check engine SKODA ROOMSTER 2013 1.G Owner's Guide

[x] Cancel search | Manufacturer: SKODA, Model Year: 2013, Model line: ROOMSTER, Model: SKODA ROOMSTER 2013 1.GPages: 219, PDF Size: 13.83 MB

Page 169 of 219

■A coolant additive that does not comply with the correct specifications can sig-

nificantly reduce the corrosion protection.■

Any faults resulting from corrosion may cause a loss of coolant and can conse-

quently result in major engine damage!

■

Do not fill the coolant above the mark

A

» Fig. 131 on page 166.

■

If a fault causes the engine to overheat, we recommend visiting a specialist ga-

rage, as otherwise serious engine damage may occur.

Capacity

First read and observe the introductory information and safety warn-

ings

on page 165.

Coolant capacity (in litres) 1)

Petrol enginesCapacity1.2 litres/51 kW5.51.2 litres/63 kW TSI7.71.2 litres/77 kW TSI7.71.4 litres/63 kW5.51.6 litres/77 kW5.5Diesel enginesCapacity1.2 ltr./55 kW TDI CR DPF6.61.6 litres/66 kW TDI CR DPF8.41.6 litres/77 kW TDI CR DPF8.4

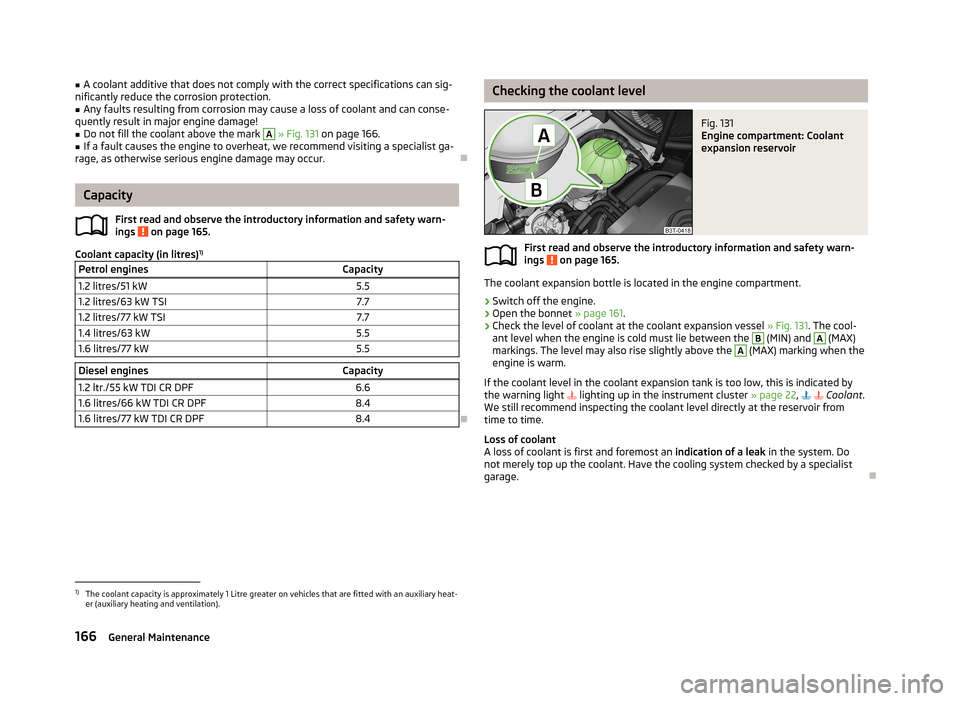

Checking the coolant levelFig. 131

Engine compartment: Coolant

expansion reservoir

First read and observe the introductory information and safety warn-

ings on page 165.

The coolant expansion bottle is located in the engine compartment.

›

Switch off the engine.

›

Open the bonnet » page 161.

›

Check the level of coolant at the coolant expansion vessel » Fig. 131. The cool-

ant level when the engine is cold must lie between the

B

(MIN) and

A

(MAX)

markings. The level may also rise slightly above the

A

(MAX) marking when the

engine is warm.

If the coolant level in the coolant expansion tank is too low, this is indicated by

the warning light

lighting up in the instrument cluster » page 22,

Coolant .

We still recommend inspecting the coolant level directly at the reservoir from

time to time.

Loss of coolant

A loss of coolant is first and foremost an indication of a leak in the system. Do

not merely top up the coolant. Have the cooling system checked by a specialist

garage.

1)

The coolant capacity is approximately 1 Litre greater on vehicles that are fitted with an auxiliary heat-

er (auxiliary heating and ventilation).

166General Maintenance

Page 170 of 219

ReplenishingFirst read and observe the introductory information and safety warn-

ings

on page 165.

Only top up with new coolant.

›

Switch off the engine.

›

Allow the engine to cool.

›

Place a cloth over the cap of the coolant expansion tank and carefully unscrew

the cap.

›

Replenish the coolant.

›

Turn the cap until it clicks into place.

Do not use an alternative additive if the specified coolant is not available in an emergency. In this case, use just water and have the correct mixing ratio of waterand coolant additive restored by a specialist garage as soon as possible.

Do not fill the coolant above the mark

A

(max.) » Fig. 131 on page 166. Excess

coolant heats up and then is forced out of the cooling system through the pres-

sure relief valve in the cap.

Brake fluid

Introduction

This chapter contains information on the following subjects:

Checking the brake fluid level

167

Changing

168WARNING■ The engine compartment of your car is a hazardous area. The following

warning instructions must be followed at all times when working in the en-

gine compartment » page 159.■

Do not continue your journey if the fluid level has fallen below the MIN

marking » Fig. 132 on page 167 - there is a risk of an accident. Seek help from

a specialist garage.

■

Do not use used brake fluid - the function of the brake system may be im-

paired – risk of accident!

CAUTIONBrake fluid damages the paintwork of the vehicle.

Note

The brake fluid is changed as part of a compulsory inspection service.

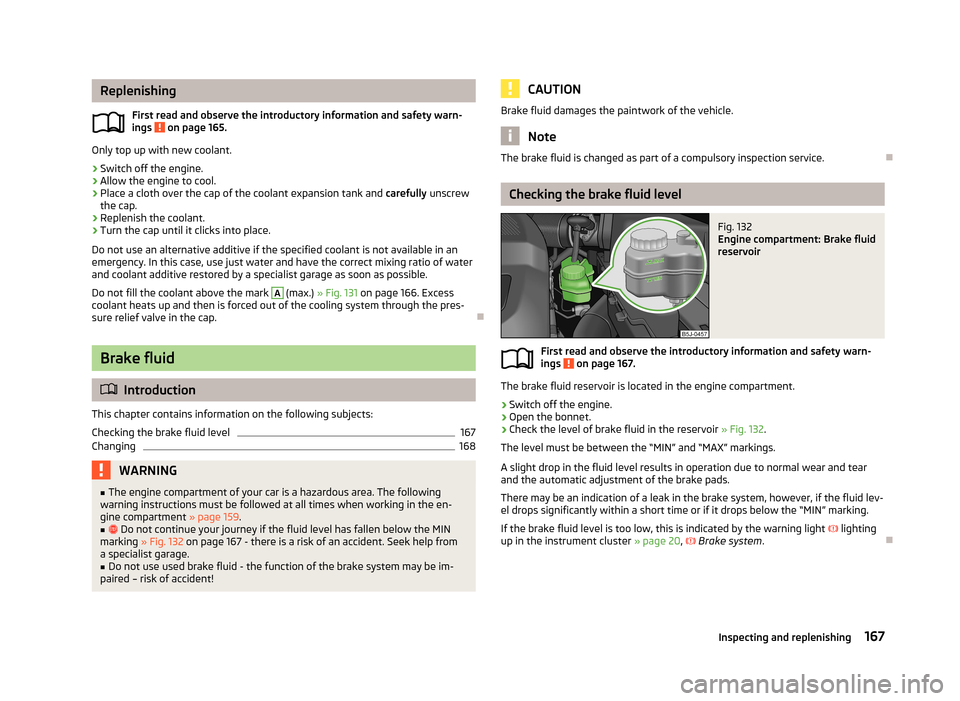

Checking the brake fluid level

Fig. 132

Engine compartment: Brake fluid

reservoir

First read and observe the introductory information and safety warn-

ings on page 167.

The brake fluid reservoir is located in the engine compartment.

›

Switch off the engine.

›

Open the bonnet.

›

Check the level of brake fluid in the reservoir » Fig. 132.

The level must be between the “MIN” and “MAX” markings.

A slight drop in the fluid level results in operation due to normal wear and tear and the automatic adjustment of the brake pads.

There may be an indication of a leak in the brake system, however, if the fluid lev-

el drops significantly within a short time or if it drops below the “MIN” marking.

If the brake fluid level is too low, this is indicated by the warning light

lighting

up in the instrument cluster » page 20,

Brake system .

167Inspecting and replenishing

Page 173 of 219

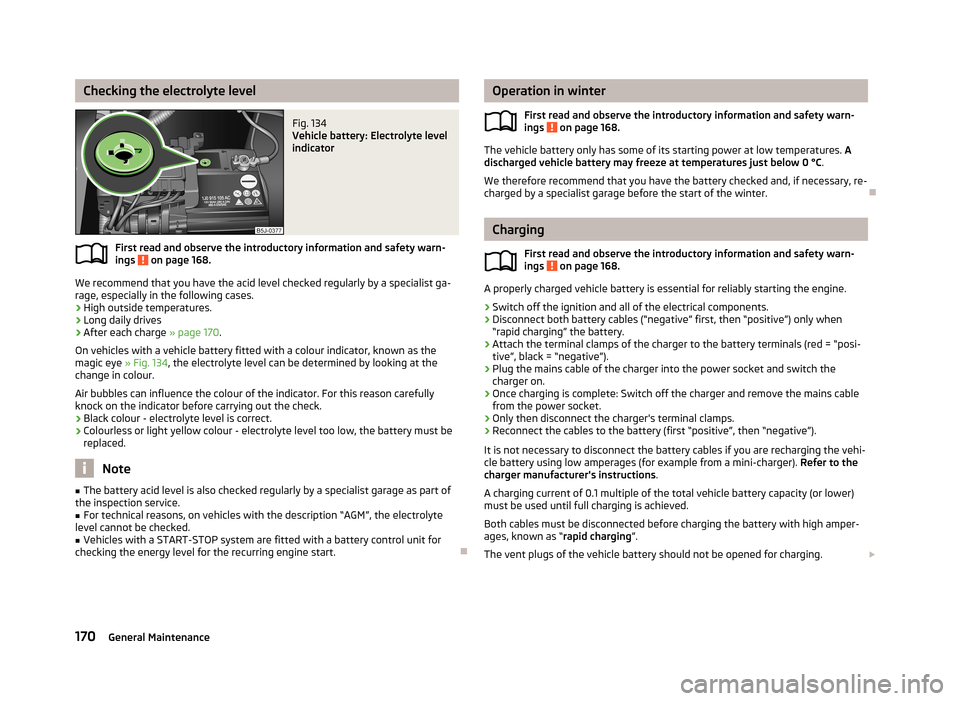

Checking the electrolyte levelFig. 134

Vehicle battery: Electrolyte level

indicator

First read and observe the introductory information and safety warn-

ings on page 168.

We recommend that you have the acid level checked regularly by a specialist ga-

rage, especially in the following cases.

› High outside temperatures.

› Long daily drives

› After each charge

» page 170.

On vehicles with a vehicle battery fitted with a colour indicator, known as the

magic eye » Fig. 134, the electrolyte level can be determined by looking at the

change in colour.

Air bubbles can influence the colour of the indicator. For this reason carefully

knock on the indicator before carrying out the check.

› Black colour - electrolyte level is correct.

› Colourless or light yellow colour - electrolyte level too low, the battery must be

replaced.

Note

■ The battery acid level is also checked regularly by a specialist garage as part of

the inspection service.■

For technical reasons, on vehicles with the description “AGM”, the electrolyte

level cannot be checked.

■

Vehicles with a START-STOP system are fitted with a battery control unit for

checking the energy level for the recurring engine start.

Operation in winter

First read and observe the introductory information and safety warn-

ings

on page 168.

The vehicle battery only has some of its starting power at low temperatures. A

discharged vehicle battery may freeze at temperatures just below 0 °C .

We therefore recommend that you have the battery checked and, if necessary, re-

charged by a specialist garage before the start of the winter.

Charging

First read and observe the introductory information and safety warn-ings

on page 168.

A properly charged vehicle battery is essential for reliably starting the engine.

›

Switch off the ignition and all of the electrical components.

›

Disconnect both battery cables (“negative” first, then “positive”) only when

“rapid charging” the battery.

›

Attach the terminal clamps of the charger to the battery terminals (red = “posi-

tive”, black = “negative”).

›

Plug the mains cable of the charger into the power socket and switch thecharger on.

›

Once charging is complete: Switch off the charger and remove the mains cable

from the power socket.

›

Only then disconnect the charger's terminal clamps.

›

Reconnect the cables to the battery (first “positive”, then “negative”).

It is not necessary to disconnect the battery cables if you are recharging the vehi-

cle battery using low amperages (for example from a mini-charger). Refer to the

charger manufacturer's instructions .

A charging current of 0.1 multiple of the total vehicle battery capacity (or lower)

must be used until full charging is achieved.

Both cables must be disconnected before charging the battery with high amper-

ages, known as “ rapid charging”.

The vent plugs of the vehicle battery should not be opened for charging.

170General Maintenance

Page 174 of 219

WARNING“Quick-charging” the vehicle battery is dangerous and requires a special

charger and specialist knowledge.

CAUTION

On vehicles with the START/STOP system, the pole terminal of the charger must

not be connected directly to the negative terminal of the vehicle battery, but only

to the engine earth » page 188, Jump-starting in vehicles with the START-STOP

system .

Note

We therefore recommend that vehicle batteries be rapid charged by a specialist

garage.

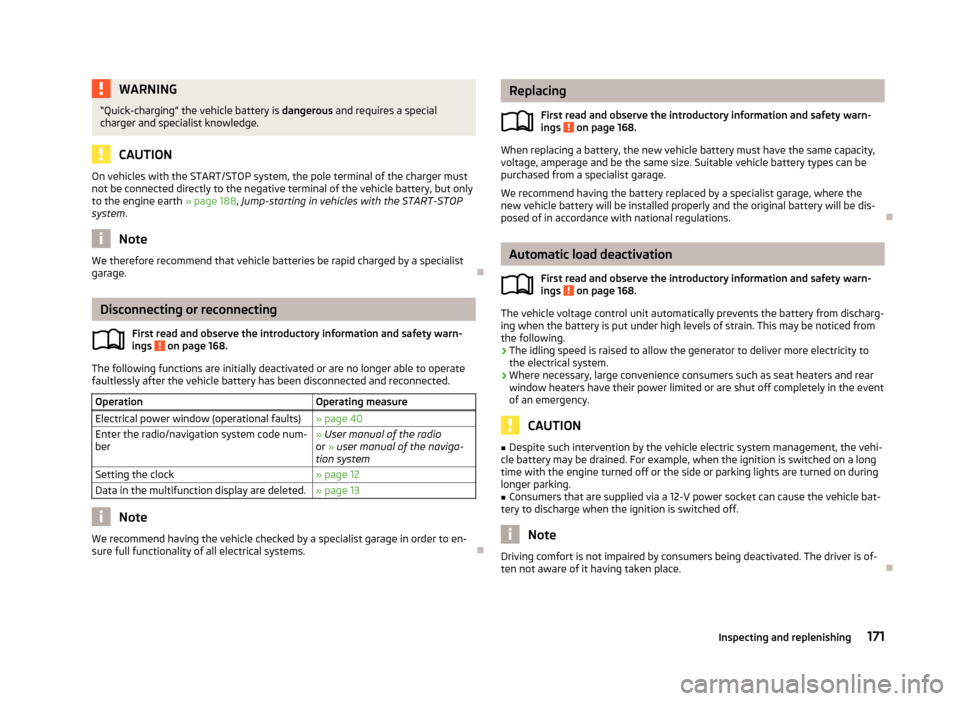

Disconnecting or reconnecting

First read and observe the introductory information and safety warn-ings

on page 168.

The following functions are initially deactivated or are no longer able to operate

faultlessly after the vehicle battery has been disconnected and reconnected.

OperationOperating measureElectrical power window (operational faults)» page 40Enter the radio/navigation system code num-

ber» User manual of the radio

or » user manual of the naviga-

tion systemSetting the clock» page 12Data in the multifunction display are deleted.» page 13

Note

We recommend having the vehicle checked by a specialist garage in order to en-

sure full functionality of all electrical systems.

Replacing

First read and observe the introductory information and safety warn-

ings

on page 168.

When replacing a battery, the new vehicle battery must have the same capacity,

voltage, amperage and be the same size. Suitable vehicle battery types can be purchased from a specialist garage.

We recommend having the battery replaced by a specialist garage, where the

new vehicle battery will be installed properly and the original battery will be dis-

posed of in accordance with national regulations.

Automatic load deactivation

First read and observe the introductory information and safety warn-ings

on page 168.

The vehicle voltage control unit automatically prevents the battery from discharg-

ing when the battery is put under high levels of strain. This may be noticed from

the following.

› The idling speed is raised to allow the generator to deliver more electricity to

the electrical system.

› Where necessary, large convenience consumers such as seat heaters and rear

window heaters have their power limited or are shut off completely in the event

of an emergency.

CAUTION

■ Despite such intervention by the vehicle electric system management, the vehi-

cle battery may be drained. For example, when the ignition is switched on a long

time with the engine turned off or the side or parking lights are turned on during longer parking.■

Consumers that are supplied via a 12-V power socket can cause the vehicle bat-

tery to discharge when the ignition is switched off.

Note

Driving comfort is not impaired by consumers being deactivated. The driver is of-

ten not aware of it having taken place.

171Inspecting and replenishing

Page 188 of 219

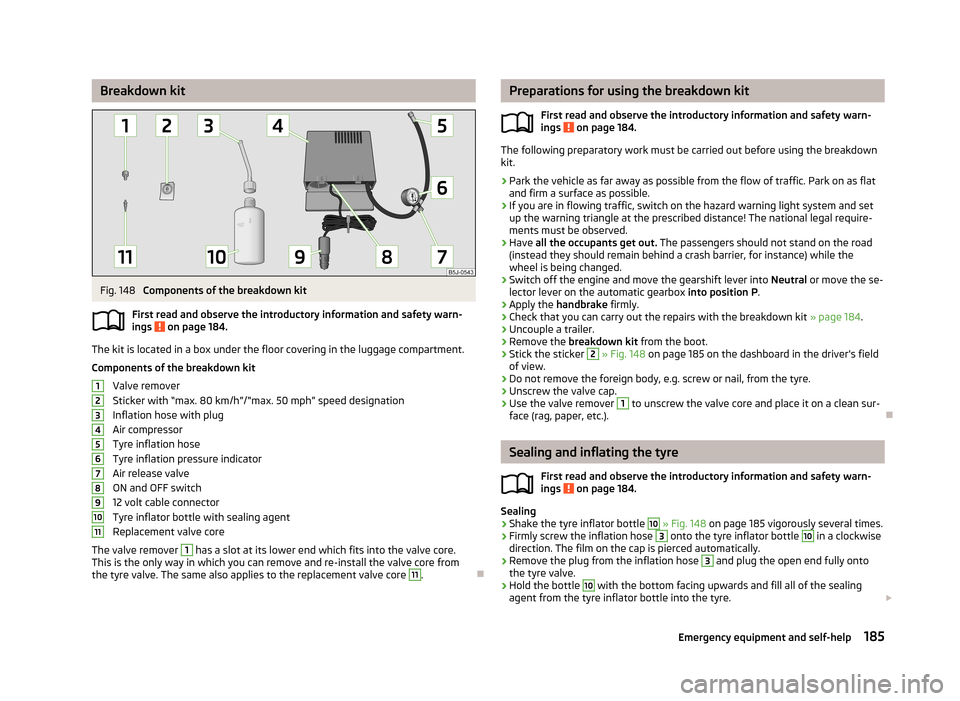

Breakdown kitFig. 148

Components of the breakdown kit

First read and observe the introductory information and safety warn-

ings

on page 184.

The kit is located in a box under the floor covering in the luggage compartment.

Components of the breakdown kit Valve remover

Sticker with “max. 80 km/h”/“max. 50 mph” speed designation

Inflation hose with plug

Air compressor

Tyre inflation hose

Tyre inflation pressure indicator

Air release valve

ON and OFF switch

12 volt cable connector

Tyre inflator bottle with sealing agent

Replacement valve core

The valve remover

1

has a slot at its lower end which fits into the valve core.

This is the only way in which you can remove and re-install the valve core from

the tyre valve. The same also applies to the replacement valve core

11

.

1234567891011Preparations for using the breakdown kit

First read and observe the introductory information and safety warn-

ings

on page 184.

The following preparatory work must be carried out before using the breakdown

kit.

›

Park the vehicle as far away as possible from the flow of traffic. Park on as flat and firm a surface as possible.

›

If you are in flowing traffic, switch on the hazard warning light system and setup the warning triangle at the prescribed distance! The national legal require-

ments must be observed.

›

Have all the occupants get out. The passengers should not stand on the road

(instead they should remain behind a crash barrier, for instance) while the wheel is being changed.

›

Switch off the engine and move the gearshift lever into Neutral or move the se-

lector lever on the automatic gearbox into position P.

›

Apply the handbrake firmly.

›

Check that you can carry out the repairs with the breakdown kit » page 184.

›

Uncouple a trailer.

›

Remove the breakdown kit from the boot.

›

Stick the sticker

2

» Fig. 148 on page 185 on the dashboard in the driver's field

of view.

›

Do not remove the foreign body, e.g. screw or nail, from the tyre.

›

Unscrew the valve cap.

›

Use the valve remover

1

to unscrew the valve core and place it on a clean sur-

face (rag, paper, etc.).

Sealing and inflating the tyre

First read and observe the introductory information and safety warn-

ings

on page 184.

Sealing

›

Shake the tyre inflator bottle

10

» Fig. 148 on page 185 vigorously several times.

›

Firmly screw the inflation hose

3

onto the tyre inflator bottle

10

in a clockwise

direction. The film on the cap is pierced automatically.

›

Remove the plug from the inflation hose

3

and plug the open end fully onto

the tyre valve.

›

Hold the bottle

10

with the bottom facing upwards and fill all of the sealing

agent from the tyre inflator bottle into the tyre.

185Emergency equipment and self-help

Page 189 of 219

›Remove the empty tyre inflator bottle from the valve.›Screw the valve core back into the tyre valve using the valve remover 1.

Inflating›

Screw the air compressor tyre inflation hose

5

» Fig. 148 on page 185 firmly on-

to the tyre valve.

›

Check that the air release valve

7

is closed.

›

Start the engine and run it in idle.

›

Plug the connector

9

into 12 Volt socket » page 67, 12-volt power outlet .

›

Switch on the air compressor with the ON and OFF switch

8

.

›

Allow the air compressor to run until a pressure of 2.0 - 2.5 bar is achieved. Max-

imum run time of 8 minutes » !

›

Switch off the air compressor.

›

If you cannot reach an air pressure of 2.0 – 2.5 bar, unscrew the tyre inflation

hose

5

from the tyre valve.

›

Drive the vehicle 10 metres forwards or backwards to allow the sealing agent to

“distribute” in the tyre.

›

Firmly screw the tyre inflation hose

5

back onto the tyre valve and repeat the

inflation process.

›

If you cannot reach the required tyre inflation pressure here either, this means

the tyre has sustained too much damage. You cannot seal with tyre with the breakdown kit »

.

›

Switch off the air compressor.

›

Remove the tyre inflation hose

5

from the tyre valve.

Once a tyre pressure of 2.0 – 2.5 bar is reached, the journey may be continued at a maximum speed of 80 km/h (50 mph).

Check the tyre inflation pressure after driving for 10 minutes » page 186.

WARNING■

The tyre inflation hose and air compressor may get hot as the tyre is being

inflated – there is a risk of injury.■

Do not place the hot tyre inflation hose or hot air compressor on flammable

materials – there is a risk of fire.

■

If you cannot inflate the tyre to at least 2.0 bar, this means the damage sus-

tained was too serious. The sealing agent cannot be used to seal the tyre.

Do not drive the vehicle. Seek help from a specialist garage.

CAUTIONSwitch off the air compressor after running 8 minutes at the latest – there is a

risk of overheating. Allow the air compressor to cool a few minutes before switch- ing it on again.

Check after 10 minutes' driving

First read and observe the introductory information and safety warn-ings

on page 184.

Check the tyre inflation pressure after driving for 10 minutes!

If the tyre pressure is 1.3 bar or less

›

Do not drive the vehicle! You cannot properly seal with tyre with the break-

down kit.

If the tyre pressure is 1.3 bar or more

›

Adjust the tyre pressure to the correct value again (see inside of fuel filler cap).

›

Continue driving carefully to the nearest specialist garage at a maximum speed

of 80 km/h (50 mph).

Jump-starting

Introduction

This chapter contains information on the following subjects:

Jump-starting using the battery from another vehicle

187

Jump-starting in vehicles with the START-STOP system

188WARNING■ A discharged vehicle battery may already freeze at temperatures just below

0 °C. If the battery is frozen, do not jump start with the battery of another ve- hicle – there is a risk of explosion.■

Pay attention to the warning instructions relating to working in the engine

compartment » page 159, Engine compartment .

186Do-it-yourself

Page 194 of 219

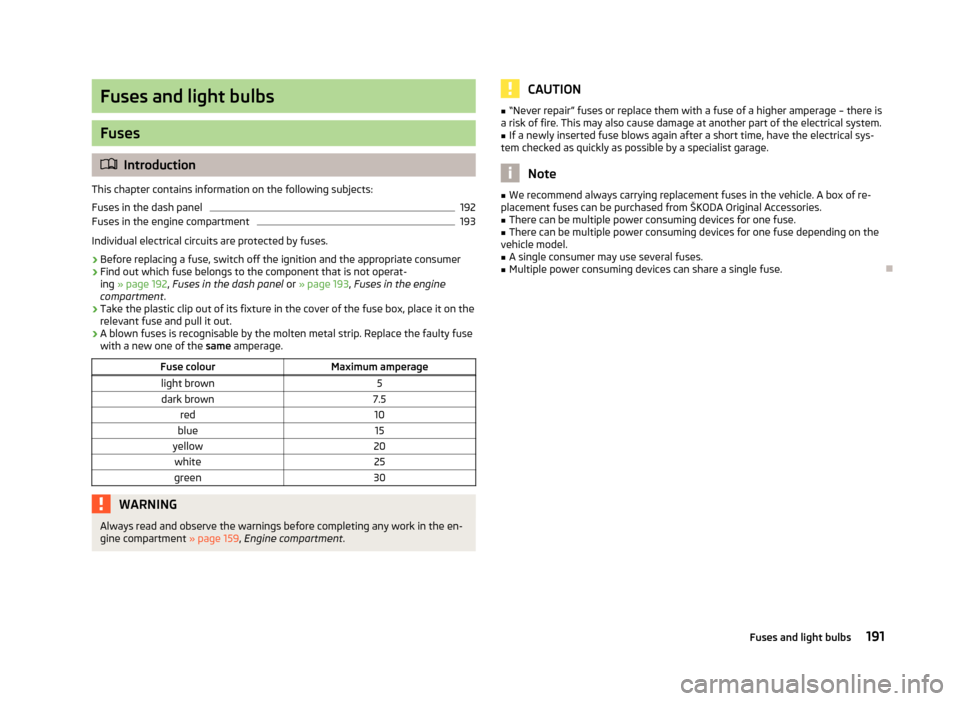

Fuses and light bulbs

Fuses

Introduction

This chapter contains information on the following subjects:

Fuses in the dash panel

192

Fuses in the engine compartment

193

Individual electrical circuits are protected by fuses.

› Before replacing a fuse, switch off the ignition and the appropriate consumer

› Find out which fuse belongs to the component that is not operat-

ing » page 192 , Fuses in the dash panel or » page 193 , Fuses in the engine

compartment .

› Take the plastic clip out of its fixture in the cover of the fuse box, place it on the

relevant fuse and pull it out.

› A blown fuses is recognisable by the molten metal strip. Replace the faulty fuse

with a new one of the same amperage.

Fuse colourMaximum amperagelight brown5dark brown7.5red10blue15yellow20white25green30WARNINGAlways read and observe the warnings before completing any work in the en-

gine compartment » page 159, Engine compartment .CAUTION■

“Never repair” fuses or replace them with a fuse of a higher amperage – there is

a risk of fire. This may also cause damage at another part of the electrical system.■

If a newly inserted fuse blows again after a short time, have the electrical sys-

tem checked as quickly as possible by a specialist garage.

Note

■ We recommend always carrying replacement fuses in the vehicle. A box of re-

placement fuses can be purchased from ŠKODA Original Accessories.■

There can be multiple power consuming devices for one fuse.

■

There can be multiple power consuming devices for one fuse depending on the

vehicle model.

■

A single consumer may use several fuses.

■

Multiple power consuming devices can share a single fuse.

191Fuses and light bulbs

Page 197 of 219

No.Consumer5Interior6Glow plugs, radiator fan7Electrohydraulic power steering8ABS or TCS or ESC9Radiator fan10Automatic gearbox11ABS or TCS or ESC12Central control unit13Electrical auxiliary heating system

Note

Fuses 1-7 are replaced by a specialist garage.

Bulbs

Introduction

This chapter contains information on the following subjects:

Headlights

195

Changing the low beam and high beam bulb (halogen headlights)

195

Changing the high beam bulb (halogen projector headlights)

195

Changing the high beam bulb (halogen projector headlights)

196

Changing the front turn signal bulb

196

Changing the front parking light bulb

196

Fog lights and daytime running lights

196

Fog light, Roomster Scout

197

Replacing the bulb for the licence plate light

197

Tail light

198

Some manual skills are required to change a bulb. For this reason, we recommend

having bulbs replaced by a specialist garage or seeking other expert help in the

event of any uncertainties.

› Switch off the ignition and all of the lights before replacing a bulb.

› Faulty bulbs must only be replaced with the same type of bulbs. The designa-

tion is located on the light socket or the glass bulb.

› A stowage compartment for replacement bulbs is located in a plastic box in the

spare wheel or underneath the floor covering in the boot.WARNING■ Accidents can be caused if the road in front of the vehicle is not sufficiently

illuminated and the vehicle cannot or can only be seen with difficulty by other

road users.■

Always read and observe the warnings before completing any work in the

engine compartment » page 159, Engine compartment .

■

Bulbs H7 and H4 are pressurised and may burst when changed - there is a

risk of injury. We therefore recommended wearing gloves and safety glasses

when changing a bulb.

CAUTION

■ Do not take hold of the glass bulb with naked fingers (even the smallest

amount of dirt reduces the working life of the light bulb). Use a clean cloth, nap-

kin, or similar.■

When removing and installing the number plate light and tail light make sure

that the paintwork of the vehicle and the tail light are not damaged.

Note

■ This Owner's Manual only describes the replacement of bulbs where it is possi-

ble to replace the bulbs on your own without any complications arising. Other bulbs must be replaced by a specialist garage.■

We recommend that a box of replacement bulbs always be carried in the vehi-

cle. Replacement bulbs can be purchased from ŠKODAOriginal Accessories.

■

We recommend having the headlight settings checked by a specialist garage af-

ter replacing a bulb in the main or low beam.

■

Visit a specialist garage if an LED is faulty.

194Do-it-yourself

Page 210 of 219

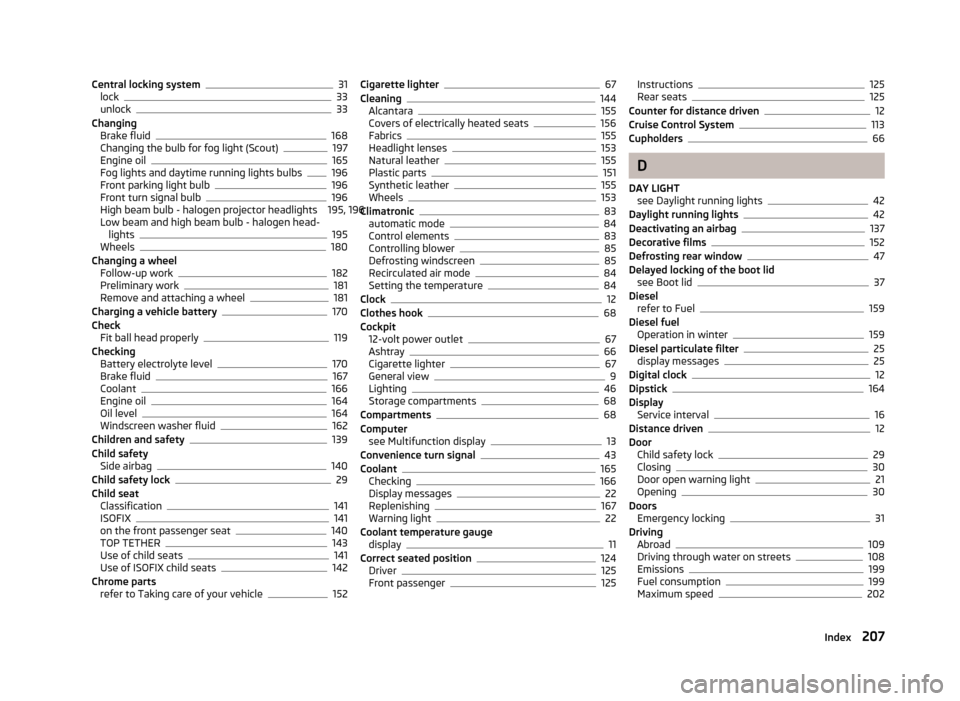

Central locking system31

lock33

unlock33

Changing Brake fluid

168

Changing the bulb for fog light (Scout)197

Engine oil165

Fog lights and daytime running lights bulbs196

Front parking light bulb196

Front turn signal bulb196

High beam bulb - halogen projector headlights 195, 196

Low beam and high beam bulb - halogen head- lights

195

Wheels180

Changing a wheel Follow-up work

182

Preliminary work181

Remove and attaching a wheel181

Charging a vehicle battery170

Check Fit ball head properly

119

Checking Battery electrolyte level

170

Brake fluid167

Coolant166

Engine oil164

Oil level164

Windscreen washer fluid162

Children and safety139

Child safety Side airbag

140

Child safety lock29

Child seat Classification

141

ISOFIX141

on the front passenger seat140

TOP TETHER143

Use of child seats141

Use of ISOFIX child seats142

Chrome parts refer to Taking care of your vehicle

152

Cigarette lighter67

Cleaning144

Alcantara155

Covers of electrically heated seats156

Fabrics155

Headlight lenses153

Natural leather155

Plastic parts151

Synthetic leather155

Wheels153

Climatronic83

automatic mode84

Control elements83

Controlling blower85

Defrosting windscreen85

Recirculated air mode84

Setting the temperature84

Clock12

Clothes hook68

Cockpit 12-volt power outlet

67

Ashtray66

Cigarette lighter67

General view9

Lighting46

Storage compartments68

Compartments68

Computer see Multifunction display

13

Convenience turn signal43

Coolant165

Checking166

Display messages22

Replenishing167

Warning light22

Coolant temperature gauge display

11

Correct seated position124

Driver125

Front passenger125

Instructions125

Rear seats125

Counter for distance driven12

Cruise Control System113

Cupholders66

D

DAY LIGHT see Daylight running lights

42

Daylight running lights42

Deactivating an airbag137

Decorative films152

Defrosting rear window47

Delayed locking of the boot lid see Boot lid

37

Diesel refer to Fuel

159

Diesel fuel Operation in winter

159

Diesel particulate filter25

display messages25

Digital clock12

Dipstick164

Display Service interval

16

Distance driven12

Door Child safety lock

29

Closing30

Door open warning light21

Opening30

Doors Emergency locking

31

Driving Abroad

109

Driving through water on streets108

Emissions199

Fuel consumption199

Maximum speed202

207Index

Page 211 of 219

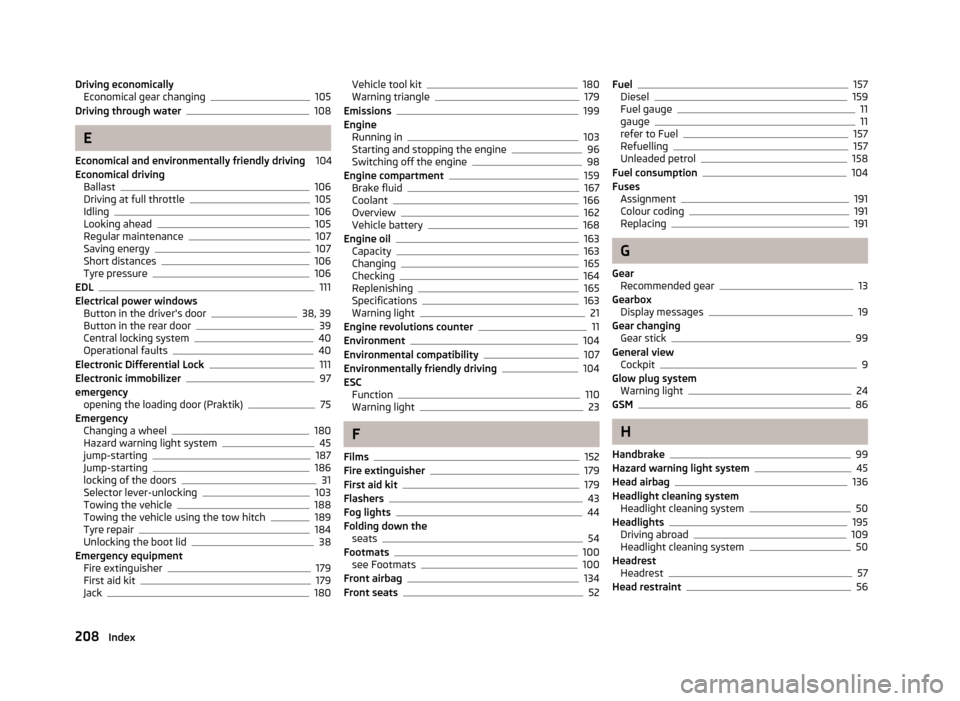

Driving economicallyEconomical gear changing105

Driving through water108

E

Economical and environmentally friendly driving 104

Economical driving Ballast

106

Driving at full throttle105

Idling106

Looking ahead105

Regular maintenance107

Saving energy107

Short distances106

Tyre pressure106

EDL111

Electrical power windows Button in the driver's door

38, 39

Button in the rear door39

Central locking system40

Operational faults40

Electronic Differential Lock111

Electronic immobilizer97

emergency opening the loading door (Praktik)

75

Emergency Changing a wheel

180

Hazard warning light system45

jump-starting187

Jump-starting186

locking of the doors31

Selector lever-unlocking103

Towing the vehicle188

Towing the vehicle using the tow hitch189

Tyre repair184

Unlocking the boot lid38

Emergency equipment Fire extinguisher

179

First aid kit179

Jack180

Vehicle tool kit180

Warning triangle179

Emissions199

Engine Running in

103

Starting and stopping the engine96

Switching off the engine98

Engine compartment159

Brake fluid167

Coolant166

Overview162

Vehicle battery168

Engine oil163

Capacity163

Changing165

Checking164

Replenishing165

Specifications163

Warning light21

Engine revolutions counter11

Environment104

Environmental compatibility107

Environmentally friendly driving104

ESC Function

110

Warning light23

F

Films

152

Fire extinguisher179

First aid kit179

Flashers43

Fog lights44

Folding down the seats

54

Footmats100

see Footmats100

Front airbag134

Front seats52

Fuel157

Diesel159

Fuel gauge11

gauge11

refer to Fuel157

Refuelling157

Unleaded petrol158

Fuel consumption104

Fuses Assignment

191

Colour coding191

Replacing191

G

Gear Recommended gear

13

Gearbox Display messages

19

Gear changing Gear stick

99

General view Cockpit

9

Glow plug system Warning light

24

GSM86

H

Handbrake

99

Hazard warning light system45

Head airbag136

Headlight cleaning system Headlight cleaning system

50

Headlights195

Driving abroad109

Headlight cleaning system50

Headrest Headrest

57

Head restraint56

208Index