise direction. The film on the cap is pierced automatically.

›

Remove the plug from the inflation hose

3

and plug the open end fully onto

the tyre valve.

›

Hold the bottle

10

with the bottom facing upwards and fill all of the sealing

agent from the tyre inflater bottle into the tyre.

›

Remove the empty tyre inflater bottle from the valve.

›

Screw the valve core back into the tyre valve using the valve remover

2

.

Inflating

›

Screw the tyre inflation hose

7

» Fig. 143 on page 155 of the air compressor

firmly onto the tyre valve.

›

Start the engine and run it in idle.

›

Plug the connector

6

into 12 Volt socket » page 71, 12-Volt power outlet .

›

Switch on the air compressor with the ON and OFF switch

9

.

›

Allow the air compressor to run until a pressure of 2.0-2.5 bar is achieved.

Maximum run time of 8 minutes »

›

Switch off the air compressor.

›

If you cannot reach an air pressure of 2.0–2.5 bar, unscrew the tyre inflation

hose

7

from the tyre valve.

›

Drive the vehicle 10 metres forwards or backwards to allow the sealing agent

to “distribute” in the tyre.

›

Firmly screw the tyre inflation hose

7

back onto the tyre valve and repeat

the inflation process.

›

If you cannot reach the required tyre inflation pressure here either, this

means the tyre has sustained too much damage. You cannot seal with tyre with the breakdown kit »

.

›

Switch off the air compressor.

›

Remove the tyre inflation hose

7

from the tyre valve.

Once a tyre inflation pressure of 2.0–2.5 bar is achieved, continue the journey

at a maximum speed of 80 km/h (50 mph).

Check the tyre inflation pressure after driving for 10 minutes » page 157.

156Do-it-yourself

Page 161 of 193

Driver of the tow vehicle›Engage the clutch gently when starting off or depress the accelerator partic-

ularly gently if the vehicle is fitted with an automatic gearbox.›

Only then, approach correctly when the rope is taut.

The maximum towing speed is 50 km/h.

Driver of the towed vehicle

›

Switch on the ignition so that the steering wheel is not locked and so that

the turn signal lights, horn, windscreen wipers and windscreen washer sys-

tem can be used.

›

Take the vehicle out of gear or move the selector lever into position N if the

vehicle is fitted with an automatic gearbox.

Please note that the brake servo unit and power steering only operate if the

engine is running. If the engine is not running, significantly more physical force

is required to depress the brake pedal and steer the vehicle.

If using a tow rope, ensure that it is always kept taught.

Towing another vehicle requires a certain amount of practice. Both drivers

should be familiar with the particular points about towing a vehicle. Unskilled

drivers should not attempt to tow another vehicle or to be towed in one.

The vehicle must be transported on a special breakdown vehicle or trailer if it

is not possible to tow the vehicle in the way described or if the towing dis-

tance is greater than 50 km.

Attach the tow rope or the tow bar to the towing eyes » page 159

or » page 160 to the detachable ball head of the towing equip-

ment » page 112 .

WARNING■

The tow rope must not be twisted as it may in certain circumstances re-

sult in the front towing eye becoming unscrewed from your vehicle.■

Do not use one-sided twisted tow rope, because the towing eye could

become unscrewed on the vehicle under certain circumstances.

■

When towing, respect the national legal provisions, especially those

which relate to the identification of the towing vehicle and the vehicle be- ing towed.

CAUTION■ Do not start the engine by towing – there is a risk of damaging the engine

and the catalytic converter! The battery from another vehicle can be used as a

jump-start aid » page 157, Jump-starting .■

If the gearbox no longer contains any oil because of a defect, your vehicle

must only be towed with the drive wheels raised clear of the ground or on a

special breakdown vehicle or trailer.

■

To protect both vehicles when tow-starting or towing, the tow rope should

be elastic. Thus only plastic fibre rope or a rope made out of a similarly elastic

material should be used.

■

There is always a risk of excessive stresses and damage resulting at the

points to which you attach the tow rope or tow bar when you attempt to tow a

vehicle which is not standing on a paved road.

Note

We recommend using a tow rope from ŠKODA Original Accessories, which is

available from a ŠKODA Partner.

Front towing eye

Fig. 146

Removing the cap/installing the towing eye

Read and observe

and on page 159 first.

Removing/installing the cap

›

Press on the cap in the area

A

» Fig. 146 .

›

Remove the cap in the direction of the arrow

1

.

›

After unscrewing the cap of the towing eye

B

, insert the cap in area

A

and

then press the opposite side of the cap.

The cap must engage firmly.

159Emergency equipment and self-help

Page 166 of 193

CAUTION■“Never repair” fuses, and do not replace them with fuses of a higher amper-

age – risk of fire! This may also cause damage at other points in the electrical

system.■

If a newly inserted fuse blows again after a short time, have the electrical

system checked as quickly as possible by a specialist garage.

■

A blown fuse is recognisable by the molten metal strip. Replace the faulty

fuse with a new one of the same amperage.

Note

■

We recommend always carrying replacement fuses in the vehicle. A box of

replacement fuses can be purchased from ŠKODA Original Accessories.■

There can be several power-consuming devices for one fuse.

■

Multiple fuses may exist for a single power-consuming device.

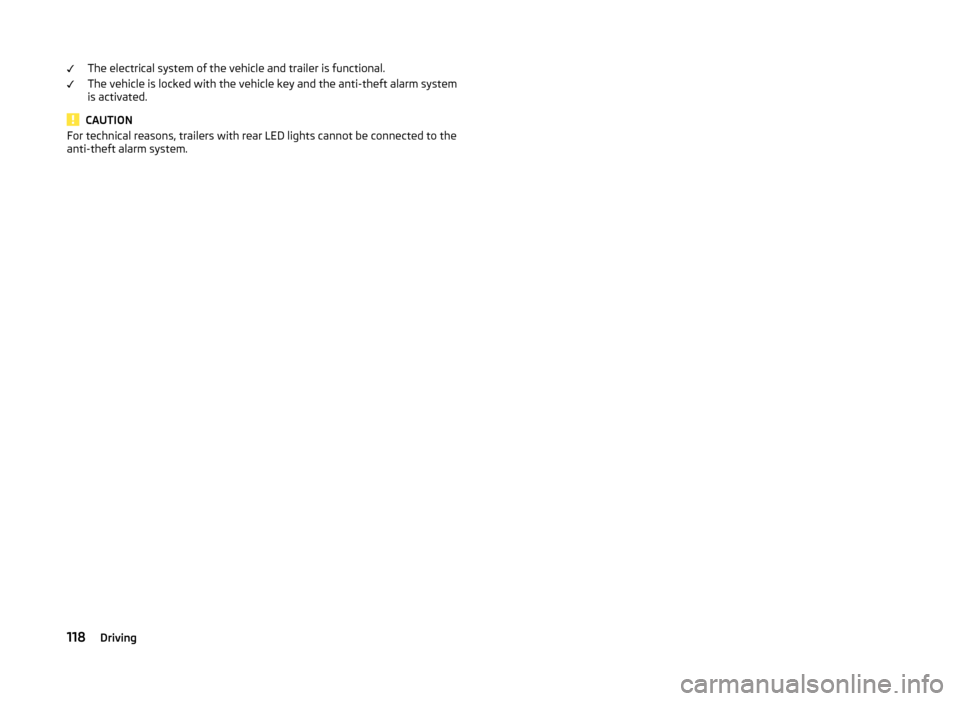

Fuses in the dash panel

Fig. 154

Underside of the dash panel: Dis-

tribution board cover

Read and observe and on page 163 first.

The fuses are located on the bottom of the dash panel behind a cover.

Replacing fuses

›

Remove the cover of the fuse box » Fig. 154 in the direction of the arrow.

›

Remove the plastic clip from the holder in the fuse box cover in the dash

panel.

›

Place the clip on the respective fuse and pull this fuse out.

›

Insert a new fuse.

›

Reinsert the cover into the dash panel in the opposite direction to the arrow

such that the guide pins are guided into the dash panel openings.

Carefully push the cover in.

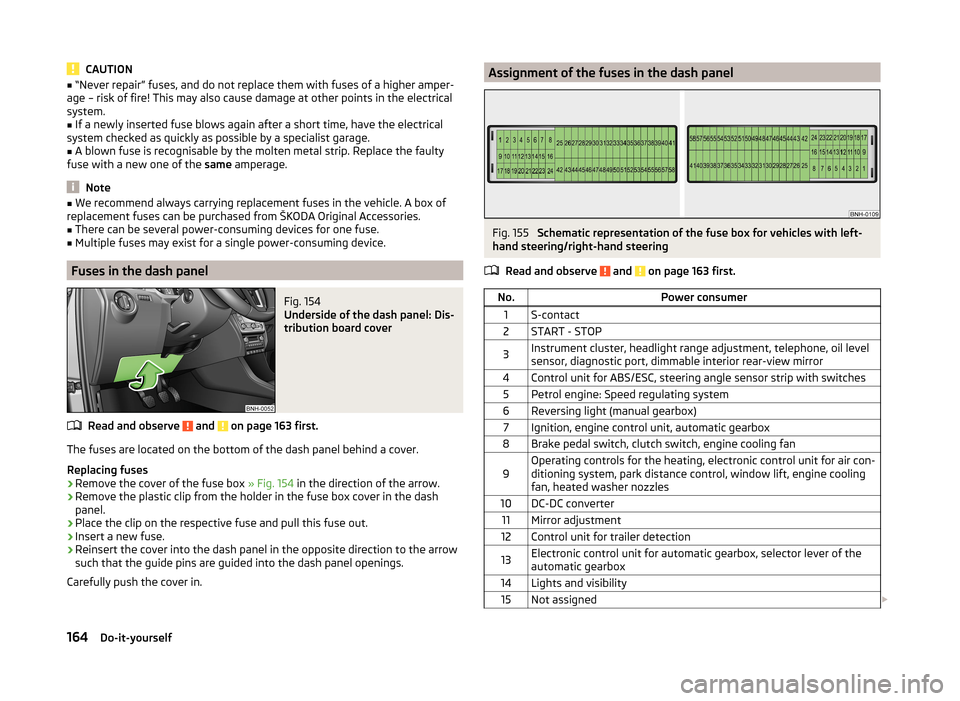

Assignment of the fuses in the dash panelFig. 155

Schematic representation of the fuse box for vehicles with left-

hand steering/right-hand steering

Read and observe

and on page 163 first.

No.Power consumer1S-contact2START - STOP3Instrument cluster, headlight range adjustment, telephone, oil level

sensor, diagnostic port, dimmable interior rear-view mirror4Control unit for ABS/ESC, steering angle sensor strip with switches5Petrol engine: Speed regulating system6Reversing light (manual gearbox)7Ignition, engine control unit, automatic gearbox8Brake pedal switch, clutch switch, engine cooling fan9Operating controls for the heating, electronic control unit for air con-

ditioning system, park distance control, window lift, engine cooling

fan, heated washer nozzles10DC-DC converter11Mirror adjustment12Control unit for trailer detection13Electronic control unit for automatic gearbox, selector lever of the

automatic gearbox14Lights and visibility15Not assigned 164Do-it-yourself

Page 174 of 193

Technical data

Technical data

Vehicle data

Introduction

This chapter contains information on the following subjects:

Vehicle characteristics

172

Operating weight and payload

172

Measurement of fuel consumption and CO 2 emissions according to ECE

Regulations and EU Directives

173

Dimensions

174

Angle

175

Vehicle-specific details per engine type

176

The details given in the vehicle's technical documentation always take prece-

dence over the details in the Owner's Manual.

The listed performance values were determined without performance-reduc- ing equipment, e.g. air conditioning system.

Vehicle characteristics

Fig. 169

Vehicle data sticker/type plate

Vehicle data sticker

The vehicle data sticker » Fig. 169 -

is located on the base of the luggage

compartment and is also stuck into the service schedule.

The vehicle data sticker contains the following data.

Vehicle identification number (VIN)

Vehicle type

Gearbox code/paint number/interior equipment/engine output/engine

code

Partial vehicle description

Type plate

The type plate » Fig. 169 -

is located at the bottom of the B-pillar on the

driver's side.

The type plate contains the following data. Vehicle identification number (VIN)

Maximum permissible gross weight

Maximum permissible towed weight (towing vehicle and trailer)

Maximum permissible front axle load

Maximum permissible rear axle load

Vehicle identification number (VIN)

The vehicle identification number - VIN (vehicle body number) is stamped into

the engine compartment on the right hand suspension strut dome. This num-

ber is also located on a sign on the lower left hand edge below the windscreen

(together with a VIN bar code), and on the type plate.

Engine number

The engine number (three-digit identifier and serial number) is stamped on the engine block.WARNINGDo not exceed the specified maximum permissible weights – risk of acci-

dent and damage!

Operating weight and payload

Operating weight

This value represents the minimum operating weight without additional

weight-increasing equipment such as air conditioning system, spare wheel, or

trailer hitch.

The specified operating weight is for orientation purposes only.

123456789172Technical data