inflation pressure SKODA SUPERB 2011 Owner´s Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 2011, Model line: SUPERB, Model: SKODA SUPERB 2011Pages: 252, PDF Size: 16.33 MB

Page 212 of 252

Puncture set

Introduction

This chapter contains information on the following subjects:

Components of the puncture repair kits

209

Preparations for using the breakdown kit

210

Sealing and inflating the tyre

210

Notes for driving with tyre repaired

211

Use the breakdown kit to reliably repair tyre damage caused by foreign bodies

or a puncture with diameters up to approx. 4 mm.

A repair made using the breakdown kit is never intended to replace a perma-

nent repair on the tyre. Its purpose is to get you to the nearest specialist ga-

rage.

The wheel need not be removed during the repair.

Do not remove foreign bodies , e.g. screws or nails, from the tyre.

The breakdown kit must not be used under the following circumstances. › There is damage to the rim.

› The outside temperature is less than -20 °C.

› The tears or punctures are greater than 4 mm in size.

› There is damage to the tyre wall.

› Driving with very low tyre pressure or with a completely flat tyre.

› If the use-by-date (see inflation bottle) has passed.

WARNING■

If you are in flowing traffic, switch on the hazard warning light system

and set up the warning triangle at the prescribed distance! The national le-

gal requirements must be observed.■

Park the vehicle as far away as possible from the flow of traffic. Park on

as flat and firm a surface as possible.

WARNING■ A tyre filled with sealant has the same driving characteristics as a stand-

ard tyre.■

Do not drive faster than 80 km/h (50 mph).

■

Avoid accelerating at full throttle, sharp braking and fast cornering.

WARNING (Continued)■ The sealant is hazardous to heath. Remove immediately if it comes into

contact with the skin.■

Observe the manufacturer's usage instructions for the breakdown kit.

For the sake of the environment

Used sealant or sealant whose expiry date has passed must be disposed of in

accordance with environmental protection regulations.

Note

■ A new bottle of sealant can be purchased from ŠKODA Original Parts.■Immediately replace the tyre that was repaired using the breakdown kit, or

consult a specialist garage about repair options.■

The national legal requirements must be observed when repairing a tyre.

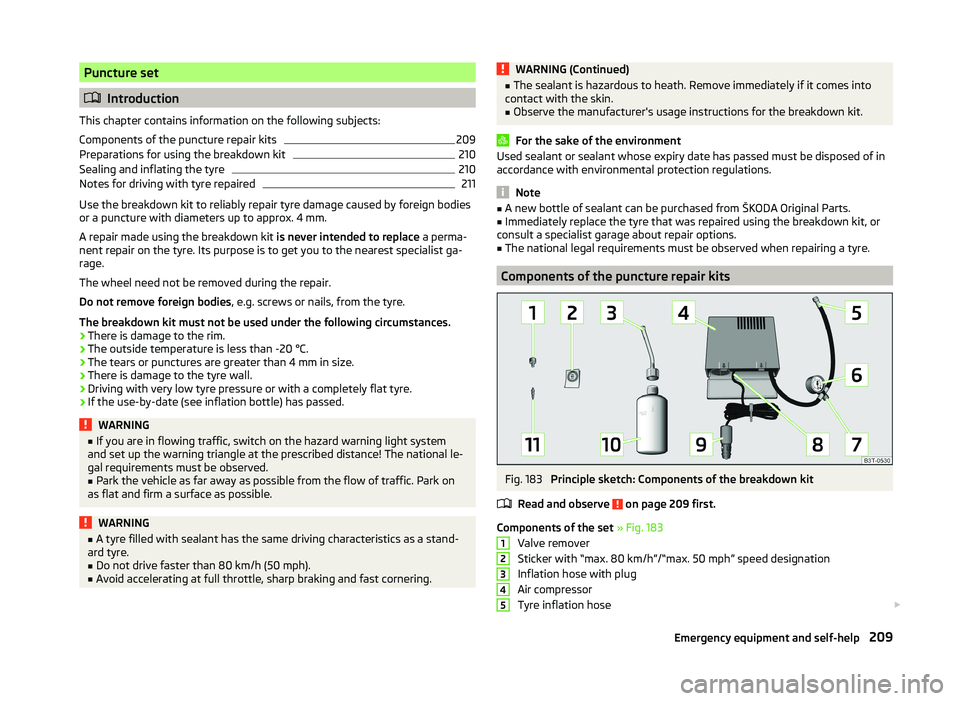

Components of the puncture repair kits

Fig. 183

Principle sketch: Components of the breakdown kit

Read and observe

on page 209 first.

Components of the set » Fig. 183

Valve remover

Sticker with “max. 80 km/h”/“max. 50 mph” speed designation

Inflation hose with plug

Air compressor

Tyre inflation hose

12345209Emergency equipment and self-help

Page 213 of 252

Tyre inflation pressure indicator

Air release valve

ON and OFF switch

12 volt cable connector

Tyre inflator bottle with sealing agent

Replacement valve core

The valve remover 1

has a slot at its lower end which fits into the valve core.

The kit is located in a box under the floor covering in the luggage compart-

ment. This contains a sealing means and an air compressor.

Note

The declaration of conformity is included with the air compressor or the log

folder.

Preparations for using the breakdown kit

Read and observe

on page 209 first.

The following preparatory work must be carried out before using the puncturerepair kit.

›

Have all the occupants get out. The passengers should not stand on the

road (instead they should remain behind a crash barrier, for instance) while

the wheel is being changed.

›

Switch off the engine.

›

Select the 1st gear or place the selector lever of the automatic transmission

in the P-position .

›

Apply the handbrake firmly.

›

Check that you can carry out the repairs with the breakdown kit

» page 209.

›

Uncouple a trailer.

›

Remove the breakdown kit from the boot.

›

Stick the appropriate sticker

2

» Fig. 183 on page 209 onto the dashboard in

the driver's field of view.

›

Unscrew the valve cap.

›

Use the valve remover

1

to unscrew the valve core and place it on a clean

surface (rag, paper, etc.).

67891011Sealing and inflating the tyre

Read and observe

on page 209 first.

Sealing

›

Shake the tyre inflator bottle

10

» Fig. 183 on page 209 vigorously several

times.

›

Firmly screw the inflation hose

3

onto the tyre inflator bottle

10

in a clock-

wise direction. The film on the cap is pierced automatically.

›

Remove the plug from the inflation hose

3

and plug the open end fully onto

the tyre valve.

›

Hold the bottle

10

with the bottom facing upwards and fill all of the sealing

agent from the tyre inflator bottle into the tyre.

›

Remove the empty tyre inflator bottle from the valve.

›

Screw the valve core back into the tyre valve using the valve remover

1

.

Inflating

›

Screw the air compressor tyre inflation hose

5

» Fig. 183 on page 209 firmly

onto the tyre valve.

›

Check that the air release valve

7

is closed.

›

Start the engine and run it in idle.

›

Plug the connector

9

into 12 Volt socket » page 91, Cigarette lighter .

›

Switch on the air compressor with the ON and OFF switch

8

.

›

Allow the air compressor to run until a pressure of 2.0 - 2.5 bar is achieved.

Maximum run time of 8 minutes » .

›

Switch off the air compressor.

›

If you cannot reach an air pressure of 2.0 - 2.5 bar, unscrew the tyre inflation

hose

5

from the tyre valve.

›

Drive the vehicle 10 metres forwards or backwards to allow the sealing agent

to “distribute” in the tyre.

›

Firmly screw the tyre inflation hose

5

back onto the tyre valve and repeat

the inflation process.

›

If you cannot reach the required tyre inflation pressure here either, this

means the tyre has sustained too much damage. You cannot seal with tyre with the breakdown kit »

.

›

Switch off the air compressor.

›

Remove the tyre inflation hose

5

from the tyre valve.

Once a tyre pressure of 2.0 - 2.5 bar is reached, the journey may be continued

at a maximum speed of 80 km/h (50 mph).

210Do-it-yourself

Page 214 of 252

WARNING■If you cannot inflate the tyre to at least 2.0 bar, this means the damage

sustained was too serious. The sealing agent cannot be used to seal the

tyre.

Do not continue to drive! Seek help from a specialist garage.■

The tyre inflation hose and air compressor may get hot as the tyre is be-

ing inflated – there is a risk of burning.

CAUTION

Switch off the air compressor after running 8 minutes at the latest – there is a

risk of overheating. Allow the air compressor to cool a few minutes before

switching it on again.

Notes for driving with tyre repaired

Read and observe

on page 209 first.

The inflation pressure of the repaired tyre must be checked after driving for 10minutes.

If the tyre pressure is 1.3 bar or less

›

Do not continue to drive! You cannot properly seal with tyre with the

breakdown kit.

If the tyre pressure is 1.3 bar or more

›

Set the tyre pressure back to the correct value.

›

Continue driving carefully to the nearest specialist garage at a maximum speed of 80 km/h (50 mph).

Jump-starting

Introduction

This chapter contains information on the following subjects:

Jump-starting using the battery from another vehicle

211

Jump-starting in vehicles with the START STOP system

212

Jump-starting vehicles with the vehicle battery in the boot

212

The battery of another vehicle can be used to jump-start your vehicle if the en-

gine will not start because the battery is flat.

WARNING■ Pay attention to the warning instructions relating to work in the engine

compartment » page 186.■

A discharged vehicle battery may already freeze at temperatures just be-

low 0 °C. If the battery is frozen, do not jump-start with the battery of an-

other vehicle – there is a risk of explosion.

■

Keep any sources of ignition (naked flame, smouldering cigarettes, etc.)

away from the battery – risk of explosion!

■

Never jump-start vehicle batteries with insufficient acid levels – risk of

explosion and chemical burns.

■

The vent screws of the battery cells must be tightened firmly.

Note

We recommend you buy jump-start cables from a car battery specialist.

Jump-starting using the battery from another vehicle

Fig. 184

Jump-starting: A – flat battery, B

– battery providing current

Read and observe on page 211 first.

The starting process using the battery of another vehicle requires the use of

jumper cables.

The jump-start cables must be attached in the following sequence.

›

Attach clamp

1

to the positive terminal of the discharged battery

A

» Fig. 184 .

›

Attach clamp

2

to the positive terminal of the battery supplying power

B

.

›

Attach clamp

3

to the negative terminal of the battery supplying power

B

.

›

Attach clamp

4

to a solid metal component firmly connected to the engine

block or to the engine block itself.

Starting engine

›

Start the engine on the vehicle providing the power and allow it to idle.

211Emergency equipment and self-help

Page 247 of 252

Switch off ignitionRefer to KESSY141

Switch on ignition Refer to KESSY

141

Synchronous adjustment of the rear-view mir- ror

80

Synthetic leather182

T

Tailgate TwinDoor

58

Taking care of the vehicle Natural leather

181

Seat belts183

Taking care of your vehicle Automatic car wash system

177

Cavity protection180

Chrome parts178

Cleaning the wheels180

Decorative films179

Door lock cylinders179

Headlight lenses179

High-pressure cleaner177

Plastic parts178

Polishing the paintwork178

Rubber seals178

Taking care of the interior181

Taking care of your vehicle exterior177

Washing by hand176

Wash system177

Wax treatment178

Taking care of your vehicles Fabric covers

182

Technical data228

Telephone124, 126

Temporary spare wheel200

Tilting roof see Electric sliding/tilting roof

64

Tiptronic146

Tools205

TOP TETHER27

Towing213

Towing a trailer171

Towing device Description

167

Operation and maintenance180

Towing eye Front

214

Rear214

Towing protection56

Traction Control System (ASR)155

Trailer170

13-pin socket170

connection and disconnection170

Loading171

Safety eye170

Towing a trailer171

Trailer operation166

Trailer stabilisation172

Transport Luggage compartment

97

Roof rack108

Transporting children safely22

Triangle204

TSA172

Turn signal69

Turn signal system Warning light

41

Twindoor see boot lid

57

Two-way radio systems121

Tyre Explanation of the labelling

201

see wheels201

Tyre inflation pressure Warning light

40

Tyre load bearing capacity Refer to Wheels

201

Tyre pressure monitoring165

Save tyre pressure values166

Tyre repair Preparations

210

Pressure test211

Sealing and inflating the tyre210

Tyres197

Inflation pressure198

Sizes198

Tyre wear indicator198

Tyre size201

see wheels201

U

Umbrella Tray

95

Underbody protection180

Unleaded petrol153

Unlock Vehicle key

51

Unlocking Individual settings

54

KESSY53

Remote control52

Unlocking and locking50

Using the information system42

Using the selector lever145

V

Variable loading floor

104

Dividing the luggage compartment104

Remove104

slides off on aluminium rails105

Vehicle battery Automatic load deactivation

197

Charging196

Checking the battery electrolyte level195

Cover195

Disconnecting and reconnecting196

244Index