trailer SKODA SUPERB 2012 2.G / (B6/3T) User Guide

[x] Cancel search | Manufacturer: SKODA, Model Year: 2012, Model line: SUPERB, Model: SKODA SUPERB 2012 2.G / (B6/3T)Pages: 235, PDF Size: 5.86 MB

Page 166 of 235

Towing a trailer

Towing a trailer

Technical requirements

If your vehicle has already been factory-fitted with a towing device or is fitted

with a towing device from ŠKODA Original Accessories, then it meets all of the

technical requirements and national legal provisions for towing a trailer.

On vehicles with a towing device, the ball rod is detachable and is stowed togeth-

er with separate operating instructions in the spare wheel well or in the compart-

ment for the spare wheel within the boot » page 196, Vehicle tool kit.

Your vehicle is fitted with a 13-pin power socket for the electrical connection be-

tween the vehicle and trailer. If the trailer that is to be towed has a 7-pin connec-

tor, you can use a suitable adapter from

ŠKODA Original Accessories.

If a towing device is retrofitted, it must be completed in accordance with the

manufacturer's specifications. Note

If you have any questions, please contact a ŠKODA Service Partner. ÐLoading a trailer

Loading a trailer

The vehicle/trailer combination must be balanced, whereby the maximum permis-

sible drawbar load must be utilised. If the drawbar load is too low, it jeopardises

the performance of the vehicle/trailer combination.

Distribution of the load

Distribute the load in the trailer in such a way that heavy items are located as

close to the axle as possible. Secure the items from slipping.

The distribution of the weight is very poor if your vehicle is unladen and the trail-

er is laden. Maintain a particularly low speed if you cannot avoid driving with this

combination. Tyre pressure

Correct the tyre inflation pressure on your vehicle for a

“full load” » page 188 ,

Service life of tyres.

Trailer load

The permissible trailer load must not be exceeded under any circumstan-

ces » page 216, Technical data .

The trailer loads specified apply only to altitudes up to 1 000 metres above mean

sea level. As the engine output drops at an increasing altitude due to the declin-

ing air pressure and therefore the climbing ability is also reduced, this means that

the maximum permissible towed weight must be reduced by 10 % for every fur-

ther increase of 1 000 m in height. The towed weight comprises the actual weight

of the (loaded) towing vehicle and the (loaded) trailer. Always drive particularly

carefully with the trailer.

The trailer and drawbar load information on the type plate of the towing device

are merely test data for the towing device The vehicle-specific values are detailed

in the vehicle documents. WARNING

■ If the maximum permissible axle and drawbar load and the maximum per-

missible total or towed weight of the vehicle and the trailer are exceeded this

can cause accidents and serious injuries.

■ Slipping loads can significantly affect the stability and safety of the vehicle/

trailer combination, causing accidents and serious injuries. Ð Towing a trailer

Exterior mirrors

You have to have additional exterior mirrors fitted if you are not able to see the

traffic behind the trailer with the standard rear-view mirrors. The national legal

requirements must be observed.

Headlights

The headlight settings must be checked before starting a journey with a coupled

trailer. If necessary, adjust the settings with the headlight beam adjust-

ment » page 53, Headlight beam adjustment .

Driving speed

For safety reasons, do not drive faster than the maximum permissible speed indi-

cated on the trailer. £

164 Driving Tips

Page 167 of 235

Immediately reduce your speed as soon as even the slightest swaying of the trail-

er is detected. Never attempt to stop the trailer from “swaying” by accelerating.

Brakes

Apply the brakes in good time! If the trailer is fitted with a trailer brake, apply the

brakes gently at first, then brake firmly. This will avoid brake jolts resulting from

the trailer wheels locking. On downhill sections shift down a gear in good time to

also use the engine as a brake.

Trailer stabilisation

The trailer stabilisation is an extension of the stabilisation control that works in

conjunction with the counter-steering assistance to reduce the amount the trail-

er "sways". After turning on the ignition, the ESC indicator light in the instru-

ment cluster lights up for about 2 seconds longer than the ABS indicator light.

Prerequisites for stabilising the trailer.

› The towing device is factory-fitted or a compatible towing device has been ret-

rofitted.

› The ESC is active. The indicator light

or in the instrument cluster is not illu-

minated.

› The trailer is electrically connected to the towing vehicle by means of the trailer

socket.

› The speed is higher than approx. 60 km/h.

› Trailers must have a fixed drawbar.

› The ESC works for both braked and unbraked trailers.

Trailer is connected to the anti-theft alarm system. › If the vehicle is factory-fitted with an anti-theft alarm system and a towing de-

vice.

› If the trailer is electrically connected to the towing vehicle by means of the trail-

er socket.

› If the electrical system of the vehicle and trailer is fully functional.

› If the vehicle is locked with the car key and the anti-theft alarm system is acti-

vated.

When the vehicle is locked, the alarm is activated as soon as the electrical con-

nection to the trailer is interrupted.

Always deactivate the anti-theft alarm system before a trailer is connected/dis-

connected. Otherwise, the anti-theft alarm system could accidentally be trig-

gered » page 33 , Anti-theft alarm system . Engine overheating

If the needle for the coolant temperature gauge moves into the right-hand area

or the red area of the scale, the speed must be reduced immediately. Stop and

switch off the engine if the indicator light

in the instrument cluster starts to

flash. Wait a few minutes and check the level of coolant in the coolant expansion

bottle » page 180 , Checking the coolant level .

The following guidelines must be observed » page 21, Coolant temperature/cool-

ant level .

The coolant temperature can be reduced by switching on the heating. WARNING

■ The increased safety offered by the trailer stabilisation must not tempt you

to take greater risks than otherwise. ■ Adapt your speed to the conditions of the road surface and to the traffic sit-

uation.

■ Improper or incorrectly connected electric cables can energise the trailer and

cause functional faults to the vehicle's entire electrical system as well as acci-

dents and severe injuries.

■ Any work on the electrical system must be carried out only by ŠKODA spe-

cialist garages.

■ Never directly connect the trailer's electrical system with the electrical con-

nections for the tail lights or other current sources. CAUTION

■ The trailer stabilisation need not be able to correctly detect all of driving situa-

tions.

■ Trailers that sway slightly are not always detected by the trailer stabilisation

and thus are not stabilised accordingly.

■ Release the pressure on the accelerator pedal if the system is being regulated.

■ Avoid abrupt and sudden driving/braking manoeuvres.

■ When the ball rod is removed, the mounting shaft must be sealed with an ap-

propriate cover. This prevents foreign matter from penetrating into the mounting

shaft. See the fitting instructions for the towing device. £

165

Towing a trailer

Page 168 of 235

Note

■ We recommend that you also have your vehicle inspected between service in-

tervals if you tow a trailer frequently. ■ The handbrake on the towing vehicle must be put on when coupling and decou-

pling the trailer.

■ For technical reasons, trailers with rear LED lights cannot be connected to the

anti-theft alarm system. Ð

166 Driving Tips

Page 181 of 235

One should therefore check the oil level at regular intervals, preferably every time

after the fuel tank is filled or after driving for long stretches.

We recommend maintaining the oil level within the range

A

, but not above

, if

the engine has been operating at high loads, for example, during a lengthy motor-

way trip during the summer months, towing a trailer or negotiating a high moun-

tain pass.

The indicator light in the instrument cluster will indicate whether the oil level is

too low » page 22, Engine oil level . In this case, check the oil level with the dip-

stick, as soon as possible. Add oil accordingly. CAUTION

■ The oil level must on no account extend beyond the range A

» Fig. 158

. Risk of

damaging the exhaust system!

■ Do not continue your journey if for some reason it is not possible to top up

the engine oil under the prevailing conditions! Switch off the engine and obtain

professional assistance from a

ŠKODA specialist garage, otherwise it could cause

severe engine damage. Note

Engine oil specifications » page 219, Specification and engine oil capacity .Ð Replenishing the engine oil

First read and observe the introductory information and safety warn-

ings on page 176.

›

Check the engine oil level

» page 178.

› Unscrew the cap of the engine oil filler opening.

› Replenish the oil in portions of 0.5 litres in accordance with the correct specifi-

cations » page 219, Specification and engine oil capacity .

› Check the oil level

» page 178.

› Carefully screw on the oil filler opening cap and push the dipstick in fully. ÐChanging engine oil

First read and observe the introductory information and safety warn-

ings on page 176.ä

ä The engine oil must be changed at the intervals stated in the Service schedule or

according to the service interval indicator » page 10, Service Interval Display. CAUTION

Additives must not be added to the engine oil - risk of causing considerable dam-

age to parts of the engine! Damage, which results from such product, are exclu-

ded from the warranty. Note

If your skin has come into contact with oil, it must be washed thoroughly. Ð Coolant

First read and observe the introductory information and safety warn-

ings on page 176.

The cooling system is filled with a coolant in the factory.

The coolant consists of water with a concentration of coolant additive of 40 %.

This mixture provides antifreeze protection down to -25 °C and also protects the

cooling and heating system from corrosion. It also prevents the formation of scale

and significantly increases the boiling point of the coolant.

The concentration of coolant must therefore not be reduced by adding water dur-

ing the summer months or in countries with a warm climate. The concentration of

coolant additive in the coolant must be at least 40 %.

If a higher concentration of antifreeze is required for climatic reasons, the amount

of coolant additive can only be increased up to 60 % (antifreeze protection down

to approx. -40 °C). The antifreeze protection tails off above that concentration.

Vehicles exported to countries with a cold climate are already factory-filled with a

coolant which offers antifreeze protection down to about -35 °C. In these coun-

tries the concentration of coolant additive should be at least 50 %.

When refilling, we only recommend you use the same antifreeze written on the

antifreeze expansion tank » Fig. 159 on page 180. £

ä

179

Inspecting and replenishing

Page 194 of 235

Tyre control display

Fig. 169

Button for setting the tyre infla-

tion pressure control value

First read and observe the introductory information and safety warn-

ings on page 187.

The tyre control display compares the speed and thus the rolling circumference of

the individual wheels with the help of the ABS sensors. If the rolling circumfer-

ence of a wheel is changed, the indicator light

in the instrument clus-

ter » page 25, Tyre control display and an audible signal sounds.

The rolling circumference of the tyre can change if: › the tyre inflation pressure is too low;

› the structure of the tyre is damaged;

› the vehicle is loaded on one side;

› the wheels of an axle are loaded heavily (e.g. when towing a trailer or when

driving uphill or downhill);

› snow chains are mounted;

› the temporary spare wheel is mounted;

› one wheel per axle was changed.

Basic setting of the system

After changing the tyre inflation pressure, after changing one or several wheels,

the position of a wheel on the vehicle (e.g. exchanging the wheels between the

axles) or when the indicator light lights up while driving, a basic setting of the

system must be carried out as follows: › Inflate all of the tyres to the specified inflation pressure

» page 188, Service life

of tyres.

› Switch on the ignition.

ä

›

Press and hold the button

» Fig. 169

for longer than 2 seconds. While

pressing the button, the indicator light illuminates. At the same time the sys-

tem memory is erased and the new calibration is started, which is confirmed

with an audible signal and then the indicator light goes out.

› If the indicator light

does not go out after the basic setting, this indicates a

system fault. Seek help from a ŠKODA specialist garage.

The indicator light is lit

If the tyre inflation pressure of at least one wheel is insufficiently inflated in com-

parison to the stored basic value, the indicator light » lights up.

The indicator light flashes

If the indicator light flashes, there is a system fault. Seek help from a

ŠKODA spe-

cialist garage to correct the fault. WARNING

■ When the indicator light illuminates, immediately reduce the speed and

avoid sudden steering and brake manoeuvres. Stop the vehicle as soon as

possible and inspect the tyres and their inflation pressure.

■ Under certain circumstances (e.g. sporty style of driving, wintry or unpaved

roads) the indicator light can be delayed or does not light up at all.

■ The tyre control display does not absolve the driver of the responsibility to

ensure the correct tyre inflation pressure. For this reason, the tyre inflation

pressure must be checked regularly. Note

■ The tyre control display does therefore not replace the regular tyre inflation

pressure control, as the system cannot detect an even loss of pressure. ■ The tyre control display cannot provide a warning in the event of very rapid tyre

inflation pressure loss, e.g. in the case of sudden tyre damage. In this case care-

fully bring the vehicle to a standstill without sudden steering movements or

sharp braking.

■ To ensure a proper functioning of the tyre control display, it is necessary to re-

peat the basic setting every 10 000 km or once a year. Ð

192 General Maintenance

Page 198 of 235

WARNING

The fire extinguisher must always be secured safely so that they do not come

loose when making an emergency braking or in a vehicle collision which could

cause injuries to occupants. Note

■ The fire extinguisher must comply with the relevant applicable national legal re-

quirements. ■ Pay attention to the expiration date of the fire extinguisher. If the fire extin-

guisher is used after the expiration date, its proper function is no longer assured.

■ The fire extinguisher is part of the scope of delivery in certain countries only. ÐVehicle tool kit

Fig. 172

Boot: Storage compartment for

vehicle too kit

The vehicle tool kit and the lifting jack with sticker are housed in a plastic box in

the spare wheel » Fig. 172 or in the storage space for the spare wheel. There is

also space here for the removable ball rod for the trailer towing device. The box is

attached with a strap on the spare wheel.

The vehicle tool kit contains the following parts (depending on equipment fitted):

› wire clamps for removing the full wheel trims;

› wheel wrench;

› towing eye;

› Adapter for anti-theft wheel bolts;

› Extraction pliers for wheel bolt caps;

› Replacement bulb set;

› Torx wrench. Before placing the lifting jack back into its storage area, screw in the arm of the

lifting jack fully. WARNING

■ The factory-supplied lifting jack is only intended for your model of vehicle.

Under no circumstances attempt to lift heavier vehicles or other loads - risk of

injury! ■ Ensure that the vehicle tool kit is safely secured in the boot. Note

Ensure that the box is always secured with the strap. Ð Changing a wheel

ä

Introduction

This chapter contains information on the following subjects:

Preliminary work 197

Changing a wheel 197

Subsequent steps 198

Loosening and tightening wheel bolts 198

Raising the vehicle 199

Securing wheels against theft 199

WARNING

■ If you are in flowing traffic, switch on the hazard warning light system and

set up the warning triangle at the prescribed distance! The national legal re-

quirements must be observed. In this way you are not only protecting yourself

but other road users as well.

■ If the wheel is damaged or in the event of a puncture, park the vehicle as far

away as possible from the flow of traffic. Park on as flat and firm a surface as

possible. £

196 Do-it-yourself

Page 199 of 235

WARNING (Continued)

■ If the wheel has to be changed on a slope, first of all block the opposite

wheel with a stone or similar object to prevent the vehicle from unexpectedly

rolling away.

■ If the vehicle is subsequently fitted with tyres which are different to those it

was fitted with at the works, follow these guidelines »

page 189, New wheels

and tyres.

■ Always raise the vehicle with the doors closed.

■ Never position any body parts, such as arms or legs under the vehicle, while

the vehicle is raised with a lifting jack. ■ Secure the base plate of the lifting jack with suitable means to prevent pos-

sible moving. A soft and slippery ground under the base plate may move the

lifting jack, causing the vehicle to fall down. It is therefore always necessary to

place the lifting jack on a solid surface or use a wide and stable base. Use a

non-slip base (e.g. a rubber foot mat) if the surface is smooth, such as cobbled

stones, tiled floor, etc.

■ Never start the engine with the vehicle sitting on the raised jack - danger of

suffering injury.

■ Only attach the lifting jack to the attachment points provided for this pur-

pose. CAUTION

■ The prescribed tightening torque of the wheel bolts for steel and light alloy

wheels is 120 Nm.

■ If the anti-theft wheel bolt is fastened too tightly, it can cause damage to the

anti-theft wheel bolt and adapter. Note

■ The anti-theft wheel bolt set and adapter can be purchased from a

ŠKODA Serv-

ice Partner. ■ The national legal requirements must be observed when changing a wheel. ÐPreliminary work

First read and observe the introductory information and safety warn-

ings on page 196.

The following steps must be carried out before actually changing the wheel:

ä ›

In the event of a puncture, park the vehicle as far away as possible from the

flow of traffic. The place you choose should be level.

› Let all of the occupants get out.

While changing a tyre, the occupants of the

vehicle should not stand on the road (instead they should remain behind a crash

barrier).

› Switch off the engine and move the gearshift lever into

Neutral or move the

selector lever

for the automatic gearbox into position P .

› Firmly apply the

handbrake.

› If a trailer is connected, remove it.

› Remove the vehicle tool kit

» page 196 and the spare wheel »

page 190 from

the boot. Ð Changing a wheel

First read and observe the introductory information and safety warn-

ings on page 196.

Always change a wheel on a level surface as far as possible.

›

Remove the full wheel trim

» page 191 or caps » page 191.

› In the case of light alloy wheel rims remove the wheel trim cap

» page 191.

› First of all slacken the anti-theft wheel bolt and then the other wheel

bolts » page 198.

› Jack up the vehicle until the wheel that needs changing is clear of the

ground » page 199.

› Unscrew the wheel bolts and place them on a clean surface (cloth, paper, etc.).

› Remove the wheel.

› Attach the spare wheel and slightly screw on the wheel bolts.

› Lower the vehicle.

› Alternately tighten the wheel bolts opposite each other using the wheel

wrench (crosswise) and then tighten the anti-theft wheel bolt » page 198.

› Replace the wheel trim or the caps. Note

■ All bolts must be clean and must turn easily.

■ Under no circumstances grease or oil the wheel bolts!

■ When fitting unidirectional tyres, ensure that the direction of rotation is cor-

rect »

page 190 . Ð

ä

197

Do-it-yourself

Page 203 of 235

Components of the breakdown kit

Fig. 177

Components of the breakdown kit

First read and observe the introductory information and safety warn-

ings on page 200.

The breakdown kit contains the following parts:

Valve remover

Sticker with speed designation

“max. 80 km/h”/“max. 50 mph”

Inflation hose with plug

Air compressor

Tyre inflation hose

Tyre inflation pressure indicator

Air release valve

ON and OFF switch

12 volt cable connector

Tyre inflator bottle with sealing agent

Replacement valve core

The valve remover 1

has a slot at its lower end which fits into the valve core.

This is the only way in which you can remove and re-install the valve core from

the tyre valve. The same also applies to the replacement valve core 11

.

Ð

ä 1

2

3

4

5

6

7

8

9

10

11 Preparing to use the breakdown kit

First read and observe the introductory information and safety warn-

ings on page 200.

The following preparatory work must be carried out before using the breakdown

kit.

›

In the event of a puncture, park the vehicle as far away as possible from the

flow of traffic. Park on as flat and firm a surface as possible.

› Let all of the occupants get out.

While changing a tyre, the occupants of the

vehicle should not stand on the road (instead they should remain behind a crash

barrier).

› Switch off the engine and move the gearshift lever into

Neutral or move the

selector lever

for the automatic gearbox into position P .

› Firmly apply the

handbrake.

› Check that you can carry out the repairs with the breakdown kit

» page 200.

› If a trailer is connected, remove it.

› Remove the breakdown kit

from the boot.

› Stick the sticker 2

»

Fig. 177 on page 201 on the dash panel in view of the driv-

er.

› Do not remove the foreign body, e.g. screw or nail, from the tyre.

› Unscrew the valve cap.

› Use the valve remover 1

to unscrew the valve core and place it on a clean sur-

face (rag, paper, etc.). Ð Sealing and inflating tyres

First read and observe the introductory information and safety warn-

ings on page 200.

Sealing

›

Forcefully shake the tyre inflator bottle 10

» Fig. 177

on page 201 several times.

› Firmly screw the inflation hose 3

onto the tyre inflator bottle 10

in a clockwise

direction. The film on the cap is pierced automatically.

› Remove the plug from the inflation hose 3

and plug the open end fully onto

the tyre valve.

› Hold the bottle 10

with the bottom facing upwards and fill all of the sealing

agent from the tyre inflator bottle into the tyre.

› Remove the empty tyre inflator bottle from the valve.

› Screw the valve core back into the tyre valve using the valve remover 1

.

£

ä

ä

201

Do-it-yourself

Page 207 of 235

Please note that the brake servo unit and power steering only operate if the en-

gine is running. If the engine is not running, significantly more physical force is re-

quired to depress the brake pedal and steer the vehicle.

If using a tow rope, ensure that it is always kept taught.

CAUTION

■ Do not tow start the engine - danger of damaging the engine! On vehicles with

a catalytic converter, unburnt fuel may get into the catalytic converter where it

may ignite. This in turn may damage or destroy the catalytic converter. The bat-

tery from another vehicle can be used as a jump-start aid » page 202, Jump-start-

ing .

■ If the gearbox of your vehicle no longer contains any oil because of a defect,

your vehicle must only be towed in with the driven wheels raised clear of the

ground, or on a special vehicle transporter or trailer.

■ The vehicle must be transported on a special vehicle or trailer if it is not possible

to tow in the vehicle in the way described or if the towing distance is greater than

50 km. ■ To protect both vehicles when tow-starting or towing, the tow rope should be

elastic. Thus one should only use plastic fibre rope or a rope made out of a simi-

larly elastic material.

■ One should be constantly vigilant not to allow impermissibly high towing forces

or jerky loadings. There is always a risk of excessive stresses and damage result-

ing at the points to which you attach the tow rope or tow bar when you attempt

to tow a vehicle which is not standing on a paved road.

■ Attach the tow rope or the tow bar to the towing eyes or to the detachable ball

head of the towing device » page 205 or »

page 206. Note

■ We recommend using a tow rope from

ŠKODA Original Accessories available

from a ŠKODA Service Partner. ■ Towing another vehicle requires a certain amount of practice. Both drivers

should be familiar with the particular points about towing a vehicle. Unskilled

drivers should not attempt to tow in another vehicle or to be towed in. ■ When towing, respect the national legal provisions, especially those which re-

late to the identification of the towing vehicle and the vehicle being towed. ■ The tow rope must not be twisted as it may in certain circumstances result in

the front towing eye being unscrewed out of your vehicle. Ð Front towing eye

Fig. 181

Front bumper: Removing the cap/installing the towing eye

First read and observe the introductory information and safety warn-

ings on page 204.

›

Remove the cap from the front bumper

»

Fig. 181 - .

› Screw in the towing eye by turning to the left up to the stop

» Fig. 181 - and

tighten as much as possible. For tightening purposes, we recommend, for exam-

ple, using the wheel wrench, towing eye from another vehicle or a similar object

that can be pushed through the eye.

› After unscrewing the towing eye, put the cap on and press into place. The cap

must engage firmly. CAUTION

The towing eye must always be screwed in fully and firmly tightened, otherwise

the towing eye can tear when towing in or tow-starting. Ð

ä

205

Do-it-yourself

Page 210 of 235

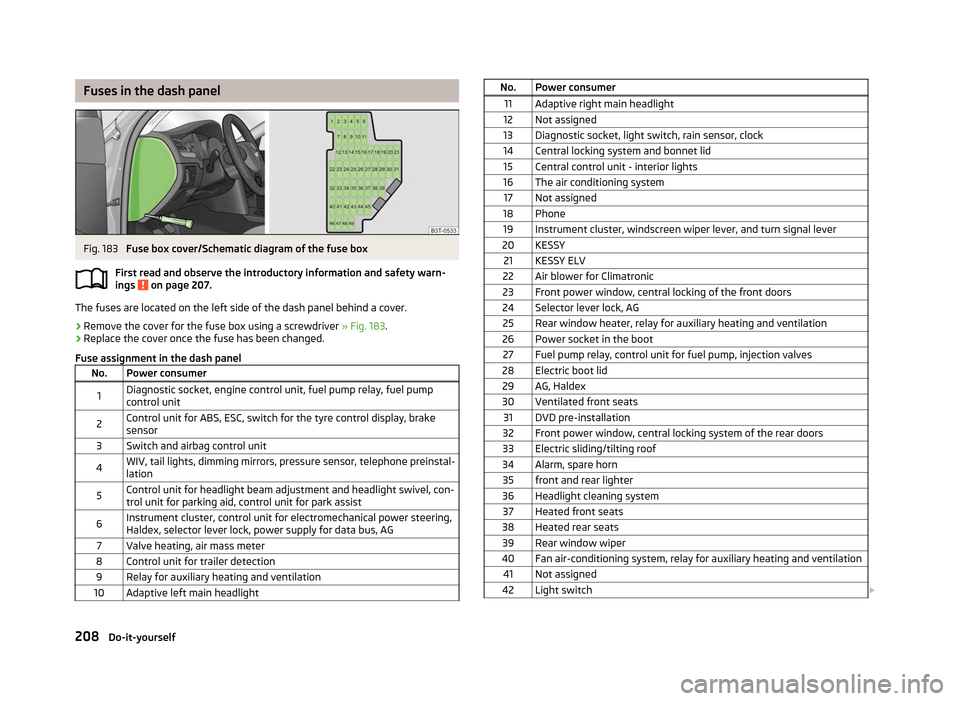

Fuses in the dash panel

Fig. 183

Fuse box cover/Schematic diagram of the fuse box

First read and observe the introductory information and safety warn-

ings on page 207.

The fuses are located on the left side of the dash panel behind a cover.

›

Remove the cover for the fuse box using a screwdriver

» Fig. 183.

› Replace the cover once the fuse has been changed.

Fuse assignment in the dash panel No. Power consumer

1 Diagnostic socket, engine control unit, fuel pump relay, fuel pump

control unit

2 Control unit for ABS, ESC, switch for the tyre control display, brake

sensor

3 Switch and airbag control unit

4 WIV, tail lights, dimming mirrors, pressure sensor, telephone preinstal-

lation

5 Control unit for headlight beam adjustment and headlight swivel, con-

trol unit for parking aid, control unit for park assist

6 Instrument cluster, control unit for electromechanical power steering,

Haldex, selector lever lock, power supply for data bus, AG

7 Valve heating, air mass meter

8 Control unit for trailer detection 9 Relay for auxiliary heating and ventilation

10 Adaptive left main headlight ä

No. Power consumer

11 Adaptive right main headlight

12 Not assigned

13 Diagnostic socket, light switch, rain sensor, clock

14 Central locking system and bonnet lid 15 Central control unit - interior lights

16 The air conditioning system 17 Not assigned

18 Phone 19 Instrument cluster, windscreen wiper lever, and turn signal lever

20 KESSY 21 KESSY ELV

22 Air blower for Climatronic

23 Front power window, central locking of the front doors

24 Selector lever lock, AG 25 Rear window heater, relay for auxiliary heating and ventilation

26 Power socket in the boot 27 Fuel pump relay, control unit for fuel pump, injection valves

28 Electric boot lid 29 AG, Haldex

30 Ventilated front seats 31 DVD pre-installation

32 Front power window, central locking system of the rear doors

33 Electric sliding/tilting roof

34 Alarm, spare horn 35 front and rear lighter

36 Headlight cleaning system 37 Heated front seats

38 Heated rear seats 39 Rear window wiper

40 Fan air-conditioning system, relay for auxiliary heating and ventilation 41 Not assigned

42 Light switch £208

Do-it-yourself