check engine SKODA RAPID SPACEBACK 2015 1.G Owner's Guide

[x] Cancel search | Manufacturer: SKODA, Model Year: 2015, Model line: RAPID SPACEBACK, Model: SKODA RAPID SPACEBACK 2015 1.GPages: 208, PDF Size: 29.2 MB

Page 152 of 208

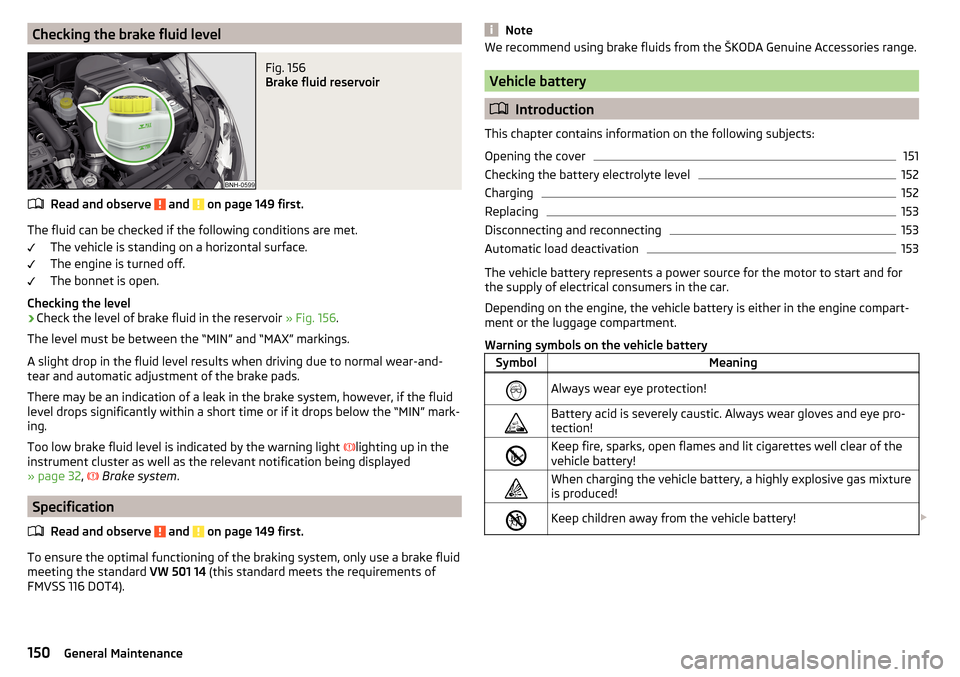

Checking the brake fluid levelFig. 156

Brake fluid reservoir

Read and observe and on page 149 first.

The fluid can be checked if the following conditions are met.The vehicle is standing on a horizontal surface.

The engine is turned off.

The bonnet is open.

Checking the level

›

Check the level of brake fluid in the reservoir » Fig. 156.

The level must be between the “MIN” and “MAX” markings.

A slight drop in the fluid level results when driving due to normal wear-and-

tear and automatic adjustment of the brake pads.

There may be an indication of a leak in the brake system, however, if the fluid

level drops significantly within a short time or if it drops below the “MIN” mark-

ing.

Too low brake fluid level is indicated by the warning light lighting up in the

instrument cluster as well as the relevant notification being displayed

» page 32 ,

Brake system

.

Specification

Read and observe

and on page 149 first.

To ensure the optimal functioning of the braking system, only use a brake fluid

meeting the standard VW 501 14 (this standard meets the requirements of

FMVSS 116 DOT4).

NoteWe recommend using brake fluids from the ŠKODA Genuine Accessories range.

Vehicle battery

Introduction

This chapter contains information on the following subjects:

Opening the cover

151

Checking the battery electrolyte level

152

Charging

152

Replacing

153

Disconnecting and reconnecting

153

Automatic load deactivation

153

The vehicle battery represents a power source for the motor to start and for

the supply of electrical consumers in the car.

Depending on the engine, the vehicle battery is either in the engine compart-

ment or the luggage compartment.

Warning symbols on the vehicle battery

SymbolMeaningAlways wear eye protection!Battery acid is severely caustic. Always wear gloves and eye pro-

tection!Keep fire, sparks, open flames and lit cigarettes well clear of the

vehicle battery!When charging the vehicle battery, a highly explosive gas mixture

is produced!Keep children away from the vehicle battery! 150General Maintenance

Page 154 of 208

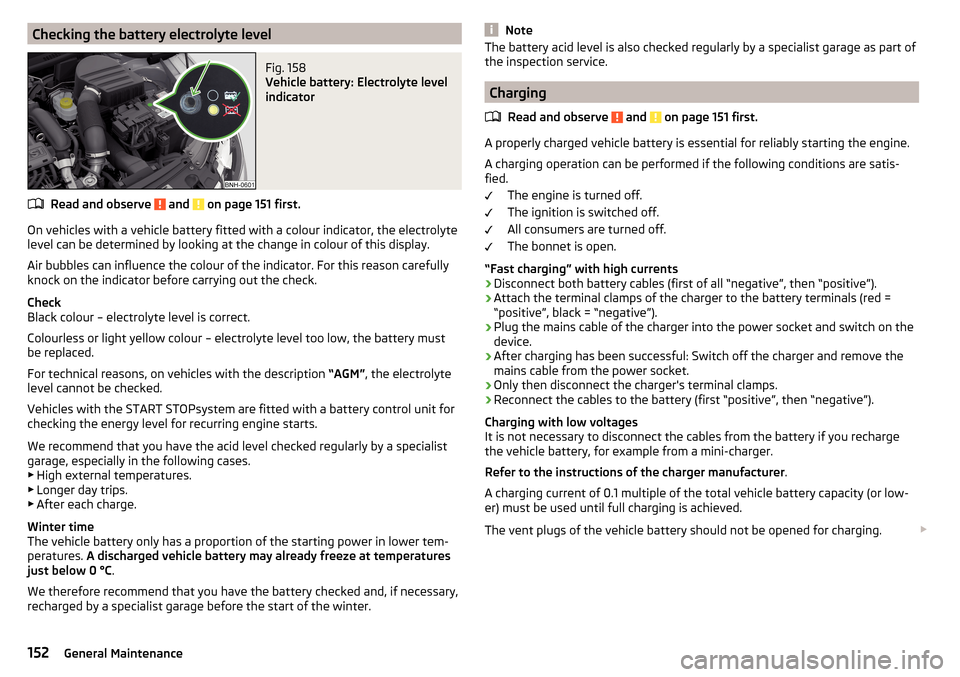

Checking the battery electrolyte levelFig. 158

Vehicle battery: Electrolyte level

indicator

Read and observe and on page 151 first.

On vehicles with a vehicle battery fitted with a colour indicator, the electrolyte

level can be determined by looking at the change in colour of this display.

Air bubbles can influence the colour of the indicator. For this reason carefully

knock on the indicator before carrying out the check.

Check

Black colour – electrolyte level is correct.

Colourless or light yellow colour – electrolyte level too low, the battery must

be replaced.

For technical reasons, on vehicles with the description “AGM”, the electrolyte

level cannot be checked.

Vehicles with the START STOPsystem are fitted with a battery control unit for

checking the energy level for recurring engine starts.

We recommend that you have the acid level checked regularly by a specialist

garage, especially in the following cases. ▶ High external temperatures.

▶ Longer day trips.

▶ After each charge.

Winter time

The vehicle battery only has a proportion of the starting power in lower tem-

peratures. A discharged vehicle battery may already freeze at temperatures

just below 0 °C .

We therefore recommend that you have the battery checked and, if necessary,

recharged by a specialist garage before the start of the winter.

NoteThe battery acid level is also checked regularly by a specialist garage as part of

the inspection service.

Charging

Read and observe

and on page 151 first.

A properly charged vehicle battery is essential for reliably starting the engine.

A charging operation can be performed if the following conditions are satis-

fied.

The engine is turned off.

The ignition is switched off.

All consumers are turned off.

The bonnet is open.

“Fast charging” with high currents

›

Disconnect both battery cables (first of all “negative”, then “positive”).

›

Attach the terminal clamps of the charger to the battery terminals (red =

“positive”, black = “negative”).

›

Plug the mains cable of the charger into the power socket and switch on the

device.

›

After charging has been successful: Switch off the charger and remove the

mains cable from the power socket.

›

Only then disconnect the charger's terminal clamps.

›

Reconnect the cables to the battery (first “positive”, then “negative”).

Charging with low voltages

It is not necessary to disconnect the cables from the battery if you recharge

the vehicle battery, for example from a mini-charger.

Refer to the instructions of the charger manufacturer .

A charging current of 0.1 multiple of the total vehicle battery capacity (or low-

er) must be used until full charging is achieved.

The vent plugs of the vehicle battery should not be opened for charging.

152General Maintenance

Page 155 of 208

WARNING■When you charge a battery, hydrogen is released, and a highly explosive

gas mixture is also produced. An explosion can be caused through sparkling

over during unclamping or loosening of the cable plug while the ignition is

on.■

Creating a bridge between the poles on the battery (e.g. with metal ob-

jects - cables) creates a short circuit - risk of damage to the battery, explo-

sion and burning of the battery, jets of acid spurting out.

■

Avoid creating sparks when working with cables and electrical devices.

Strong sparking represents a risk of injury.

■

Before carrying out any work on the electrical system, switch off the en-

gine, the ignition and all electrical consumers and disconnect the negative

terminal

.

■

“Quick-charging” the vehicle battery is dangerous and requires a special

charger and specialist knowledge.

■

We therefore recommend that vehicle batteries be “rapidly charged” by a

specialist garage.

CAUTION

On vehicles with the START/STOP system, the pole terminal of the charger

must not be connected directly to the negative terminal of the vehicle battery,

but only to the engine earth » page 168, Jump-starting using the battery from

another vehicle .

Replacing

Read and observe

and on page 151 first.

The new vehicle battery must have the same capacity, voltage, current and

size as the original battery. Suitable vehicle battery types can be purchased

from a specialist garage.

We recommend you have the battery replaced by a specialist garage.

Disconnecting and reconnecting

Read and observe

and on page 151 first.

Disconnecting

›

Switch off the ignition.

›

First, disconnect the negative terminal

first, then the positive

terminal

of the battery.

Connecting›First, connect the positive first, then the negative battery terminal.

After disconnecting and re-connecting the vehicle battery, the following func-

tions or devices are partially or completely inoperative.Function / deviceCommissioningTime settings» page 31

CAUTION

■ Disconnect the vehicle battery only with the ignition turned off - there is a

risk of damaging the electrical system of the vehicle.■

Under no circumstances must the battery cables be connected incorrectly –

risk of a cable fire.

Note

■ After disconnecting and re-connecting the vehicle battery, we recommend

having the vehicle checked by a specialist to ensure that the full functionality

of all electrical systems is guaranteed.■

The data of the multi-function display will be reset.

Automatic load deactivation

Read and observe

and on page 151 first.

The vehicle's electrical system automatically prevents the battery from dis-

charging when the battery is being heavily used. This manifests itself by the

following. ▶ The idling speed is raised to allow the generator to deliver more electricity to

the electrical system.

▶ Where necessary, large convenience consumers such as seat heaters and

rear window heaters have their power limited or are shut off completely in

the event of an emergency.

CAUTION

■ Despite such intervention by the vehicle electric system management, the

vehicle battery may be drained. For example, when the ignition is switched on

a long time with the engine turned off or the side or parking lights are turned

on during longer parking.■

Consumers that are supplied via a 12-V power socket can cause the vehicle

battery to discharge when the ignition is switched off.

153Inspecting and replenishing

Page 167 of 208

WARNING (Continued)■Never position any body parts, such as arms or legs under the vehicle,

while the vehicle is raised with a lifting jack.■

When the vehicle is raised, never start the engine.

CAUTION

It is important to ensure that the jack is correctly attached to the web of the

lower fork leg, otherwise there is a risk of damage to the vehicle occurring.

Remove the wheel / fix

When changing a wheel, the following instructions must be followed.

›

Remove the full wheel trim or the caps of the wheel bolts.

›

First of all slacken the anti-theft wheel bolt and then the other wheel bolts.

›

Jack up the vehicle until the wheel that needs changing is clear of the

ground.

›

Unscrew the wheel bolts and place them on a clean surface (cloth, paper,

etc.).

›

Remove the wheel carefully.

›

Attach the wheel and slightly screw on the wheel bolts.

›

Lower the vehicle.

›

Alternately tighten wheel bolts opposite (diagonally) with the wheel wrench.

Tighten the anti-theft wheel bolt last.

›

Replace the wheel trim or the caps.

When fitting unidirectional tyres, ensure that the direction of rotation is cor-

rect » page 157 .

All bolts must be clean and must turn easily.

If it is established when changing a wheel that the wheel bolts are corroded and difficult to move, then these must be replaced.

Under no circumstances grease or oil the wheel bolts!

WARNINGUndo the wheel bolts only a little (about one turn) provided that the vehicle

has not yet been jacked up. Otherwise the wheel could become loose and

fall off.Follow-up work

After changing the wheel, the following work must be carried out.›

Stow the replaced wheel in the wheel well and secure it with a special screw.

›

Stow the tool kit in the space provided and secure using the band.

›

Check the tyre pressure on the installed wheel as soon as possible.

›

Have the tightening torque of the wheel bolts checked with a torque wrench

as soon as possible.

After changing the wheel, the tyre pressure should be adjusted. In vehicles

with tyre pressure monitoring, save tyre pressure values » page 120.

Replace the damaged wheel or consult a specialist garage about repair op-

tions.

The prescribed tightening torque of the wheel bolts is 120 Nm.

WARNING■

If the wheel bolts are tightened to a too low tightening torque, the rim

can come loose when the car is moving. A tightening torque which is too

high can damage the bolts and threads and this can result in permanent

deformation of the contact surfaces on the rim.■

Drive cautiously and only at a moderate speed until the tightening torque

has been checked.

Puncture set

Introduction

This chapter contains information on the following subjects:

Components of the puncture repair kits

166

General information

166

Preparations for using the breakdown kit

167

Sealing and inflating the tyre

167

Notes for driving with tyre repaired

167

Use the breakdown kit to reliably repair tyre damage caused by foreign bodies

or a puncture with diameters up to approx. 4 mm.

A repair made using the breakdown kit is never intended to replace a perma-

nent repair on the tyre. Its purpose is to get you to the nearest specialist ga-

rage.

165Emergency equipment and self-help

Page 169 of 208

Preparations for using the breakdown kitRead and observe

on page 166 first.

The following preparatory work must be carried out before using the puncture

repair kit.

›

Switch off the engine.

›

For vehicles with manual transmission select gear 1.

›

On vehicles with automatic transmission , place the selector lever in the P

position.

›

Firmly apply the handbrake.

›

Check that you can carry out the repairs with the breakdown kit » page 166,

General information .

›

Uncouple trailer, if attached.

›

Remove the breakdown kit from the boot.

›

Stick the sticker

1

» Fig. 171 on page 166 on the dashboard in the driver's

field of view.

›

Unscrew the valve cap.

›

Use the valve remover

2

to unscrew the valve core and place it on a clean

surface (rag, paper, etc.).

Sealing and inflating the tyre

Read and observe

on page 166 first.

Sealing

›

Forcefully shake the tyre inflater bottle

10

» Fig. 171 on page 166 back and

forth several times.

›

Firmly screw the inflation hose

3

onto the tyre inflater bottle

10

. The film on

the cap is pierced automatically.

›

Remove the plug from the inflation hose

3

and plug the open end fully onto

the tyre valve.

›

Hold the bottle

10

with the bottom facing upwards and fill all of the sealing

agent from the tyre inflater bottle into the tyre.

›

Remove the filler plug from the tyre valve.

›

Screw the valve core back into the tyre valve using the valve remover

2

.

Inflating

›

Screw the tyre inflation hose

7

» Fig. 171 on page 166 of the air compressor

firmly onto the tyre valve.

›

For vehicles with manual transmission the lever into the neutral position.

›On vehicles with

automatic transmission , place the selector lever in the P

position.›

Start the engine and run it in idle.

›

Plug the connector

6

into the 12-volt socket » page 75.

›

Switch on the air compressor with the ON and OFF switch

9

.

›

Allow the air compressor to run until a pressure of 2.0 - 2.5 bar is achieved.

Maximum run time of 8 minutes » .

›

Switch off the air compressor.

›

If you cannot reach an air pressure of 2.0 - 2.5 bar, unscrew the tyre inflation

hose

7

from the tyre valve.

›

Drive the vehicle 10 metres forwards or backwards to allow the sealing agent

to “distribute” in the tyre.

›

Firmly screw the tyre inflation hose

7

back onto the tyre valve and repeat

the inflation process.

›

Switch off the air compressor.

›

Remove the tyre inflation hose

7

from the tyre valve.

Once a tyre inflation pressure of 2.0 - 2.5 bar is achieved, you can continue the journey.

WARNING■ If the tyre cannot be inflated to at least. 2.0 bar, the damage is too great.

The sealing agent cannot be used to seal the tyre. Do not continue to

drive! Seek help from a specialist garage.■

The tyre inflation hose and air compressor may get hot as the tyre is be-

ing inflated – there is a risk of burning.

CAUTION

Switch off the air compressor after running 8 minutes at the latest – there is a

risk of overheating! Allow the air compressor to cool a few minutes before

switching it on again.

Notes for driving with tyre repaired

Read and observe

on page 166 first.

The inflation pressure of the repaired tyre must be checked after driving for 10

minutes.

If the tyre pressure is 1.3 bar or less

›

Do not continue to drive! The tyre cannot be properly sealed with the

breakdown kit.

167Emergency equipment and self-help

Page 176 of 208

Attaching the windscreen wiper blade›Push the windscreen wiper blade to the stop until it locks into place.›

Check that the windscreen wiper blade is correctly attached.

›

Fold the windscreen wiper arm back to the windscreen.

Fuses and light bulbs

Fuses

Introduction

This chapter contains information on the following subjects:

Fuses in the dash panel

175

Assignment of the fuses in the dash panel

175

Fuses in the engine compartment

176

Fuse assignment in the engine compartment

177

Individual electrical circuits are protected by fuses.

Switch off the ignition and the corresponding power consuming device before

replacing a fuse.

Find out which fuse belongs to the component that is not operating

» page 175 , Assignment of the fuses in the dash panel or » page 177 , Fuse

assignment in the engine compartment .

Colour coding of fuses

Fuse colourMaximum amperagepurple3light brown5dark brown7.5red10blue15yellow/blue20white25green/pink30green40red50WARNINGAlways read and observe the warning notes before completing any work in

the engine compartment » page 143, Engine compartment .174Do-it-yourself

Page 177 of 208

CAUTION■“Never repair” fuses, and do not replace them with fuses of a higher amper-

age – risk of fire! This may also cause damage at other points in the electrical

system.■

If a newly inserted fuse blows again after a short time, have the electrical

system checked as quickly as possible by a specialist garage.

■

A blown fuse is recognisable by the molten metal strip. Replace the faulty

fuse with a new one of the same amperage.

Note

■

We recommend always carrying replacement fuses in the vehicle. A box of

replacement fuses and bulbs can be purchased from ŠKODA Genuine Accesso-

ries.■

There can be several power-consuming devices for one fuse.

■

Multiple fuses may exist for a single power-consuming device.

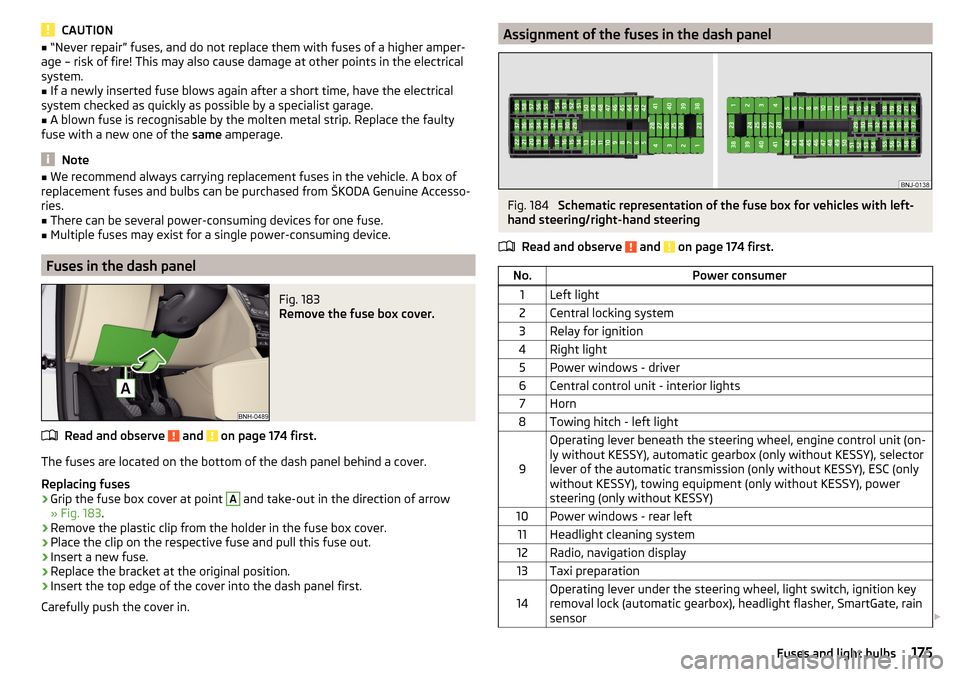

Fuses in the dash panel

Fig. 183

Remove the fuse box cover.

Read and observe and on page 174 first.

The fuses are located on the bottom of the dash panel behind a cover.

Replacing fuses

›

Grip the fuse box cover at point

A

and take-out in the direction of arrow

» Fig. 183 .

›

Remove the plastic clip from the holder in the fuse box cover.

›

Place the clip on the respective fuse and pull this fuse out.

›

Insert a new fuse.

›

Replace the bracket at the original position.

›

Insert the top edge of the cover into the dash panel first.

Carefully push the cover in.

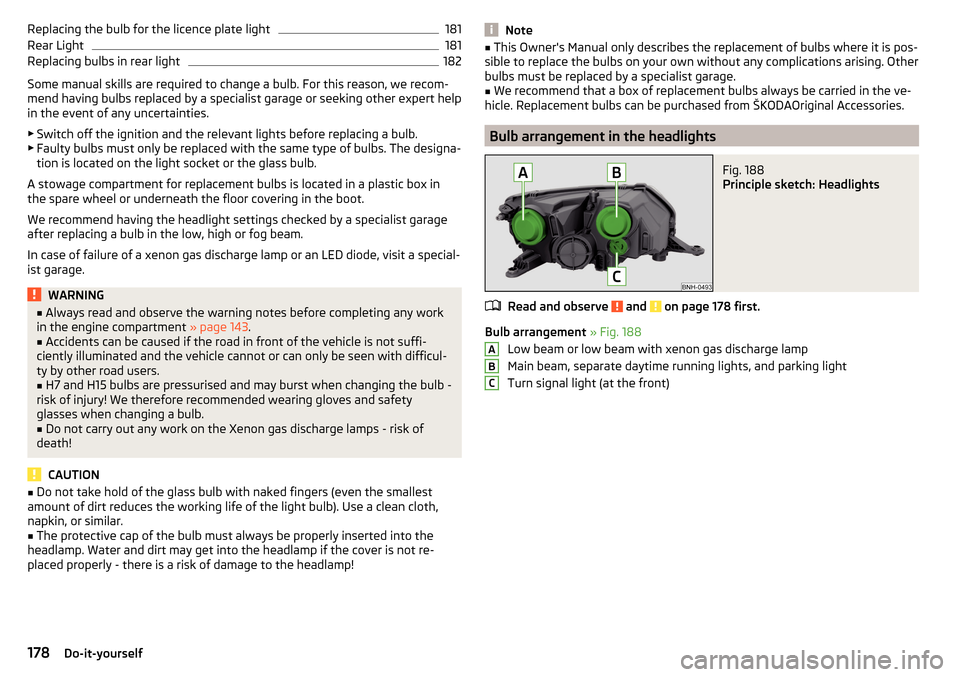

Assignment of the fuses in the dash panelFig. 184

Schematic representation of the fuse box for vehicles with left-

hand steering/right-hand steering

Read and observe

and on page 174 first.

No.Power consumer1Left light2Central locking system3Relay for ignition4Right light5Power windows - driver6Central control unit - interior lights7Horn8Towing hitch - left light

9

Operating lever beneath the steering wheel, engine control unit (on-

ly without KESSY), automatic gearbox (only without KESSY), selector

lever of the automatic transmission (only without KESSY), ESC (only

without KESSY), towing equipment (only without KESSY), power

steering (only without KESSY)10Power windows - rear left11Headlight cleaning system12Radio, navigation display13Taxi preparation14Operating lever under the steering wheel, light switch, ignition key

removal lock (automatic gearbox), headlight flasher, SmartGate, rain

sensor 175Fuses and light bulbs

Page 180 of 208

Replacing the bulb for the licence plate light181Rear Light181

Replacing bulbs in rear light

182

Some manual skills are required to change a bulb. For this reason, we recom-

mend having bulbs replaced by a specialist garage or seeking other expert help

in the event of any uncertainties.

▶ Switch off the ignition and the relevant lights before replacing a bulb.

▶ Faulty bulbs must only be replaced with the same type of bulbs. The designa-

tion is located on the light socket or the glass bulb.

A stowage compartment for replacement bulbs is located in a plastic box in

the spare wheel or underneath the floor covering in the boot.

We recommend having the headlight settings checked by a specialist garage

after replacing a bulb in the low, high or fog beam.

In case of failure of a xenon gas discharge lamp or an LED diode, visit a special- ist garage.

WARNING■ Always read and observe the warning notes before completing any work

in the engine compartment » page 143.■

Accidents can be caused if the road in front of the vehicle is not suffi-

ciently illuminated and the vehicle cannot or can only be seen with difficul-

ty by other road users.

■

H7 and H15 bulbs are pressurised and may burst when changing the bulb -

risk of injury! We therefore recommended wearing gloves and safety

glasses when changing a bulb.

■

Do not carry out any work on the Xenon gas discharge lamps - risk of

death!

CAUTION

■ Do not take hold of the glass bulb with naked fingers (even the smallest

amount of dirt reduces the working life of the light bulb). Use a clean cloth,

napkin, or similar.■

The protective cap of the bulb must always be properly inserted into the

headlamp. Water and dirt may get into the headlamp if the cover is not re-

placed properly - there is a risk of damage to the headlamp!

Note■ This Owner's Manual only describes the replacement of bulbs where it is pos-

sible to replace the bulbs on your own without any complications arising. Other

bulbs must be replaced by a specialist garage.■

We recommend that a box of replacement bulbs always be carried in the ve-

hicle. Replacement bulbs can be purchased from ŠKODAOriginal Accessories.

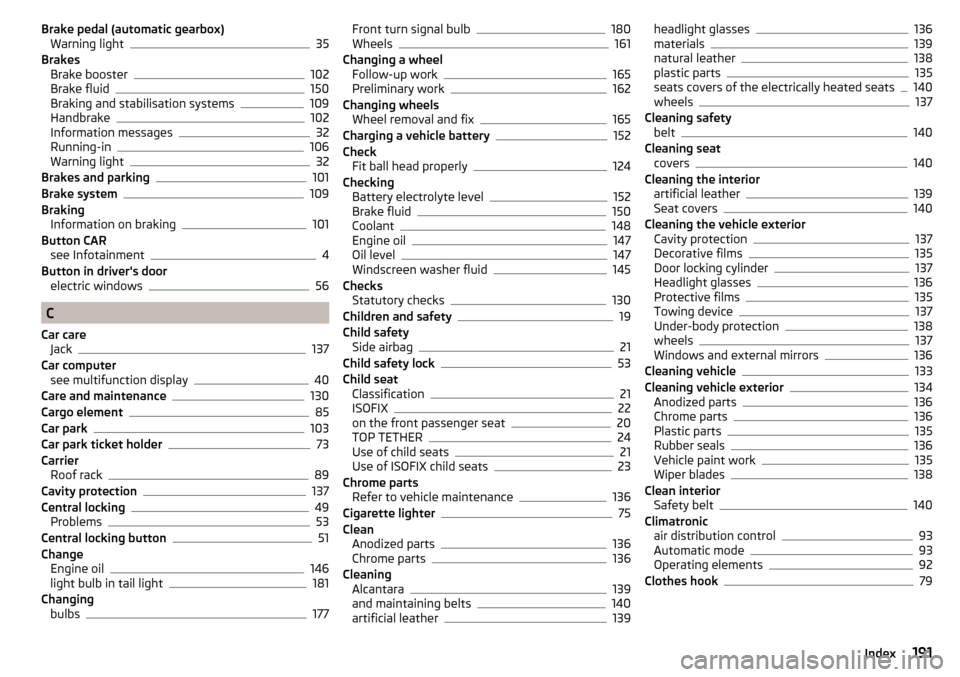

Bulb arrangement in the headlights

Fig. 188

Principle sketch: Headlights

Read and observe and on page 178 first.

Bulb arrangement » Fig. 188

Low beam or low beam with xenon gas discharge lamp

Main beam, separate daytime running lights, and parking light

Turn signal light (at the front)

ABC178Do-it-yourself

Page 193 of 208

Brake pedal (automatic gearbox)Warning light35

Brakes Brake booster

102

Brake fluid150

Braking and stabilisation systems109

Handbrake102

Information messages32

Running-in106

Warning light32

Brakes and parking101

Brake system109

Braking Information on braking

101

Button CAR see Infotainment

4

Button in driver's door electric windows

56

C

Car care Jack

137

Car computer see multifunction display

40

Care and maintenance130

Cargo element85

Car park103

Car park ticket holder73

Carrier Roof rack

89

Cavity protection137

Central locking49

Problems53

Central locking button51

Change Engine oil

146

light bulb in tail light181

Changing bulbs

177

Front turn signal bulb180

Wheels161

Changing a wheel Follow-up work

165

Preliminary work162

Changing wheels Wheel removal and fix

165

Charging a vehicle battery152

Check Fit ball head properly

124

Checking Battery electrolyte level

152

Brake fluid150

Coolant148

Engine oil147

Oil level147

Windscreen washer fluid145

Checks Statutory checks

130

Children and safety19

Child safety Side airbag

21

Child safety lock53

Child seat Classification

21

ISOFIX22

on the front passenger seat20

TOP TETHER24

Use of child seats21

Use of ISOFIX child seats23

Chrome parts Refer to vehicle maintenance

136

Cigarette lighter75

Clean Anodized parts

136

Chrome parts136

Cleaning Alcantara

139

and maintaining belts140

artificial leather139

headlight glasses136

materials139

natural leather138

plastic parts135

seats covers of the electrically heated seats140

wheels137

Cleaning safety belt

140

Cleaning seat covers

140

Cleaning the interior artificial leather

139

Seat covers140

Cleaning the vehicle exterior Cavity protection

137

Decorative films135

Door locking cylinder137

Headlight glasses136

Protective films135

Towing device137

Under-body protection138

wheels137

Windows and external mirrors136

Cleaning vehicle133

Cleaning vehicle exterior134

Anodized parts136

Chrome parts136

Plastic parts135

Rubber seals136

Vehicle paint work135

Wiper blades138

Clean interior Safety belt

140

Climatronic air distribution control

93

Automatic mode93

Operating elements92

Clothes hook79

191Index

Page 194 of 208

Cockpit12-Volt power outlet75

Ashtray75

Cigarette lighter75

General view27

Lights63

storage compartments73

useful equipment73

COMING HOME62

compartments73

Component protection132

Components of the puncture repair kits166

Computer see multifunction display

40

convenience turn signal61

Coolant148

Checking148

Replenishing149

Temperature gauge29

Warning light36

Warning messages36

CORNER see Headlights with CORNER function

62

Correct routing of seat belt

12

Correct seated position8

Front passenger10

Rear seats10

Correct seat position Driver

9

Counter for distance driven30

cruise control operation

114

operation description115

Cruise control system Warning light

35

Cup holders74

D

DAY LIGHT See Daytime running lights

60

Daytime running lights60

Dazzle see sun screen of the panoramic roof

65

De-icing windows

136

Deactivating an airbag18

Decorative films135

Defrosting rear window64

Delayed locking of the boot lid see boot lid

55

Departure angle187

Diesel refer to Fuel

142

Diesel fuel Operation in winter

142

Diesel particulate filter37

information messages37

Digital Clock31

Dipstick147

Disconnecting and reconnecting vehicle battery

153

Display29

Compass points45

Coolant temperature29

Fuel supply30

Gear changes39

Service intervals46

Disposal Acceptance and recycling of used vehicles

133

Distance driven30

Distance warning Warning light

38

Door Child safety lock

53

Closing53

Emergency locking172

Opening53

Door warning39

Drive Driving through water

108

DriveGreen107

Driving Emissions

184

Fuel consumption184

Maximum speed188

through water108

driving data operation

40

E

Economical driving Tips

106

EDL111

Electrical power windows Button in the rear doors

57

Electric power windows Operational faults

58

Electric Windows56

Button in driver's door56

Electronic Differential Lock (EDL)111

Electronic immobilizer95

Emergency Changing a wheel

161

Hazard warning light system62

Jump-starting168

Locking the door without a locking cylinder172

Selector lever-unlocking172

Switch off the engine by pressing a button98

Towing the vehicle169

Towing the vehicle using the tow hitch171

tyre repair165

emergency equipment reflective vest

160

192Index