tow bar SKODA SUPERB 2008 Owner´s Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 2008, Model line: SUPERB, Model: SKODA SUPERB 2008Pages: 252, PDF Size: 16.33 MB

Page 32 of 252

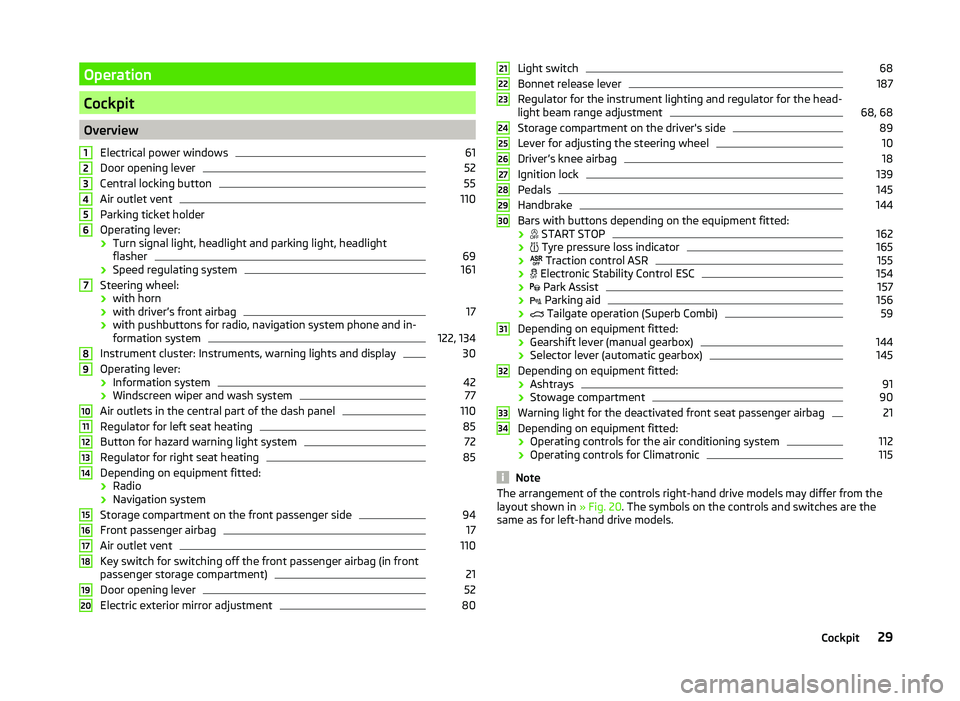

Operation

Cockpit

OverviewElectrical power windows

61

Door opening lever

52

Central locking button

55

Air outlet vent

110

Parking ticket holder

Operating lever: › Turn signal light, headlight and parking light, headlight

flasher

69

› Speed regulating system

161

Steering wheel:

› with horn

› with driver’s front airbag

17

› with pushbuttons for radio, navigation system phone and in-

formation system

122, 134

Instrument cluster: Instruments, warning lights and display

30

Operating lever:

› Information system

42

›Windscreen wiper and wash system

77

Air outlets in the central part of the dash panel

110

Regulator for left seat heating

85

Button for hazard warning light system

72

Regulator for right seat heating

85

Depending on equipment fitted:

› Radio

› Navigation system

Storage compartment on the front passenger side

94

Front passenger airbag

17

Air outlet vent

110

Key switch for switching off the front passenger airbag (in front

passenger storage compartment)

21

Door opening lever

52

Electric exterior mirror adjustment

801234567891011121314151617181920Light switch68

Bonnet release lever

187

Regulator for the instrument lighting and regulator for the head-

light beam range adjustment

68, 68

Storage compartment on the driver's side

89

Lever for adjusting the steering wheel

10

Driver’s knee airbag

18

Ignition lock

139

Pedals

145

Handbrake

144

Bars with buttons depending on the equipment fitted:

›

START STOP

162

›

Tyre pressure loss indicator

165

›

Traction control ASR

155

›

Electronic Stability Control ESC

154

›

Park Assist

157

›

Parking aid

156

›

Tailgate operation (Superb Combi)

59

Depending on equipment fitted:

› Gearshift lever (manual gearbox)

144

›Selector lever (automatic gearbox)

145

Depending on equipment fitted:

› Ashtrays

91

›Stowage compartment

90

Warning light for the deactivated front seat passenger airbag

21

Depending on equipment fitted:

› Operating controls for the air conditioning system

112

›

Operating controls for Climatronic

115

Note

The arrangement of the controls right-hand drive models may differ from the

layout shown in » Fig. 20. The symbols on the controls and switches are the

same as for left-hand drive models.212223242526272829303132333429Cockpit

Page 169 of 252

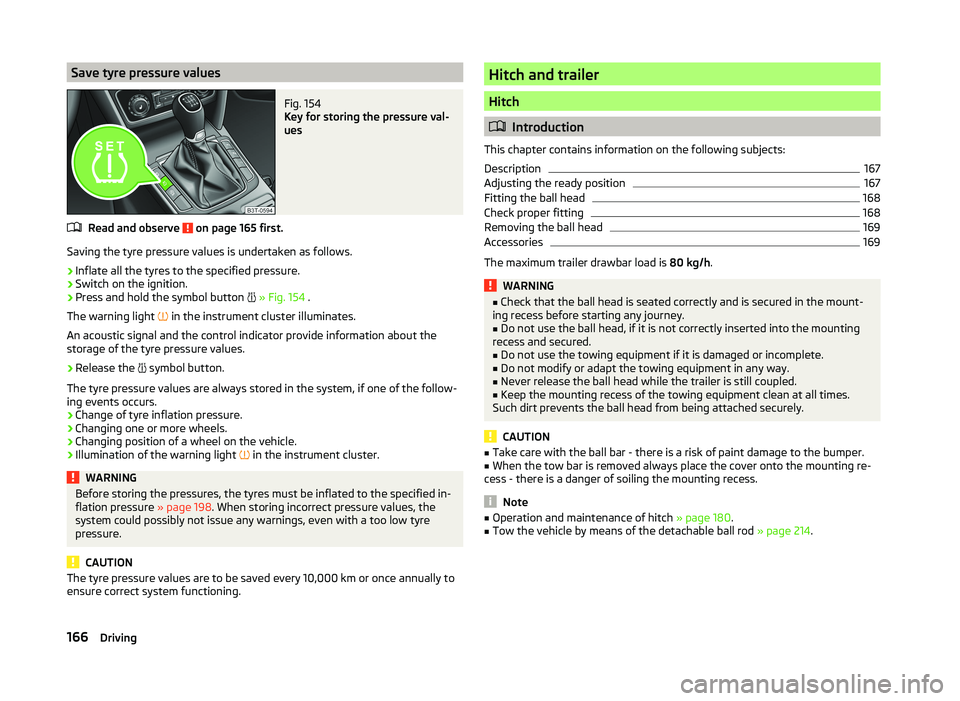

Save tyre pressure valuesFig. 154

Key for storing the pressure val-

ues

Read and observe on page 165 first.

Saving the tyre pressure values is undertaken as follows.

›

Inflate all the tyres to the specified pressure.

›

Switch on the ignition.

›

Press and hold the symbol button

» Fig. 154 .

The warning light in the instrument cluster illuminates.

An acoustic signal and the control indicator provide information about the

storage of the tyre pressure values.

›

Release the symbol button.

The tyre pressure values are always stored in the system, if one of the follow-

ing events occurs.

› Change of tyre inflation pressure.

› Changing one or more wheels.

› Changing position of a wheel on the vehicle.

› Illumination of the warning light

in the instrument cluster.

WARNINGBefore storing the pressures, the tyres must be inflated to the specified in-

flation pressure » page 198. When storing incorrect pressure values, the

system could possibly not issue any warnings, even with a too low tyre

pressure.

CAUTION

The tyre pressure values are to be saved every 10,000 km or once annually to

ensure correct system functioning.Hitch and trailer

Hitch

Introduction

This chapter contains information on the following subjects:

Description

167

Adjusting the ready position

167

Fitting the ball head

168

Check proper fitting

168

Removing the ball head

169

Accessories

169

The maximum trailer drawbar load is 80 kg/h.

WARNING■

Check that the ball head is seated correctly and is secured in the mount-

ing recess before starting any journey.■

Do not use the ball head, if it is not correctly inserted into the mounting

recess and secured.

■

Do not use the towing equipment if it is damaged or incomplete.

■

Do not modify or adapt the towing equipment in any way.

■

Never release the ball head while the trailer is still coupled.

■

Keep the mounting recess of the towing equipment clean at all times.

Such dirt prevents the ball head from being attached securely.

CAUTION

■ Take care with the ball bar - there is a risk of paint damage to the bumper.■When the tow bar is removed always place the cover onto the mounting re-

cess - there is a danger of soiling the mounting recess.

Note

■ Operation and maintenance of hitch » page 180.■Tow the vehicle by means of the detachable ball rod » page 214.166Driving

Page 170 of 252

DescriptionFig. 155

Carrier for the towing device / tow bar

Read and observe

and on page 166 first.

The ball head can be removed and is kept in the spare wheel well or in a com-

partment for the spare wheel in the luggage compartment.

Support for the towing device and tow bar » Fig. 155

13-pin power socket

Safety eyelet

Mounting recess

Cap

Dust cap

Ball head

Operating lever

Lock cap

Release pin

Key

locking ball

Note

If you lose the key, please get in touch with a specialist garage.1234567891011Adjusting the ready positionFig. 156

Setting the ready position/ready position

Read and observe

and on page 166 first.

The coupling ball bar must be set prior to installation in the standby position.

If this is not in the ready position, then this must be set to the standby posi-

tion as follows.

›

Grip the ball head below the protective cap

2

.

›

Remove the cap from the lock.

›

Insert the key into the lock, so that its green marking is pointing upwards.

›

Turn key

1

in direction of the arrow, so that the red marking is facing up-

wards » Fig. 156 .

›

Press the release pin

3

as far as the stop in the direction of the arrow and

at the same time push the lever

4

downwards as far as it will go in the di-

rection of the arrow.

The operating lever remains locked in this position.

CAUTION

In the ready position, the key cannot be removed nor turned to a different po-

sition.167Hitch and trailer

Page 171 of 252

Fitting the ball headFig. 157

Insert the ball head/lock the lock, and put the lock cover on

Read and observe

and on page 166 first.

›

Pull cap

4

» Fig. 155 on page 167 downwards.

›

Adjust the ball head to the ready position » page 167.

›

Grip the tow bar from underneath » Fig. 157 and insert into the mounting re-

cess until you hear it click into place » .

The operating lever

1

automatically turns upwards and the release pin

2

pops out (its red and green parts are visible) » .

If the operating lever

1

does not automatically emerge, or if the release pin

2

does not pop out, remove the ball head from the mounting recess by turn-

ing the lever downwards as far as it will go. Clean the tapered surfaces on the

ball head and the mounting recess.

›

Turn the key

3

180° to the right so that its green marker points upward.

›

Remove the key in the direction of the arrow.

›

Insert and press the cap

4

onto the lock in the direction of the arrow » .

›

Check the ball head for secure mounting » page 168.

WARNING■

Keep your hands outside the lever's range of motion when attaching the

ball head – there is a risk of fingers being injured!■

Never attempt to pull the operating lever upwards forcibly to turn the

key. Doing so would mean the ball head is not attached correctly.

CAUTION■ After removing the key, always replace the cover on the lock – there is a risk

of the lock getting dirty.■

Keep the mounting recess of the towing equipment clean at all times. Such

dirt prevents the ball head from being attached securely.

Check proper fitting

Fig. 158

Correctly secured ball head

Read and observe and on page 166 first.

Check that the ball head is fitted properly each time before use.

Correctly secured ball head » Fig. 158

Lever

1

is up as far as it will go » Fig. 158.

The release pin

2

is completely exposed (both its red and green parts are

visible).

The key is removed.

Cap

3

is on the lock.

The ball head does not come out of the mounting recess even after heavy

“shaking”.

WARNINGThe towing device can only be used when the tow bar is correctly locked –

there is the risk of an accident occurring.168Driving

Page 172 of 252

Removing the ball headFig. 159

Unlock the operating lever of the ball head/removing the ball

head

Read and observe

and on page 166 first.

›

Remove cover

1

» Fig. 159 from the lock in the direction of the arrow.

›

Insert the key into the lock, so that its green marking is pointing upwards.

›

Turn the key

2

180° to the left so that its red marker points upward.

›

Grasp the ball head from underneath.

›

Press the release pin

3

as far as the stop in the direction of the arrow and

at the same time push the lever

4

downwards as far as it will go in the di-

rection of the arrow.

The ball head is released in this position and falls freely into the hand. If it

does not fall freely into the hand, use your other hand to push it upwards.

At the same time, the ball head latches into the ready position and is thus

ready to be re-inserted into the mounting recess »

.

›

Place the cap

4

» Fig. 155 on page 167 onto the mounting recess.

WARNINGNever allow the ball head to remain unsecured in the boot. This could

cause damage to the boot upon sudden braking, and could put the safety

of the occupants at risk.CAUTION■ If the lever is held firmly and not pushed downwards as far as it can go, it will

go back up after the ball head is removed and will not latch into the ready po-

sition. The ball head then needs to be brought into this position before the

next time it is fitted.■

Tuck the ball bar in the ready position, with the golden key up, in the box -

otherwise there is a risk of damage to the key!

■

Do not use excessive force when handling the operating lever (e.g. do not

step on it).

Note

■ We recommend that you put the protective cap on the ball before removing

the ball head.■

Clean any dirt from the ball head before stowing it away in the box with the

vehicle tool kit.

Accessories

Fig. 160

Representation of the maximum

permissible level of the ball head

of the towing hitch and the per-

missible total weight of the ac-

cessories including the load de-

pending on the load center of

gravity

Read and observe and on page 166 first.

An accessory can mounted on the ball head of the towing hitch (e.g. bike carri-

ers).

If this accessory is used, the maximum permissible overhang of the ball head

of the towing hitch and the permissible gross vehicle weight of the accesso-

ries including load are to be checked.

The maximum permissible overhang of the ball head of the towing hitch is 70

cm » Fig. 160 .

The total permitted weight of the accessory including load changes with in-

creasing distance of the centre of gravity of the load from the ball head of the

towing hitch.

169Hitch and trailer

Page 173 of 252

Distance of the centre of gravity ofthe load from the ball headPermissible total weight of the ac- cessory, including load0 cm80 kg30 cm75 kg60 cm35 kg70 cm0 kgWARNING■Never exceed the permissible gross weight of the accessory including

load - there is a risk of damaging the ball head of the towing hitch.■

Never exceed the permissible overhang of the ball head of the towing

hitch - there is a risk of damaging the ball head of the towing hitch.

Note

We recommend that you use accessories from ŠKODA Original Accessories.

Trailer

Introduction

This chapter contains information on the following subjects:

Attaching and detaching trailers

170

Loading a trailer

171

Towing a trailer

171

Trailer stabilisation (TSA)

172

Anti-theft alarm system

172

If your vehicle has already been factory fitted with towing equipment or is fit-

ted with towing equipment from ŠKODA Original Accessories, then it meets all

of the technical requirements and national legal provisions for towing a trailer.

Note

If there is an error in the trailer lighting system, check the fuses in the fuse box

in the dashboard » page 220.Attaching and detaching trailersFig. 161

Swivel out the 13-pin power

socket, safety eyelet

Coupling

›

Install the tow bar.

›

Grip the 13-pin socket at point

A

and swing out in the direction of ar-

row » Fig. 161 .

›

Lift off protective cap

5

» Fig. 155 on page 167 towards the top.

›

Place the trailer onto the ball.

›

Insert the trailer cable into the 13-pin socket.

If the trailer that is to be towed has a 7-pin connector, you can use a suitable

adapter from ŠKODA Original Accessories to establish a connection to the elec-

tricity.

›

Hook the breakaway cable of the trailer to the security lock slot

B

.

The breakaway cable of the trailer has to sag when mounted into the security

lock slot for all trailer positions relative to the vehicle (sharp curves, reverse

driving and the like).

Uncoupling

The uncoupling of the trailer is carried out in reverse order.

›

Unhook the breakaway cable of the trailer from the security lock slot

B

» Fig. 161 .

›

Pull the trailer cable out of the 13-pin socket.

›

Remove the trailer from the ball head.

›

Place the cover

5

on the ball head » Fig. 155 on page 167 .

›

Grip the 13-pin socket at point

A

and swing in the opposite direction to the

arrow » Fig. 161 .

170Driving

Page 174 of 252

Exterior mirrors

You have to have additional exterior mirrors fitted if you are not able to see

the traffic behind the trailer with the standard rear-view mirrors. National legal

requirements must be observed.

Headlights

The front of the vehicle can be lifted when a trailer is being towed and the

headlights can dazzle other road users.

Adjust the headlight setting on the headlight range control » page 68, Operat-

ing the lights and the instrument illumination .WARNING■

Incorrect or improperly connected electrical installation can cause acci-

dents and serious injury due to electric shock.■

Work on the electrical system must only be carried out by specialist ga-

rages.

■

Never directly connect the trailer's electrical system with the electrical

connections for the tail lights or other current sources.

■

After coupling the trailer and connecting up the power socket, check the

rear lights on the trailer to ensure they are working.

■

The handbrake on the towing vehicle must be applied when coupling and

uncoupling the trailer.

■

Never use the safety eyelet for towing!

CAUTION

Incorrect or improperly connected electrical installations may cause malfunc-

tion of the entire vehicle electronics.

Loading a trailer

The vehicle/trailer combination must be balanced, whereby the maximum per-

missible drawbar load must be utilised. If the drawbar load is too low, it jeop-

ardises the performance of the vehicle/trailer combination.

Distribution of the load

Distribute the load in the trailer in such a way that heavy items are located as

close to the axle as possible. Secure the items from slipping.

The distribution of the weight is very poor if your vehicle is unladen and the

trailer is laden. Maintain a particularly low speed if you cannot avoid driving

with this combination.

Tyre pressure

Correct the tyre inflation pressure on your vehicle for a “full load” » page 198.

Trailer load

The permissible trailer load must not be exceeded under any circumstan-

ces » page 228 , Technical data .

The details given in the vehicle's technical documentation always take prece- dence over the details in the Owner's Manual.

The trailer loads specified apply only to altitudes up to 1,000 metres above

mean sea level.

The engine output falls as altitude increases, as does the ability to climb.

Therefore, for every additional 1,000 m in height (or part), the maximum per-

missible towed weight must be reduced by 10 %.

The towed weight comprises the actual weights of the (loaded) towing vehicle

and the (loaded) trailer.

The trailer and drawbar load information on the type plate of the towing

equipment are merely test data for the towing equipment. The vehicle-specific

values are detailed in the vehicle documents.WARNING■ The maximum permissible axle and drawbar load and the permissible

weight of the trailer must not exceed - this could cause an accident!■

A sliding cargo can significantly adversely affect stability and driving safe-

ty - there is a risk of accident!

Towing a trailer

Driving speed

For safety reasons, do not drive faster than 80 km/h when towing a trailer.

Immediately reduce your speed as soon as even the slightest swaying of the

trailer is detected. Never attempt to stop the trailer from “swaying” by acceler-

ating.

Brakes

Apply the brakes in good time! If the trailer is fitted with a trailer brake, apply

the brakes gently at first and then brake firmly. This will avoid brake jolts re-

sulting from the trailer wheels locking.

On downhill sections shift down a gear in good time to also use the engine as

a brake.

171Hitch and trailer

Page 175 of 252

Engine overheating

The speed must be reduced immediately if the needle for the coolant tempera-

ture gauge moves into the right-hand area or the red area of the scale.

Stop and switch off the engine if the warning light

in the instrument cluster

illuminates.

The following guidelines must be observed » page 36,

Coolant .

The coolant temperature can be reduced by switching on the heating.WARNING■ Always drive particularly carefully with the trailer.■Adapt your speed to the conditions of the road surface and to the traffic

situation.

CAUTION

If you tow a trailer frequently, you should also have your vehicle inspected be-

tween service intervals.

Trailer stabilisation (TSA)

The trailer stabilisation is an extension of the stabilisation control that works

in conjunction with the counter-steering assistance to reduce the amount the

trailer "sways".

After turning on the ignition, the ESC warning light

in the instrument cluster

illuminates for about 2 seconds longer than the ABS warning light.

Function requirements for trailer stabilisation. The trailer was shipped from the factory or purchased from the ŠKODA

genuine accessories.

The ESC is active. (Warning lights

or

do not illuminate in the instru-

ment cluster).

The trailer is electrically connected to the towing vehicle by means of the

trailer socket.

The speed is higher than approx. 60 km/h.

The trailer has a rigid drawbar.

WARNING■ The increased safety offered by the trailer stabilisation must not tempt

you to take greater risks than otherwise.■

Avoid abrupt and sudden driving and braking manoeuvres - there is a risk

of accidents.

CAUTION

■ The trailer stabilisation need not be able to correctly detect all of driving sit-

uations.■

Light trailers that sway are not always detected and therefore stabilised ac-

cordingly by the trailer stabilisation.

■

Release the pressure on the accelerator pedal if the system is being regula-

ted.

Note

The trailer stabilisation works for both braked and unbraked trailers.

Anti-theft alarm system

When the vehicle is locked, the alarm is activated when the electrical connec-

tion to the trailer is interrupted.

Always switch off the anti-theft alarm system before a trailer is coupled or un-

coupled » page 55 .

Conditions for including a trailer in the anti-theft alarm system. The vehicle is factory fitted with an anti-theft alarm system and towing

equipment.

The trailer is electrically connected to the towing vehicle by means of the

trailer socket.

The electrical system of the vehicle and trailer is functional.

The vehicle is locked with the vehicle key and the anti-theft alarm system

is activated.

CAUTION

For technical reasons, trailers with rear LED lights cannot be connected to the

anti-theft alarm system.172Driving

Page 209 of 252

WARNING■If you are in flowing traffic, switch on the hazard warning light system

and set up the warning triangle at the prescribed distance! The national le-

gal requirements must be observed.■

Park the vehicle as far away as possible from the flow of traffic. Park on

as flat and firm a surface as possible.

■

The following instructions must be followed if the vehicle is subsequently

fitted with tyres or rims that differ from the factory fitted ones » page 201,

Explanation of the tyre labelling .

WARNINGInformation on the wheel bolts■The wheel bolts must be clean and must turn easily. Never treat them

with grease or oil.■

The prescribed tightening torque of the wheel bolts for steel and light al-

loy wheels is 120 Nm.

■

If the wheel bolts are tightened to a too low tightening torque, the rim

can come loose when the car is moving. A tightening torque which is too

high can damage the bolts and threads and this can result in permanent

deformation of the contact surfaces on the rim.

■

In case of incorrect treatment of the wheel bolts, the wheel can loosen

when the car is moving.

Note

The national legal requirements must be observed when changing a wheel.

Preliminary work

Read and observe

on page 206 first.

Before changing the wheel, the following work must be carried out.

›

Have all the occupants get out. The passengers should not stand on the

road (instead they should remain behind a crash barrier, for instance) while

the wheel is being changed.

›

Switch off the engine.

›

Select the 1st gear or place the selector lever of the automatic transmission

in the P-position .

›

Apply the handbrake firmly.

›

Uncouple a trailer.

›Remove the

vehicle tool kit » page 205 and the spare wheel » page 200 from

the boot.

Changing a wheel

Read and observe

on page 206 first.

When changing a wheel, the following instructions must be followed.

›

Remove the full wheel trim or the caps of the wheel bolts.

›

First of all slacken the anti-theft wheel bolt and then the other wheel bolts.

›

Jack up the vehicle until the wheel that needs changing is clear of the

ground.

›

Unscrew the wheel bolts and place them on a clean surface (cloth, paper, etc.).

›

Remove the wheel carefully.

›

Attach the spare wheel and slightly screw on the wheel bolts.

›

Lower the vehicle.

›

Tighten the opposite wheel bolts alternately (cross-wise) with the wheelwrench. Tighten the anti-theft wheel bolt last.

›

Replace the wheel trim or the caps.

When fitting unidirectional tyres, ensure that the indication is cor-

rect » page 197 .

WARNINGIf it is established when changing a wheel that the wheel bolts are corro-

ded and difficult to move, then these must be replaced.

Follow-up work

Read and observe

on page 206 first.

After changing the wheel, the following work must be carried out.

›

Stow and attach the replaced wheel in the spare wheel well using a special

bolt » page 200 .

›

Stow the tool kit in the space provided and secure using the strap.

›

Check the tyre pressure on the installed spare wheel as soon as possible.

›

Have the tightening torque of the wheel bolts checked with a torque

wrench as soon as possible.

206Do-it-yourself

Page 211 of 252

The mounting points are located on the metal bar of the lower sill on the un-

derside of your vehicle. The positions of these are embossed by means of

markings on the side surface of the lower sill » Fig. 181.›

Support the base plate of the jack with its full area resting on level ground

and ensure that the jack is located in a vertical position at the jacking

point » Fig. 181 -

.

›

Position the lifting jack below the jacking point with the crank and move it up

until its claw encloses the web » Fig. 181 -

.

›

Continue turning up the jack until the wheel is just about lifted off the

ground.

WARNINGNotes for vehicle lifting■Choose a flat and firm surface for jacking the vehicle.■

If the wheel has to be changed on a slope, first of all block the opposite

wheel with a stone or similar object to prevent the vehicle from unexpect-

edly rolling away.

■

Secure the base plate of the lifting jack with suitable means to prevent

possible moving. A soft and slippery ground under the base plate may move

the lifting jack, causing the vehicle to fall down. It is therefore always nec-

essary to place the lifting jack on a solid surface or use a wide and stable

base. Use a non-slip base (e.g. a rubber foot mat) if the surface is smooth,

such as cobbled stones, tiled floor, etc.

■

Only attach the lifting jack to the attachment points provided for this pur-

pose.

■

Always raise the vehicle with the doors closed.

■

Never position any body parts, such as arms or legs under the vehicle,

while the vehicle is raised with a lifting jack.

■

When the vehicle is raised, never start the engine.

CAUTION

It is important to ensure that the jack is correctly attached to the web of the

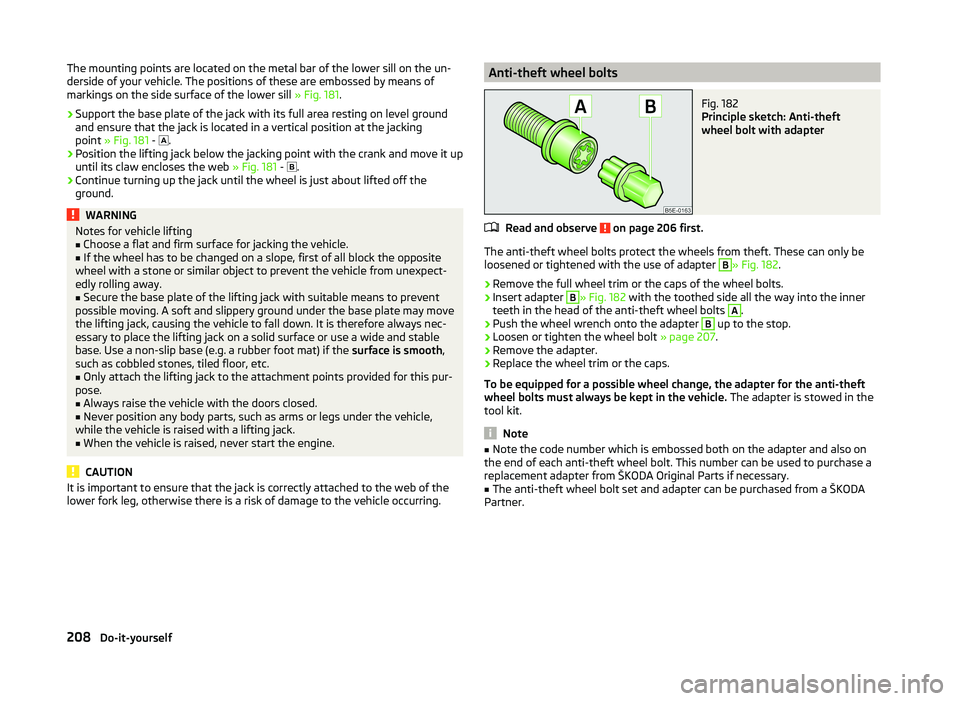

lower fork leg, otherwise there is a risk of damage to the vehicle occurring.Anti-theft wheel boltsFig. 182

Principle sketch: Anti-theft

wheel bolt with adapter

Read and observe on page 206 first.

The anti-theft wheel bolts protect the wheels from theft. These can only be loosened or tightened with the use of adapter

B

» Fig. 182 .

›

Remove the full wheel trim or the caps of the wheel bolts.

›

Insert adapter

B

» Fig. 182 with the toothed side all the way into the inner

teeth in the head of the anti-theft wheel bolts

A

.

›

Push the wheel wrench onto the adapter

B

up to the stop.

›

Loosen or tighten the wheel bolt » page 207.

›

Remove the adapter.

›

Replace the wheel trim or the caps.

To be equipped for a possible wheel change, the adapter for the anti-theft

wheel bolts must always be kept in the vehicle. The adapter is stowed in the

tool kit.

Note

■ Note the code number which is embossed both on the adapter and also on

the end of each anti-theft wheel bolt. This number can be used to purchase a

replacement adapter from ŠKODA Original Parts if necessary.■

The anti-theft wheel bolt set and adapter can be purchased from a ŠKODA

Partner.

208Do-it-yourself