lock SKODA ROOMSTER 2010 1.G Technical Change

[x] Cancel search | Manufacturer: SKODA, Model Year: 2010, Model line: ROOMSTER, Model: SKODA ROOMSTER 2010 1.GPages: 14, PDF Size: 0.63 MB

Page 2 of 14

Introduction1

IntroductionThis supplement to the FABIA Owner's manual Edition 05.10 and the ROOMSTER

Owner's manual Edition 03.10, henceforth referred to as the Owner's manual.

The information given in this supplement takes preference over the information in the

Owner's manual.

Special equipment is marked with the symbol *.

We wish you a good journey

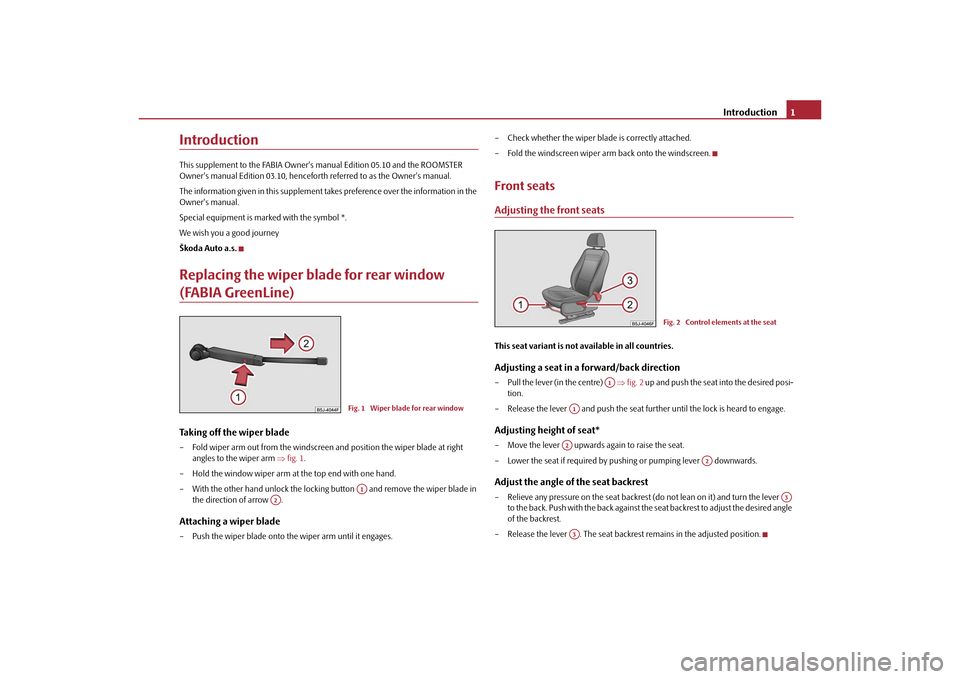

Škoda Auto a.s.Replacing the wiper blade for rear window (FABIA GreenLine)Taking off the wiper blade – Fold wiper arm out from the windscreen and position the wiper blade at right angles to the wiper arm fig. 1 .

– Hold the window wiper arm at the top end with one hand.

– With the other hand unlock the locking button and remove the wiper blade in the direction of arrow .Attaching a wiper blade– Push the wiper blade onto th e wiper arm until it engages. – Check whether the wiper blade is correctly attached.

– Fold the windscreen wiper ar

m back onto the windscreen.

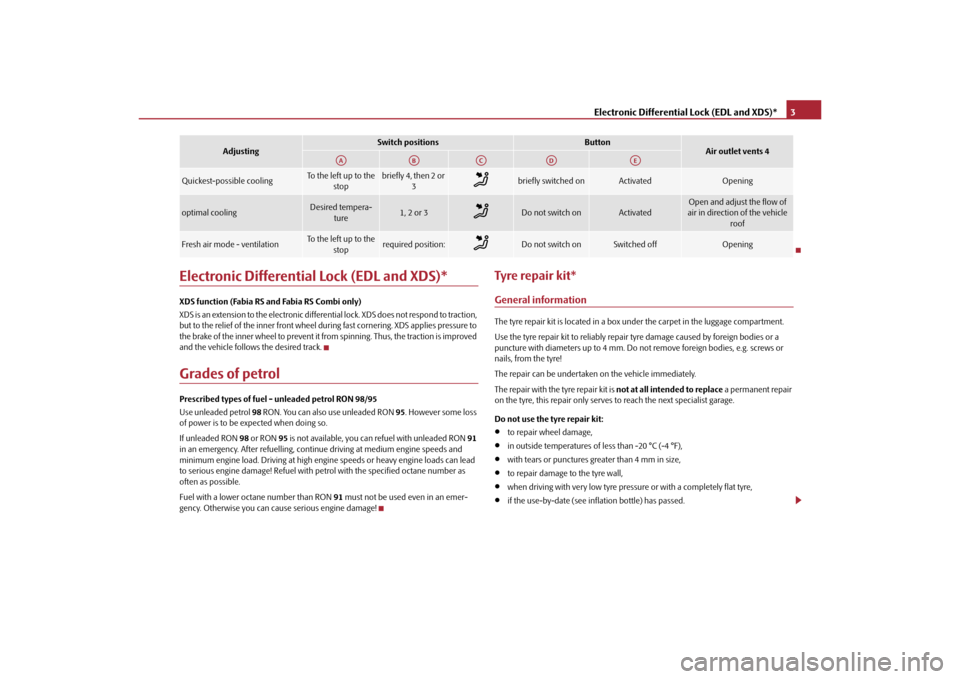

Front seatsAdjusting the front seatsThis seat variant is not available in all countries.Adjusting a seat in a forward/back direction– Pull the lever (in the centre) fig. 2 up and push the seat into the desired posi-

tion.

– Release the lever and push the seat further until the lock is heard to engage.Adjusting height of seat*– Move the lever upwards again to raise the seat.

– Lower the seat if required by pushing or pumping lever downwards.Adjust the angle of the seat backrest– Relieve any pressure on the seat backrest (do not lean on it) and turn the lever

to the back. Push with the ba ck against the seat backrest to adjust the desired angle

of the backrest.

– Release the lever . The seat backrest remains in the adjusted position.

Fig. 1 Wiper blade for rear windowA1

A2

Fig. 2 Control elements at the seat

A1

A1A2

A2

A3

A3

s35k.1j.book Page 1 Thursday, September 16, 2010 1:02 PM

Page 4 of 14

Electronic Differential Lock (EDL and XDS)*3

Electronic Differential Lock (EDL and XDS)*XDS function (Fabia RS and Fabia RS Combi only)

XDS is an extension to the electronic differential lock. XDS does not respond to traction,

but to the relief of the inner front wheel during fast cornering. XDS applies pressure to

the brake of the inner wheel to prevent it fr om spinning. Thus, the traction is improved

and the vehicle follows the desired track.Grades of petrolPrescribed types of fuel - unleaded petrol RON 98/95

Use unleaded petrol 98 RON. You can also use unleaded RON 95. However some loss

of power is to be expected when doing so.

If unleaded RON 98 or RON 95 is not available, you ca n refuel with unleaded RON 91

in an emergency. After refuelling, conti nue driving at medium engine speeds and

minimum engine load. Driving at high engine speeds or heavy engine loads can lead

to serious engine damage! Refuel with pe trol with the specified octane number as

often as possible.

Fuel with a lower octane number than RON 91 must not be used even in an emer-

gency. Otherwise you can ca use serious engine damage!

Tyre repair kit*General informationThe tyre repair kit is located in a box un der the carpet in the luggage compartment.

Use the tyre repair kit to re liably repair tyre damage ca used by foreign bodies or a

puncture with diameters up to 4 mm. Do no t remove foreign bodies, e.g. screws or

nails, from the tyre!

The repair can be undertaken on the vehicle immediately.

The repair with the tyre repair kit is not at all intended to replace a permanent repair

on the tyre, this repair only serves to reach the next specialist garage.

Do not use the tyre repair kit:•

to repair wheel damage,

•

in outside temperatures of less than -20 °C (-4 °F),

•

with tears or punctures greater than 4 mm in size,

•

to repair damage to the tyre wall,

•

when driving with very low tyre pressure or with a completely flat tyre,

•

if the use-by-date (see inflation bottle) has passed.

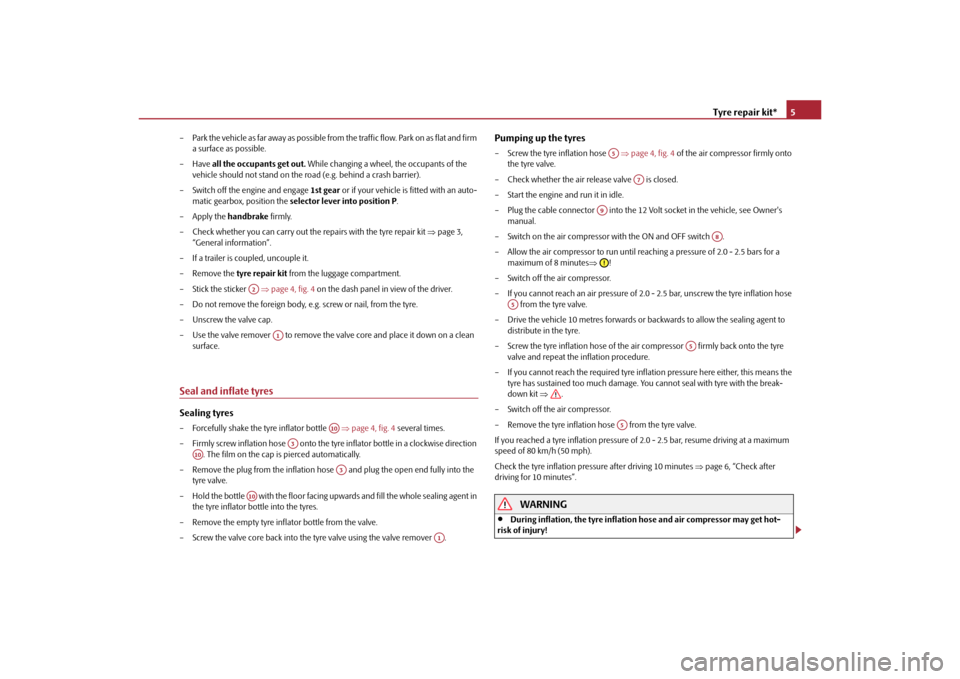

Quickest-possible cooling

To the left up to the

stop

briefly4, then 2or 3

briefly switched on

Activated

Opening

optimal cooling

Desired tempera-ture

1, 2 or 3

Do not switch on

Activated

Open and adjust the flow of

air in direction of the vehicle roof

Fresh air mode - ventilation

To the left up to the

stop

required position:

Do not switch on

Switched off

Opening

Adjusting

Switch positions

Button

Air outlet vents 4

AA

AB

AC

AD

AE

s35k.1j.book Page 3 Thursday, September 16, 2010 1:02 PM

Page 6 of 14

Tyre repair kit*5

– Park the vehicle as far away as possible from the traffic flow. Park on as flat and firm

a surface as possible.

–Have all the occupants get out. While changing a wheel, the occupants of the

vehicle should not stand on the road (e.g. behind a crash barrier).

– Switch off the engine and engage 1st gear or if your vehicle is fitted with an auto-

matic gearbox, position the selector lever into position P .

– Apply the handbrake firmly.

– Check whether you can carry out the repairs with the tyre repair kit page 3,

“General information”.

– If a trailer is coupled, uncouple it.

– Remove the tyre repair kit from the luggage compartment.

– Stick the sticker page 4, fig. 4 on the dash panel in view of the driver.

– Do not remove the foreign body, e.g. screw or nail, from the tyre.

– Unscrew the valve cap.

– Use the valve remover to remove the va lve core and place it down on a clean

surface.Seal and inflate tyresSealing tyres– Forcefully shake the tyre inflator bottle page 4, fig. 4 several times.

– Firmly screw inflation hose onto the tyre inflator bottle in a clockwise direction . The film on the cap is pierced automatically.

– Remove the plug from the inflation hose and plug the open end fully into the tyre valve.

– Hold the bottle with the floor facing up wards and fill the whole sealing agent in

the tyre inflator bottle into the tyres.

– Remove the empty tyre inflator bottle from the valve.

– Screw the valve core back into the tyre valve using the valve remover .

Pumping up the tyres– Screw the tyre inflation hose page 4, fig. 4 of the air compressor firmly onto

the tyre valve.

– Check whether the air re lease valve is closed.

– Start the engine and run it in idle.

– Plug the cable connector into the 12 Vo lt socket in the vehicle, see Owner's

manual.

– Switch on the air compressor with the ON and OFF switch .

– Allow the air compressor to run until reac hing a pressure of 2.0 - 2.5 bars for a

maximum of 8 minutes !

– Switch off the air compressor.

– If you cannot reach an air pressure of 2.0 - 2.5 bar, unscrew the tyre inflation hose from the tyre valve.

– Drive the vehicle 10 metres forwards or backwards to allow the sealing agent to

distribute in the tyre.

– Screw the tyre inflation hose of the air compressor firmly back onto the tyre

valve and repeat the inflation procedure.

– If you cannot reach the required tyre inflation pressure here either, this means the tyre has sustained too much damage. You cannot seal with tyre with the break-

down kit .

– Switch off the air compressor.

– Remove the tyre inflation hose from the tyre valve.

If you reached a tyre inflation pressure of 2.0 - 2.5 bar, resume driving at a maximum

speed of 80 km/h (50 mph).

Check the tyre inflation pressure after driving 10 minutes page 6, “Check after

driving for 10 minutes”.

WARNING

•

During inflation, the tyre inflation hose and air compressor may get hot-

risk of injury!

A2

A1

A10

A3

A10

A3

A10

A1

A5

A7

A9

A8

A5

A5

A5

s35k.1j.book Page 5 Thursday, September 16, 2010 1:02 PM