change wheel SKODA SUPERB 2011 Owner´s Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 2011, Model line: SUPERB, Model: SKODA SUPERB 2011Pages: 252, PDF Size: 16.33 MB

Page 169 of 252

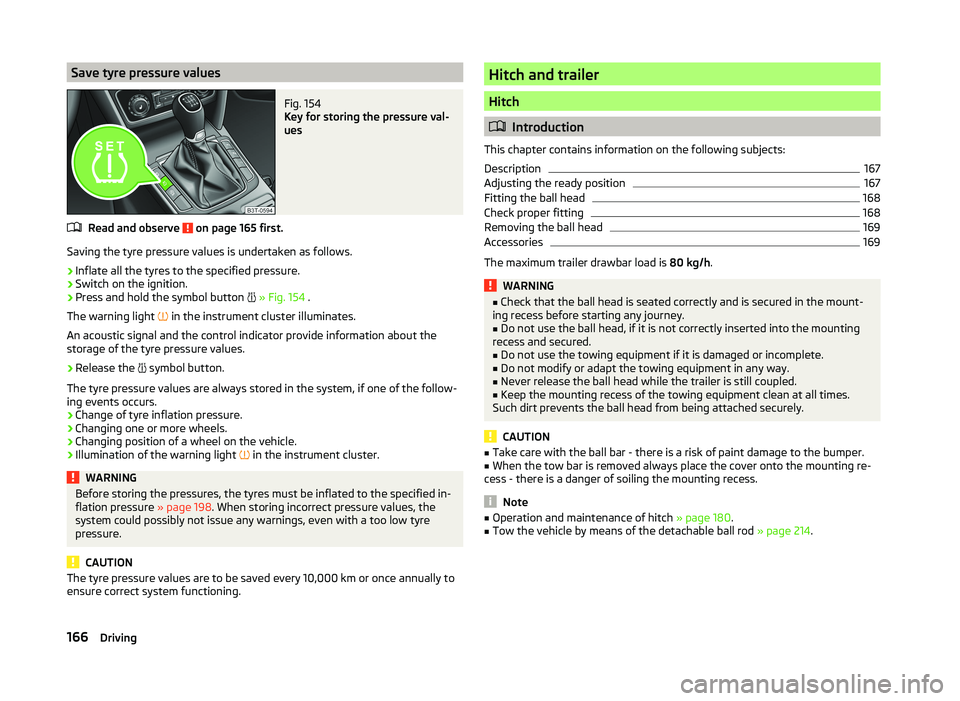

Save tyre pressure valuesFig. 154

Key for storing the pressure val-

ues

Read and observe on page 165 first.

Saving the tyre pressure values is undertaken as follows.

›

Inflate all the tyres to the specified pressure.

›

Switch on the ignition.

›

Press and hold the symbol button

» Fig. 154 .

The warning light in the instrument cluster illuminates.

An acoustic signal and the control indicator provide information about the

storage of the tyre pressure values.

›

Release the symbol button.

The tyre pressure values are always stored in the system, if one of the follow-

ing events occurs.

› Change of tyre inflation pressure.

› Changing one or more wheels.

› Changing position of a wheel on the vehicle.

› Illumination of the warning light

in the instrument cluster.

WARNINGBefore storing the pressures, the tyres must be inflated to the specified in-

flation pressure » page 198. When storing incorrect pressure values, the

system could possibly not issue any warnings, even with a too low tyre

pressure.

CAUTION

The tyre pressure values are to be saved every 10,000 km or once annually to

ensure correct system functioning.Hitch and trailer

Hitch

Introduction

This chapter contains information on the following subjects:

Description

167

Adjusting the ready position

167

Fitting the ball head

168

Check proper fitting

168

Removing the ball head

169

Accessories

169

The maximum trailer drawbar load is 80 kg/h.

WARNING■

Check that the ball head is seated correctly and is secured in the mount-

ing recess before starting any journey.■

Do not use the ball head, if it is not correctly inserted into the mounting

recess and secured.

■

Do not use the towing equipment if it is damaged or incomplete.

■

Do not modify or adapt the towing equipment in any way.

■

Never release the ball head while the trailer is still coupled.

■

Keep the mounting recess of the towing equipment clean at all times.

Such dirt prevents the ball head from being attached securely.

CAUTION

■ Take care with the ball bar - there is a risk of paint damage to the bumper.■When the tow bar is removed always place the cover onto the mounting re-

cess - there is a danger of soiling the mounting recess.

Note

■ Operation and maintenance of hitch » page 180.■Tow the vehicle by means of the detachable ball rod » page 214.166Driving

Page 178 of 252

any other agreements. You should keep the confirmed warranty certificate and

the receipt for these accessories for this period, so that the commencement of

the warranty term may be verified.

In addition, ŠKODA Service Partners also stock a range of suitable car care

products as well as those parts which are subject to natural wear and tear,

such as tyres, batteries, bulbs and wiper blades.

Note

The accessories authorized by ŠKODA AUTO a.s. will be offered by the ŠKODA

Partners in all countries where ŠKODA AUTO a.s. has a sales and service net- work. This will usually be in the form of a printed catalogue of Original ŠKODA

Accessories, in the form of separate printed brochures or in the form of offers

for ŠKODA Genuine Accessories on the ŠKODA Partner's website.

Spoiler

Read and observe

on page 173 first.

If your new vehicle is fitted with a spoiler on the front bumper in combination

with the spoiler on the luggage compartment lid, then the following instruc-

tions must be adhered to.

› For safety reasons, the vehicle must only be fitted with a spoiler on the front

bumper in combination with the associated spoiler on the luggage compart-

ment lid.

› This kind of spoiler cannot be left on the front bumper either on its own, in

combination with another spoiler not on the luggage compartment lid or in

combination with an unsuitable spoiler on the luggage compartment lid.

› We recommend that you consult the ŠKODA service partner for any repairs to

or replacement, addition or removal of spoilers.

WARNING■ If work on your vehicle's spoilers is not carried out properly, this can lead

to operational faults - risk of accident and serious injuries.■

If a front spoiler, full wheel trim, etc. is mounted retrospectively, it must

be ensured that the air supply to the front wheel brakes is not reduced.

The front brakes may overheat, which can have a negative impact on the

functioning of the braking system – there is a risk of an accident!

Airbags

Read and observe

on page 173 first.

The system components of the airbag system can be situated in the front

bumper, doors, front seats, roof lining or body.

WARNINGAny work on the airbag system including the installation and removal of

system components due to other repair work (e.g. removal of the steering

wheel) must only be carried out by a specialist garage.■

Modifications, repairs and technical alterations that have been carried out

unprofessionally can cause damage and operational faults, and can also se-

riously impair the effectiveness of the airbag system – risk of accident and

fatal injury!

■

The airbag system must then be replaced if the airbag has been deployed.

Airbag modules cannot be repaired.

WARNINGInformation on the use of the airbag system■It is prohibited to manipulate individual parts of the airbag system, as this

might result in the airbag being deployed.■

Never install any airbag parts into the vehicle that have been removed

from old cars or have been recycled.

■

Never install damaged airbag parts in the vehicle. The airbags may then

not be deployed properly or even at all in the event of an accident.

■

No modifications of any kind must be made to parts of the airbag system.

WARNING■ A change to the vehicle's wheel suspension, including the use of non-ap-

proved wheels and tyre combinations, can alter the functioning of the air-

bag system - risk of accident and fatal injury!■

Never make any changes to the front bumper or the bodywork.

175Car care

Page 185 of 252

■Sharp-edged objects on items of clothing such as zip fasteners, rivets, sharp-

edged belts, jewellery and pendants may leave permanent scratches or signs

of rubbing on the surface. Such damage cannot be subsequently recognised as

a justified complaint.■

The use of an additional mechanical steering wheel lock may damage the

leather surface of the steering wheel.

■

Use a care cream with light blocker and impregnation effect on a regular ba-

sis and each time after cleaning. The cream nourishes the leather, allows it to

breathe and keeps it supple and also provides moisture. It also creates surface

protection.

■

Some clothing materials, e.g. dark denim, do not have sufficient colour fast-

ness. This can cause damage or clearly visible discolouration to seat covers,

even when used correctly. This applies particularly to light-coloured seat cov-

ers. This does not relate to a fault in the seat cover, but rather to poor colour

fastness of the clothing textiles.

Note

When using the vehicle, minor visible changes may occur to the leather parts

of the covers (e.g. wrinkles or creases) as a result of the stress applied to the

covers.

Synthetic leather, fabrics and Alcantara ®

Read and observe

and on page 181 first.

Artificial leather

Clean artificial leather with a damp cloth.

If this method does not completely clean the artificial leather, use a mild soap

solution or cleaning products specially designed for this purpose.

Fabric

Clean upholstery cover materials and cloth trims on doors, boot cover, etc. us-

ing specific cleaning agents, e.g., dry foam.

Use a soft sponge, brush, or commercially available microfibre cloth.

Use a cloth and special detergent to clean the headlining.

Remove any lumps on the cover fabric and any fabric residue using a brush.

Remove stubborn hair using a “cleaning glove”.

Alcantara ®

Dust and fine dirt particles in pores, creases and seams may chafe and damage

the surface.

If you leave your vehicle parked in the open for lengthy periods, protect the Al-

cantara ®

seat upholstery from direct sunlight to prevent fading.

Minor changes in colour caused by use are normal.

CAUTION

■ Do not use leather cleaners on Alcantara ®

seat upholstery.■Do not use solvents, floor wax, shoe cream, stain remover or similar agents

on Alcantara ®

seat upholstery.■

Avoid leaving the vehicle in bright sunlight for long periods of time in order

to stop the fabric from bleaching. If the vehicle is parked outside for long peri-

ods of time, cover the fabric to protect it from direct sunlight.

■

Some clothing materials, e.g. dark denim, do not have sufficient colour fast-

ness. This can cause damage or clearly visible discolouration to seat covers,

even when used correctly. This applies particularly to light-coloured seat cov-

ers. This does not relate to a fault in the seat cover, but rather to poor colour

fastness of the clothing textiles.

Seat covers

Read and observe

and on page 181 first.

Electrically heated seats

Do not clean the covers by moistening, as this can damage the seat heating

system.

Use a specific cleaning agent such as dry foam or similar to clean the covers.

Seats without seat heating

Thoroughly vacuum the seat covers with a vacuum cleaner before cleaning.

Clean the seat covers with a damp cloth or cleaning products specially de-

signed for this purpose.

Indented points arising on the fabrics by everyday use, can be removed by

brushing against the direction of hair with a damp brush.

Always clean all parts of the covers, so that there are no visible edges. Then

allow the seat to dry completely.

CAUTION

■ Regularly remove dust from the seat covers using a vacuum cleaner.■Electrically heated seats must not be dried after cleaning by switching on the

heater. 182General Maintenance

Page 202 of 252

In vehicles with tyre pressure monitoring, tyre pressure values are to be stor-

ed » page 166 .

With greater additional load, adjust the tyre inflation pressure accordingly.

Driving style

Fast cornering, sharp acceleration and braking increase the wear of your tyres.

Wheel balance

The wheels of a new vehicle are balanced. When driving, however, there are a

range of factors that may result in an imbalance. This may become apparent by

“vibration” in the steering. If this is the case, have the wheels checked by a

specialist garage.

Have the wheels likewise rebalanced after replacing the tyres.

Setting the vehicle geometry

Incorrect wheel alignment at the front or rear leads to excess wear on the

tyres and impairs driving safety. With a distinctive tyre wear, we recommend

that you check the setting of the vehicle geometry in a specialist workshop.

Tyre damage

We recommend checking your tyres and wheel rims for damage (punctures,

cuts, splits and bulges, etc.) on a regular basis. Remove foreign bodies (e.g.

small stones) from the tyre tread immediately.

Drive over kerbs and other such obstacles slowly and at right angles wherever

possible in order to avoid damage to tyres and wheel trims.

Immediately replace damaged wheel rims or tyres.

Exchanging the wheels

For uniform wear on all tyres, we recommend that you change the wheels ev-

ery 10 000 km according to schedule » Fig. 172. You will then obtain approxi-

mately the same life for all the tyres.

After a wheel has been replaced, the tyre pressure has to be adjusted.

In vehicles with tyre pressure monitoring, tyre pressure values are to be stor-

ed » page 166 .

Tyre storage

Identify disassembled tyres so that the previous direction of rotation can be

maintained if the tyres are reassembled.

Always store wheels or tyres in a cool, dry place that is as dark as possible.

Tyres which are not fixed to a wheel trim should be stored upright.Wear indicators

The base of the tread of the tyres contains has a 1.6 mm high wear indica-

tor » Fig. 171 -

. In some countries, different tyre wear rates may apply.

Markings on the walls of the tyres through the letters “TWI”, triangular sym-

bols or other symbols identify the position of the wear indicators.

Tyre age

Tyres age and lose their original characteristics, even if they are not being

used. The service life of the tyres is 6 years. Therefore, we recommend not us-

ing tyres that are older than 6 years.

Wheel bolts

Wheels and wheel bolts are matched to each other in terms of design. We rec-

ommend that you use wheel rims and wheel bolts from ŠKODA Original Acces-

sories.

Note

In some countries, the vehicles have a sticker with tyre inflation pressure val-

ues without pictograms.

Unidirectional tyres

Read and observe

and on page 197 first.

The direction of rotation of the tyres is marked by arrows on the wall of the

tyre .

The indicated direction of rotation must be adhered to in order to ensure the

optimal characteristics of these tyres.

These characteristics mainly relate to the following: › Increased driving stability.

› Reduced risk of aquaplaning.

› Reduced tyre noise and tyre wear.

199Wheels

Page 209 of 252

WARNING■If you are in flowing traffic, switch on the hazard warning light system

and set up the warning triangle at the prescribed distance! The national le-

gal requirements must be observed.■

Park the vehicle as far away as possible from the flow of traffic. Park on

as flat and firm a surface as possible.

■

The following instructions must be followed if the vehicle is subsequently

fitted with tyres or rims that differ from the factory fitted ones » page 201,

Explanation of the tyre labelling .

WARNINGInformation on the wheel bolts■The wheel bolts must be clean and must turn easily. Never treat them

with grease or oil.■

The prescribed tightening torque of the wheel bolts for steel and light al-

loy wheels is 120 Nm.

■

If the wheel bolts are tightened to a too low tightening torque, the rim

can come loose when the car is moving. A tightening torque which is too

high can damage the bolts and threads and this can result in permanent

deformation of the contact surfaces on the rim.

■

In case of incorrect treatment of the wheel bolts, the wheel can loosen

when the car is moving.

Note

The national legal requirements must be observed when changing a wheel.

Preliminary work

Read and observe

on page 206 first.

Before changing the wheel, the following work must be carried out.

›

Have all the occupants get out. The passengers should not stand on the

road (instead they should remain behind a crash barrier, for instance) while

the wheel is being changed.

›

Switch off the engine.

›

Select the 1st gear or place the selector lever of the automatic transmission

in the P-position .

›

Apply the handbrake firmly.

›

Uncouple a trailer.

›Remove the

vehicle tool kit » page 205 and the spare wheel » page 200 from

the boot.

Changing a wheel

Read and observe

on page 206 first.

When changing a wheel, the following instructions must be followed.

›

Remove the full wheel trim or the caps of the wheel bolts.

›

First of all slacken the anti-theft wheel bolt and then the other wheel bolts.

›

Jack up the vehicle until the wheel that needs changing is clear of the

ground.

›

Unscrew the wheel bolts and place them on a clean surface (cloth, paper, etc.).

›

Remove the wheel carefully.

›

Attach the spare wheel and slightly screw on the wheel bolts.

›

Lower the vehicle.

›

Tighten the opposite wheel bolts alternately (cross-wise) with the wheelwrench. Tighten the anti-theft wheel bolt last.

›

Replace the wheel trim or the caps.

When fitting unidirectional tyres, ensure that the indication is cor-

rect » page 197 .

WARNINGIf it is established when changing a wheel that the wheel bolts are corro-

ded and difficult to move, then these must be replaced.

Follow-up work

Read and observe

on page 206 first.

After changing the wheel, the following work must be carried out.

›

Stow and attach the replaced wheel in the spare wheel well using a special

bolt » page 200 .

›

Stow the tool kit in the space provided and secure using the strap.

›

Check the tyre pressure on the installed spare wheel as soon as possible.

›

Have the tightening torque of the wheel bolts checked with a torque

wrench as soon as possible.

206Do-it-yourself

Page 211 of 252

The mounting points are located on the metal bar of the lower sill on the un-

derside of your vehicle. The positions of these are embossed by means of

markings on the side surface of the lower sill » Fig. 181.›

Support the base plate of the jack with its full area resting on level ground

and ensure that the jack is located in a vertical position at the jacking

point » Fig. 181 -

.

›

Position the lifting jack below the jacking point with the crank and move it up

until its claw encloses the web » Fig. 181 -

.

›

Continue turning up the jack until the wheel is just about lifted off the

ground.

WARNINGNotes for vehicle lifting■Choose a flat and firm surface for jacking the vehicle.■

If the wheel has to be changed on a slope, first of all block the opposite

wheel with a stone or similar object to prevent the vehicle from unexpect-

edly rolling away.

■

Secure the base plate of the lifting jack with suitable means to prevent

possible moving. A soft and slippery ground under the base plate may move

the lifting jack, causing the vehicle to fall down. It is therefore always nec-

essary to place the lifting jack on a solid surface or use a wide and stable

base. Use a non-slip base (e.g. a rubber foot mat) if the surface is smooth,

such as cobbled stones, tiled floor, etc.

■

Only attach the lifting jack to the attachment points provided for this pur-

pose.

■

Always raise the vehicle with the doors closed.

■

Never position any body parts, such as arms or legs under the vehicle,

while the vehicle is raised with a lifting jack.

■

When the vehicle is raised, never start the engine.

CAUTION

It is important to ensure that the jack is correctly attached to the web of the

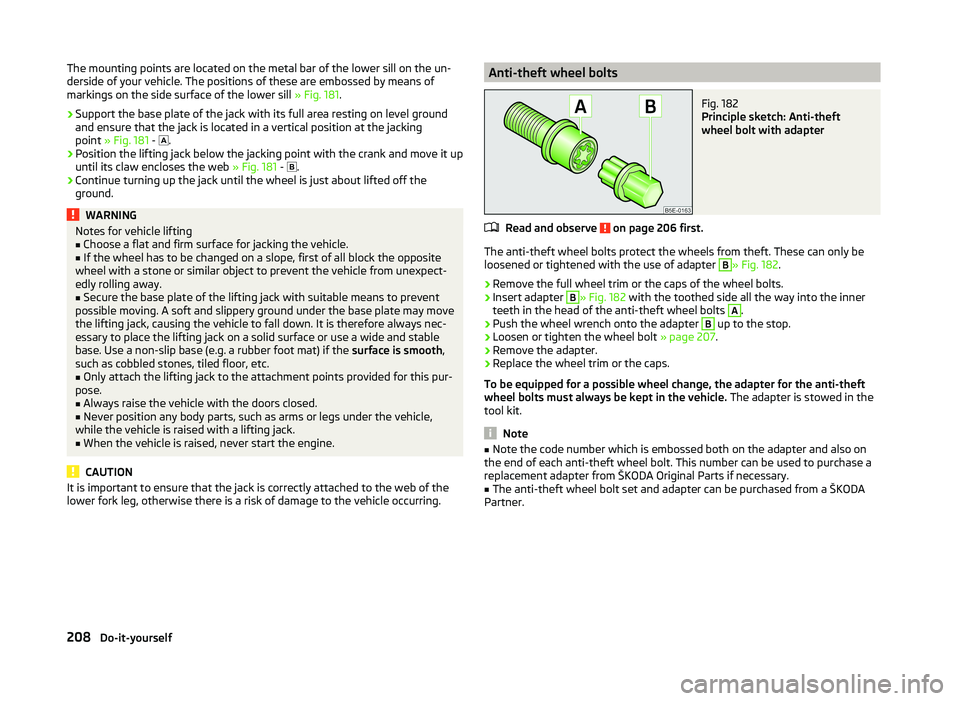

lower fork leg, otherwise there is a risk of damage to the vehicle occurring.Anti-theft wheel boltsFig. 182

Principle sketch: Anti-theft

wheel bolt with adapter

Read and observe on page 206 first.

The anti-theft wheel bolts protect the wheels from theft. These can only be loosened or tightened with the use of adapter

B

» Fig. 182 .

›

Remove the full wheel trim or the caps of the wheel bolts.

›

Insert adapter

B

» Fig. 182 with the toothed side all the way into the inner

teeth in the head of the anti-theft wheel bolts

A

.

›

Push the wheel wrench onto the adapter

B

up to the stop.

›

Loosen or tighten the wheel bolt » page 207.

›

Remove the adapter.

›

Replace the wheel trim or the caps.

To be equipped for a possible wheel change, the adapter for the anti-theft

wheel bolts must always be kept in the vehicle. The adapter is stowed in the

tool kit.

Note

■ Note the code number which is embossed both on the adapter and also on

the end of each anti-theft wheel bolt. This number can be used to purchase a

replacement adapter from ŠKODA Original Parts if necessary.■

The anti-theft wheel bolt set and adapter can be purchased from a ŠKODA

Partner.

208Do-it-yourself

Page 213 of 252

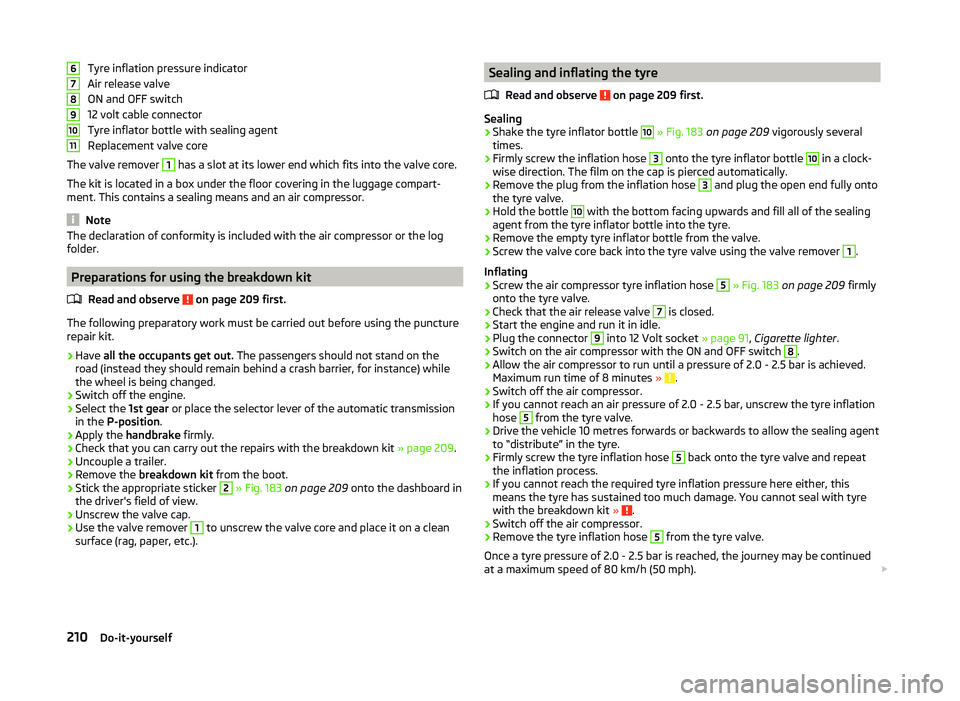

Tyre inflation pressure indicator

Air release valve

ON and OFF switch

12 volt cable connector

Tyre inflator bottle with sealing agent

Replacement valve core

The valve remover 1

has a slot at its lower end which fits into the valve core.

The kit is located in a box under the floor covering in the luggage compart-

ment. This contains a sealing means and an air compressor.

Note

The declaration of conformity is included with the air compressor or the log

folder.

Preparations for using the breakdown kit

Read and observe

on page 209 first.

The following preparatory work must be carried out before using the puncturerepair kit.

›

Have all the occupants get out. The passengers should not stand on the

road (instead they should remain behind a crash barrier, for instance) while

the wheel is being changed.

›

Switch off the engine.

›

Select the 1st gear or place the selector lever of the automatic transmission

in the P-position .

›

Apply the handbrake firmly.

›

Check that you can carry out the repairs with the breakdown kit

» page 209.

›

Uncouple a trailer.

›

Remove the breakdown kit from the boot.

›

Stick the appropriate sticker

2

» Fig. 183 on page 209 onto the dashboard in

the driver's field of view.

›

Unscrew the valve cap.

›

Use the valve remover

1

to unscrew the valve core and place it on a clean

surface (rag, paper, etc.).

67891011Sealing and inflating the tyre

Read and observe

on page 209 first.

Sealing

›

Shake the tyre inflator bottle

10

» Fig. 183 on page 209 vigorously several

times.

›

Firmly screw the inflation hose

3

onto the tyre inflator bottle

10

in a clock-

wise direction. The film on the cap is pierced automatically.

›

Remove the plug from the inflation hose

3

and plug the open end fully onto

the tyre valve.

›

Hold the bottle

10

with the bottom facing upwards and fill all of the sealing

agent from the tyre inflator bottle into the tyre.

›

Remove the empty tyre inflator bottle from the valve.

›

Screw the valve core back into the tyre valve using the valve remover

1

.

Inflating

›

Screw the air compressor tyre inflation hose

5

» Fig. 183 on page 209 firmly

onto the tyre valve.

›

Check that the air release valve

7

is closed.

›

Start the engine and run it in idle.

›

Plug the connector

9

into 12 Volt socket » page 91, Cigarette lighter .

›

Switch on the air compressor with the ON and OFF switch

8

.

›

Allow the air compressor to run until a pressure of 2.0 - 2.5 bar is achieved.

Maximum run time of 8 minutes » .

›

Switch off the air compressor.

›

If you cannot reach an air pressure of 2.0 - 2.5 bar, unscrew the tyre inflation

hose

5

from the tyre valve.

›

Drive the vehicle 10 metres forwards or backwards to allow the sealing agent

to “distribute” in the tyre.

›

Firmly screw the tyre inflation hose

5

back onto the tyre valve and repeat

the inflation process.

›

If you cannot reach the required tyre inflation pressure here either, this

means the tyre has sustained too much damage. You cannot seal with tyre with the breakdown kit »

.

›

Switch off the air compressor.

›

Remove the tyre inflation hose

5

from the tyre valve.

Once a tyre pressure of 2.0 - 2.5 bar is reached, the journey may be continued

at a maximum speed of 80 km/h (50 mph).

210Do-it-yourself

Page 227 of 252

Replacing the bulb for the licence plate light226Rear light (Superb Combi)226

Replacing bulbs in rear light (Superb Combi)

227

Some manual skills are required to change a bulb. For this reason, we recom-

mend having bulbs replaced by a specialist garage or seeking other expert help

in the event of any uncertainties.

› Switch off the ignition and all of the lights before replacing a bulb.

› Faulty bulbs must only be replaced with the same type of bulbs. The designa-

tion is located on the light socket or the glass bulb.

› A stowage compartment for replacement bulbs is located in a plastic box in

the spare wheel or underneath the floor covering in the boot.

WARNING■ Always read and observe the warnings before completing any work in the

engine compartment » page 186.■

Accidents can be caused if the road in front of the vehicle is not suffi-

ciently illuminated and the vehicle cannot or can only be seen with difficul-

ty by other road users.

■

Bulbs H7 H8 and H15 are pressurised and may burst when changing the

bulb - risk of injury! We therefore recommended wearing gloves and safety

glasses when changing a bulb.

■

Gas discharge bulbs (xenon bulbs) operate with a high voltage, professio-

nal knowledge is required – risk of death!

■

Switch off the respective vehicle light when changing the bulb.

CAUTION

Do not take hold of the glass bulb with naked fingers (even the smallest

amount of dirt reduces the working life of the light bulb). Use a clean cloth,

napkin, or similar.

Note

■ This Owner's Manual only describes the replacement of bulbs where it is pos-

sible to replace the bulbs on your own without any complications arising. Other

bulbs must be replaced by a specialist garage.■

We recommend that a box of replacement bulbs always be carried in the ve-

hicle. Replacement bulbs can be purchased from ŠKODAOriginal Accessories.

■

We recommend having the headlight settings checked by a specialist garage

after replacing a bulb in the main beam, low beam or fog lights.

■

In case of failure of a xenon gas discharge lamp or an LED diode, visit a spe-

cialist garage.

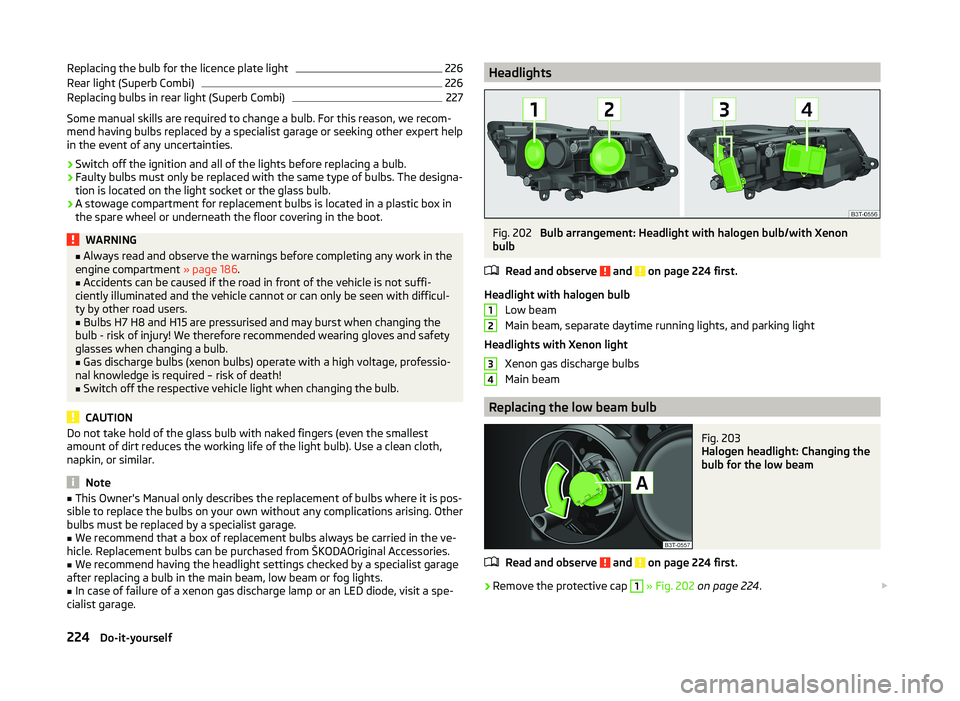

HeadlightsFig. 202

Bulb arrangement: Headlight with halogen bulb/with Xenon

bulb

Read and observe

and on page 224 first.

Headlight with halogen bulb Low beam

Main beam, separate daytime running lights, and parking light

Headlights with Xenon light Xenon gas discharge bulbs

Main beam

Replacing the low beam bulb

Fig. 203

Halogen headlight: Changing the

bulb for the low beam

Read and observe and on page 224 first.

›

Remove the protective cap

1

» Fig. 202 on page 224 .

1234224Do-it-yourself

Page 240 of 252

BootAutomatic retraction (Superb Combi)101

Extending variable loading floor105

Folding hook99

Non-closable side pocket (Superb Combi)102

Removable Light (Superb Combi)103

Roll up boot cover (Superb Combi)101

Side compartment with battery102

Boot cover (Superb Combi)101

Boot lid57

automatic locking58

Warning light36

(Superb Combi)58

Brake booster144

Brake fluid192

Checking193

Information messages35

specification193

Brake linings warning light

41

Brakes Brake assist systems

154

Brake booster144

Brake fluid193

Handbrake144

Information messages35

Running in149

Warning light35

Braking Information on braking

143

Break recommendation See Fatigue detection

165

Button in the driver's door Electrical power windows

61

C

Car care

173

Jack180

Car computer See multifunction display

44

Car park ticket holder89

Carrier Roof rack

108

Cavity protection180

CD changer136

Central locking50

Central locking button55

Changing brake fluid

193

bulbs223

Wheels205

Changing a wheel Follow-up work

206

Preliminary work206

Remove and attaching a wheel206

Changing brake fluid

193

Charging a vehicle battery196

Check Fit ball head properly

168

Checking Battery electrolyte level

195

Brake fluid193

Coolant192

Engine oil190

Oil level190

Windscreen washer fluid188

Checks Statutory checks

173

Children and safety22

Child safety Side airbag

24

Child safety lock55

Child seat Classification

25

ISOFIX25

on the front passenger seat23

TOP TETHER27

Use of child seats25

Use of ISOFIX child seats26

Chrome parts refer to Taking care of your vehicle178

Cigarette lighter91

Cleaning Alcantara

182

Covers of electrically heated seats182

Fabrics182

Headlight lenses179

Natural leather181

Plastic parts178

Synthetic leather182

Wheels180

Cleaning the vehicle Towing device

180

Cleaning vehicle176

Climatronic115

Air recirculation117

automatic mode116

Control elements115

Controlling blower118

Cooling system116

Defrosting windscreen118

Setting the temperature116

Clothes hook94

Cockpit 12-Volt power outlet

92

Ashtray91

Cigarette lighter91

General view29

Lighting73

Practical features88

Storage compartments88

Comfort control window

63

COMING HOME72

Compartments88

Components of the puncture repair kits209

Computer See multifunction display

44

237Index

Page 241 of 252

Convenience operationsliding / tilting roof65

sliding / tilting roof (Superb Estate)67

Convenience turn signal70

Coolant191

Checking192

Messages36

Replenishing192

Temperature gauge31

Warning light36

CORNER See Fog lights with CORNER function

71

Correct seated position9

Driver9

Front passenger10

Instructions11

Rear seats11

Counter for distance driven32

Cruise control system Activating/deactivating

161

Changing the stored speed162

Storing and maintaining speed162

Switching off temporarily162

Warning light41

Cruise Control System161

Cup holders90

D

DAY LIGHT see Daylight running lights

69

Daylight running lights69

De-icing the windscreen and rear window75

Deactivating an airbag21

Decorative films179

Delayed locking of the boot lid see boot lid

58

Diesel refer to Fuel

185

diesel - particulate filter39

Diesel fuel Operation in winter

185

Diesel particulate filter warning light

39

Digital Clock Time

32

Dipstick190

Display31

Compass points48

Coolant temperature31

Fuel supply32

Gear changes43

Service intervals48

Display a low temperature43

Display of the second speed33

Distance driven32

Door Child safety lock

55

Closing52

Emergency locking217

Emergency locking the driver's door216

Opening52

Warning light for open door36

Door open Warning light

36

Driver Steering Recommendation (DSR)155

Driving Abroad

153

Driving through water on streets152

Emissions229

Fuel consumption229

Driving economically Economical gear changing

149

Driving through water152

DSR155

DVD-preinstallation136

E

Economical and environmentally friendly driv- ing

149

Economical driving Ballast

151

Driving at full throttle150

Idling150

Looking ahead149

Regular maintenance151

Saving energy151

Short distances150

Tyre pressure150

EDL Operation

155

Electrical power windows63

Button in the driver's door61, 62

Button in the rear doors63

Operational faults64

Electric boot lid Force limit

59

Manual operation59

Electric luggage compartment lid Acoustic signals

61

Adjusting the top lid position61

Deleting the top lid position61

Malfunctions61

Operating59

Electric sliding/tilting roof64

Electronic Differential Lock (EDL)155

Electronic immobilizer139

Electronic Stability Control (ESC)154

Emergency Activation of the sliding/tilting roof

218

Changing a wheel205

Hazard warning light system72

jump-starting211

Jump-starting211

Locking the door without a locking cylinder217

Locking the driver's door216

238Index