handbrake SKODA SUPERB 2008 Owner´s Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 2008, Model line: SUPERB, Model: SKODA SUPERB 2008Pages: 252, PDF Size: 16.33 MB

Page 159 of 252

The ABS is activated faster and more effectively with the intervention of the

HBA.

Hill Hold Control (HHC)

Read and observe

and on page 154 first.

When driving on slopes, HHC allows you to move your foot from the brake ped-al to the accelerator pedal without having to use the handbrake.

The system holds the brake pressure produced by the activation of the brake pedal for approx. 2 seconds after the brake pedal is released.

The brake pressure drops gradually the more you operate the accelerator ped-

al. If the vehicle does not start off within 2 seconds, it starts to roll back.

HHC is active on slopes of >5 % when the driver door is closed. HHC is always only active on slopes when in forward or reverse start off. When driving down-

hill, it is inactive.

Parking aid

Introduction

This chapter contains information on the following subjects:

Function

157

Activation/deactivation

157WARNING■ The parking aid is not a substitute for the driver paying proper attention

and it is always the driver's responsibility to take care when reversing the

vehicle or carrying out similar manoeuvres. Pay particular attention to small

children and animals as they may not be recognised by the system sensors.■

Before reversing, you should make sure that there are no small obstacles,

such as rocks, thin posts, trailer drawbars etc. in front or behind your vehi-

cle. Such obstacles may not be recognised by the system sensors.

■

Under certain circumstances, surfaces of certain objects and types of

clothing cannot reflect the system signals. Thus, these objects or people

who wear such clothing are not recognised by the System sensors.

■

External sound sources can have a detrimental effect on the system. Un-

der adverse conditions, this may cause objects or people to not be recog-

nised by the system.

CAUTION■ If a warning signal sounds for about 3 seconds after activating the system

and there is no obstacle close to your car, this indicates a system fault. The

fault is also indicated by the symbol

flashing in the button » Fig. 148 on

page 157 . Seek help from a specialist garage.■

The sensors must be kept clean (free of ice, etc.) to enable the system to op-

erate properly.

■

Under adverse weather conditions (heavy rain, water vapour, very low or

high temperatures etc.), the system function may be limited - “incorrect recog-

nition of obstacle”.

■

Additionally installed accessories such as e.g. bicycle carriers can impair the

system function.

Note

■ The signal tones for front obstacle recognition are factory-set to be higher

than for rear obstacle recognition.■

If not all fields around the vehicle are shown after the system is activated,

the vehicle will need to be moved a few metres forwards or in reverse.

■

The sound of the park assist can be adjusted via the MAXI DOT display in the

Assistants menu option » page 47.

■

If the system is activated and the selector lever of the automatic gearbox is

in position P (the vehicle cannot move), the warning tone is interrupted and no

obstacles are displayed.

156Driving

Page 174 of 252

Exterior mirrors

You have to have additional exterior mirrors fitted if you are not able to see

the traffic behind the trailer with the standard rear-view mirrors. National legal

requirements must be observed.

Headlights

The front of the vehicle can be lifted when a trailer is being towed and the

headlights can dazzle other road users.

Adjust the headlight setting on the headlight range control » page 68, Operat-

ing the lights and the instrument illumination .WARNING■

Incorrect or improperly connected electrical installation can cause acci-

dents and serious injury due to electric shock.■

Work on the electrical system must only be carried out by specialist ga-

rages.

■

Never directly connect the trailer's electrical system with the electrical

connections for the tail lights or other current sources.

■

After coupling the trailer and connecting up the power socket, check the

rear lights on the trailer to ensure they are working.

■

The handbrake on the towing vehicle must be applied when coupling and

uncoupling the trailer.

■

Never use the safety eyelet for towing!

CAUTION

Incorrect or improperly connected electrical installations may cause malfunc-

tion of the entire vehicle electronics.

Loading a trailer

The vehicle/trailer combination must be balanced, whereby the maximum per-

missible drawbar load must be utilised. If the drawbar load is too low, it jeop-

ardises the performance of the vehicle/trailer combination.

Distribution of the load

Distribute the load in the trailer in such a way that heavy items are located as

close to the axle as possible. Secure the items from slipping.

The distribution of the weight is very poor if your vehicle is unladen and the

trailer is laden. Maintain a particularly low speed if you cannot avoid driving

with this combination.

Tyre pressure

Correct the tyre inflation pressure on your vehicle for a “full load” » page 198.

Trailer load

The permissible trailer load must not be exceeded under any circumstan-

ces » page 228 , Technical data .

The details given in the vehicle's technical documentation always take prece- dence over the details in the Owner's Manual.

The trailer loads specified apply only to altitudes up to 1,000 metres above

mean sea level.

The engine output falls as altitude increases, as does the ability to climb.

Therefore, for every additional 1,000 m in height (or part), the maximum per-

missible towed weight must be reduced by 10 %.

The towed weight comprises the actual weights of the (loaded) towing vehicle

and the (loaded) trailer.

The trailer and drawbar load information on the type plate of the towing

equipment are merely test data for the towing equipment. The vehicle-specific

values are detailed in the vehicle documents.WARNING■ The maximum permissible axle and drawbar load and the permissible

weight of the trailer must not exceed - this could cause an accident!■

A sliding cargo can significantly adversely affect stability and driving safe-

ty - there is a risk of accident!

Towing a trailer

Driving speed

For safety reasons, do not drive faster than 80 km/h when towing a trailer.

Immediately reduce your speed as soon as even the slightest swaying of the

trailer is detected. Never attempt to stop the trailer from “swaying” by acceler-

ating.

Brakes

Apply the brakes in good time! If the trailer is fitted with a trailer brake, apply

the brakes gently at first and then brake firmly. This will avoid brake jolts re-

sulting from the trailer wheels locking.

On downhill sections shift down a gear in good time to also use the engine as

a brake.

171Hitch and trailer

Page 189 of 252

CAUTION■Just filling the tank once with diesel fuel that does not comply with the

standard, can cause severe damage to parts of the engine, the fuel and ex-

haust system!■

If a different fuel other than diesel fuel, which complies to the above men-

tioned standards (e.g. petrol) is used, do not start the engine or switch on the

ignition! Engine parts could be significantly damaged!

■

Water which has collected in the fuel filter can cause engine faults.

CAUTION

■ The vehicle cannot be operated with biofuel RME, therefore this fuel must

not be filled in the tank and used for driving the vehicle. The use of biofuel

RME can cause considerable damage to parts of the engine or fuel system.■

Do not mix any fuel additives, so-called “flow improvers” (petrol and similar

agents), into the diesel. This can result in considerable damage to parts of the

engine or the exhaust system!

Engine compartment

Introduction

This chapter contains information on the following subjects:

Opening and closing the bonnet

187

Engine compartment overview

188

Radiator fan

188

Windscreen washer system

188WARNINGInjuries or scolding or risks of accident or fire may occur when working in

the engine compartment. For this reason, it is essential to comply with the

warning instructions outlined below and with the general applicable safety

rules. The engine compartment of your car is a hazardous area!WARNINGInstructions before beginning work in the engine compartment■Turn off the engine and withdraw the ignition key.■

Firmly apply the handbrake.

WARNING (Continued)■ If the vehicle is fitted with a manual gearbox, move the gearshift lever in-

to Neutral, or if the vehicle is fitted with an automatic gearbox, move the

selector lever into position P.■

Allow the engine to cool.

■

Never open the bonnet if you can see steam or coolant escaping from the

engine compartment – risk of scalding! Wait until no more steam or coolant

is escaping.

WARNINGInformation for working in the engine compartment■Keep all people, especially children, away from the engine compartment.■

Never touch the radiator fan while the engine is still warm. The fan might

suddenly start running!

■

Do not touch any hot engine parts – risk of burns!

■

The coolant is harmful to health.

■

Avoid contact with the coolant.

■

Coolant vapours are harmful to health.

■

Never open the end cover of the coolant expansion reservoir while the

engine is still warm. The cooling system is pressurized!

■

When opening the end cover of the coolant expansion reservoir, cover it

with a cloth to protect your face, hands and arms from hot steam or hot

coolant.

■

If any coolant splashes into your eyes, immediately rinse out your eyes

with clear water and contact a doctor as soon as possible.

■

Always keep the coolant in the original container, safe from people who

are not completely independent, especially children - there is a danger of

poisoning!

■

Consult a doctor immediately if coolant is swallowed.

■

Never spill fluids on the hot engine. Such fluids (e.g. the antifreeze con-

tained in the coolant) may ignite!

WARNINGInformation for working in the engine compartment with the engine run-

ning■

Pay particular attention to rotating engine parts (e.g. V-ribbed belt, gen-

erator, radiator fan) and the high voltage ignition system – risk to life!

■

Never touch the electric wiring on the ignition system.

186General Maintenance

Page 209 of 252

WARNING■If you are in flowing traffic, switch on the hazard warning light system

and set up the warning triangle at the prescribed distance! The national le-

gal requirements must be observed.■

Park the vehicle as far away as possible from the flow of traffic. Park on

as flat and firm a surface as possible.

■

The following instructions must be followed if the vehicle is subsequently

fitted with tyres or rims that differ from the factory fitted ones » page 201,

Explanation of the tyre labelling .

WARNINGInformation on the wheel bolts■The wheel bolts must be clean and must turn easily. Never treat them

with grease or oil.■

The prescribed tightening torque of the wheel bolts for steel and light al-

loy wheels is 120 Nm.

■

If the wheel bolts are tightened to a too low tightening torque, the rim

can come loose when the car is moving. A tightening torque which is too

high can damage the bolts and threads and this can result in permanent

deformation of the contact surfaces on the rim.

■

In case of incorrect treatment of the wheel bolts, the wheel can loosen

when the car is moving.

Note

The national legal requirements must be observed when changing a wheel.

Preliminary work

Read and observe

on page 206 first.

Before changing the wheel, the following work must be carried out.

›

Have all the occupants get out. The passengers should not stand on the

road (instead they should remain behind a crash barrier, for instance) while

the wheel is being changed.

›

Switch off the engine.

›

Select the 1st gear or place the selector lever of the automatic transmission

in the P-position .

›

Apply the handbrake firmly.

›

Uncouple a trailer.

›Remove the

vehicle tool kit » page 205 and the spare wheel » page 200 from

the boot.

Changing a wheel

Read and observe

on page 206 first.

When changing a wheel, the following instructions must be followed.

›

Remove the full wheel trim or the caps of the wheel bolts.

›

First of all slacken the anti-theft wheel bolt and then the other wheel bolts.

›

Jack up the vehicle until the wheel that needs changing is clear of the

ground.

›

Unscrew the wheel bolts and place them on a clean surface (cloth, paper, etc.).

›

Remove the wheel carefully.

›

Attach the spare wheel and slightly screw on the wheel bolts.

›

Lower the vehicle.

›

Tighten the opposite wheel bolts alternately (cross-wise) with the wheelwrench. Tighten the anti-theft wheel bolt last.

›

Replace the wheel trim or the caps.

When fitting unidirectional tyres, ensure that the indication is cor-

rect » page 197 .

WARNINGIf it is established when changing a wheel that the wheel bolts are corro-

ded and difficult to move, then these must be replaced.

Follow-up work

Read and observe

on page 206 first.

After changing the wheel, the following work must be carried out.

›

Stow and attach the replaced wheel in the spare wheel well using a special

bolt » page 200 .

›

Stow the tool kit in the space provided and secure using the strap.

›

Check the tyre pressure on the installed spare wheel as soon as possible.

›

Have the tightening torque of the wheel bolts checked with a torque

wrench as soon as possible.

206Do-it-yourself

Page 213 of 252

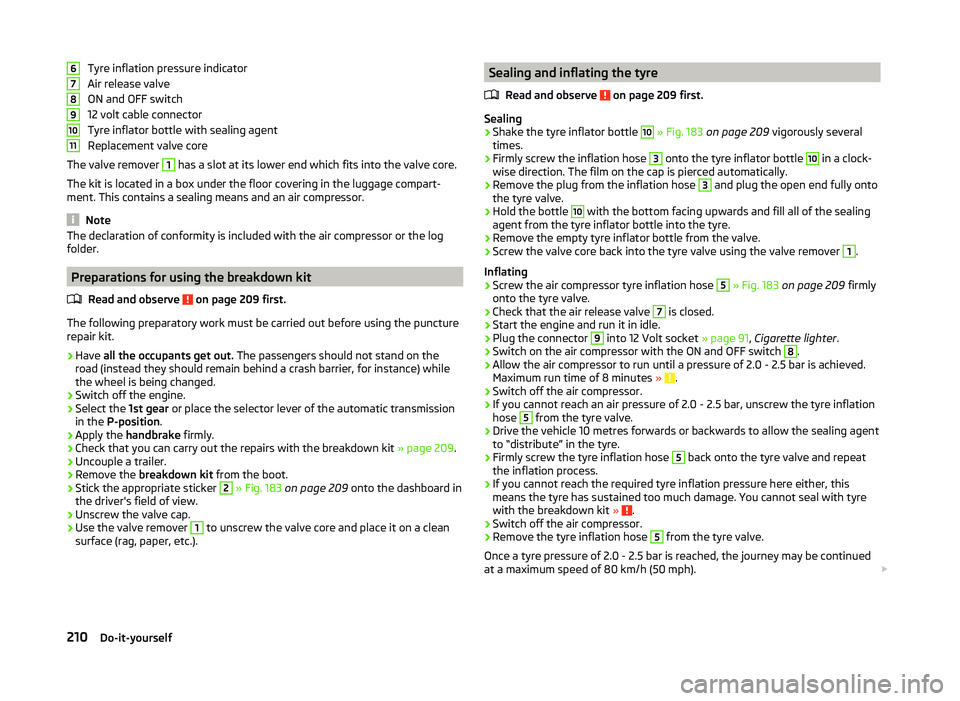

Tyre inflation pressure indicator

Air release valve

ON and OFF switch

12 volt cable connector

Tyre inflator bottle with sealing agent

Replacement valve core

The valve remover 1

has a slot at its lower end which fits into the valve core.

The kit is located in a box under the floor covering in the luggage compart-

ment. This contains a sealing means and an air compressor.

Note

The declaration of conformity is included with the air compressor or the log

folder.

Preparations for using the breakdown kit

Read and observe

on page 209 first.

The following preparatory work must be carried out before using the puncturerepair kit.

›

Have all the occupants get out. The passengers should not stand on the

road (instead they should remain behind a crash barrier, for instance) while

the wheel is being changed.

›

Switch off the engine.

›

Select the 1st gear or place the selector lever of the automatic transmission

in the P-position .

›

Apply the handbrake firmly.

›

Check that you can carry out the repairs with the breakdown kit

» page 209.

›

Uncouple a trailer.

›

Remove the breakdown kit from the boot.

›

Stick the appropriate sticker

2

» Fig. 183 on page 209 onto the dashboard in

the driver's field of view.

›

Unscrew the valve cap.

›

Use the valve remover

1

to unscrew the valve core and place it on a clean

surface (rag, paper, etc.).

67891011Sealing and inflating the tyre

Read and observe

on page 209 first.

Sealing

›

Shake the tyre inflator bottle

10

» Fig. 183 on page 209 vigorously several

times.

›

Firmly screw the inflation hose

3

onto the tyre inflator bottle

10

in a clock-

wise direction. The film on the cap is pierced automatically.

›

Remove the plug from the inflation hose

3

and plug the open end fully onto

the tyre valve.

›

Hold the bottle

10

with the bottom facing upwards and fill all of the sealing

agent from the tyre inflator bottle into the tyre.

›

Remove the empty tyre inflator bottle from the valve.

›

Screw the valve core back into the tyre valve using the valve remover

1

.

Inflating

›

Screw the air compressor tyre inflation hose

5

» Fig. 183 on page 209 firmly

onto the tyre valve.

›

Check that the air release valve

7

is closed.

›

Start the engine and run it in idle.

›

Plug the connector

9

into 12 Volt socket » page 91, Cigarette lighter .

›

Switch on the air compressor with the ON and OFF switch

8

.

›

Allow the air compressor to run until a pressure of 2.0 - 2.5 bar is achieved.

Maximum run time of 8 minutes » .

›

Switch off the air compressor.

›

If you cannot reach an air pressure of 2.0 - 2.5 bar, unscrew the tyre inflation

hose

5

from the tyre valve.

›

Drive the vehicle 10 metres forwards or backwards to allow the sealing agent

to “distribute” in the tyre.

›

Firmly screw the tyre inflation hose

5

back onto the tyre valve and repeat

the inflation process.

›

If you cannot reach the required tyre inflation pressure here either, this

means the tyre has sustained too much damage. You cannot seal with tyre with the breakdown kit »

.

›

Switch off the air compressor.

›

Remove the tyre inflation hose

5

from the tyre valve.

Once a tyre pressure of 2.0 - 2.5 bar is reached, the journey may be continued

at a maximum speed of 80 km/h (50 mph).

210Do-it-yourself

Page 220 of 252

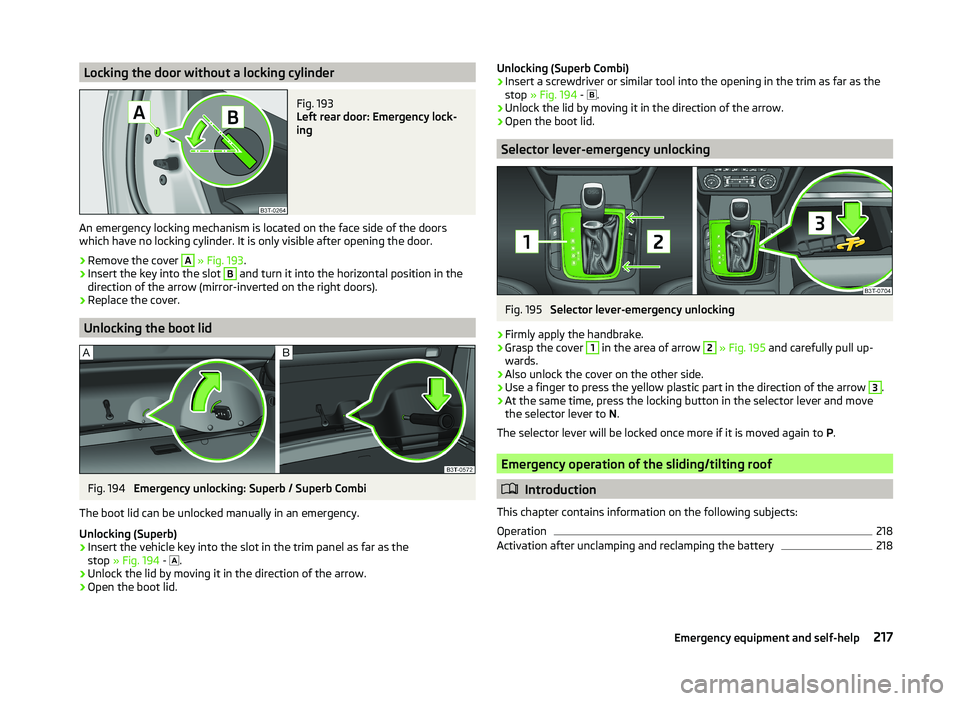

Locking the door without a locking cylinderFig. 193

Left rear door: Emergency lock-

ing

An emergency locking mechanism is located on the face side of the doors

which have no locking cylinder. It is only visible after opening the door.

›

Remove the cover

A

» Fig. 193 .

›

Insert the key into the slot

B

and turn it into the horizontal position in the

direction of the arrow (mirror-inverted on the right doors).

›

Replace the cover.

Unlocking the boot lid

Fig. 194

Emergency unlocking: Superb / Superb Combi

The boot lid can be unlocked manually in an emergency.

Unlocking (Superb)

›

Insert the vehicle key into the slot in the trim panel as far as the

stop » Fig. 194 -

.

›

Unlock the lid by moving it in the direction of the arrow.

›

Open the boot lid.

Unlocking (Superb Combi)›Insert a screwdriver or similar tool into the opening in the trim as far as the

stop » Fig. 194 -

.›

Unlock the lid by moving it in the direction of the arrow.

›

Open the boot lid.

Selector lever-emergency unlocking

Fig. 195

Selector lever-emergency unlocking

›

Firmly apply the handbrake.

›

Grasp the cover

1

in the area of arrow

2

» Fig. 195 and carefully pull up-

wards.

›

Also unlock the cover on the other side.

›

Use a finger to press the yellow plastic part in the direction of the arrow

3

.

›

At the same time, press the locking button in the selector lever and move the selector lever to N.

The selector lever will be locked once more if it is moved again to P.

Emergency operation of the sliding/tilting roof

Introduction

This chapter contains information on the following subjects:

Operation

218

Activation after unclamping and reclamping the battery

218217Emergency equipment and self-help

Page 240 of 252

BootAutomatic retraction (Superb Combi)101

Extending variable loading floor105

Folding hook99

Non-closable side pocket (Superb Combi)102

Removable Light (Superb Combi)103

Roll up boot cover (Superb Combi)101

Side compartment with battery102

Boot cover (Superb Combi)101

Boot lid57

automatic locking58

Warning light36

(Superb Combi)58

Brake booster144

Brake fluid192

Checking193

Information messages35

specification193

Brake linings warning light

41

Brakes Brake assist systems

154

Brake booster144

Brake fluid193

Handbrake144

Information messages35

Running in149

Warning light35

Braking Information on braking

143

Break recommendation See Fatigue detection

165

Button in the driver's door Electrical power windows

61

C

Car care

173

Jack180

Car computer See multifunction display

44

Car park ticket holder89

Carrier Roof rack

108

Cavity protection180

CD changer136

Central locking50

Central locking button55

Changing brake fluid

193

bulbs223

Wheels205

Changing a wheel Follow-up work

206

Preliminary work206

Remove and attaching a wheel206

Changing brake fluid

193

Charging a vehicle battery196

Check Fit ball head properly

168

Checking Battery electrolyte level

195

Brake fluid193

Coolant192

Engine oil190

Oil level190

Windscreen washer fluid188

Checks Statutory checks

173

Children and safety22

Child safety Side airbag

24

Child safety lock55

Child seat Classification

25

ISOFIX25

on the front passenger seat23

TOP TETHER27

Use of child seats25

Use of ISOFIX child seats26

Chrome parts refer to Taking care of your vehicle178

Cigarette lighter91

Cleaning Alcantara

182

Covers of electrically heated seats182

Fabrics182

Headlight lenses179

Natural leather181

Plastic parts178

Synthetic leather182

Wheels180

Cleaning the vehicle Towing device

180

Cleaning vehicle176

Climatronic115

Air recirculation117

automatic mode116

Control elements115

Controlling blower118

Cooling system116

Defrosting windscreen118

Setting the temperature116

Clothes hook94

Cockpit 12-Volt power outlet

92

Ashtray91

Cigarette lighter91

General view29

Lighting73

Practical features88

Storage compartments88

Comfort control window

63

COMING HOME72

Compartments88

Components of the puncture repair kits209

Computer See multifunction display

44

237Index

Page 242 of 252

Selector lever-unlocking217

Sliding/tilting roof218

Start engine - KESSY142

Switching off the ignition –KESSY143

Towing the vehicle213

Towing the vehicle using the tow hitch214

tyre repair209

Unlocking the boot lid217

Unlocking the driver's door216

Emergency equipment Fire extinguisher

204

First-aid kit 204

Jack205

Vehicle tool kit205

Warning triangle204

Emissions229

Engine Running in

148

Engine compartment186

Brake fluid193

Coolant191

Overview188

Vehicle battery193

Engine number228

Engine oil189

Capacity189

Checking190

Note messages36

Replenishing191

Specifications189

Engine oil level Warning light

37

Engine oil pressure Warning light

36

Entry lighting75

Environment149

Environmental compatibility151

Environmentally friendly driving149

EPC Warning light

39

ESCFunction154

Warning light37

Exhaust inspection system Warning light

38

Extendable variable loading floor Fixing set

106

Extending variable loading floor105

Divide boot105

Movable lashing eyes107

Partial extension105

F

Fastening elements

99

Fatigue detection165

Function165

Information messages165

Films179

Fire extinguisher204

First-aid kit 204

Floor covering Fixing

100

Fog lights71

Warning light41

Fog lights with CORNER function71

Folding hook99

Fold in passenger's mirror80

Footmats145

see Footmats145

Force limit Electric boot lid (Superb Combi)

59

Power windows63

Sliding/tilting roof64

Sliding/tilting roof (Superb Combi)66

Front airbag17

Front door warning light74

Front interior light73

Fuel183

Diesel185

Fuel gauge32

refer to Fuel183

Refuelling184

Unleaded petrol184

Fuel consumption149, 229

Fuel reserve Warning light

39

Fuses Assignment

220

Colour coding220

Fuse assignment in the engine compartment222

Replacing220

G

Gearbox Warning messages

33

Gear change Gear recommendation

43

Information on the selected gear43

Gear changing Gear stick

144

General view Cockpit

29

Generator Indicator light

35

Genuine parts174

Glasses storage box93

Glow plug system Warning light

38

GSM124, 126

H

Handbrake

144

Warning light35

Hands-free system Voice control

131

Hazard warning light system72

239Index