torque SKODA RAPID SPACEBACK 2013 1.G Owner's Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 2013, Model line: RAPID SPACEBACK, Model: SKODA RAPID SPACEBACK 2013 1.GPages: 193, PDF Size: 14.8 MB

Page 7 of 193

AbbreviationsAbbreviationDefinitionrpmEngine revolutions per minuteA2DPa Bluetooth software profile for a one-way transfer of audio

dataABSAnti-lock brake systemAGAutomatic gearboxAGMVehicle battery typeTCSTraction controlCO 2 in g/kmdischarged quantity of carbon dioxide in grams per driven

kilometreDPFDiesel particle filterDSGAutomatic double clutch gearboxEDLElectronic differential lockECEEconomic Commission for EuropeEPCEPC fault lightESCElectronic Stability ControlEUEuropean UnionGSMGlobal System for Mobile communicationsHBAHydraulic brake assistHHCUphill start assistkWKilowatt, measuring unit for the engine outputMDIInputs for connecting external devicesMFDMultifunction displayMGManual gearboxMPIGasoline engine with a multi-point fuel injectionN1Panel van intended exclusively or mainly for the transporta-

tion of goodsNmNewton meter, measuring unit for the engine torquePINpersonal identification numberSIM carda card for the identification of the mobile network operatorAbbreviationDefinitionTDI CRDiesel engine with turbo charging and common rail injection

systemTSIPetrol engine with turbocharging and direct injection5Abbreviations

Page 153 of 193

WARNINGThe factory-supplied lifting jack is only intended for your model of vehicle.

Under no circumstances attempt to lift heavier vehicles or other loads.

CAUTION

■ Ensure that the vehicle tool kit is safely secured in the boot.■Ensure that the box is always secured with the strap.

Changing a wheel

Introduction

This chapter contains information on the following subjects:

Preliminary work

151

Full wheel trim

152

Wheel bolts

152

Changing a wheel

152

Follow-up work

153

Loosening/tightening wheel bolts

153

Raise vehicle

153

Securing wheels against theft

154WARNING■ If you are in flowing traffic, switch on the hazard warning light system

and set up the warning triangle at the prescribed distance! The national le-

gal requirements must be observed.■

Park the vehicle as far away as possible from the flow of traffic. Park on

as flat and firm a surface as possible.

■

The following instructions must be followed if the vehicle is subsequently

fitted with tyres or rims that differ from the factory-fitted ones » page 144,

New tyres .

WARNINGNotes for vehicle lifting■If the wheel has to be changed on a slope, first of all block the opposite

wheel with a stone or similar object to prevent the vehicle from unexpect-

edly rolling away.WARNING (Continued)■ Secure the base plate of the lifting jack with suitable means to prevent

possible moving. A soft and slippery ground under the base plate may move

the lifting jack, causing the vehicle to fall down. It is therefore always nec-

essary to place the lifting jack on a solid surface or use a wide and stable

base. Use a non-slip base (e.g. a rubber foot mat) if the surface is smooth,

such as cobbled stones, tiled floor, etc.■

Only attach the lifting jack to the attachment points provided for this pur-

pose.

■

Always raise the vehicle with the doors closed.

■

Never position any body parts, such as arms or legs under the vehicle,

while the vehicle is raised with a lifting jack.

■

When the vehicle is raised, never start the engine.

WARNINGInformation on the wheel bolts■The wheel bolts must be clean and must turn easily. Never apply grease

or oil.■

The prescribed tightening torque of the wheel bolts for steel and light al-

loy wheels is 120 Nm.

■

If the wheel bolts are tightened to a too low tightening torque, the rim

can come loose when the car is moving. A tightening torque which is too

high can damage the bolts and threads and this can result in permanent

deformation of the contact surfaces on the rim.

■

In case of incorrect treatment of the wheel bolts, the wheel can loosen

when the car is moving.

Note

The national legal requirements must be observed when changing a wheel.

Preliminary work

Read and observe

on page 151 first.

Always change a wheel on a level surface as far as possible.

The following steps must be carried out before actually changing the wheel:

›

Have all of the occupants get out of the vehicle. While changing a tyre, the

occupants of the vehicle should not stand on the road (they should instead

remain behind a crash barrier).

›

Switch off the engine.

151Emergency equipment and self-help

Page 155 of 193

WARNING■All bolts must be clean and must turn easily.■Under no circumstances grease or oil the wheel bolts!■

When fitting unidirectional tyres, ensure that the direction of rotation is

correct » page 145 .

Follow-up work

Read and observe

on page 151 first.

The following steps must also be performed after changing the wheel.

›

Stow and attach the replaced wheel in the spare wheel well using a special

bolt » page 146 .

›

Stow the tool kit in the space provided and secure using the band.

›

Check the tyre pressure on the installed spare wheel as soon as possible.

›

Have the tightening torque of the wheel bolts checked with a torque

wrench as soon as possible.

Replace the damaged wheel or consult a specialist garage about repair op-

tions.

WARNING■ If it is established when changing a wheel that the wheel bolts are corro-

ded and difficult to move, then these must be replaced.■

Drive cautiously and only at a moderate speed until the tightening torque

has been checked.

Loosening/tightening wheel bolts

Fig. 139

Changing a wheel: Loosening the

wheel bolts

Read and observe on page 151 first.

Loosening

›

Push the wheel wrench onto the wheel bolt to the stop 1)

.

›

Grasp the end of the wrench and turn the bolt about one turn in the direction

of the arrow » Fig. 139.

Tightening

›

Push the wheel wrench onto the wheel bolt to the stop 1)

.

›

Grasp the end of the wrench and turn the bolt against the direction of the

arrow » Fig. 139 until it is tight.

WARNING■

Undo the wheel bolts only a little (about one turn) provided that the vehi-

cle has not yet been jacked up. Otherwise the wheel could become loose

and fall off.■

If it proves difficult to undo the bolts, carefully apply pressure to the end

of the wrench with your foot. Keep hold of the vehicle when doing so, and

make sure you keep your footing.

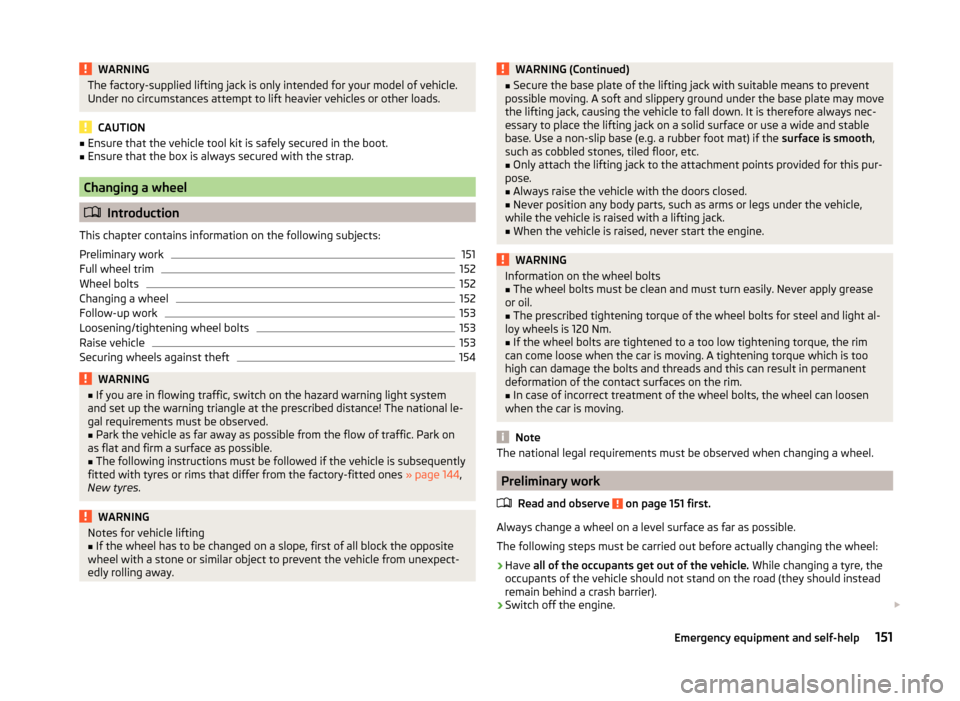

Raise vehicle

Fig. 140

Jacking points for positioning

lifting jack

1)

Use the appropriate adapter for undoing and tightening the anti-theft wheel bolts

» page 154.

153Emergency equipment and self-help

Page 156 of 193

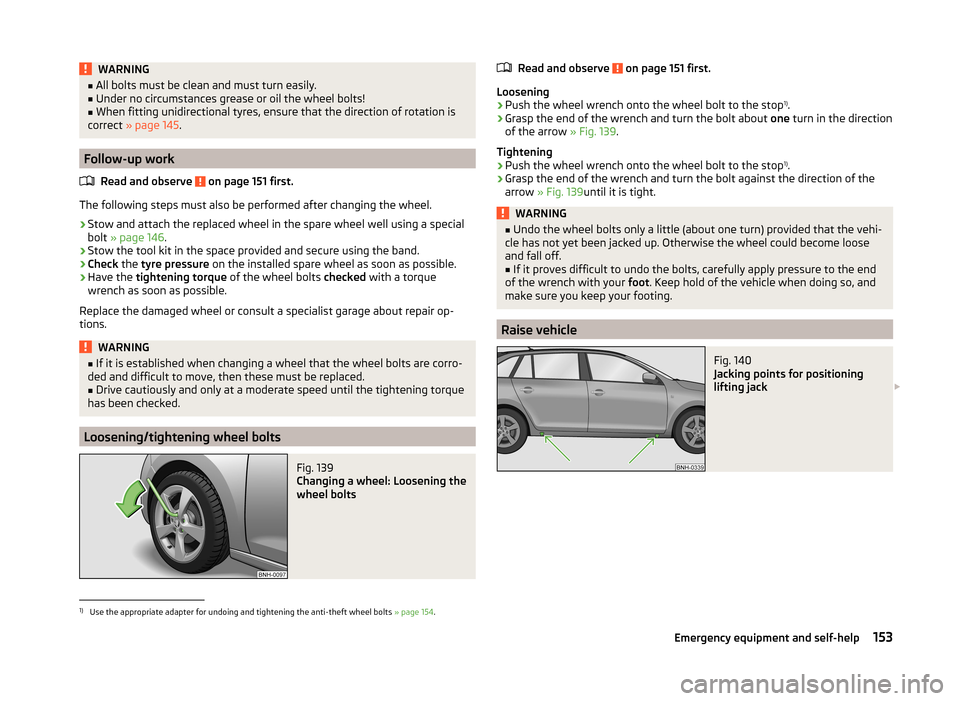

Fig. 141

Attach lifting jack

Read and observe

on page 151 first.

Position the lifting jack below the jacking point closest to the faulty

wheel » Fig. 140 .

The mounting points are located on the metal bar of the lower sill on the un-

derside of your vehicle » Fig. 140.

›

Support the base plate of the jack with its full area resting on level ground

and ensure that the jack is located in a vertical position at the jacking

point » Fig. 141 -

.

›

Position the lifting jack below the jacking point with the crank and move it up

until its claw encloses the web » Fig. 141 -

.

›

Continue turning up the jack until the wheel is just about lifted off the

ground.

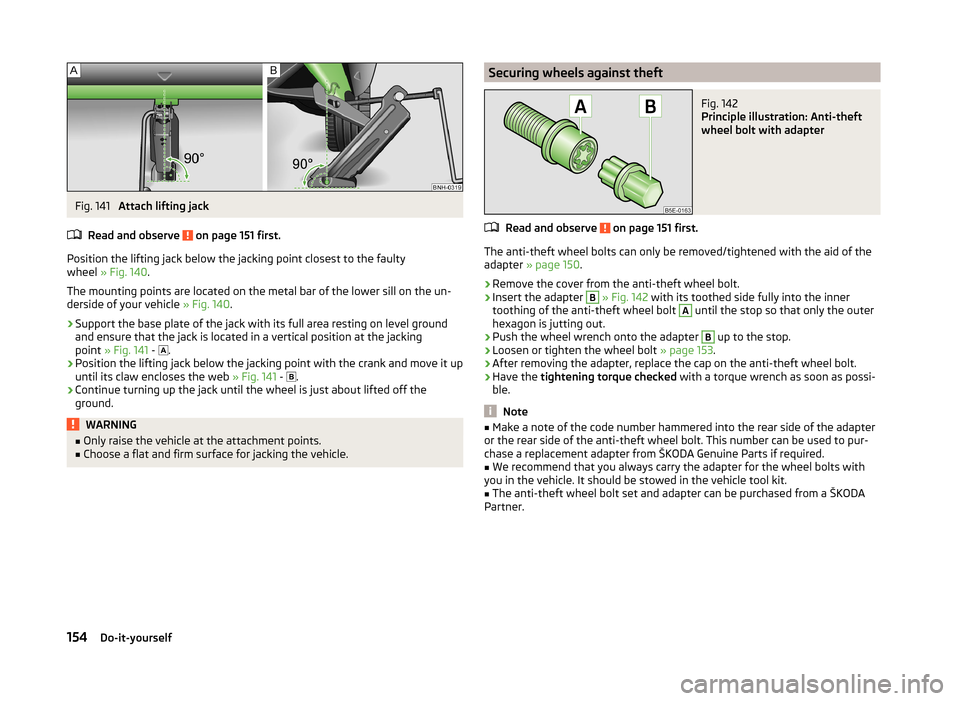

WARNING■ Only raise the vehicle at the attachment points.■Choose a flat and firm surface for jacking the vehicle.Securing wheels against theftFig. 142

Principle illustration: Anti-theft

wheel bolt with adapter

Read and observe on page 151 first.

The anti-theft wheel bolts can only be removed/tightened with the aid of the

adapter » page 150 .

›

Remove the cover from the anti-theft wheel bolt.

›

Insert the adapter

B

» Fig. 142 with its toothed side fully into the inner

toothing of the anti-theft wheel bolt

A

until the stop so that only the outer

hexagon is jutting out.

›

Push the wheel wrench onto the adapter

B

up to the stop.

›

Loosen or tighten the wheel bolt » page 153.

›

After removing the adapter, replace the cap on the anti-theft wheel bolt.

›

Have the tightening torque checked with a torque wrench as soon as possi-

ble.

Note

■ Make a note of the code number hammered into the rear side of the adapter

or the rear side of the anti-theft wheel bolt. This number can be used to pur-

chase a replacement adapter from ŠKODA Genuine Parts if required.■

We recommend that you always carry the adapter for the wheel bolts with

you in the vehicle. It should be stowed in the vehicle tool kit.

■

The anti-theft wheel bolt set and adapter can be purchased from a ŠKODA

Partner.

154Do-it-yourself

Page 178 of 193

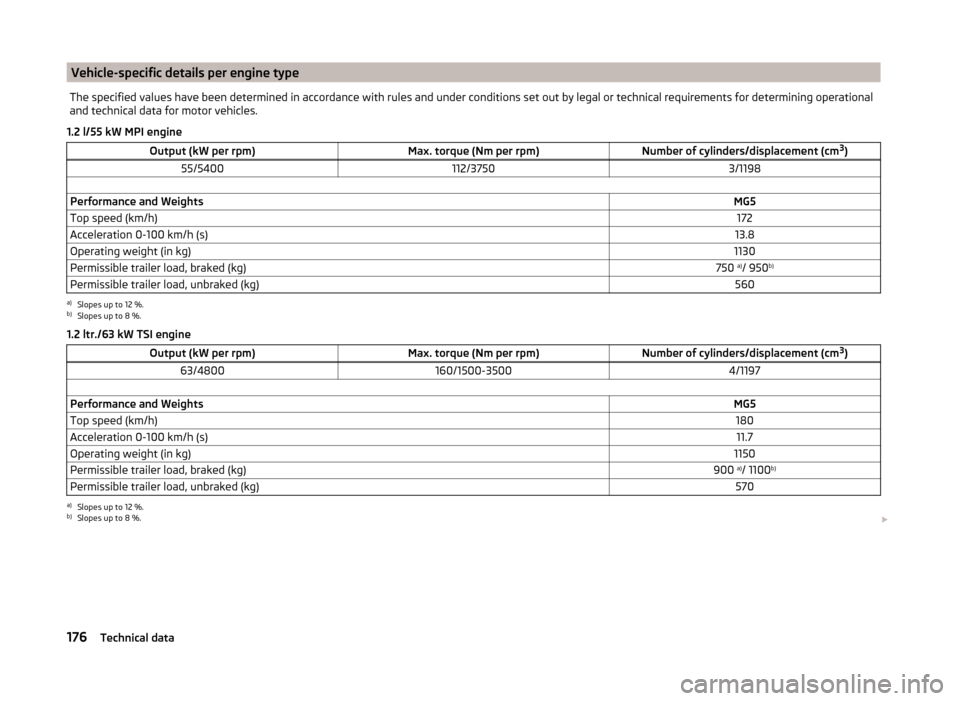

Vehicle-specific details per engine typeThe specified values have been determined in accordance with rules and under conditions set out by legal or technical requirements for determining operational

and technical data for motor vehicles.

1.2 l/55 kW MPI engine

Output (kW per rpm)Max. torque (Nm per rpm)Number of cylinders/displacement (cm 3

)55/5400112/37503/1198 Performance and WeightsMG5Top speed (km/h)172Acceleration 0-100 km/h (s)13.8Operating weight (in kg)1130Permissible trailer load, braked (kg)750 a)

/ 950 b)Permissible trailer load, unbraked (kg)560a)

Slopes up to 12 %.

b)

Slopes up to 8 %.

1.2 ltr./63 kW TSI engine

Output (kW per rpm)Max. torque (Nm per rpm)Number of cylinders/displacement (cm 3

)63/4800160/1500-35004/1197 Performance and WeightsMG5Top speed (km/h)180Acceleration 0-100 km/h (s)11.7Operating weight (in kg)1150Permissible trailer load, braked (kg)900 a)

/ 1100 b)Permissible trailer load, unbraked (kg)570a)

Slopes up to 12 %.

b)

Slopes up to 8 %.

176Technical data

Page 179 of 193

1.2 ltr./77 kW TSI engineOutput (kW per rpm)Max. torque (Nm per rpm)Number of cylinders/displacement (cm3

)77/5000175/1550-41004/1197 Performance and WeightsMG6Top speed (km/h)193Acceleration 0-100 km/h (s)10.2Operating weight (in kg)1170Permissible trailer load, braked (kg)1100 a)

/ 1200 b)Permissible trailer load, unbraked (kg)580a)

Slopes up to 12 %.

b)

Slopes up to 8 %.

1.2 ltr./90 kW TSI engine

Output (kW per rpm)Max. torque (Nm per rpm)Number of cylinders/displacement (cm 3

)90/5000200/1500-40004/1390 Performance and WeightsDSG7Top speed (km/h)203Acceleration 0-100 km/h (s)9.4Operating weight (in kg)1225Permissible trailer load, braked (kg)1200Permissible trailer load, unbraked (kg)610 177Technical data

Page 180 of 193

1.6 l/77 kW MPI engineOutput (kW per rpm)Max. torque (Nm per rpm)Number of cylinders/displacement (cm3

)77/5600153/38004/1598 Performance and WeightsMG5AG6Top speed (km/h)191190Acceleration 0-100 km/h (s)10.511.8Operating weight (in kg)11501190Permissible trailer load, braked (kg)1000 a)

/ 1200 b)Permissible trailer load, unbraked (kg)570590a)

Slopes up to 12 %.

b)

Slopes up to 8 %.

1.6 ltr./66 kW TDI CR engine

Output (kW per rpm)Max. torque (Nm per rpm)Number of cylinders/displacement (cm 3

)66/4200230/1500-25004/1598 Performance and WeightsMG5DSG7Top speed (km/h)182/184 a)182Acceleration 0-100 km/h (s)11.912.1Operating weight (in kg)1260/1258 a)1280Permissible trailer load, braked (kg)1200/1000 a)1200Permissible trailer load, unbraked (kg)630/628a)640a)

GreenLine

178Technical data

Page 181 of 193

1.6 ltr./77 kW TDI CR engineOutput (kW per rpm)Max. torque (Nm per rpm)Number of cylinders/displacement (cm3

)77/4400250/1500-25004/1598 Performance and WeightsMG5Top speed (km/h)190Acceleration 0-100 km/h (s)10.3Operating weight (in kg)1260Permissible trailer load, braked (kg)1200Permissible trailer load, unbraked (kg)630179Technical data