check engine SKODA SUPERB 2008 2.G / (B6/3T) Owner's Guide

[x] Cancel search | Manufacturer: SKODA, Model Year: 2008, Model line: SUPERB, Model: SKODA SUPERB 2008 2.G / (B6/3T)Pages: 272, PDF Size: 18.25 MB

Page 210 of 272

Inspecting and Replenishing211

Using the systemSafetyDriving TipsGeneral MaintenanceBreakdown assistanceTechnical Data

Engine oil specifications for vehicles with fixed service intervals (QG2)

Engine oil specifications for models with flexible service intervals (QG1)

Caution

Only the above-mentioned oils

may be used on vehicles with flexible service inter-

vals (QG1). We recommend always refilling with oil of the same specification since

this will maintain the properties of the oil. In exceptional cases, you must top up

only once engine oil complying with Sp ecification VW 502 00 (only for petrol

engines) or Specification VW 505 01 (only for diesel engines) to maximum 0.5 litres.

You must not use other engine oi ls - risk of engine damage!

Note

•Before a long drive we recommend th at you purchase and carry with you

engine oil which complies with the specif ication for your vehicle. Consequently,

you will always have the correct engine oil for refilling.

•We recommend using a preservative from the Škoda original accessories

offered by your Škoda dealer.

•For further information - see Service shedule.

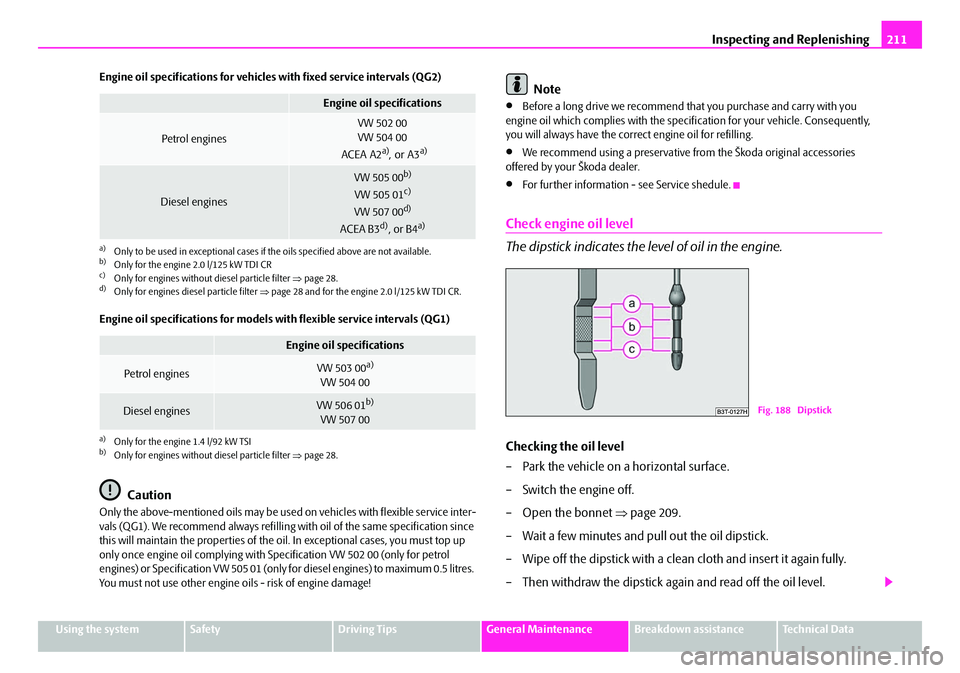

Check engine oil level

The dipstick indicates the le vel of oil in the engine.

Checking the oil level

– Park the vehicle on a horizontal surface.

– Switch the engine off.

– Open the bonnet ⇒page 209.

– Wait a few minutes and pull out the oil dipstick.

– Wipe off the dipstick with a clean cloth and insert it again fully.

– Then withdraw the dipstick again and read off the oil level.

Engine oil specifications

Petrol engines

VW 502 00

VW 504 00

ACEA A2

a), or A3a)

a)Only to be used in exceptional cases if the oils specified above are not available.

Diesel engines

VW 505 00b)

VW 505 01c)

VW 507 00d)

ACEA B3d), or B4a)

b)Only for the engine 2.0 l/125 kW TDI CRc)Only for engines without diesel particle filter ⇒page 28.d)Only for engines diesel particle filter ⇒page 28 and for the engine 2.0 l/125 kW TDI CR.

Engine oil specifications

Petrol enginesVW 503 00a)

VW 504 00

a)Only for the engine 1.4 l/92 kW TSI

Diesel enginesVW 506 01b)

VW 507 00

b)Only for engines without diesel particle filter ⇒page 28.

Fig. 188 Dipstick

NKO B6 20.book Page 211 Wednesday, March 26, 2008 3:15 PM

Page 211 of 272

Inspecting and Replenishing

212

Oil level within range

–You must not top up the oil.

Oil level within range

–You may top up the oil. It is possible that the oil level may then be

within range after doing this.

Oil level within range

–You must top up the oil ⇒page 212. It is sufficient, once this is done,

to keep the oil level is within range .

It is normal for the engine to consume oil. The oil cons umption may be as much as

0.5 l/1 000 km depending on your style of driving and the conditions under which

you operate your vehicle. The oil consumpt ion may be slightly higher than this

during the first 5 000 kilometres.

One should therefore check the oil level at regular intervals, preferably every time

after the fuel tank is filled or after driving for long stretches.

We recommend maintaining the oil level within the range if the engine has been

operating at high loads, for example during a lengthy motorway trip during the

summer months, towing a trailer or negotiating a high mountain pass, but not

above this .

The warning light in the instrument cluster* will indicate ⇒page 35, “Engine oil

level* ” whether the oil level is too low. In this case, check the oil level as soon as

possible. Top up with an a ppropriate quantity of oil.

Caution

•The oil level must on no account ex tend beyond the range . Danger of

damaging the catalytic converter.

•Do not continue your journey if for some reason it is not possible under the

conditions prevailing to top up with oil. Switch of the engine and contact and

obtain professional assistance from a specialist garage.

Replenishing engine oil

– Inspecting the engine oil level ⇒page 211.

– Unscrew the cap of the engine oil filler opening.

– Pour in a suitable grade of oil in portions of 0.5 litres ⇒page 210.

– Inspect the oil level ⇒page 211, “Check engine oil level”.

– Carefully screw on the cap of the filler opening and push the dipstick in fully.

WARNING

•Avoid dripping oil onto hot parts of the engine when topping up will oil -

a risk of fire!

•Read and observe the warning notes ⇒page 209, “Working in the engine

compartment” before working in the engine compartment.

For the sake of the environment

The oil level must on no account be above the range ⇒page 211. Oil will other-

wise be drawn in through the crankcase ventilation and may pass through the

exhaust system to atmosphere. The oil ma y combust in the catalytic converter and

damage it.

Changing engine oil

The engine oil must be changed at the intervals stated in the Service schedule or

according to the service interval indicator ⇒page 12, “Service Interval Display”.

WARNING

•Only carry out the engine oil change, if you have the required profes-

sional knowledge!

Aa

Ab

Aa

Ac

Ab

Aa

Aa

Aa

NKO B6 20.book Page 212 Wednesday, March 26, 2008 3:15 PM

Page 213 of 272

Inspecting and Replenishing

214

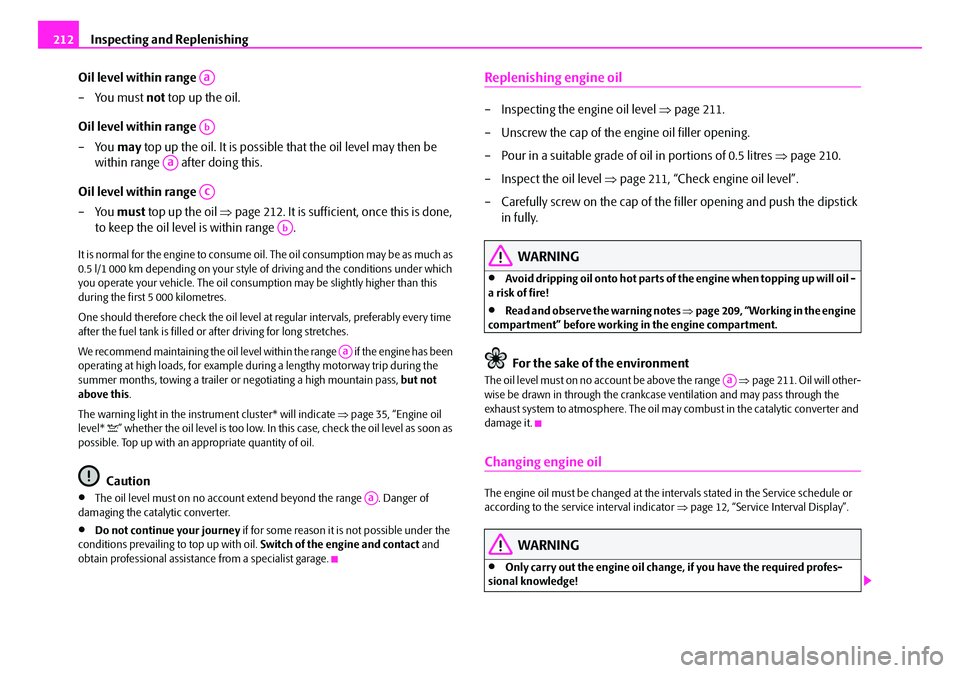

Inspecting the coolant level

The coolant expansion bottle is loca ted in the engine compartment on

the right.

– Switch the engine off.

– Open the bonnet ⇒page 209, “Working in the engine compartment”.

– Check the level of coolant in the coolant expansion bottle ⇒fig. 189 .

The coolant level when the engine is cold must lie between the

(MIN) and (MAX) markings. The level may also rise slightly above

the (MAX) marking when the engine is warm.

If the coolant level in the reservoir is too low, this is indicated by the warning light

in the instrument cluster ⇒ page 31. We nevertheless recommend inspecting

the coolant level directly at th e reservoir from time to time.

Loss of coolant

A loss of coolant is first and foremost an indication of a leak in the system. You

should not merely top up the coolant in the reservoir. It is also important to have

the cooling system inspected without delay by a specialist garage.

Losses can only occur through the pressure relief in the cap of the coolant expan-

sion bottle which is completely free of leak s if the coolant boils as a result of over-

heating and is forced out of the cooling system.

WARNING

Read and observe the warning notes ⇒page 209, “Working in the engine

compartment” before working in the engine compartment.

Caution

One should contact a specialist garage as soon as possible if the source of over-

heating itself cannot be determined and removed, since there may be grave

damage to the engine.

Replenishing the coolant

– Switch the engine off.

– Allow the engine to cool down.

– Place a cloth over the cap of the coolant expansion reservoir ⇒fig. 189 and unscrew the cap carefully by turning it to the left

⇒ .

– Top up the coolant.

– Screw the cap tight until it is heard to lock.

The coolant which you use for replenishing the system, must comply with one

specific specification ⇒page 213, “Coolant”. Do not use an alternative additive if

the coolant additive G12 PLUS is not available in exceptional cases. Just top up the

system with water and as soon as possible arrange adjustment to correct the mixing

ratio of water and coolant additive again by a specialist garage.

Only use fresh coolant for topping up the system.

Do not fill up over the “MAX” marking! Excess coolant which is heated up is forced

out of the cooling system through the pressure relief valve in the cap of the coolant

compensation bottle.

Wait until the engine has cooled down for a system which has suffered a major loss

of coolant before pouring in coolant. This is necessary to avoid engine damage.

Fig. 189 Engine compart-

ment: Coolant expansion

bottle

Ab

Aa

Aa

NKO B6 20.book Page 214 Wednesday, March 26, 2008 3:15 PM

Page 218 of 272

Inspecting and Replenishing219

Using the systemSafetyDriving TipsGeneral MaintenanceBreakdown assistanceTechnical Data

Inspecting the electrolyte level

The battery is practically maintenance-free under normal oper ating conditions.

We do, however, recommend that you have the electrolyte level inspected from

time to time by a Škoda Service Partner when outside temperatures are high or

when driving on long trips. You shou ld also check the electrolyte level ⇒page 219

each time the battery is charged.

The battery acid level will also be chec ked as part of the Inspection Service.

Operation in winter

The battery has to provide greater amounts of electricity during the winter. It also

has only part of the initial power output at low temperatures that it has at normal

temperatures.

A discharged battery may already freez e at temperatures just below 0°C.

We therefore recommend that you have the battery checked by a Škoda dealer

before the start of the winter, and recharged if necessary.

WARNING

Never charge a frozen or thawed battery - risk of explosion and caustic

burns. Replace a frozen battery.

Charging the battery

A properly charged battery is essential for reliably starting the

engine.

–Read the warning notes ⇒ in “Working on the battery” on

page 216 and ⇒.

– Switch the ignition and all electrical components off.

– Only for “quick-charging”: Disconnect both battery cables (first of all

“negative”, then “positive”). – Carefully attach the terminal clamps of the charger to the battery

terminals (red = “positive”, black = “negative”).

– You can now plug the mains cable of the charger into the power socket

and switch on the charger.

– When charging is completed: switch the charger off and unplug the mains cable from the power socket.

– Only then should you disconnect the terminal clamps of the charger.

– Reconnect the cables to the battery (first of all “positive”, then “nega- tive”).

It is not normally necessary to disconnect the cables of the battery if you recharge

the battery using low amperages (as for example from a mini-charger). Please also

refer to the instructions from the charger manufacturer.

A charging current of 0.1 of the total battery capacity (or lower) is that which should

be used until full charging is achieved.

It is, however, necess ary to disconnect both cables be fore charging the battery with

high amperages, so-called “ quick-charging”.

“Quick-charging” a battery is dangerous ⇒ in “Working on the battery” on

page 216. It requires a special charger an d appropriate knowledge. We therefore

recommend that you have your battery qu ick-charged only by your Škoda Service

Par tner.

A discharged battery may already freeze at temperatures just below 0°C ⇒. We

recommend that you no longer use a ba ttery which has thawed out because the

casing of the battery may be cracked through the formation of ice and this would

allow battery electrolyte to flow out.

The vent plugs of the battery should not be opened for charging.

WARNING

Never charge a frozen or thawed battery - risk of explosion and caustic

burns. Replace a frozen battery.

NKO B6 20.book Page 219 Wednesday, March 26, 2008 3:15 PM

Page 219 of 272

Inspecting and Replenishing

220

Disconnecting and reconnecting the battery

On disconnecting and reconnecting the battery the following functions are initially

deactivated or are no longer able to operate fault-free.

We recommend having the vehicle checked by a Škoda Service Partner to ensure

full functionality of all electrical systems.

Replacing the battery

You should only replace a battery with a new battery of the same capacity, voltage

(12 V), amperage and of the same size. Škoda Service Partners have a range of suit-

able batteries available.

We recommend that you only have an old battery disposed of by your Škoda dealer

since it does require special disposal.

For the sake of the environment

Batteries contain poisonous substances such as sulphuric acid and lead. They must

be disposed of in accordance with local environmental protection regulations and

on no account as domestic waste.

Windshield washer system

The windshield washer reserv oir contains the cleaning fluid for the windscreen or

rear window and for the headlamp cleaning system*. The reservoir is located at the

front right of the engine compartment ⇒fig. 194 .

The filling level of the container is 3 litres, 5.5 li tres on vehicles which also have a

headlight washing system.

Clear water is not sufficient to intensivel y clean the windscreen and headlights. We

therefore recommend using clean washing water together with the screen cleaner

from Škoda genuine accessorie s (in winter additionally with antifreeze) which is

capable of removing stubborn dirt. Follow the instructions for use on the packaging

when using screen cleaning products.

You should always add antifreeze to the cleaning water in winter even if your

vehicle is fitted with heated windscreen washer nozzles*.

It is also possible in exceptional cases to use methylated spirits when no screen

cleaner with antifreeze is available. The concentration of methylated spirits must

not be more than 15 %. Please note, however, that the antifreeze protection at this

concentration is only adequate down to -5°C.

WARNING

Read and observe the warning notes ⇒page 209, “Working in the engine

compartment” before working in the engine compartment.

OperationOperating measure

Electrical power window (operational faults)⇒ page 49

Enter radio code numbersee Radio Operating Instructions

Set hours⇒page 14

Data in the multi-functional indicator* are

deleted.⇒page 14Fig. 194 Engine compart-

ment: Windshield washer

fluid reservoir

NKO B6 20.book Page 220 Wednesday, March 26, 2008 3:15 PM

Page 231 of 272

Breakdown assistance

232

•Never start the engine with the vehicle sitting on the raised jack - danger

of suffering injury!

Caution

If you have to change a wheel on a slope first block the opposite wheel with a stone

or similar object in order to secure th e vehicle from unexpectedly rolling away.

Note

Comply with the national legal regulations.

Changing a wheel

Always change a wheel on a level surface as far as possible.

– Take off the full wheel trim* ⇒page 233 or the caps ⇒page 233.

– In the case of light alloy wheels remove the wheel trim cap ⇒page 234.

– First of all slacken the theft-de terrent wheel bolt*, afterwards the

other wheel bolts ⇒page 234.

– Jack up the vehicle until the wheel to be changed is clear of the ground

⇒ page 235.

– Unscrew the wheel bolts and place them on a clean surface (cloth, paper etc.).

– Take off the wheel.

– Fit on the spare wheel and tighten the wheel bolts slightly.

–Lower the car. – Tighten the wheel bolts firmly, al

ternately and diagonally using the

wheel wrench (crosswise) and last the theft-deterrent wheel bolt*

⇒ page 234.

– Mount the full wheel trim/w heel trim cap or the caps.

Note

•All bolts must be clean and must turn easily.

•You must never grease or oil the wheel bolts!

•When fitting on unidirectional tyres, ensure that the tyres rotate in the correct

direction ⇒page 222.

Subsequent steps

After changing the wheel, you must perform the following steps.

– Stow and attach the replaced wheel in the spare wheel well using the

special screw ⇒page 231, fig. 201 .

– Stow the vehicle tool kit in the space provided.

– Check the tyre pressure on the spare wheel just mounted as soon as

possible.

– Have the tightening torque of the wheel bolts checked with a torque

wrench as soon as possible. Steel and light alloy wheels must be tight-

ened to a tightening torque of 120 Nm.

– Have the defective tyre repaired as soon as possible.

WARNING

It is necessary to observe the guidelines given on ⇒page 224 if the vehicle is

subsequently fitted with tyres which are different to those it was fitted with

at the works.

WARNING (continued)

NKO B6 20.book Page 232 Wednesday, March 26, 2008 3:15 PM

Page 235 of 272

Breakdown assistance

236

– Reinstall the full wheel trim/wheel cap after removing the adapter or place the cap onto the safety wheel bolt.

– Have the tightening torque checked w i t h a t o rq u e w re n c h a s s o o n a s

possible. Steel and light alloy wheels must be tightened to a tightening

torque of 120 Nm.

The safety wheel bolts on vehicles fitted with them (one safety wheel bolt per

wheel) can only be loosened or tigh ten up by using the adapter provided.

It is meaningful to note the code numbe r hammered into the rear side of the

adapter or the rear side of the safety wheel bolts. You can obtain a replacement

adapter from a Škoda Service Partner, if necessary, by quoting this number.

We recommend that you always carry the adapter for the wheel bolts with you in

the vehicle. It should be st owed in the vehicle tool kit.

Caution

Damage can occur to the adapter and safety wheel bolt if the safety wheel bolt is

tightened up too much.

Note

The set of safety wheel bolts can be obtained from a Škoda Service Partner.

Jump-starting

Initial steps

You can use the battery of another vehicl e for jump-starting yours if the engine

does not start because the battery on your vehicle is flat. You will require jump-start

cables for this purpose.

Both batteries must have a rated voltage of 12 V. The capacity (Ah) of the battery

supplying the power must not be significa ntly less than the capacity of the

discharged battery in your vehicle. Jump-start cables

Only use jump-start cables which have an

adequately large cross-section and insu-

lated terminal clamps. Please pay attent ion to the manufacturer's instructions.

Positive cable - colour coding in the majority of cases red.

Negative cable - colour coding in the majority of cases black.

WARNING

•A discharged battery may already freeze at temperatures just below 0°C.

In case of frozen battery carry out no jump-starting - risk of explosion!

•Please pay attention to the warning instructions relating to working in

the engine compartment ⇒page 209, “Working in the engine compart-

ment”.

Note

•There must not be any contact between the two vehicles otherwise current may

flow as soon as the negative terminals are connected.

•The discharged battery must be properly connected to the system of the

vehicle.

•Switch off any mobile phone, pay attent ion to the instructions for use of the

mobile phone in such a situation.

•We recommend purchasing jump-start cabl es from Škoda Service Partners as a

Škoda original accessory or from retailers who sell branded batteries.

NKO B6 20.book Page 236 Wednesday, March 26, 2008 3:15 PM

Page 240 of 272

Fuses and light bulbs241

Using the systemSafetyDriving TipsGeneral MaintenanceBreakdown assistanceTechnical Data

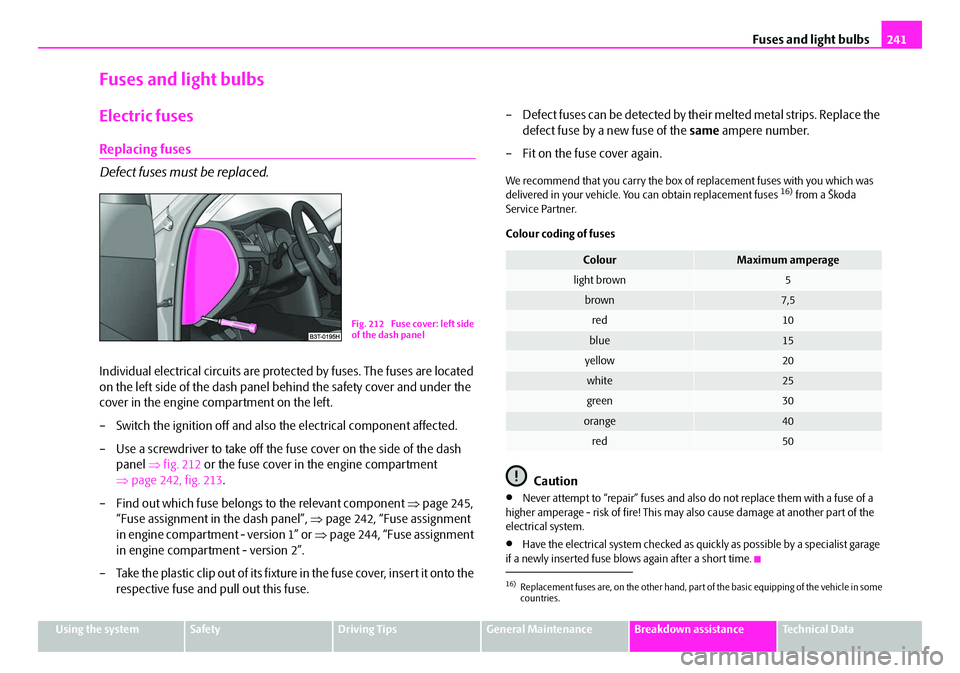

Fuses and light bulbs

Electric fuses

Replacing fuses

Defect fuses must be replaced.

Individual electrical circuits are protected by fuses. The fuses are located

on the left side of the dash panel behind the safety cover and under the

cover in the engine compartment on the left.

– Switch the ignition off and also the electrical component affected.

– Use a screwdriver to take off the fuse cover on the side of the dash panel ⇒fig. 212 or the fuse cover in the engine compartment

⇒ page 242, fig. 213 .

– Find out which fuse belongs to the relevant component ⇒page 245,

“Fuse assignment in the dash panel”, ⇒page 242, “Fuse assignment

in engine compartment - version 1” or ⇒page 244, “Fuse assignment

in engine compartment - version 2”.

– Take the plastic clip out of its fixture in the fuse cover, insert it onto the respective fuse and pull out this fuse. – Defect fuses can be detected by their melted metal strips. Replace the

defect fuse by a new fuse of the same ampere number.

– Fit on the fuse cover again.

We recommend that you carry the box of replacement fuses with you which was

delivered in your vehicle. You can obtain replacement fuses 16) from a Škoda

Service Partner.

Colour coding of fuses

Caution

•Never attempt to “repair” fuses and also do not replace them with a fuse of a

higher amperage - risk of fire! This may also cause damage at another part of the

electrical system.

•Have the electrical system checked as quickly as possible by a specialist garage

if a newly inserted fuse blows again after a short time.

Fig. 212 Fuse cover: left side

of the dash panel

16)Replacement fuses are, on the other hand, part of the basic equipping of the vehicle in some

countries.

ColourMaximum amperage

light brown5

brown7,5

red10

blue15

yellow20

white25

green30

orange40

red50

NKO B6 20.book Page 241 Wednesday, March 26, 2008 3:15 PM

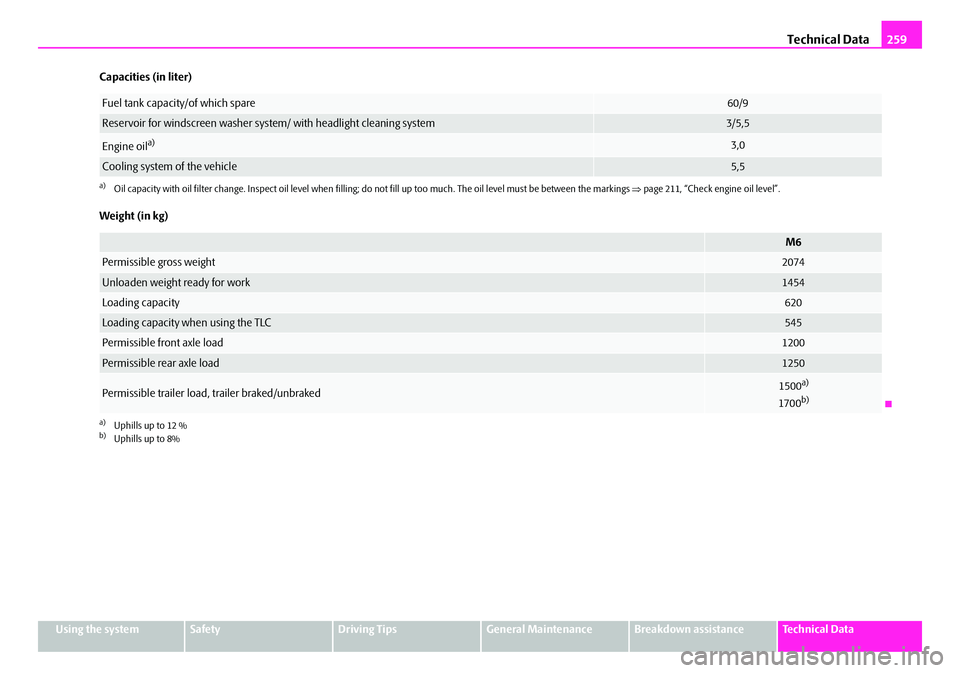

Page 258 of 272

Technical Data259

Using the systemSafetyDriving TipsGeneral MaintenanceBreakdown assistanceTechnical Data

Capacities (in liter)

Weight (in kg)

Fuel tank capacity/of which spare60/9

Reservoir for windscreen washer system/ with headlight cleaning system3/5,5

Engine oila)

a)Oil capacity with oil filter change. Inspec

t oil level when filling; do not fill up too much. The oil level must be between the markings ⇒page 211, “Check engine oil level”.

3,0

Cooling system of the vehicle5,5

M6

Permissible gross weight2074

Unloaden weight ready for work1454

Loading capacity620

Loading capacity when using the TLC545

Permissible front axle load1200

Permissible rear axle load1250

Permissible trailer load, trailer braked/unbraked1500a)

1700b)

a)Uphills up to 12 %b)Uphills up to 8%

NKO B6 20.book Page 259 Wednesday, March 26, 2008 3:15 PM

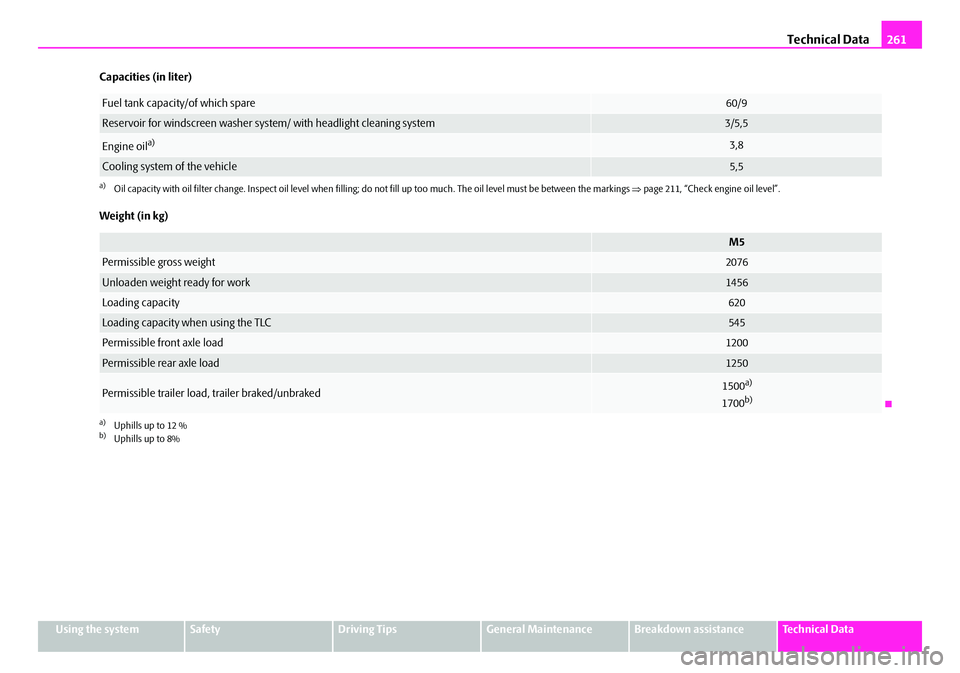

Page 260 of 272

Technical Data261

Using the systemSafetyDriving TipsGeneral MaintenanceBreakdown assistanceTechnical Data

Capacities (in liter)

Weight (in kg)

Fuel tank capacity/of which spare60/9

Reservoir for windscreen washer system/ with headlight cleaning system3/5,5

Engine oila)

a)Oil capacity with oil filter change. Inspec

t oil level when filling; do not fill up too much. The oil level must be between the markings ⇒page 211, “Check engine oil level”.

3,8

Cooling system of the vehicle5,5

M5

Permissible gross weight2076

Unloaden weight ready for work1456

Loading capacity620

Loading capacity when using the TLC545

Permissible front axle load1200

Permissible rear axle load1250

Permissible trailer load, trailer braked/unbraked1500a)

1700b)

a)Uphills up to 12 %b)Uphills up to 8%

NKO B6 20.book Page 261 Wednesday, March 26, 2008 3:15 PM