engine SKODA SUPERB 2006 1.G / (B5/3U) Manual PDF

[x] Cancel search | Manufacturer: SKODA, Model Year: 2006, Model line: SUPERB, Model: SKODA SUPERB 2006 1.G / (B5/3U)Pages: 281, PDF Size: 12.67 MB

Page 229 of 281

Inspecting and Replenishing

228

•If the fluid level has dropped below the MIN marking, do not

drive any further - risk of accident! Contact a Škoda dealer to obtain

professional assistance.

Replacing brake fluid

Brake fluid absorbs moisture. This causes the fluid to absorb moisture

from the surrounding air over a period of time. Excessive water in the

brake fluid may be the cause of corrosion in the brake system. The water

content also lowers the boiling point of the brake fluid. This is why brake

fluid must be replaced every two years.

One may only use new genuine brake fluid from Škoda Auto a.s. The

specification for the brake fluid is “FMVSS 116 DOT 4”.

We recommend that you have the brake fluid replaced by a Škoda

Service Partner as part of an Inspection Service.

WARNING

•Using old brake fluid can result in severe stress on the brakes

because of the formation of vapour bubbles in the brake system.

This greatly impairs the braking efficiency and thus also the safety

of your vehicle.

•Brake fluid is toxic! It must therefore be kept safely in closed

original containers and well away from children and unauthorized

persons.

Caution

Brake fluid damages the paintwork of the vehicle.

For the sake of the environment

In view of the problems involved with proper disposal of brake fluid, the

special tools and the professional knowledge required, you should have

the brake fluid replaced by a Škoda Service Partner.

Battery

Working on the battery

Particular care is required when carrying out any work on

the battery!

The battery is located in the engine compartment in the plenum

chamber below a cover.

WARNING (continued)

Fig. 178 Engine

compartment: plenum

chamber - battery

cover

NKO B5 20.book Page 228 Monday, July 3, 2006 2:09 PM

Page 230 of 281

Inspecting and Replenishing229

Using the systemSafetyDriving TipsGeneral MaintenanceBreakdown assistanceTechnical Data

Taking off cover

– Press the cover in direction of arrow ⇒fig. 178.

There is a risk of injuries, scalding, accidents and burns when carrying out

any work on the battery and on the electrical system. For this reason, it is

essential to comply with the warning instructions ⇒ stated below and

with the general applicable rules of safety.

WARNING

•The battery acid is strongly corrosive and must, therefore, be

handled with the greatest of care. Always wear protective gloves,

eye and skin protection when handling batteries. Corrosive fumes

in the air irritate the air passages and lead to conjunctivitis and

inflammation of the air passages in the lungs. Battery acid

corrodes dental enamel and creates deep wounds after contact

with the skin which take a long time to heal. Repeated contact with

diluted acids causes skin diseases (inflammations, ulcers, slin

cracks). Acids coming into contact with water are diluted accompa-

nied by significant development of heat.

•Do not tilt the battery otherwise battery electrolyte may flow out

of the battery vent openings. Protect the eyes with safety glasses

or a shield! There is the danger of suffering blindness! If any

battery electrolyte gets into your eye, rinse out your eye immedi-

ately with clear water for several minutes. Contact a doctor without

delay.

•Splashes of acid on your skin or clothes should be neutralised

as soon as possible using soap suds and then rinsed with plenty

of water. Contact a doctor immediately if you swallow battery elec-

trolyte.

•Keep batteries out of the reach of children.

•Hydrogen is released when you charge a battery and a highly

explosive gas mixture is produced. An explosion can be caused through sparkling over during unclamping or loosening of the

cable plug while the ignition is on.

•Bridging of the poles

will create a short circuit (e.g. through

metal objects, cables). Possible consequences of a short circuit:

Melting of lead struts, explosion and burning of the battery, jets of

acid spurting out.

•It is prohibited to work with a naked flame and light, to smoke or

to carry out any activities which produce sparks. Avoid creating

sparks when working with cables and electrical devices. Strong

sparking represents a risk of injury.

•Before carrying out any work on the electrical system, switch

off the engine, the ignition as well as all electrical components and

disconnect the negative cable (-) on the battery. If you wish to

replace a bulb it is sufficient to switch off the appropriate light.

•Never charge a frozen or thawed battery - risk of explosion and

caustic burns! Replace a frozen battery.

•Never use a battery which is damaged - risk of explosion! Imme-

diately replace a damaged battery.

Caution

•You must only disconnect the battery if the ignition is switched off,

otherwise the electrical system (electronic components) of the vehicle

may be damaged. When disconnecting the battery from the electrical

system of the vehicle, first disconnect the negative terminal (-) of the

battery. Then disconnect the positive terminal (+).

•When reconnecting the battery, first connect the positive terminal (+)

and only then the negative terminal (-) of the battery. You must on no

account connect the cables wrongly - risk of a cable fire!

•Ensure that battery acid does not come into contact with the vehicle

body otherwise damage could occur to the paintwork.

WARNING (continued)

NKO B5 20.book Page 229 Monday, July 3, 2006 2:09 PM

Page 231 of 281

Inspecting and Replenishing

230

•Do not place the battery in direct daylight in order to protect the battery

housing from the effects of ultra-violet light.

For the sake of the environment

A removed battery is a special type of waste which is harmful to the envi-

ronment - contact your specialist garage regarding disposing of the

battery.

Note

Please also refer to the guidelines ⇒page 233, “Disconnecting and

reconnecting the battery”, also after connecting the battery.

Battery with a charge level indicator, the so-called

magic eye

There is a so-called magic eye ⇒fig. 179 located on the top of the battery.

The “magic eye” changes its colour in line with the charge state of and

electrolyte level in the battery.

Air bubbles can influence the colour of the “magic eye”. For this reason

carefully knock on the “magic eye” before carrying out the check.

•Green colour - the battery is adequately charged.

•Dark colour - the battery has to be charged

•Colourless or yellow colour. Have the battery checked by a specialist

garage.

Batteries, which are more than 5 years old, must be replaced. We recom-

mend you have the electrolyte level inspected and adjusted to the correct

level or the battery replaced if necessary by a specialist garage.

Caution

If the vehicle has not been driven for more than 3 to 4 weeks, the battery

will discharge because certain electrical components consume electricity

(e.g. control units) also in idle state. You can prevent the discharging of

the battery by disconnecting the negative terminal or charging the battery

constantly with a very low charging current. Please also refer to the notes

when working on the battery ⇒page 228, “Working on the battery”.

Inspecting the electrolyte level

The battery is practically maintenance-free under normal operating

conditions. We do, however, recommend that you have the electrolyte

level inspected from time to time by a specialist garage when outside

temperatures are high or when driving on long trips. You should also

check the electrolyte level ⇒page 231 each time the battery is charged.

The battery acid level will also be checked as part of the Inspection

Service.

Fig. 179 Engine

compartment: Battery

with magic eye

NKO B5 20.book Page 230 Monday, July 3, 2006 2:09 PM

Page 232 of 281

Inspecting and Replenishing231

Using the systemSafetyDriving TipsGeneral MaintenanceBreakdown assistanceTechnical Data

Operation in winter

The battery has to provide greater amounts of electricity during the winter.

It also has only part of the initial power output at low temperatures that it

has at normal temperatures.

A discharged battery may already freeze at temperatures just below

0°C.

We therefore recommend that you have the battery checked by a

specialist garage before the start of the winter, and recharged if neces-

sary.

Note

If the vehicle is not going to be driven for a period of some weeks when

there is very severe frost one should remove ⇒page 232 the battery and

store it in a place which is protected from frost. This prevents the battery

from freezing up and thereby being destroyed.

Charging the battery

A properly charged battery is essential for reliably starting

the engine.

– Read the warning notes ⇒ in “Working on the battery” on

page 228 and ⇒.

– Switch the ignition and all electrical components off.

– Only for “quick-charging”: Disconnect both battery cables (first of all “negative”, then “positive”). – Carefully attach the terminal clamps of the charger to the

battery terminals (red = “positive”, black = “negative”).

– You can now plug the mains cable of the charger into the power socket and switch on the charger.

– When charging is completed: switch the charger off and unplug the mains cable from the power socket.

– Only then should you disconnect the terminal clamps of the charger.

– Reconnect the cables to the battery (first of all “positive”, then “negative”).

It is not normally necessary to disconnect the cables of the battery if you

recharge the battery using low amperages (as for example from a mini-

charger ). Please also refer to the instructions from the charger manufac-

turer.

A charging current of 0.1 of the total battery capacity (or lower) is that

which should be used until full charging is achieved.

It is, however, necessary to disconnect both cables before charging the

battery with high amperages, so-called “ quick-charging”.

“Quick-charging” a battery is dangerous ⇒ in “Working on the battery”

on page 228. It requires a special charger and appropriate knowledge. We

therefore recommend that you have your battery quick-charged only by

your specialist garage.

A discharged battery may already freeze at temperatures just below 0°C.

⇒ . We recommend that you no longer use a battery which has thawed

out because the casing of the battery may be cracked through the forma-

tion of ice and this would allow battery electrolyte to flow out.

The vent plugs of the battery should not be opened for charging.

NKO B5 20.book Page 231 Monday, July 3, 2006 2:09 PM

Page 233 of 281

Inspecting and Replenishing

232

WARNING

Never charge a frozen or thawed battery - risk of explosion and

caustic burns. Replace a frozen battery.

Removing and installing the battery

Removing and installing the battery

– Please also refer to the notes when working on the battery

⇒page 228.

– Switched off all electrical components and remove the ignition key.

– Pull off gasket and take out the cover of the plenum chamber in the direction of the arrow ⇒fig. 180 .

– Unclamp the battery negative terminal (-).

– Unclamp the battery positive terminal (+).

– Unscrew the screw ⇒fig. 181 completely and remove the

locking plate.

– Move the battery in the direction of the arrow and pull it out in an upward direction.

Fig. 180 Engine

compartment: plenum

chamber - cover

Fig. 181 Engine

compartment: The

battery

AA

AB

AC

NKO B5 20.book Page 232 Monday, July 3, 2006 2:09 PM

Page 234 of 281

Inspecting and Replenishing233

Using the systemSafetyDriving TipsGeneral MaintenanceBreakdown assistanceTechnical Data

– Installation takes place in the reverse order.

Please also refer to the following notes when connecting up the battery

⇒page 233.

Note

We do not recommend that you remove and install the battery yourself

(even when you are following the instructions given in this Owner's

manual) since a battery can be heavily damaged in the process under

certain circumstances. Contact a specialist garage.

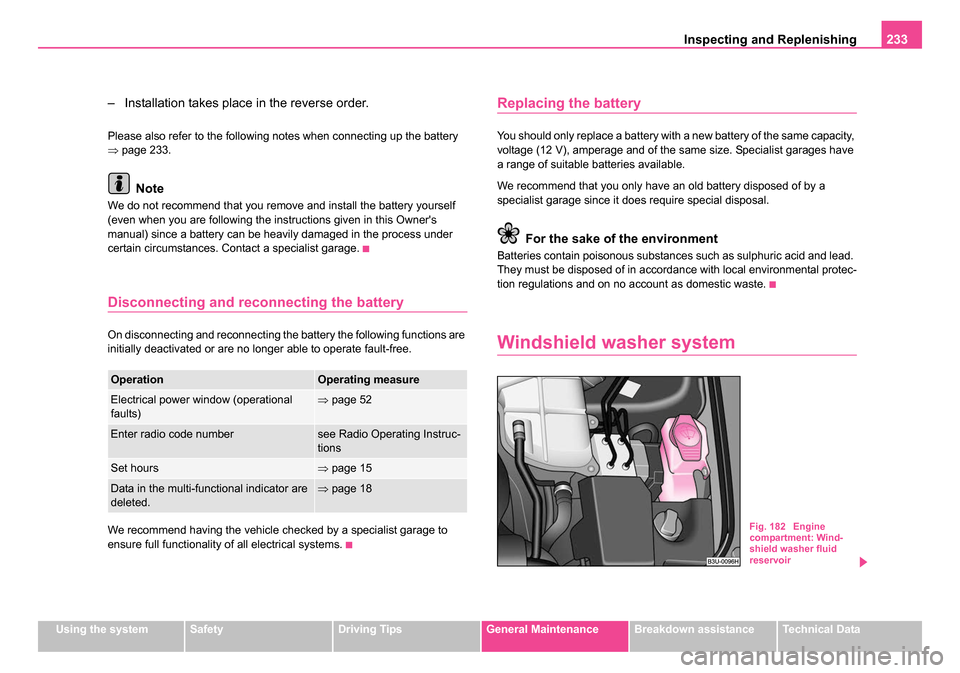

Disconnecting and reconnecting the battery

On disconnecting and reconnecting the battery the following functions are

initially deactivated or are no longer able to operate fault-free.

We recommend having the vehicle checked by a specialist garage to

ensure full functionality of all electrical systems.

Replacing the battery

You should only replace a battery with a new battery of the same capacity,

voltage (12 V), amperage and of the same size. Specialist garages have

a range of suitable batteries available.

We recommend that you only have an old battery disposed of by a

specialist garage since it does require special disposal.

For the sake of the environment

Batteries contain poisonous substances such as sulphuric acid and lead.

They must be disposed of in accordance with local environmental protec-

tion regulations and on no account as domestic waste.

Windshield washer system

OperationOperating measure

Electrical power window (operational

faults)⇒page 52

Enter radio code numbersee Radio Operating Instruc-

tions

Set hours⇒page 15

Data in the multi-functional indicator are

deleted.⇒page 18

Fig. 182 Engine

compartment: Wind-

shield washer fluid

reservoir

NKO B5 20.book Page 233 Monday, July 3, 2006 2:09 PM

Page 235 of 281

Inspecting and Replenishing

234

The windshield washer reservoir contains the cleaning fluid for the wind-

screen and for the headlamp cleaning system*. The reservoir is located in

the front left of the engine compartment ⇒fig. 182 .

The reservoir has a capacity of 4 liters.

Clear water is not sufficient to intensively clean the windscreen and head-

lights. We therefore recommend using clean washing water together with

the screen cleaner from Škoda genuine accessories (in winter additionally

with antifreeze) which is capable of removing stubborn dirt. Follow the

instructions for use on the packaging when using screen cleaning prod-

ucts.

You should always add antifreeze to the cleaning water in winter even if

your vehicle is fitted with heated windscreen washer nozzles*.

It is also possible in exceptional cases to use methylated spirits when no

screen cleaner with antifreeze is available. The concentration of methyl-

ated spirits must not be more than 15 %. Please note, however, that the

antifreeze protection at this concentration is only adequate down to -5°C.

WARNING

Read and observe the warning notes ⇒ page 219, “Working in the

engine compartment” before working in the engine compartment.

Caution

•On no account should you add radiator antifreeze or other additives to

the windscreen washer fluid.

•If the vehicle is fitted with headlight cleaning system, you should only

add cleaning products which do not attack the polycarbonate coating of

the headlights to the windscreen washer fluid. Please contact your Škoda

Service Partner, who will tell you which cleaning agent you can use.

Note

Do not take the filter out of the windscreen wash container when filling it

up again with liquid otherwise dirt can get into the liquid transportation

system and can lead to faults in operation of the windscreen wash

system.

NKO B5 20.book Page 234 Monday, July 3, 2006 2:09 PM

Page 243 of 281

Accessories, changes and replacement of parts

242

Accessories, changes an d replacement of parts

Accessories and replacement parts

Škoda vehicles have been built according to the latest discoveries in

safety engineering. Thus one should not change the condition in which the

vehicle was delivered from the manufacturer without some thought.

The following guidelines should be observed when a vehicle is to be retro-

fitted with accessories, have technical changes made to it or a part has to

be replaced at some time in the future.

•Advise should always be obtained from a Škoda Service Partner

before buying any accessories and before making any technical changes

⇒ .

•This is particularly the case when accessories are bought in a foreign

country.

•Škoda Genuine Accessories which have been released for use and

Skoda original parts can be obtained from Škoda Service Partners. They

will install them professionally and correctly.

•All Škoda original accessory which is listed in the catalogue such as

tilting roofs, spoilers, wheels etc. must have an official stamp of approval.

•Radios, aerials and other electrical accessories should only be

installed by an authorised workshop.

•The guidelines issued by Škoda Auto a.s. must be observed when

making technical changes.

•This is to ensure that no technical damage occurs to the vehicle, that

travelling and operating safety are maintained and that the chnages are

permissible. Škoda Service Partners undertake this work professionally or

refer it to an specialist company in special cases. Any damage which is done caused by technical changes made

without consulting a Skoda a.s. dealer is excluded from the guar-

antee.

WARNING

•We advise you, in your own interest, to only use Škoda Genuine

Accessories and Škoda original parts which have been expressly

approved for use on your Škoda. Reliability, safety and suitabiliity

have been established for these Škoda original parts.

•We cannot guarantee suitability of installation into your vehicle

of other products despite keeping a constant eye on market devel-

opments (also not in the case where there is an attestation or

permission can be produced).

Technical changes

Interference on the electronic components and their software can lead to

operational faults. This interference can also impair not directly affected

systems because of the networking of the electronic components. This

means that the operating safety of your vehicle can be considerably jeop-

ardized, a greater wear of vehicle parts can occur and finally the vehicle

registration documents expire.

We trust that you will understand that your Škoda Service Partner cannot

be liable for damage resulting from unprofessional work.

We therefore recommend that you have all work carried out with Škoda

original parts at your authorised Škoda Service Partners.

NKO B5 20.book Page 242 Monday, July 3, 2006 2:09 PM

Page 249 of 281

Breakdown assistance

248

•Do not drive with this spare wheel at more than 80 km/h - risk of acci-

dent. Avoid accelerating at full throttle, sharp braking and fast cornering.

•The inflation pressure for this spare wheel is identical to the inflation

pressure of the standard tyres.

•Use this spare wheel only to reach the nearest specialist garage as it

is not intended for continuous use.

Changing a wheel

Preliminary work

The following steps should be carried out before actually

changing the wheel.

– If it is necessary to change a wheel, park the vehicle as far away as possible from the traffic flow. The place you choose

should be level.

– Have all the occupants get out. While changing a wheel, the

occupants of the vehicle should not stand on the road (e.g.

behind a crash barrier).

– Apply the handbrake firmly.

– Engage 1st gear or if your vehicle is fitted with an automatic

gearbox, position the selector lever into position P .

– If a trailer is coupled, uncouple it.

– Take the vehicle tool kit and the spare wheel ⇒ page 247

out of the luggage compartment.

WARNING

•If you find yourself in flowing traffic switch on the hazard

warning lights system and place the warning triangle on the side of

the road at the prescribed distance from your vehicle while

observing all national legal provisions. In this way you are

protecting not only yourself but also other road users.

•Never start the engine with the vehicle sitting on the raised jack

- danger of suffering injury!

Caution

If you have to change a wheel on a slope first block the opposite wheel

with a stone or similar object in order to secure the vehicle from unexpect-

edly rolling away.

Note

Comply with the national legal regulations.

Changing a wheel

Always change a wheel on a level surface as far as possible.

– Take off the full wheel trim* ⇒page 249 or the caps

⇒ page 251.

– In the case of light alloy wheels remove the wheel trim cap ⇒page 250.

– Slacken the wheel bolts ⇒page 251.

NKO B5 20.book Page 248 Monday, July 3, 2006 2:09 PM

Page 253 of 281

Breakdown assistance

252

WARNING

Slacken the wheel bolts only a little (about one turn) as long as the

vehicle has not yet been jacked up - risk of an accident!.

Note

•Do not use the hexagon socket in the handle of the screwdriver for

slackening or tightening the wheel bolts.

•apply pressure carefully with your foot to the end of the wheel wrench

if it proves difficult to slacken the wheel bolts. Hold tight on the vehicle

when doing this and ensure that you have a steady position.

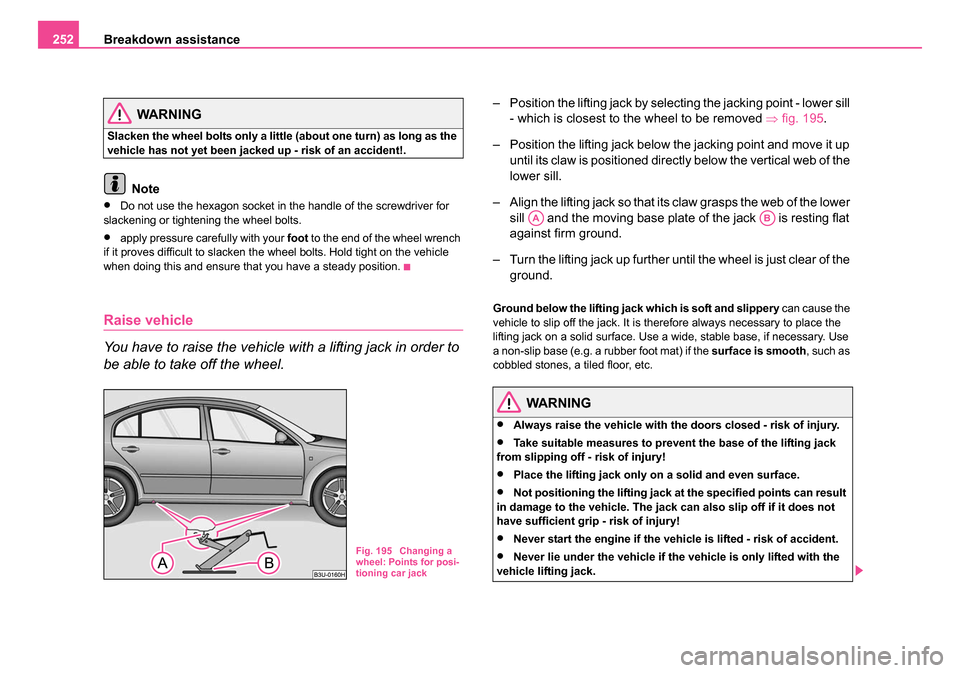

Raise vehicle

You have to raise the vehicle with a lifting jack in order to

be able to take off the wheel.

– Position the lifting jack by selecting the jacking point - lower sill - which is closest to the wheel to be removed ⇒ fig. 195.

– Position the lifting jack below the jacking point and move it up until its claw is positioned directly below the vertical web of the

lower sill.

– Align the lifting jack so that its claw grasps the web of the lower sill and the moving base plate of the jack is resting flat

against firm ground.

– Turn the lifting jack up further until the wheel is just clear of the ground.

Ground below the lifting jack which is soft and slippery can cause the

vehicle to slip off the jack. It is therefore always necessary to place the

lifting jack on a solid surface. Use a wide, stable base, if necessary. Use

a non-slip base (e.g. a rubber foot mat) if the surface is smooth, such as

cobbled stones, a tiled floor, etc.

WARNING

•Always raise the vehicle with the doors closed - risk of injury.

•Take suitable measures to prevent the base of the lifting jack

from slipping off - risk of injury!

•Place the lifting jack only on a solid and even surface.

•Not positioning the lifting jack at the specified points can result

in damage to the vehicle. The jack can also slip off if it does not

have sufficient grip - risk of injury!

•Never start the engine if the vehicle is lifted - risk of accident.

•Never lie under the vehicle if the vehicle is only lifted with the

vehicle lifting jack.Fig. 195 Changing a

wheel: Points for posi-

tioning car jack

AAAB

NKO B5 20.book Page 252 Monday, July 3, 2006 2:09 PM