warning SKODA ROOMSTER 2011 1.G Owner's Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 2011, Model line: ROOMSTER, Model: SKODA ROOMSTER 2011 1.GPages: 212, PDF Size: 3.3 MB

Page 175 of 212

●

when driving with very low tyre pressure or with a completely flat tyre,

● if the use-by-date (see inflation bottle) has passed. WARNING

● If you find yourself in flowing traffic switch on the hazard warning lights

system and place the warning triangle on the side of the road at the prescri-

bed distance from your vehicle. Comply with the national legal regulations. In

this way you are protecting not only yourself but also other road users.

● Park the vehicle as far away as possible from the traffic flow. Park on as

flat and firm a surface as possible.

● A tyre filled with sealant has the same driving characteristics as a standard

tyre.

● Do not drive faster than 80 km/h, 50 mph.

● Avoid accelerating at full throttle, sharp braking and fast cornering.

● Check the tyre inflation pressure after driving 10 minutes.

● Sealant is hazardous to heath. Remove immediately if it comes into con-

tact with the skin. For the sake of the environment

Used sealant or sealant whose expiry date has passed must be disposed of in ac-

cordance with environmental protection regulations. Note

● Observe the manufacturer's usage instructions for the tyre repair kit.

● You can purchase a new bottle of sealant from the range of the ŠKODA Origi-

nal Accessories.

● Change the wheel that was repaired using the tyre repair kit or consult a spe-

cialist garage about possibilities for getting repairs done. Components of the tyre repair kit

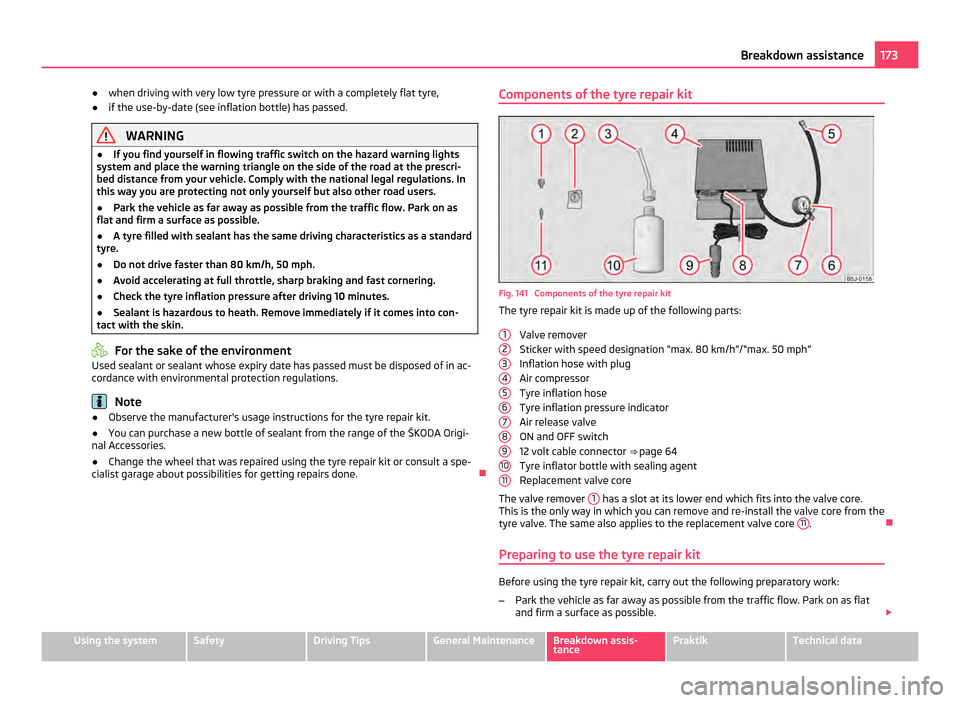

Fig. 141 Components of the tyre repair kit

The tyre repair kit is made up of the following parts:

Valve remover

Sticker with speed designation

“max. 80 km/h”/“max. 50 mph”

Inflation hose with plug

Air compressor

Tyre inflation hose

Tyre inflation pressure indicator

Air release valve

ON and OFF switch

12 volt cable connector ⇒ page 64

Tyre inflator bottle with sealing agent

Replacement valve core

The valve remover 1 has a slot at its lower end which fits into the valve core.

This is the only way in which you can remove and re-install the valve core from the

tyre valve. The same also applies to the replacement valve core 11 .

Preparing to use the tyre repair kit Before using the tyre repair kit, carry out the following preparatory work:

–

Park the vehicle as far away as possible from the traffic flow. Park on as flat

and firm a surface as possible. £

1 2

3

4

5

6

7

8

9

10

11 173

Breakdown assistance Using the system Safety Driving Tips General Maintenance Breakdown assis-

tance Praktik Technical data

Page 176 of 212

–

Have all the occupants get out. While changing a tyre, the occupants of the

vehicle should not stand on the road (instead they should remain behind a

crash barrier, for example).

– Switch off the engine and engage 1st gear or if your vehicle is fitted with an

automatic gearbox, position the selector lever into position P .

– Apply the handbrake firmly.

– Check whether you can carry out the repairs with the tyre repair kit

⇒ page 172, General information.

– If a trailer is coupled, uncouple it.

– Remove the tyre repair kit from the luggage compartment.

– Stick the sticker 2

⇒

fig. 141 on the dash panel in view of the driver.

– Do not remove the foreign body, e.g. screw or nail, from the tyre.

– Unscrew the valve cap.

– Use the valve remover 1 to remove the valve core and place it down on a

clean surface.

Seal and inflate tyres Sealing tyres

–

Forcefully shake the tyre inflator bottle 10

⇒ fig. 141 several times.

– Firmly screw inflation hose 3 onto the tyre inflator bottle in a clockwise direc-

tion 10 . The film on the cap is pierced automatically.

– Remove the plug from the inflation hose 3 and plug the open end fully into

the tyre valve.

– Hold the bottle 10 with the floor facing upwards and fill the whole sealing

agent in the tyre inflator bottle into the tyres.

– Remove the empty tyre inflator bottle from the valve.

– Screw the valve core back into the tyre valve using the valve remover 1 .

Pumping up the tyres

– Screw the tyre inflation hose 5

⇒

fig. 141 of the air compressor firmly onto the

tyre valve.

– Check whether the air release valve 7 is closed.–

On vehicles fitted with a manual gearbox, move the gearshift lever into Neu-

tral.

– Start the engine and run it in idle.

– Plug the connector 9 into 12 Volt socket ⇒

page 64.

– Switch on the air compressor with the ON and OFF switch 8 .

– Allow the air compressor to run until reaching a pressure of 2.0 - 2.5 bar. Maxi-

mum run time of 8 minutes ⇒ !

– Switch off the air compressor with the ON and OFF switch.

– If you cannot reach an air pressure of 2.0 – 2.5 bar, unscrew the tyre inflation

hose 5 from the tyre valve.

– Drive the vehicle approx. 10 metres forwards or backwards to allow the sealing

agent to distribute in the tyre.

– Screw the tyre inflation hose of the air compressor 5 firmly back onto the

tyre valve and repeat the inflation procedure.

– If you cannot reach the required tyre inflation pressure here either, this means

the tyre has sustained too much damage. You cannot seal with tyre with the

breakdown kit ⇒ .

– Switch off the air compressor with the ON and OFF switch.

– Remove the tyre inflation hose 5 from the tyre valve.

After reaching a tyre inflation pressure of 2.0 – 2.5 bar, drive at a maximum speed

of 80 km/h (50

mph).

Check the tyre inflation pressure after driving 10 minutes ⇒ page 175, Check after

driving for 10 minutes. WARNING

● During inflation, the tyre inflation hose and air compressor may get hot-

risk of injury!

● Do not place hot tyre inflation hoses or hot air compressors on flammable

materials - risk of fire!

● If you cannot inflate the tyre to at least 2.0 bar, this means the damage

sustained was too serious. The sealing agent cannot be used to seal the tyre.

Do not drive the vehicle. Get professional assistance. £174

Breakdown assistance

Page 177 of 212

CAUTION

Switch off the air compressor after running 8 minutes at the latest - danger of

overheating! Allow the air compressor to cool a few moments before switching it

on again.

Check after driving for 10 minutes Check the tyre inflation pressure after driving 10 minutes.

If the tyre inflation pressure is 1.3 bar or less:

–

Do not drive the vehicle! You cannot properly seal with tyre with the break-

down kit.

– Contact a Škoda dealer to obtain professional assistance.

If the tyre inflation pressure is 1.3 bar or more:

– Adjust the tyre inflation pressure to the correct value (see inside of fuel filler

cap).

– Continue driving carefully to the nearest specialist garage at a maximum

speed of 80 km/h (50 mph).

Jump-starting Initial steps You can use the battery of another vehicle for jump-starting yours if the engine

does not start because the battery on your vehicle is flat. You will require jump-

start cables for this purpose.

Both batteries must have a rated voltage of 12 V. The capacity

(Ah) of the battery

supplying the power must not be significantly less than the capacity of the dis-

charged battery in your vehicle.

Jump-start cables

Only use jump-start cables which have an adequately large cross-section and in-

sulated terminal clamps. Please pay attention to the manufacturer's instructions.

Positive cable - colour coding in the majority of cases red.

Negative cable -

colour coding in the majority of cases black. WARNING

● A discharged battery may already freeze at temperatures just below 0 °C.

In case of frozen battery carry out no jump-starting - risk of explosion! Also af-

ter thawing of the battery there is a risk of caustic burns due to leaking acid.

Replace the frozen battery.

● Please pay attention to the warning instructions relating to working in the

engine compartment ⇒ page 150

. Note

● There must not be any contact between the two vehicles otherwise current

may flow as soon as the negative terminals are connected.

● The discharged battery must be properly connected to the system of the vehi-

cle.

● Switch off the car phone. Heed the advice concerning the use of mobile

phones in such a situation.

● We recommend you buy jump-start cables from a car battery specialist.

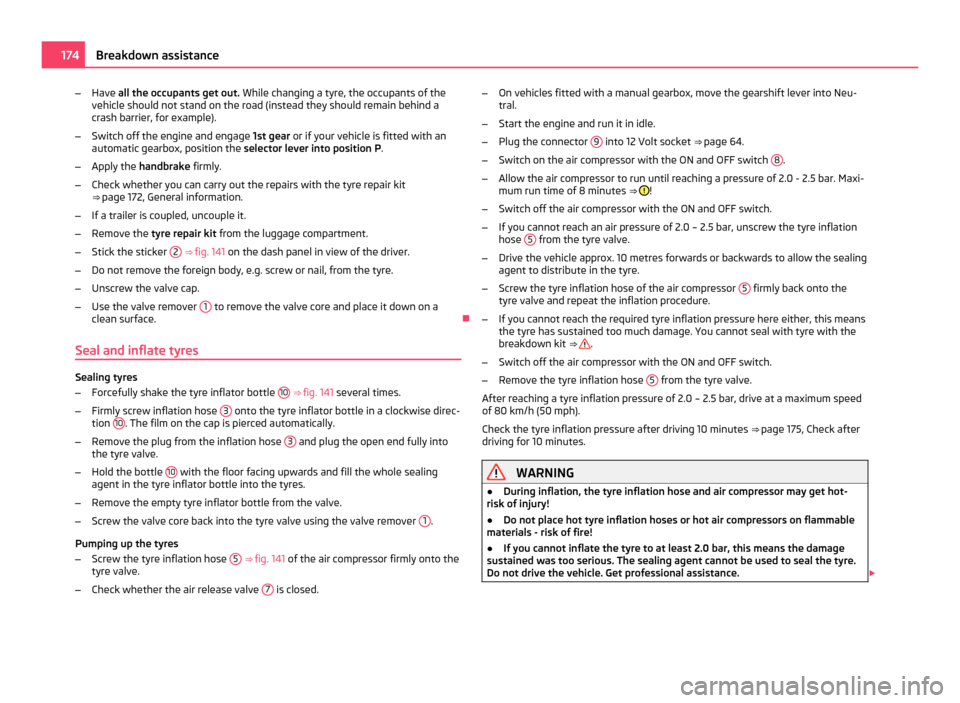

Start engine Fig. 142 Jump-starting using the battery

from another vehicle: A - flat vehicle bat-

tery, B - battery providing current

It is important to connect the jump-start cables in the correct order.

Connecting positive terminals

– Attach one end 1 to the positive terminal

⇒ fig. 142 of the discharged battery

A .

– Attach the other end 2 to the positive terminal of the battery supplying the

power B .

£ 175

Breakdown assistance Using the system Safety Driving Tips General Maintenance Breakdown assis-

tance Praktik Technical data

Page 178 of 212

Connecting negative terminal and engine block

– Attach one end 3 to the negative terminal of the battery supplying the power

B .

– Attach the other end 4 to a solid metal part which is connected firmly to the

engine block, or to the engine block itself ⇒ .

Starting engine

– Start the engine of the vehicle providing current and run the engine at idling

speed.

– Now start the engine of the vehicle with the discharged battery.

– Interrupt the attempt at starting an engine after 10 seconds if it does not start

right away and wait for about 30 seconds before repeating the attempt.

– Disconnect the cables in exactly the reverse order they were connected.WARNING

● The non-insulated parts of the terminal clamps must never make contact

with each other. In addition, the jump-start cable connected to the positive

terminal of the battery must not come into contact with electrically conduct-

ing parts of the vehicle - risk of short circuit!

● Do not affix the jump starting cables to the negative terminal of the dis-

charged battery. There is the risk of detonating gas seeping out the battery

being ignited by the strong spark which results from the engine being started.

● Do not affix the cable end 4 to parts of the fuel and brake system.

● Run the jump-start cables so that they cannot be caught by any rotating

parts in the engine compartment.

● Do not bend over the batteries - risk of caustic burns!

● The vent screws of the battery cells must be tightened firmly.

● Keep any sources of ignition (naked flame, smouldering cigarettes etc.)

away from the battery - risk of an explosion!

● Never jump-start the batteries which have a too low electrolyte level - risk

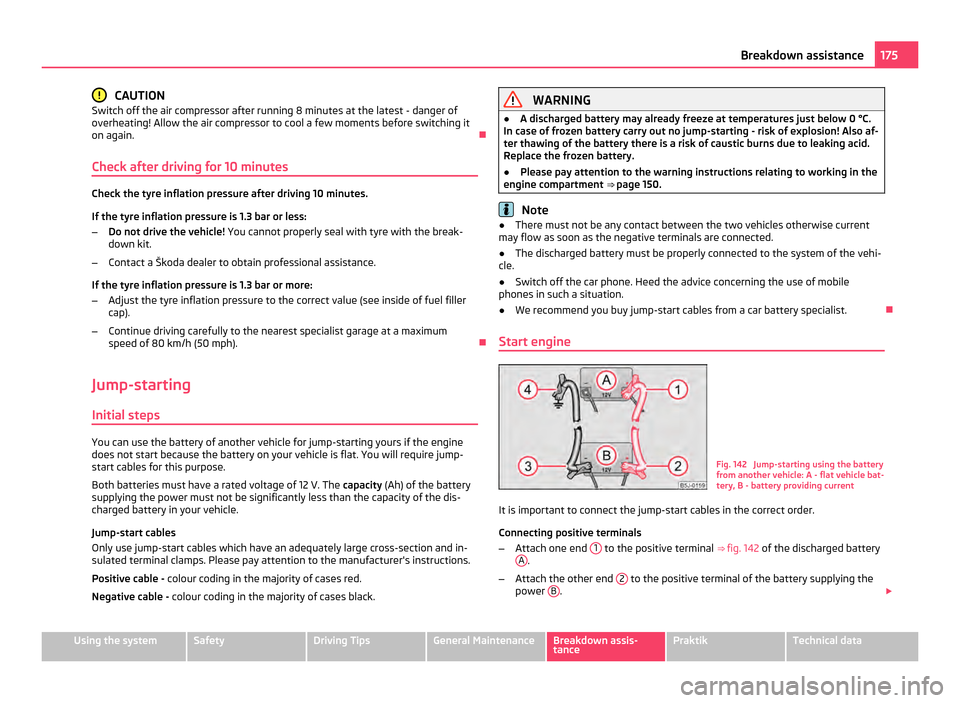

of explosion and caustic burns! Jump-starting on vehicles with the “START-STOP” system

Fig. 143 Jump-starting on vehicles with

the START-STOP system

On vehicles with the “START STOP” system, the negative cable of the charger

must never be connected directly to the negative pole of the vehicle battery, but

only to the engine earth ⇒ fig. 143 .

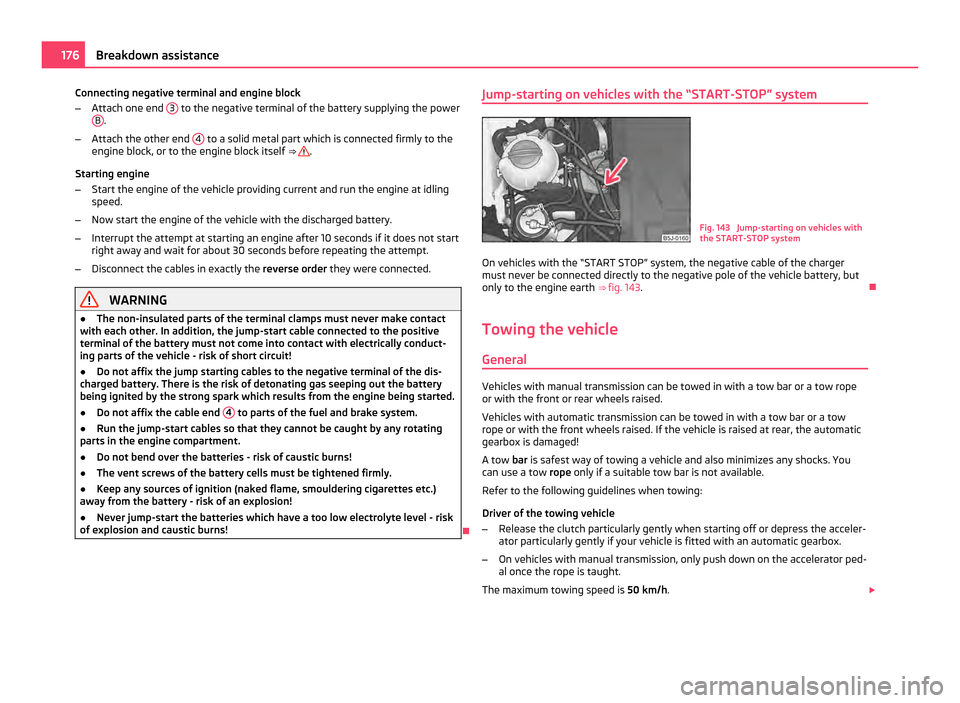

Towing the vehicle General Vehicles with manual transmission can be towed in with a tow bar or a tow rope

or with the front or rear wheels raised.

Vehicles with automatic transmission can be towed in with a tow bar or a tow

rope or with the front wheels raised. If the vehicle is raised at rear, the automatic

gearbox is damaged!

A tow bar

is safest way of towing a vehicle and also minimizes any shocks. You

can use a tow rope only if a suitable tow bar is not available.

Refer to the following guidelines when towing:

Driver of the towing vehicle

– Release the clutch particularly gently when starting off or depress the acceler-

ator particularly gently if your vehicle is fitted with an automatic gearbox.

– On vehicles with manual transmission, only push down on the accelerator ped-

al once the rope is taught.

The maximum towing speed is 50 km/h. £176

Breakdown assistance

Page 181 of 212

Fuses and light bulbs

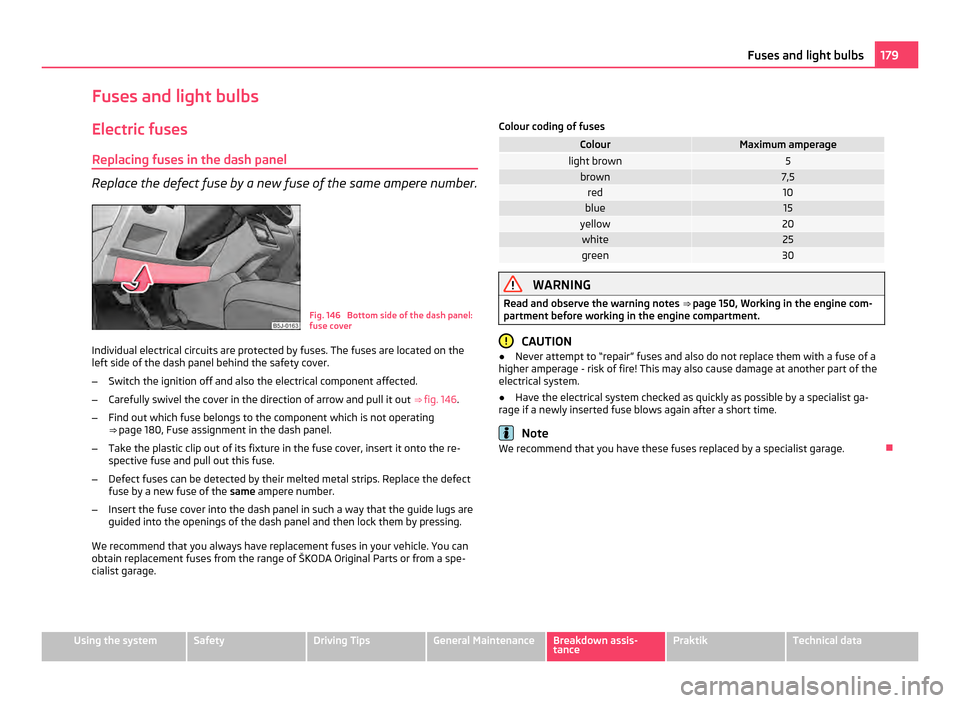

Electric fuses Replacing fuses in the dash panel Replace the defect fuse by a new fuse of the same ampere number.

Fig. 146 Bottom side of the dash panel:

fuse cover

Individual electrical circuits are protected by fuses. The fuses are located on the

left side of the dash panel behind the safety cover.

– Switch the ignition off and also the electrical component affected.

– Carefully swivel the cover in the direction of arrow and pull it out ⇒ fig. 146 .

– Find out which fuse belongs to the component which is not operating

⇒ page 180

, Fuse assignment in the dash panel.

– Take the plastic clip out of its fixture in the fuse cover, insert it onto the re-

spective fuse and pull out this fuse.

– Defect fuses can be detected by their melted metal strips. Replace the defect

fuse by a new fuse of the same ampere number.

– Insert the fuse cover into the dash panel in such a way that the guide lugs are

guided into the openings of the dash panel and then lock them by pressing.

We recommend that you always have replacement fuses in your vehicle. You can

obtain replacement fuses from the range of

ŠKODA Original Parts or from a spe-

cialist garage. Colour coding of fuses Colour Maximum amperage

light brown 5

brown 7,5

red 10

blue 15

yellow 20

white 25

green 30

WARNING

Read and observe the warning notes ⇒ page 150

, Working in the engine com-

partment before working in the engine compartment. CAUTION

● Never attempt to

“repair” fuses and also do not replace them with a fuse of a

higher amperage - risk of fire! This may also cause damage at another part of the

electrical system.

● Have the electrical system checked as quickly as possible by a specialist ga-

rage if a newly inserted fuse blows again after a short time. Note

We recommend that you have these fuses replaced by a specialist garage. 179

Fuses and light bulbs Using the system Safety Driving Tips General Maintenance Breakdown assis-

tance Praktik Technical data

Page 183 of 212

No. Power consumer

43 Horn

44 Front window wiper

45 Central control unit for convenience system

46 Engine control unit

Engine control unit

Fuel pump relay

Fuel pump control unit

47 Cigarette lighter, power socket in the luggage compartment

a)48 ABS, START-STOP - DC/DC converter ESP

49 Turn signal lights, brake lights

50 START-STOP - DC/DC converter infotainment

Radio

51 Electrical power window (front and rear) - left side

52 Electrical power window (front and rear) - right side

53 Parking light - left side

Electric sliding/tilting roof

54 START-STOP - instrument cluster

Anti-theft alarm system

55 Control unit for automatic gearbox DSG

56 Headlight cleaning system

Parking light - right side

57 Left low beam, headlight range adjustment

58 Low beam on the right

a)

If the engine is switched off already one electrical component which is connected can discharge the

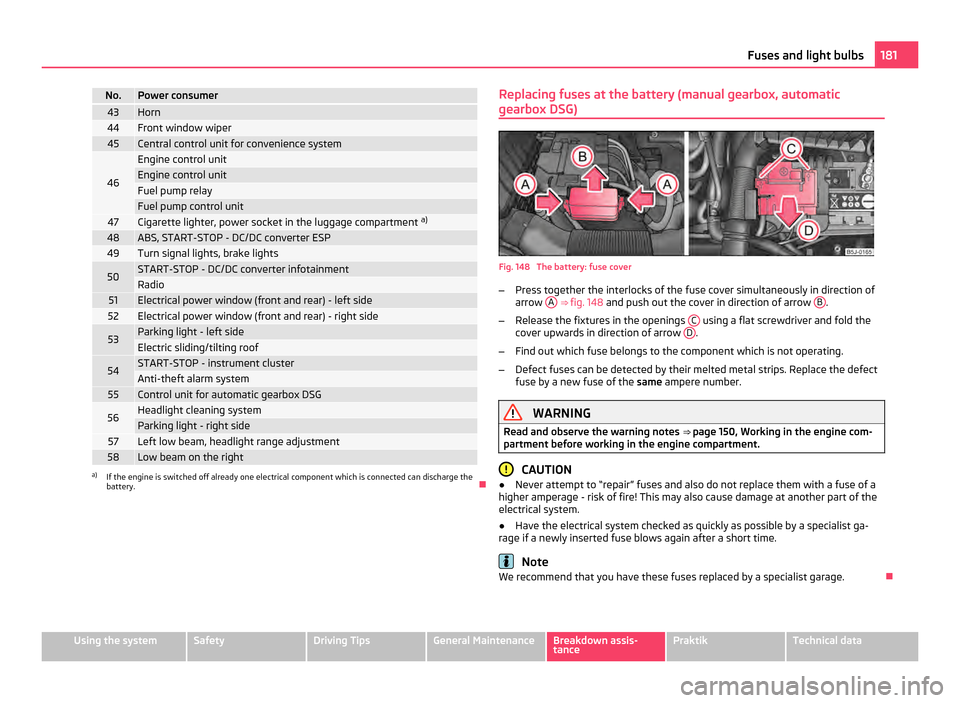

battery. Replacing fuses at the battery (manual gearbox, automatic

gearbox DSG) Fig. 148 The battery: fuse cover

– Press together the interlocks of the fuse cover simultaneously in direction of

arrow A

⇒ fig. 148 and push out the cover in direction of arrow B .

– Release the fixtures in the openings C using a flat screwdriver and fold the

cover upwards in direction of arrow D .

– Find out which fuse belongs to the component which is not operating.

– Defect fuses can be detected by their melted metal strips. Replace the defect

fuse by a new fuse of the same ampere number. WARNING

Read and observe the warning notes ⇒ page 150 , Working in the engine com-

partment before working in the engine compartment. CAUTION

● Never attempt to

“repair” fuses and also do not replace them with a fuse of a

higher amperage - risk of fire! This may also cause damage at another part of the

electrical system.

● Have the electrical system checked as quickly as possible by a specialist ga-

rage if a newly inserted fuse blows again after a short time. Note

We recommend that you have these fuses replaced by a specialist garage. 181

Fuses and light bulbs Using the system Safety Driving Tips General Maintenance Breakdown assis-

tance Praktik Technical data

Page 184 of 212

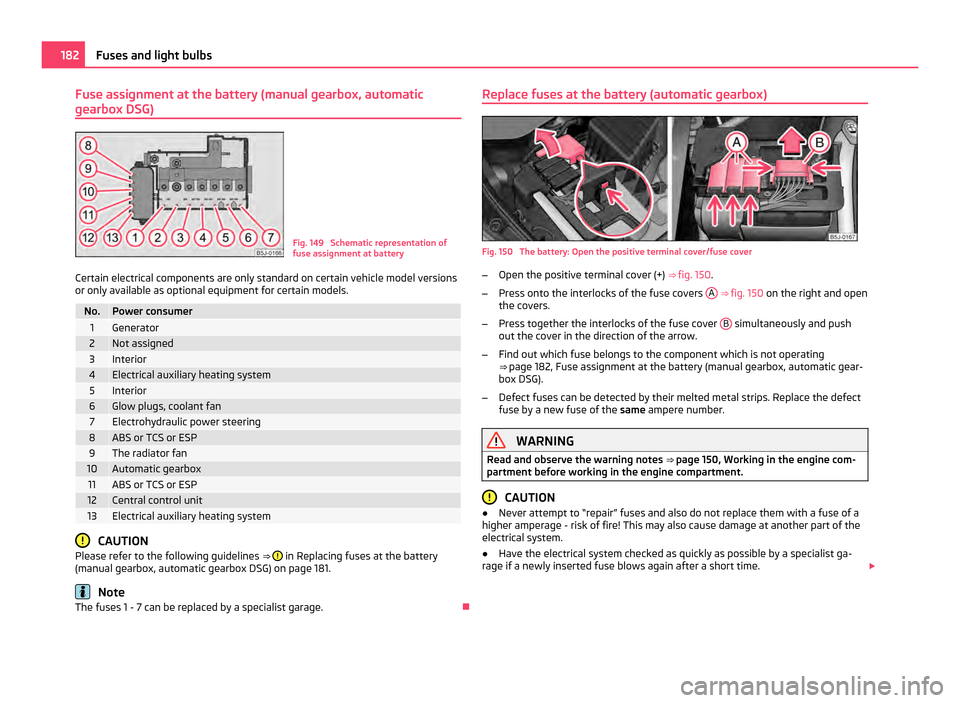

Fuse assignment at the battery (manual gearbox, automatic

gearbox DSG) Fig. 149 Schematic representation of

fuse assignment at battery

Certain electrical components are only standard on certain vehicle model versions

or only available as optional equipment for certain models. No. Power consumer

1 Generator

2 Not assigned

3 Interior

4 Electrical auxiliary heating system

5 Interior

6 Glow plugs, coolant fan

7 Electrohydraulic power steering

8 ABS or TCS or ESP

9 The radiator fan

10 Automatic gearbox

11 ABS or TCS or ESP

12 Central control unit

13 Electrical auxiliary heating system

CAUTION

Please refer to the following guidelines ⇒ in Replacing fuses at the battery

(manual gearbox, automatic gearbox DSG) on page 181 . Note

The fuses 1 - 7 can be replaced by a specialist garage. Replace fuses at the battery (automatic gearbox)

Fig. 150 The battery: Open the positive terminal cover/fuse cover

–

Open the positive terminal cover (+) ⇒ fig. 150.

– Press onto the interlocks of the fuse covers A

⇒

fig. 150 on the right and open

the covers.

– Press together the interlocks of the fuse cover B simultaneously and push

out the cover in the direction of the arrow.

– Find out which fuse belongs to the component which is not operating

⇒ page 182, Fuse assignment at the battery (manual gearbox, automatic gear-

box DSG)

.

– Defect fuses can be detected by their melted metal strips. Replace the defect

fuse by a new fuse of the same ampere number. WARNING

Read and observe the warning notes ⇒ page 150

, Working in the engine com-

partment before working in the engine compartment. CAUTION

● Never attempt to

“repair” fuses and also do not replace them with a fuse of a

higher amperage - risk of fire! This may also cause damage at another part of the

electrical system.

● Have the electrical system checked as quickly as possible by a specialist ga-

rage if a newly inserted fuse blows again after a short time. £182

Fuses and light bulbs

Page 186 of 212

Front headlight Halogen headlight Halogen projector head-

lightsParking lights W5W LL/W5W BL LL

Turn signals PY21W

Fog lights H8/HB4

a)Daylight driving lights P21W, LED

b)a)

Valid for vehicles Scout.

b) Valid for Scout vehicles with separate lights for daylight driving lights. Rear light unit Bulb

Reversing light P21W

Turn signals PY21W

Brake lights P21W

Fog lights P21W

Parking lights 2x W5W

Others Bulb

Side turn signal lights WY5W

Licence plate light C5W/T4W (5W)

3. Brake light LED

Interior lighting front/rear C10W

Reading lights W5W

Luggage compartment light W5W

Lighting in storage compartment W5W

WARNING

● Bulbs H7 LL and H4 LL are pressurised and may burst when changing the

bulb - risk of injury!

● It is recommended to wear gloves and safety glasses when changing a

bulb. Note

This Owner's Manual only describes the replacement of bulbs where it is assumed

that no major complications will arise. Other light bulbs should be changed by your

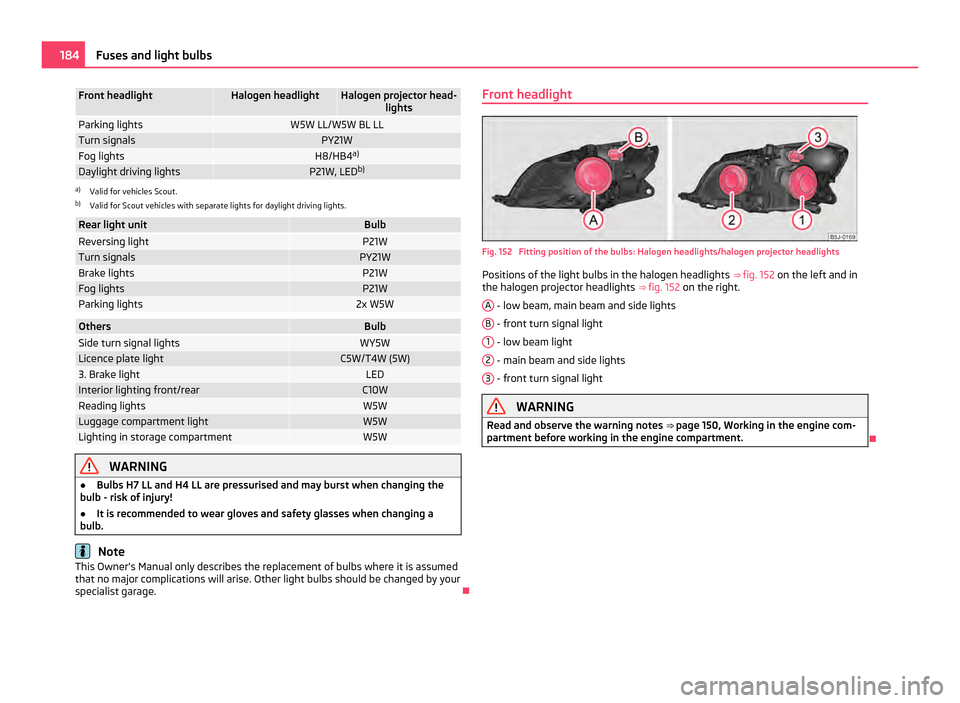

specialist garage. Front headlight

Fig. 152 Fitting position of the bulbs: Halogen headlights/halogen projector headlights

Positions of the light bulbs in the halogen headlights

⇒

fig. 152 on the left and in

the halogen projector headlights ⇒ fig. 152 on the right.

A - low beam, main beam and side lights

B - front turn signal light

1 - low beam light

2 - main beam and side lights

3 - front turn signal light

WARNING

Read and observe the warning notes ⇒ page 150

, Working in the engine com-

partment before working in the engine compartment. 184

Fuses and light bulbs

Page 191 of 212

Praktik

Praktik Rear interior lighting Switching the interior light on

–

Position the cover glass into position .

Switching the interior light off

– Position the cover glass into position O.

Door contact setting

– Position the cover glass into middle position .Note

We recommend having the bulb replaced by a specialist garage.

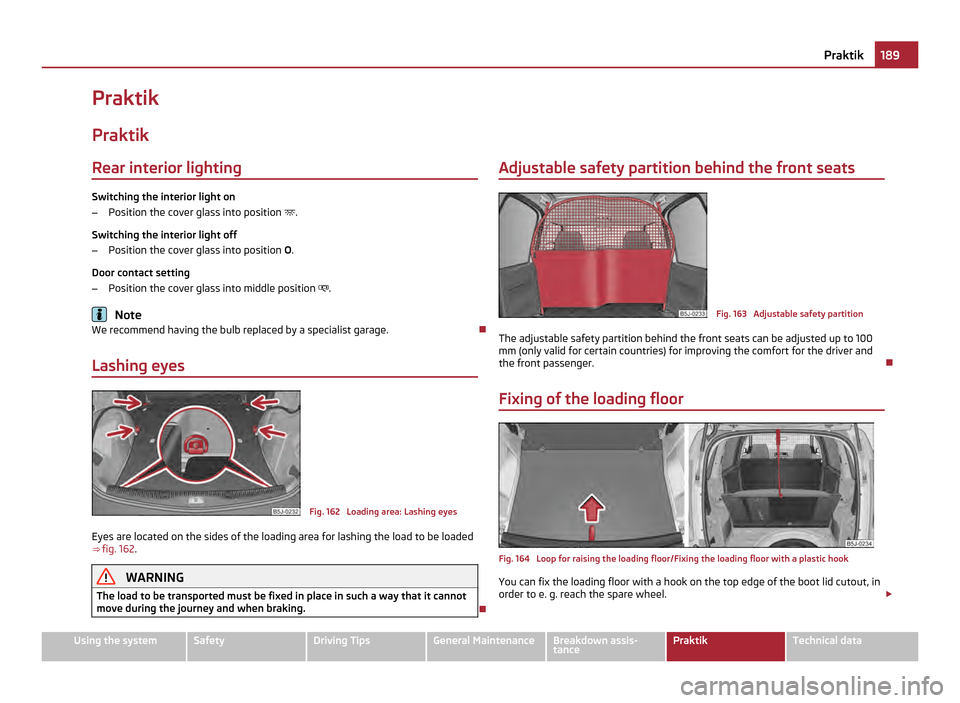

Lashing eyes Fig. 162 Loading area: Lashing eyes

Eyes are located on the sides of the loading area for lashing the load to be loaded

⇒ fig. 162 . WARNING

The load to be transported must be fixed in place in such a way that it cannot

move during the journey and when braking. Adjustable safety partition behind the front seats

Fig. 163 Adjustable safety partition

The adjustable safety partition behind the front seats can be adjusted up to 100

mm (only valid for certain countries) for improving the comfort for the driver and

the front passenger.

Fixing of the loading floor Fig. 164 Loop for raising the loading floor/Fixing the loading floor with a plastic hook

You can fix the loading floor with a hook on the top edge of the boot lid cutout, in

order to e. g. reach the spare wheel. £ 189

Praktik Using the system Safety Driving Tips General Maintenance Breakdown assis-

tance Praktik Technical data

Page 194 of 212

The following specifications are listed on the type plate

⇒ fig. 167:

Permissible gross weight

The permissible overall weight of the vehicle/trailer combination when the

vehicle is being operated with a trailer

Maximum permissible front axle load

Maximum permissible rear axle load

The identification plate is affixed to the lower part of the column between the

front and rear doors on the front passenger side. WARNING

Do not exceed the permissible overall weight - risk of accident and damage to

the vehicle.

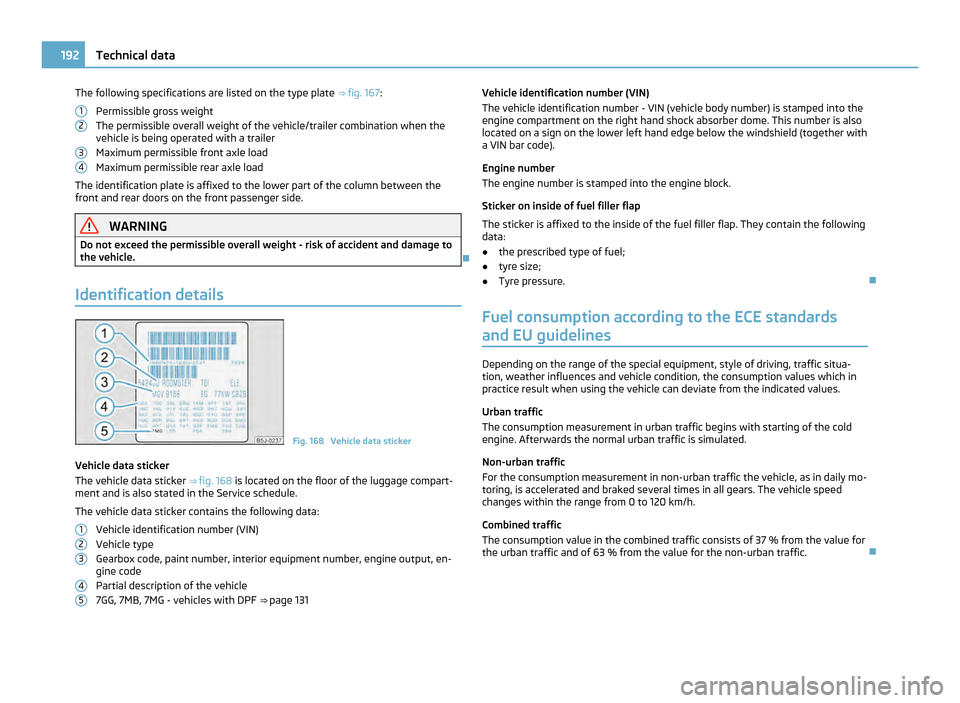

Identification details Fig. 168 Vehicle data sticker

Vehicle data sticker

The vehicle data sticker ⇒ fig. 168

is located on the floor of the luggage compart-

ment and is also stated in the Service schedule.

The vehicle data sticker contains the following data:

Vehicle identification number (VIN)

Vehicle type

Gearbox code, paint number, interior equipment number, engine output, en-

gine code

Partial description of the vehicle

7GG, 7MB, 7MG - vehicles with DPF ⇒ page 131

1 2

3

4

1

2

3

4

5 Vehicle identification number (VIN)

The vehicle identification number - VIN (vehicle body number) is stamped into the

engine compartment on the right hand shock absorber dome. This number is also

located on a sign on the lower left hand edge below the windshield (together with

a VIN bar code).

Engine number

The engine number is stamped into the engine block.

Sticker on inside of fuel filler flap

The sticker is affixed to the inside of the fuel filler flap. They contain the following

data:

● the prescribed type of fuel;

● tyre size;

● Tyre pressure.

Fuel consumption according to the ECE standards

and EU guidelines Depending on the range of the special equipment, style of driving, traffic situa-

tion, weather influences and vehicle condition, the consumption values which in

practice result when using the vehicle can deviate from the indicated values.

Urban traffic

The consumption measurement in urban traffic begins with starting of the cold

engine. Afterwards the normal urban traffic is simulated.

Non-urban traffic

For the consumption measurement in non-urban traffic the vehicle, as in daily mo-

toring, is accelerated and braked several times in all gears. The vehicle speed

changes within the range from 0 to 120 km/h.

Combined traffic

The consumption value in the combined traffic consists of 37 % from the value for

the urban traffic and of 63 % from the value for the non-urban traffic. 192

Technical data