towing SKODA RAPID SPACEBACK 2016 1.G User Guide

[x] Cancel search | Manufacturer: SKODA, Model Year: 2016, Model line: RAPID SPACEBACK, Model: SKODA RAPID SPACEBACK 2016 1.GPages: 184, PDF Size: 28.1 MB

Page 113 of 184

Towing device and trailer

Hitch

Introduction

This chapter contains information on the following subjects:

Description

111

Adjusting the ready position

112

Check the setting of the standby position

112

Assembling the tow bar – Step 1

113

Assembling the tow bar – Step 2

113

Check proper fitting

114

Removing the tow bar – Step 1

114

Removing the tow bar – Step 2

114

Vertical load with mounted accessories

115

The maximum trailer nose weight when towing a trailer is 50 kg. Other infor-

mation (e.g. on the nameplate of the trailer device) provide only about the test

values of the device information.

WARNING■ Check that the tow bar is seated correctly and is secured in the mounting

recess before the start of every journey.■

When the ball rod is not used and properly secured in the receiving shaft,

this could be damaged or incomplete and must not be used - risk of acci-

dent.

■

Do not modify or adapt the towing device in any way.

■

Keep the mounting recess of the towing equipment clean at all times.

Such dirt prevents the ball head from being attached securely.

DescriptionFig. 135

Carrier for the towing device / tow bar

Read and observe

on page 111 first.

The ball rod is detachable and is located in the stowage compartment for the spare / emergency wheel.

Support for the towing device and tow bar » Fig. 135

Cap

Mounting recess

Protective cap

Locking ball

Centering

Hand wheel

Key

Lock cap

Red marking on the hand wheel

Tow bar

Green marking on the hand wheel

White marking on tow bar

123456789101112111Towing device and trailer

Page 115 of 184

Assembling the tow bar – Step 1Fig. 139

Remove cap for receiving shaft / use ball bar

Read and observe

on page 111 first.

The tow bar must be set to the standby position » page 112, Check the setting

of the standby position . If this is not in the standby position, then it must be

set to the standby position » page 112, Adjusting the ready position .

›

To prepare for the installation , remove the cap for the receiving shaft

A

in

the direction of arrow

1

» Fig. 139 .

›

To install , hold the ball rod from underneath » Fig. 139 .

›

Push the ball rod into the receiving shaft in the direction of arrow

2

until it

stops. The ball rod must audibly snap into place » .

The hand wheel

B

rotates back automatically and rests on the ball rod » .

WARNINGDo not hold the hand wheel with your hand when attaching the ball bar -

there is a risk of finger injury.Assembling the tow bar – Step 2Fig. 140

Secure the lock and remove key / place cap on lock

Read and observe

on page 111 first.

›

First perform step 1 of the tow bar assembly » page 113.

›

Turn the key

A

in the direction of arrow

1,

so that the arrow on the key

symbol

» Fig. 140 shows.

›

Remove the key in the direction of the arrow

2

.

›

Fit the cap

B

on the lock in the direction of the arrow

3

.

›

Check that the ball rod is securely attached » page 114.

WARNINGAfter fitting the tow bar, always secure the lock and remove the key. The

tow bar must not be operated with the key inserted.113Towing device and trailer

Page 117 of 184

›Remove the tow bar from the mounting recess downwards and in the direc-

tion of the arrow 3. At the same time, the ball rod latches into the ready po-

sition and is therefore ready to be re-fitted.

After removing the ball rod, insert the cap for the receiving shaft A

against

the direction of arrow

1

» Fig. 139 on page 113 .

If the hand wheel

A

is not turned all the way to the stop, then it will return to

its initial position when the tow bar is removed and will rest on the tow bar

and not engage into the ready position. The ball head then needs to be

brought into this position before the next time it is fitted » page 112, Adjusting

the ready position .

The ball rod must be cleaned before storing in the box with the vehicle tool

always.

WARNINGNever allow the tow bar to remain unsecured in the boot. This could cause

damage to the boot upon sudden braking, and could put the safety of the

occupants at risk.

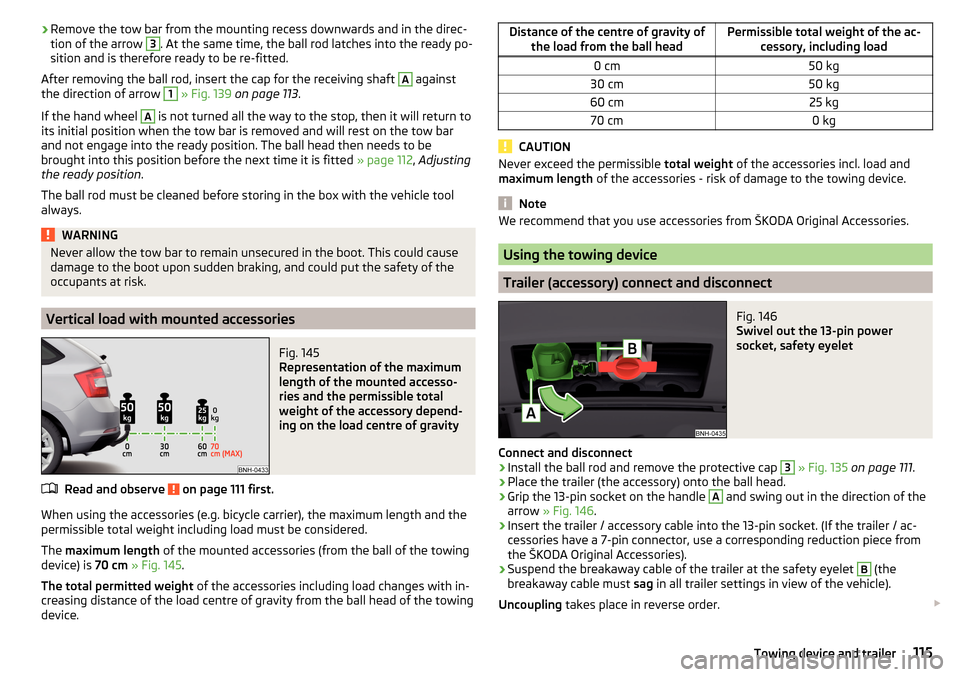

Vertical load with mounted accessories

Fig. 145

Representation of the maximum

length of the mounted accesso-

ries and the permissible total

weight of the accessory depend-

ing on the load centre of gravity

Read and observe on page 111 first.

When using the accessories (e.g. bicycle carrier), the maximum length and the

permissible total weight including load must be considered.

The maximum length of the mounted accessories (from the ball of the towing

device) is 70 cm » Fig. 145 .

The total permitted weight of the accessories including load changes with in-

creasing distance of the load centre of gravity from the ball head of the towing

device.

Distance of the centre of gravity of the load from the ball headPermissible total weight of the ac- cessory, including load0 cm50 kg30 cm50 kg60 cm25 kg70 cm0 kg

CAUTION

Never exceed the permissible total weight of the accessories incl. load and

maximum length of the accessories - risk of damage to the towing device.

Note

We recommend that you use accessories from ŠKODA Original Accessories.

Using the towing device

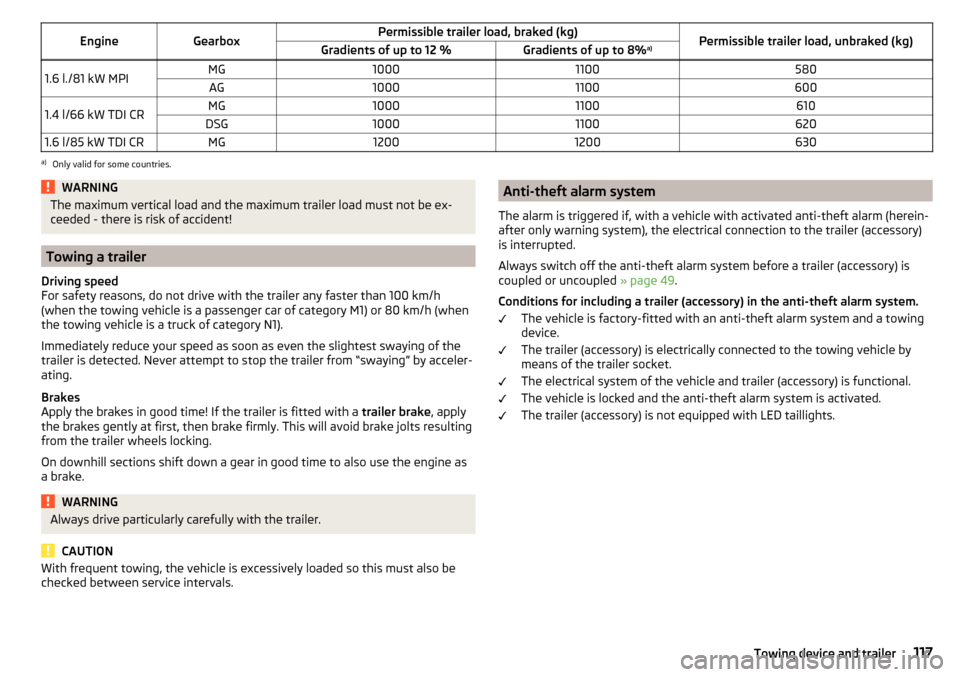

Trailer (accessory) connect and disconnect

Fig. 146

Swivel out the 13-pin power

socket, safety eyelet

Connect and disconnect

›

Install the ball rod and remove the protective cap

3

» Fig. 135 on page 111 .

›

Place the trailer (the accessory) onto the ball head.

›

Grip the 13-pin socket on the handle

A

and swing out in the direction of the

arrow » Fig. 146 .

›

Insert the trailer / accessory cable into the 13-pin socket. (If the trailer / ac-

cessories have a 7-pin connector, use a corresponding reduction piece from

the ŠKODA Original Accessories).

›

Suspend the breakaway cable of the trailer at the safety eyelet

B

(the

breakaway cable must sag in all trailer settings in view of the vehicle).

Uncoupling takes place in reverse order.

115Towing device and trailer

Page 119 of 184

EngineGearboxPermissible trailer load, braked (kg)Permissible trailer load, unbraked (kg)Gradients of up to 12 %Gradients of up to 8%a)1.6 l./81 kW MPIMG10001100580AG100011006001.4 l/66 kW TDI CRMG10001100610DSG100011006201.6 l/85 kW TDI CRMG12001200630a)

Only valid for some countries.

WARNINGThe maximum vertical load and the maximum trailer load must not be ex-

ceeded - there is risk of accident!

Towing a trailer

Driving speed

For safety reasons, do not drive with the trailer any faster than 100 km/h

(when the towing vehicle is a passenger car of category M1) or 80 km/h (when

the towing vehicle is a truck of category N1).

Immediately reduce your speed as soon as even the slightest swaying of the

trailer is detected. Never attempt to stop the trailer from “swaying” by acceler-

ating.

Brakes

Apply the brakes in good time! If the trailer is fitted with a trailer brake, apply

the brakes gently at first, then brake firmly. This will avoid brake jolts resulting

from the trailer wheels locking.

On downhill sections shift down a gear in good time to also use the engine as

a brake.

WARNINGAlways drive particularly carefully with the trailer.

CAUTION

With frequent towing, the vehicle is excessively loaded so this must also be

checked between service intervals.Anti-theft alarm system

The alarm is triggered if, with a vehicle with activated anti-theft alarm (herein-

after only warning system), the electrical connection to the trailer (accessory)

is interrupted.

Always switch off the anti-theft alarm system before a trailer (accessory) is

coupled or uncoupled » page 49.

Conditions for including a trailer (accessory) in the anti-theft alarm system. The vehicle is factory-fitted with an anti-theft alarm system and a towing

device.

The trailer (accessory) is electrically connected to the towing vehicle by

means of the trailer socket.

The electrical system of the vehicle and trailer (accessory) is functional.

The vehicle is locked and the anti-theft alarm system is activated.

The trailer (accessory) is not equipped with LED taillights.117Towing device and trailer

Page 125 of 184

WARNING■When washing your vehicle in the winter: Water and ice in the braking

system can affect the braking efficiency – risk of accident!■

Take care when cleaning the underbody or the inside of the wheel wells -

there is a risk of injury from sharp metal parts!

CAUTION

■ Do not wash the vehicle in direct sunlight, do not exert pressure on the body

while washing. The temperature of the washing water should be no more than

60 °C max. - otherwise there is a risk of damaging the vehicle paint.■

Before driving through a car wash fold in the exterior mirrors - risk of dam-

age.

■

For vehicles with roof antenna the antenna rod should be unscrewed before

driving through a car wash - there is a risk of damage.

CAUTION

Washing the vehicle with high-pressure cleaners■Films should not be washed with any high-pressure cleaners - risk of dam-

age.■

Do not aim the water jet directly at the lock cylinders or the door or opening

joints when washing the vehicle in the winter – there is a risk of freezing.

■

Hold a large spraying distance to the rear camera lens, to plastic parts (e.g.

Roof racks, spoilers, protective strips and the like), as well as soft materials

such as rubber hoses or insulation material.

■

The sensors of the parking aid can be sprayed only for a short time and there

must be a minimum distance of 10 cm - there is a risk of damage.

Exterior car care

Read and observe

and on page 122 first.

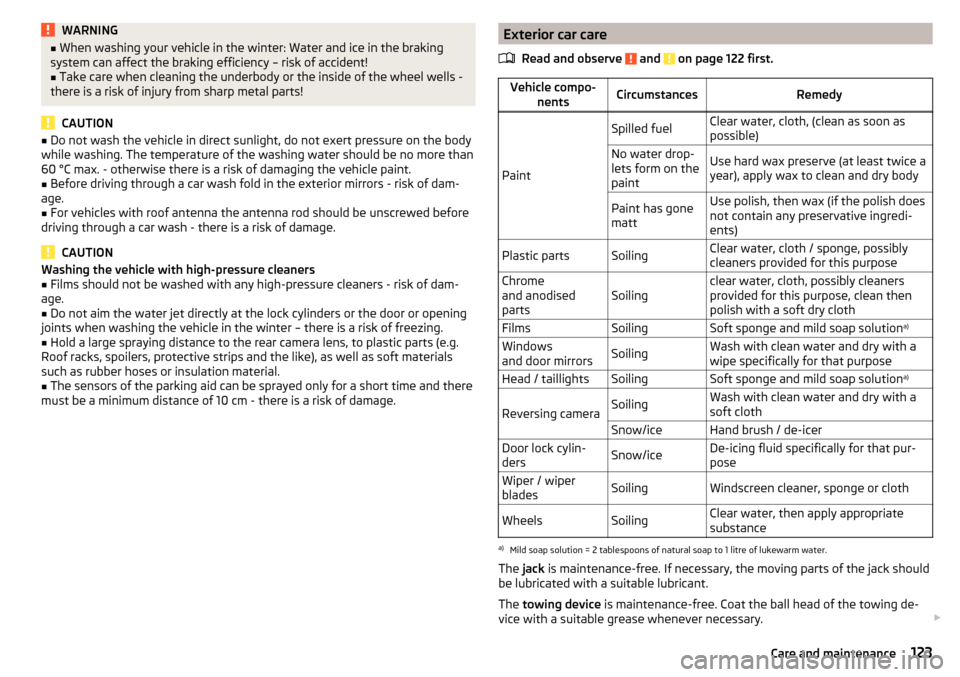

Vehicle compo- nentsCircumstancesRemedy

Paint

Spilled fuelClear water, cloth, (clean as soon as

possible)No water drop-

lets form on the

paintUse hard wax preserve (at least twice a

year), apply wax to clean and dry bodyPaint has gone

mattUse polish, then wax (if the polish does

not contain any preservative ingredi-

ents)Plastic partsSoilingClear water, cloth / sponge, possibly

cleaners provided for this purposeChrome

and anodised

partsSoilingclear water, cloth, possibly cleaners

provided for this purpose, clean then

polish with a soft dry clothFilmsSoilingSoft sponge and mild soap solution a)Windows

and door mirrorsSoilingWash with clean water and dry with a

wipe specifically for that purposeHead / taillightsSoilingSoft sponge and mild soap solution a)

Reversing cameraSoilingWash with clean water and dry with a

soft clothSnow/iceHand brush / de-icerDoor lock cylin-

dersSnow/iceDe-icing fluid specifically for that pur-

poseWiper / wiper

bladesSoilingWindscreen cleaner, sponge or clothWheelsSoilingClear water, then apply appropriate

substancea)

Mild soap solution = 2 tablespoons of natural soap to 1 litre of lukewarm water.

The jack is maintenance-free. If necessary, the moving parts of the jack should

be lubricated with a suitable lubricant.

The towing device is maintenance-free. Coat the ball head of the towing de-

vice with a suitable grease whenever necessary.

123Care and maintenance

Page 143 of 184

WARNINGAlways properly secure the fire extinguisher - there is a risk of injury in the

event of sudden braking or a vehicle collision.

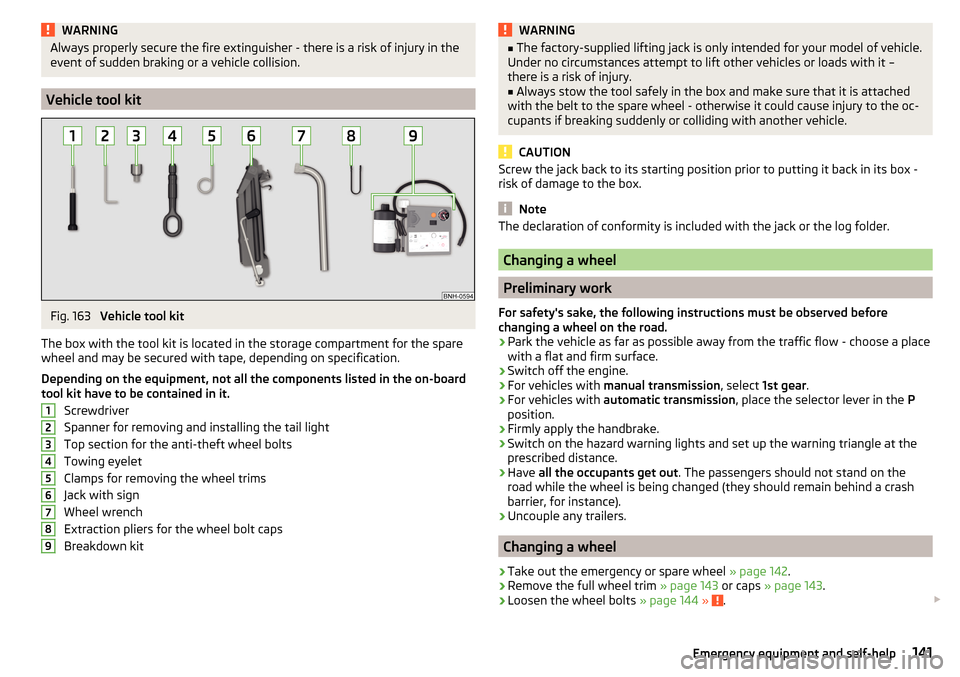

Vehicle tool kit

Fig. 163

Vehicle tool kit

The box with the tool kit is located in the storage compartment for the spare

wheel and may be secured with tape, depending on specification.

Depending on the equipment, not all the components listed in the on-board

tool kit have to be contained in it.

Screwdriver

Spanner for removing and installing the tail light

Top section for the anti-theft wheel bolts

Towing eyelet

Clamps for removing the wheel trims

Jack with sign

Wheel wrench

Extraction pliers for the wheel bolt caps

Breakdown kit

123456789WARNING■ The factory-supplied lifting jack is only intended for your model of vehicle.

Under no circumstances attempt to lift other vehicles or loads with it –

there is a risk of injury.■

Always stow the tool safely in the box and make sure that it is attached

with the belt to the spare wheel - otherwise it could cause injury to the oc-

cupants if breaking suddenly or colliding with another vehicle.

CAUTION

Screw the jack back to its starting position prior to putting it back in its box -

risk of damage to the box.

Note

The declaration of conformity is included with the jack or the log folder.

Changing a wheel

Preliminary work

For safety's sake, the following instructions must be observed before

changing a wheel on the road.

›

Park the vehicle as far as possible away from the traffic flow - choose a place

with a flat and firm surface.

›

Switch off the engine.

›

For vehicles with manual transmission , select 1st gear .

›

For vehicles with automatic transmission , place the selector lever in the P

position.

›

Firmly apply the handbrake.

›

Switch on the hazard warning lights and set up the warning triangle at the

prescribed distance.

›

Have all the occupants get out . The passengers should not stand on the

road while the wheel is being changed (they should remain behind a crash

barrier, for instance).

›

Uncouple any trailers.

Changing a wheel

›

Take out the emergency or spare wheel » page 142.

›

Remove the full wheel trim » page 143 or caps » page 143 .

›

Loosen the wheel bolts » page 144 » .

141Emergency equipment and self-help

Page 144 of 184

›Jack up the vehicle

» page 144 until the wheel that needs changing is clear of

the ground.›

Unscrew the wheel bolts and place them on a clean surface (cloth, paper,

etc.).

›

Remove the wheel carefully.

›

Attach the spare wheel and slightly screw on the wheel bolts.

›

Lower the vehicle.

›

Tighten the wheel bolts opposite each other using the wheel wrench (“pull- ing crossways”) » page 144.

›

Replace the wheel trim » page 143 and caps » page 143 .

When fitting unidirectional tyres, ensure that the direction of rotation is cor-

rect » page 136 .

All bolts must be clean and must turn easily. If screws are corroded and diffi-

cult to move, these must be replaced.

WARNING■ Undo the wheel bolts just a little (about one turn), provided the vehicle

has not yet been jacked up. Otherwise the wheel could come loose and fall

off – risk of injury.■

Under no circumstances must the bolts be greased or oiled - cause an ac-

cident.

Subsequent steps

After changing the wheel, the following work must be carried out.

›

Stow the replaced wheel in the well under the floor covering of the luggage

compartment and secure it with a nut.

›

Stow the tool kit in the space provided and secure using the band.

›

Check tyre pressure on the mounted wheel and adjust if necessary and, with

vehicles with tyre pressure monitoring, save the tyre pressure values in the

system » page 109 .

›

Have the tightening torque of the wheel bolts checked as soon as possible.

The prescribed tightening torque is 120 Nm.

Replace the damaged wheel or consult a specialist garage about repair op-

tions.

WARNINGTightening torque which is too high can damage the threads and this can

result in permanent deformation of the contact surfaces on the rim. Where

tightening torque is too low, the wheels may become loose while driving -

risk of accident. Therefore drive cautiously and only at a moderate speed

until the tightening torque has been checked.

Removing/stowing the emergency or spare wheel

Fig. 164

Take out the wheel

The wheel is located in a well under the floor covering in the luggage compart-

ment and is fixed in place with a screw.

Take out the wheel

›

Lift up the floor in the luggage compartment.

›

Loosen the retaining belt and take out the box with the tool kit.

›

Unscrew the nut in the direction of arrow » Fig. 164 and take out the wheel.

Stow the wheel

›

Place the wheel into the wheel well with the wheel rim pointing downward.

On vehicles with the vehicle battery in the boot, lay down the wheel with the

outer face upward.

›

Pull the fixing band through the opposite holes in the wheel rim.

›

Screw the nut in the opposite direction to the arrow until it stops » Fig. 164.

›

Place the box with the tool kit back inside the wheel and secure it with the

tape.

›

Fold back the floor in the luggage compartment.

142Do-it-yourself

Page 150 of 184

›Attach clamp 3 to the negative terminal of the power-supplying battery.›For vehicles

with the START-STOPsystem, attach clamp 4 to the earth point

of the engine A

» Fig. 171 .

›

For vehicles without the START-STOPsystem, attach clamp

4

to a solid

metal part firmly attached to the engine block or directly to the engine block.

Installation location of the positive terminal and the earth point in vehicles

with the vehicle battery in the luggage compartment

The positive terminal

B

is located under a cover in the engine compartment

» Fig. 172 .

›

Unlock the lock buttons of the cover in the direction of arrow

1

and remove

the cover in the direction of arrow

2

.

›

Clamp the positive terminal of the jumper cable to the position

B

» Fig. 172 .

›

Clamp the negative terminal of the jumper cable to the earth point of the en-

gine

A

or on a metal part firmly connected to the engine block or directly on

the engine block.

Starting engine

›

Start the engine on the vehicle providing the power and allow it to idle.

›

Initiate the starting process in the vehicle with the discharged battery.

›

If the engine does not start within 10 s, then cancel the starting procedure

and repeat after half a minute.

›

Remove the jump start cables in the reverse order as attachment.

WARNING■

Never clamp the jump cable to the negative terminal of the discharged

battery - risk of explosion.■

The non-insulated parts of the terminal clamps must never touch each

other – there is a risk of short circuit!

■

The jump-start cable connected to the positive terminal of the battery

must not come into contact with electrically conducting parts of the vehicle

– there is a risk of short circuit!

■

Position the jump cables so that they cannot be caught in rotating parts

in the engine compartment - danger of injuries and the risk of vehicle dam-

age.

Towing the vehicle

Information about the towing process

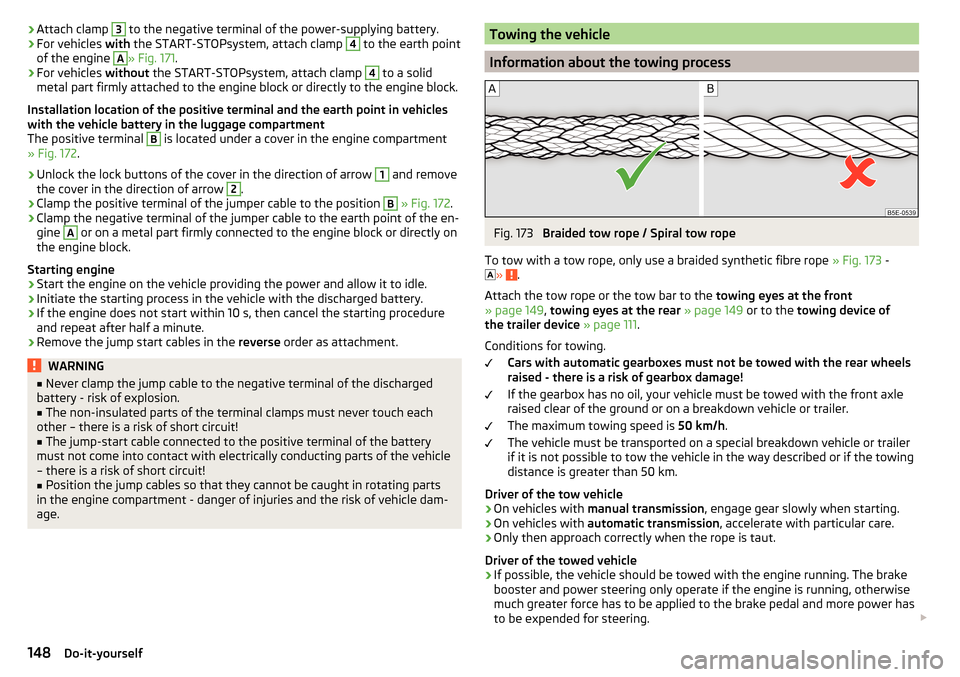

Fig. 173

Braided tow rope / Spiral tow rope

To tow with a tow rope, only use a braided synthetic fibre rope » Fig. 173 -

»

.

Attach the tow rope or the tow bar to the towing eyes at the front

» page 149 , towing eyes at the rear » page 149 or to the towing device of

the trailer device » page 111 .

Conditions for towing. Cars with automatic gearboxes must not be towed with the rear wheels

raised - there is a risk of gearbox damage!

If the gearbox has no oil, your vehicle must be towed with the front axle

raised clear of the ground or on a breakdown vehicle or trailer.

The maximum towing speed is 50 km/h.

The vehicle must be transported on a special breakdown vehicle or trailer

if it is not possible to tow the vehicle in the way described or if the towing

distance is greater than 50 km.

Driver of the tow vehicle

›

On vehicles with manual transmission , engage gear slowly when starting.

›

On vehicles with automatic transmission , accelerate with particular care.

›

Only then approach correctly when the rope is taut.

Driver of the towed vehicle

›

If possible, the vehicle should be towed with the engine running. The brake

booster and power steering only operate if the engine is running, otherwise

much greater force has to be applied to the brake pedal and more power has

to be expended for steering.

148Do-it-yourself

Page 151 of 184

›If it is not possible to start the engine, switch on the ignition so that the

steering wheel does not lock and so that the turn signal lights, windscreen

wipers and windscreen washer system can be used.›

Take the vehicle out of gear or move the selector lever into position N if the

vehicle is fitted with an automatic gearbox.

›

Keep the tow rope taut at all times during the towing procedure.

WARNING■ Spiral tow ropes must not be used for towing » Fig. 173- , the towing

eye may unscrew out of the vehicle - risk of accident.■

The tow rope should not be twisted - there is a risk of accidents.

CAUTION

■ Do not tow-start the engine – risk of damaging the engine! The battery from

another vehicle can be used as a jump-start aid » page 147, Jump-starting .■

For off-road towing manoeuvres, there is a risk to both vehicles that the fas-

teners may become overloaded and damaged.

Note

We recommend that you use a tow rope from ŠKODA Original Accessories.

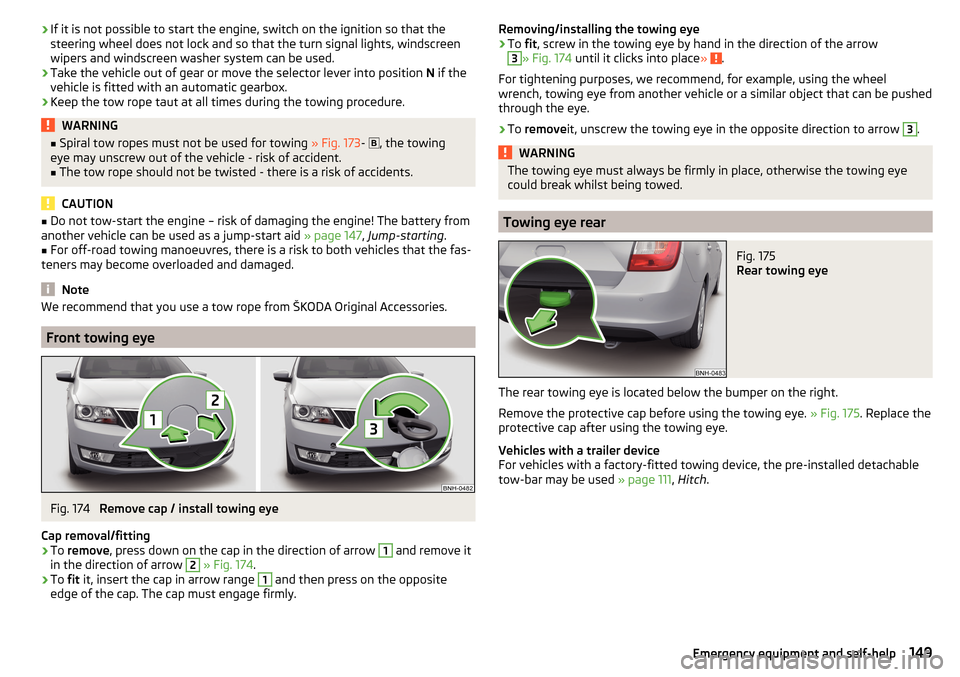

Front towing eye

Fig. 174

Remove cap / install towing eye

Cap removal/fitting

›

To remove , press down on the cap in the direction of arrow

1

and remove it

in the direction of arrow

2

» Fig. 174 .

›

To fit it, insert the cap in arrow range

1

and then press on the opposite

edge of the cap. The cap must engage firmly.

Removing/installing the towing eye›To fit, screw in the towing eye by hand in the direction of the arrow3

» Fig. 174 until it clicks into place » .

For tightening purposes, we recommend, for example, using the wheel

wrench, towing eye from another vehicle or a similar object that can be pushed through the eye.

›

To remove it, unscrew the towing eye in the opposite direction to arrow

3

.

WARNINGThe towing eye must always be firmly in place, otherwise the towing eye

could break whilst being towed.

Towing eye rear

Fig. 175

Rear towing eye

The rear towing eye is located below the bumper on the right.

Remove the protective cap before using the towing eye. » Fig. 175. Replace the

protective cap after using the towing eye.

Vehicles with a trailer device

For vehicles with a factory-fitted towing device, the pre-installed detachable

tow-bar may be used » page 111, Hitch .

149Emergency equipment and self-help

Page 156 of 184

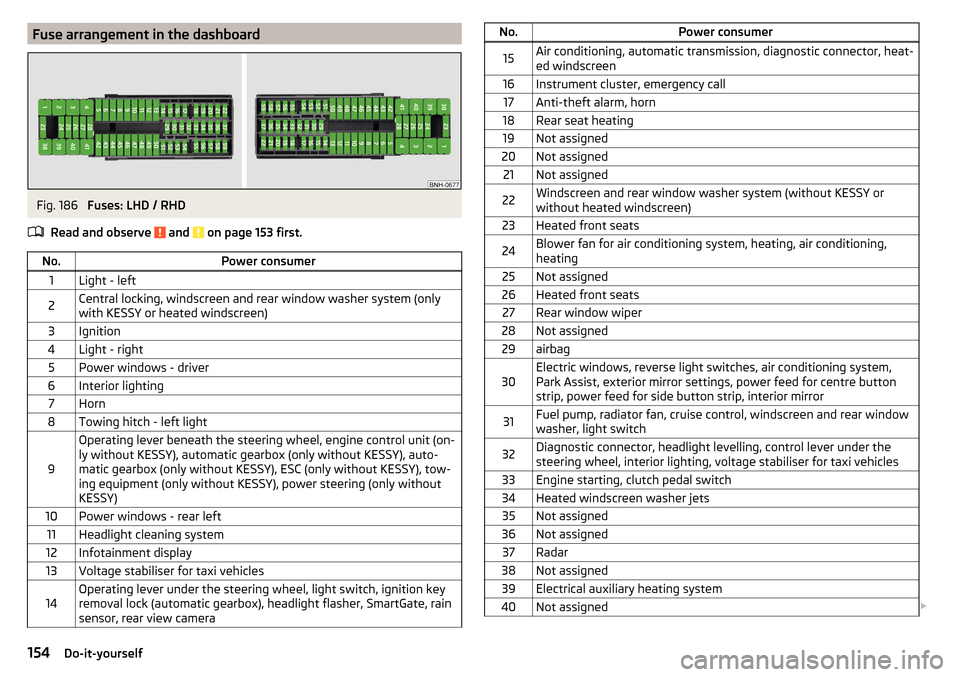

Fuse arrangement in the dashboardFig. 186

Fuses: LHD / RHD

Read and observe

and on page 153 first.

No.Power consumer1Light - left2Central locking, windscreen and rear window washer system (only

with KESSY or heated windscreen)3Ignition4Light - right5Power windows - driver6Interior lighting7Horn8Towing hitch - left light

9

Operating lever beneath the steering wheel, engine control unit (on-

ly without KESSY), automatic gearbox (only without KESSY), auto-

matic gearbox (only without KESSY), ESC (only without KESSY), tow-

ing equipment (only without KESSY), power steering (only without

KESSY)10Power windows - rear left11Headlight cleaning system12Infotainment display13Voltage stabiliser for taxi vehicles14Operating lever under the steering wheel, light switch, ignition key

removal lock (automatic gearbox), headlight flasher, SmartGate, rain

sensor, rear view cameraNo.Power consumer15Air conditioning, automatic transmission, diagnostic connector, heat-

ed windscreen16Instrument cluster, emergency call17Anti-theft alarm, horn18Rear seat heating19Not assigned20Not assigned21Not assigned22Windscreen and rear window washer system (without KESSY or

without heated windscreen)23Heated front seats24Blower fan for air conditioning system, heating, air conditioning,

heating25Not assigned26Heated front seats27Rear window wiper28Not assigned29airbag30Electric windows, reverse light switches, air conditioning system,

Park Assist, exterior mirror settings, power feed for centre button

strip, power feed for side button strip, interior mirror31Fuel pump, radiator fan, cruise control, windscreen and rear window

washer, light switch32Diagnostic connector, headlight levelling, control lever under the

steering wheel, interior lighting, voltage stabiliser for taxi vehicles33Engine starting, clutch pedal switch34Heated windscreen washer jets35Not assigned36Not assigned37Radar38Not assigned39Electrical auxiliary heating system40Not assigned 154Do-it-yourself