torque SKODA SUPERB 2012 2.G / (B6/3T) Owner's Manual

[x] Cancel search | Manufacturer: SKODA, Model Year: 2012, Model line: SUPERB, Model: SKODA SUPERB 2012 2.G / (B6/3T)Pages: 235, PDF Size: 5.86 MB

Page 7 of 235

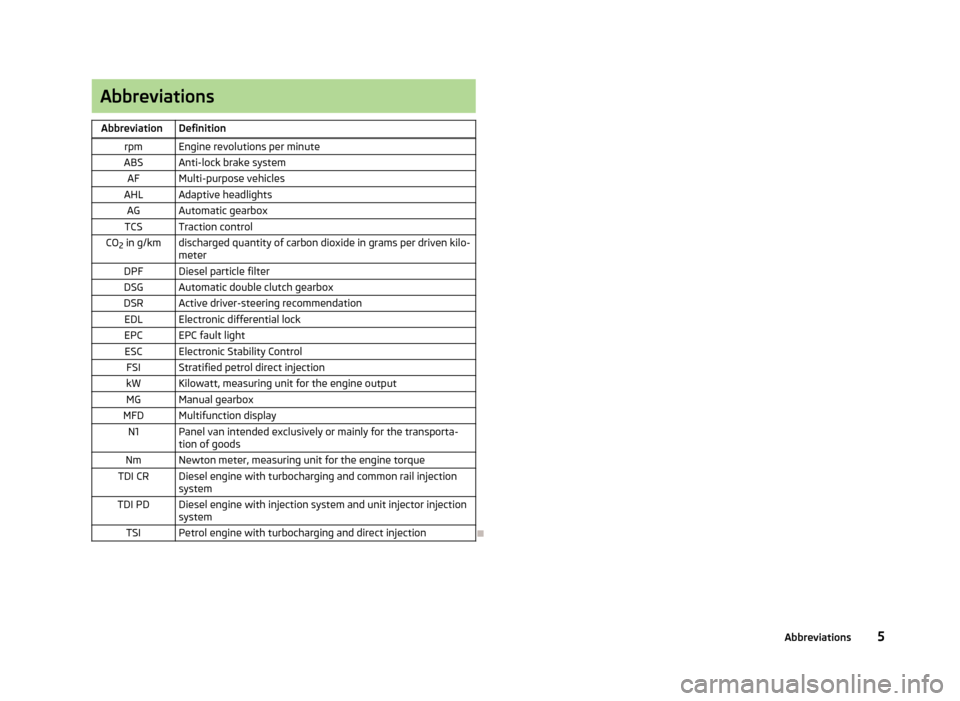

Abbreviations

Abbreviation Definition rpm Engine revolutions per minute

ABS Anti-lock brake system AF Multi-purpose vehicles

AHL Adaptive headlights AG Automatic gearbox

TCS Traction control

CO 2 in g/km discharged quantity of carbon dioxide in grams per driven kilo-

meter

DPF Diesel particle filter

DSG Automatic double clutch gearbox

DSR Active driver-steering recommendation EDL Electronic differential lock

EPC EPC fault light ESC Electronic Stability Control FSI Stratified petrol direct injection

kW Kilowatt, measuring unit for the engine output MG Manual gearbox

MFD Multifunction display N1 Panel van intended exclusively or mainly for the transporta- tion of goods

Nm Newton meter, measuring unit for the engine torque

TDI CR Diesel engine with turbocharging and common rail injection system

TDI PD Diesel engine with injection system and unit injector injection system

TSI Petrol engine with turbocharging and direct injection Ð 5

Abbreviations

Page 126 of 235

Selector lever lock

First read and observe the introductory information and safety warn-

ings on page 121.

Automatic selector lever lock

With the ignition on, the selector lever is locked when it is in the positions P and

N. The brake pedal must be depressed to move the selector lever out of this posi-

tion. The indicator light » page 26, Selector lever lock/starting (KESSY system)

illuminates in the instrument cluster as a reminder for the driver when the se-

lector lever is in the positions P and N.

The selector lever is not locked when quickly moving across the position

N (e.g.

from R to D). This, for example, helps to rock out a vehicle that is stuck. The selec-

tor lever lock will click into place if the lever is in the N position for more than 2

seconds without the brake pedal being pressed.

The selector lever lock is only active if the vehicle is stationary or moving at speed

of less than 5 km/hour. The lock is switched off automatically into position N

when the car is travelling at a higher speed.

Shiftlock button

The Shiftlock button in the handle of selector lever prevents certain selector lever

positions being engaged inadvertently. The selector lever lock is cancelled when

the Shiftlock button is pressed.

Ignition key withdrawal lock

After the ignition is switched off, the ignition key can only be withdrawn if the se-

lector lever is in the position P. If the ignition key is withdrawn, the selector lever

is blocked in position P . ÐKickdown function

First read and observe the introductory information and safety warn-

ings on page 121.

The kickdown function provides you with maximum acceleration power.

When the accelerator pedal is fully depressed, the kickdown function is activated

in the desired driving program. This function has precedence over the driving pro-

gramme and serves for maximum acceleration of the vehicle when exploiting the

maximum power potential of the engine without taking into account the current

selector lever position ( D, S or Tiptronic ). The gearbox shifts down to one or sev-

ä

ä

eral gears in line with the driving state and the vehicle accelerates. The gearbox

does not shift up into the highest gear until the engine has reached its maximum

revolutions for this gear range. Ð Dynamic shift programme

First read and observe the introductory information and safety warn-

ings on page 121.

The automatic gearbox of your vehicle is controlled electronically. Shifting up and

down through the gears is performed automatically on the basis of pre-defined

driving programmes.

Adopting a moderate style of driving

will cause the gearbox to select the most

economical driving programme. Shifting up into a higher gear as soon as possible

and shifting down as late as possible will have a favourable effect on your fuel

consumption.

When adopting a sporty style of driving with rapid movements of the accelerator

pedal combined with sharp acceleration, frequent changes in speed and exploit-

ing the top speed of the car, the gearbox will adjust to this style of driving once

the accelerator pedal (kickdown function) is depressed and will shift down earlier,

frequently by several gears in comparison to a moderate style of driving.

Selecting the most appropriate driving programme for the particular style of driv-

ing is a continuous process. Irrespective of this it is, however, possible to switch

or shift down into a dynamic shift programme by depressing the accelerator rap-

idly. The gearbox shifts down into a lower gear in accordance with the speed,

therefore enabling rapid acceleration (e.g. when overtaking) without the accelera-

tor pedal having to be depressed into the kickdown range. The original pro-

gramme will be reactivated to match your particular style of driving once the

gearbox has shifted up again.

When driving in hilly regions, the gears are selected to match uphill and downhill

sections. This avoids the gearbox frequently shifting up and down when negoti-

ating an uphill stretch. When driving downhill, it is possible to shift down into the

Tiptronic position, in order to exploit the engine brake torque. Ð

ä

124 Using the system

Page 189 of 235

Wheels and Tyres

Tyres

ä

Introduction

This chapter contains information on the following subjects:

Service life of tyres 188

Handling wheels and tyres 189

New wheels and tyres 189

Unidirectional tyres 190

Spare wheel 190

Full wheel trim 191

Wheel bolts 191

Wheel trim caps 191

Tyre control display 192

Wheel bolts 193

Winter tyres 193

Snow chains 193

WARNING

■ During the first 500 km, new tyres do not offer optimum grip and appropri-

ate care should therefore be taken when driving - risk of accident!

■ Never drive with damaged tyres - risk of accident!

■ Only use those tyres or wheel rims which have been approved by ŠKODA for

your model of vehicle. Failure to observe this instruction will adversely affect

the road safety of your vehicle - risk of accident!

■ The maximum permissible speed for your tyres must not be exceeded under

any circumstances - risk of an accident resulting from tyre damage and loss of

control of the vehicle.

■ If the inflation pressure is too low, the tyre must perform a higher rolling re-

sistance. At higher speeds the tyre will warm up as a result of this. This can

result in tread separation and a tyre blowout. WARNING (Continued)

■ Do not, where possible, replace individual tyres but at least replace them on

both wheels of a given axle at the same time. Always fit the tyres with the

deeper tread depth to the front wheels.

■ Never use tyres if you do not know anything about the condition and age.

■ You must have your tyres replaced with new ones at the latest when the

wear indicators have been worn down.

■ Worn tyres do not provide the necessary adhesion to the road surface at

high speeds on wet roads. One could experience

“aquaplaning” (uncontrolled

movements of the vehicle - “swimming” on a wet road surface).

■ Immediately replace damaged wheel rims or tyres.

■ Do not use summer or winter tyres that are older than 6 years or 4 years re-

spectively.

■ The wheel bolts must be clean and must turn easily. However, they must

never be treated with grease or oil.

■ If the wheel bolts are tightened to a too low tightening torque, the rim can

come loose when the car is moving - risk of accident! A tightening torque

which is too high can damage the bolts and threads and this can result in per-

manent deformation of the contact surfaces on the rim.

■ In case of incorrect treatment of the wheel bolts, the wheel can loosen

when the car is moving - risk of accident!

■ Observe the national legal regulations relating to the use of tyres and snow

chains. CAUTION

■ If a spare wheel is used that is not identical to the fitted tyres, the following

must be observed » page 190, Spare wheel.

■ The prescribed tightening torque of the wheel bolts for steel and light alloy

wheels is 120 Nm.

■ Protect the tyres from contact with oil, grease and fuel.

■ Replace any lost valve caps immediately. For the sake of the environment

Tyres which are insufficiently inflated increase your fuel consumption. £

187

Wheels and Tyres

Page 199 of 235

WARNING (Continued)

■ If the wheel has to be changed on a slope, first of all block the opposite

wheel with a stone or similar object to prevent the vehicle from unexpectedly

rolling away.

■ If the vehicle is subsequently fitted with tyres which are different to those it

was fitted with at the works, follow these guidelines »

page 189, New wheels

and tyres.

■ Always raise the vehicle with the doors closed.

■ Never position any body parts, such as arms or legs under the vehicle, while

the vehicle is raised with a lifting jack. ■ Secure the base plate of the lifting jack with suitable means to prevent pos-

sible moving. A soft and slippery ground under the base plate may move the

lifting jack, causing the vehicle to fall down. It is therefore always necessary to

place the lifting jack on a solid surface or use a wide and stable base. Use a

non-slip base (e.g. a rubber foot mat) if the surface is smooth, such as cobbled

stones, tiled floor, etc.

■ Never start the engine with the vehicle sitting on the raised jack - danger of

suffering injury.

■ Only attach the lifting jack to the attachment points provided for this pur-

pose. CAUTION

■ The prescribed tightening torque of the wheel bolts for steel and light alloy

wheels is 120 Nm.

■ If the anti-theft wheel bolt is fastened too tightly, it can cause damage to the

anti-theft wheel bolt and adapter. Note

■ The anti-theft wheel bolt set and adapter can be purchased from a

ŠKODA Serv-

ice Partner. ■ The national legal requirements must be observed when changing a wheel. ÐPreliminary work

First read and observe the introductory information and safety warn-

ings on page 196.

The following steps must be carried out before actually changing the wheel:

ä ›

In the event of a puncture, park the vehicle as far away as possible from the

flow of traffic. The place you choose should be level.

› Let all of the occupants get out.

While changing a tyre, the occupants of the

vehicle should not stand on the road (instead they should remain behind a crash

barrier).

› Switch off the engine and move the gearshift lever into

Neutral or move the

selector lever

for the automatic gearbox into position P .

› Firmly apply the

handbrake.

› If a trailer is connected, remove it.

› Remove the vehicle tool kit

» page 196 and the spare wheel »

page 190 from

the boot. Ð Changing a wheel

First read and observe the introductory information and safety warn-

ings on page 196.

Always change a wheel on a level surface as far as possible.

›

Remove the full wheel trim

» page 191 or caps » page 191.

› In the case of light alloy wheel rims remove the wheel trim cap

» page 191.

› First of all slacken the anti-theft wheel bolt and then the other wheel

bolts » page 198.

› Jack up the vehicle until the wheel that needs changing is clear of the

ground » page 199.

› Unscrew the wheel bolts and place them on a clean surface (cloth, paper, etc.).

› Remove the wheel.

› Attach the spare wheel and slightly screw on the wheel bolts.

› Lower the vehicle.

› Alternately tighten the wheel bolts opposite each other using the wheel

wrench (crosswise) and then tighten the anti-theft wheel bolt » page 198.

› Replace the wheel trim or the caps. Note

■ All bolts must be clean and must turn easily.

■ Under no circumstances grease or oil the wheel bolts!

■ When fitting unidirectional tyres, ensure that the direction of rotation is cor-

rect »

page 190 . Ð

ä

197

Do-it-yourself

Page 200 of 235

Subsequent steps

First read and observe the introductory information and safety warn-

ings on page 196.

The following steps must also be performed after changing the wheel.

›

Stow and attach the replaced wheel in the spare wheel well using a special

screw » page 190 .

› Stow the vehicle tool kit in the space provided.

› Check the tyre pressure

on the installed spare wheel as soon as possible.

› Have the

tightening torque of the wheel bolts checked with a torque wrench

as soon as possible.

› Change the damaged wheel or consult a ŠKODA specialist garage about repair

possibilities. Note

■ If it is determined that the wheel bolts are corroded and difficult to turn when

changing the wheel, the bolts must be replaced before checking the tightening

torque. ■ Drive cautiously and only at a moderate speed until the tightening torque has

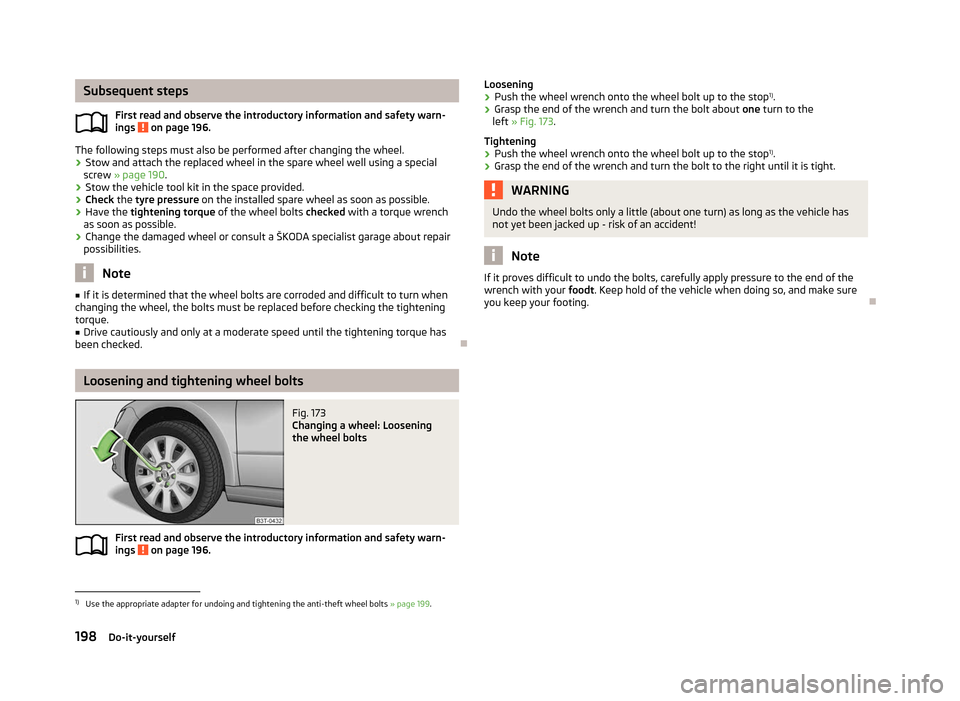

been checked. ÐLoosening and tightening wheel bolts

Fig. 173

Changing a wheel: Loosening

the wheel bolts

First read and observe the introductory information and safety warn-

ings on page 196.ä

ä

Loosening

› Push the wheel wrench onto the wheel bolt up to the stop 1)

.

› Grasp the end of the wrench and turn the bolt about

one turn to the

left »

Fig. 173.

Tightening

› Push the wheel wrench onto the wheel bolt up to the stop 1)

.

› Grasp the end of the wrench and turn the bolt to the right until it is tight. WARNING

Undo the wheel bolts only a little (about one turn) as long as the vehicle has

not yet been jacked up - risk of an accident! Note

If it proves difficult to undo the bolts, carefully apply pressure to the end of the

wrench with your foodt. Keep hold of the vehicle when doing so, and make sure

you keep your footing. Ð1)

Use the appropriate adapter for undoing and tightening the anti-theft wheel bolts » page 199.

198 Do-it-yourself

Page 201 of 235

Raising the vehicle

Fig. 174

Changing a wheel: Jacking points

for positioning lifting jack Fig. 175

Attach lifting jack

First read and observe the introductory information and safety warn-

ings on page 196.

Position the lifting jack by selecting the jacking point that is closest to the faulty

wheel

» Fig. 174. The jacking point is located directly below the engraving in the

lower sill.

› Position the lifting jack below the jacking point and move it up until its claw is

positioned directly below the vertical web of the lower sill.

› Align the lifting jack so that its claw grasps the web

» Fig. 175 -

below the

embossing in the side surface of the lower sill.

› Ensure that the entire surface of the lifting jack base plate rests on level

ground and is located in a vertical position to the area » Fig. 175 where the claw

grasps the web.

› Continue turning up the jack until the wheel is just about lifted off the ground. Ð

ä Securing wheels against theft

Fig. 176

Principle sketch: Anti-theft

wheel bolt with adapter

First read and observe the introductory information and safety warn-

ings on page 196.

The anti-theft wheel bolts on vehicles fitted with them (one anti-theft wheel bolt

per wheel) can only be loosened or tighten up by using the adapter provided.

›

Pull off the full wheel trim from the wheel rim or the cap from the anti-theft

wheel bolt.

› Insert the adapter B

» Fig. 176 with its toothed side fully into the inner tooth-

ing of the safety wheel bolt A

until the stop so that only the outer hexagon is

jutting out.

› Push the wheel wrench onto the adapter B

up to the stop.

› Loosen or tighten the wheel bolt

» page 198.

› After removing the adapter, reinstall the full wheel trim or place the cap onto

the anti-theft wheel bolt.

› Have the

tightening torque checked with a torque wrench as soon as possible.

It is advisable to make a note of the code number hammered into the rear side of

the adapter or the rear side of the anti-theft wheel bolt. This number can be used

to purchase a replacement adapter from a

ŠKODA Service Partner, if necessary.

We recommend that you always carry the adapter for the wheel bolts with you in

the vehicle. It should be stowed in the vehicle tool kit. Ð

ä

199

Do-it-yourself

Page 222 of 235

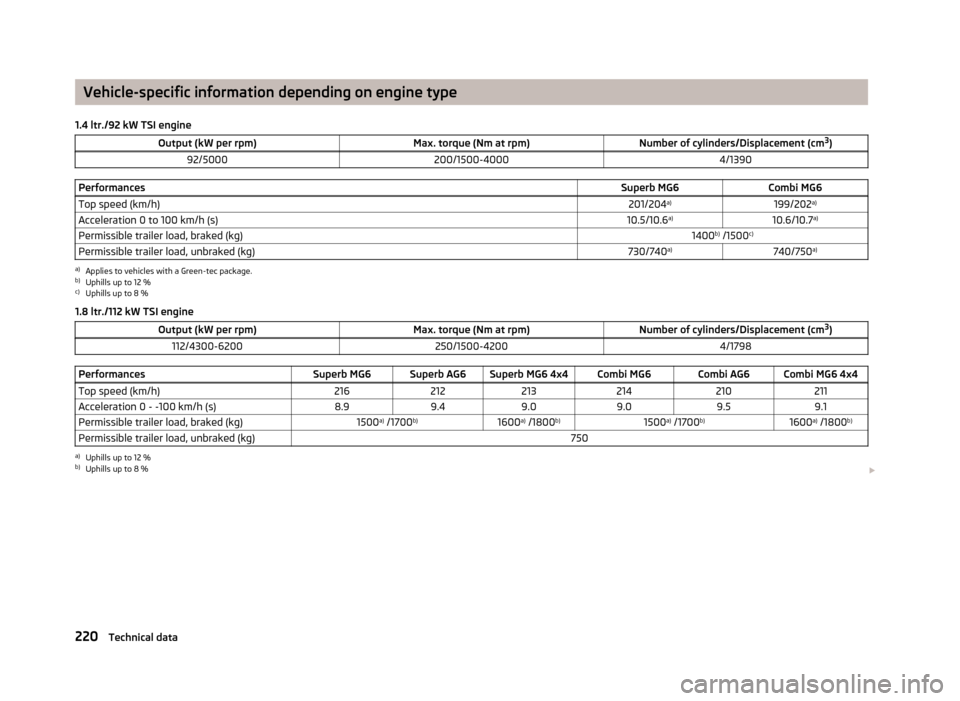

Vehicle-specific information depending on engine type

1.4 ltr./92 kW TSI engine Output (kW per rpm) Max. torque (Nm at rpm)Number of cylinders/Displacement (cm3

)

92/5000 200/1500-4000 4/1390Performances

Superb MG6Combi MG6

Top speed (km/h) 201/204a)

199/202a)

Acceleration 0 to 100 km/h (s) 10.5/10.6a)

10.6/10.7a)

Permissible trailer load, braked (kg) 1400b)

/1500 c)

Permissible trailer load, unbraked (kg) 730/740a)

740/750a)a)

Applies to vehicles with a Green-tec package.

b) Uphills up to 12 %

c) Uphills up to 8 %

1.8 ltr./112

kW TSI engineOutput (kW per rpm) Max. torque (Nm at rpm)Number of cylinders/Displacement (cm3

)

112/4300-6200 250/1500-4200 4/1798Performances

Superb MG6 Superb AG6 Superb MG6 4x4 Combi MG6 Combi AG6 Combi MG6 4x4

Top speed (km/h) 216212213 214 210211

Acceleration 0 - -100 km/h (s) 8.99.49.0 9.0 9.59.1

Permissible trailer load, braked (kg) 1500a)

/1700 b)

1600a)

/1800 b)

1500a)

/1700 b)

1600a)

/1800 b)

Permissible trailer load, unbraked (kg) 750a)

Uphills up to 12 %

b) Uphills up to 8 % £220

Technical data

Page 223 of 235

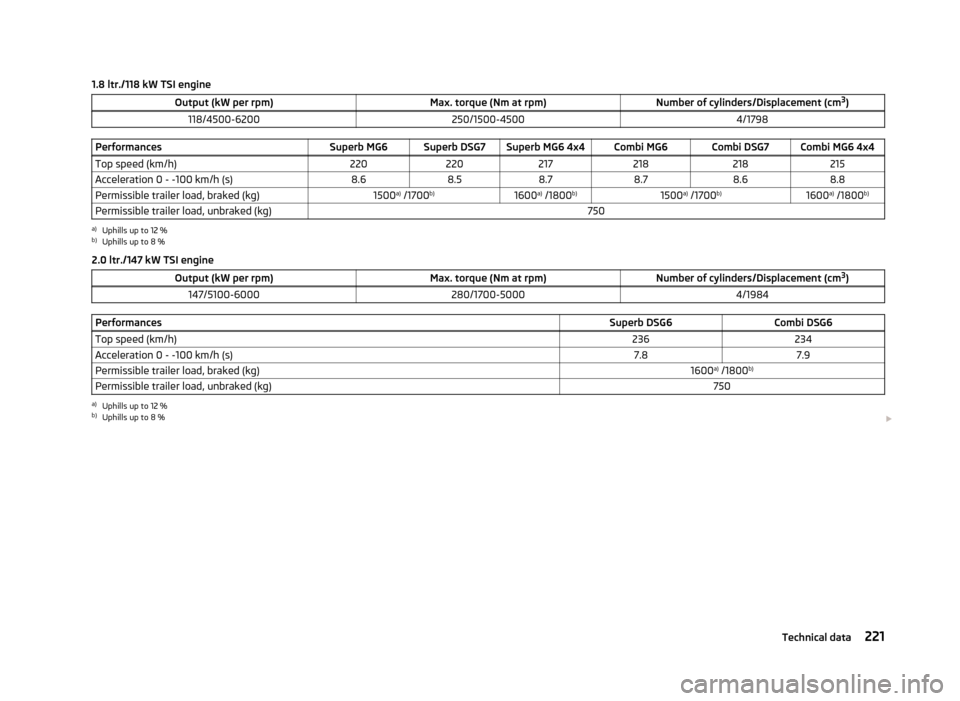

1.8 ltr./118 kW TSI engine

Output (kW per rpm) Max. torque (Nm at rpm)Number of cylinders/Displacement (cm3

)

118/4500-6200 250/1500-4500 4/1798Performances

Superb MG6 Superb DSG7 Superb MG6 4x4 Combi MG6 Combi DSG7 Combi MG6 4x4

Top speed (km/h) 220220217 218 218215

Acceleration 0 - -100 km/h (s) 8.68.58.7 8.7 8.68.8

Permissible trailer load, braked (kg) 1500a)

/1700 b)

1600a)

/1800 b)

1500a)

/1700 b)

1600a)

/1800 b)

Permissible trailer load, unbraked (kg) 750a)

Uphills up to 12 %

b) Uphills up to 8 %

2.0

ltr./147 kW TSI engine Output (kW per rpm) Max. torque (Nm at rpm)Number of cylinders/Displacement (cm3

)

147/5100-6000 280/1700-5000 4/1984Performances

Superb DSG6Combi DSG6

Top speed (km/h) 236234

Acceleration 0 - -100 km/h (s) 7.87.9

Permissible trailer load, braked (kg) 1600a)

/1800 b)

Permissible trailer load, unbraked (kg) 750a)

Uphills up to 12 %

b) Uphills up to 8 % £ 221

Technical data

Page 224 of 235

3.6 ltr/191 kW FSI engine

Output (kW per rpm) Max. torque (Nm at rpm)Number of cylinders/Displacement (cm3

)

191/6000 350/2500-5000 6/3597Performances

Superb DSG6 4x4Combi DSG6 4x4

Top speed (km/h) 250247

Acceleration 0 - -100 km/h (s) 6.56.6

Permissible trailer load, braked (kg) 2000

Permissible trailer load, unbraked (kg) 7501.6 ltr./77 kW TDI CR engine

Output (kW per rpm) Max. torque (Nm at rpm)Number of cylinders/Displacement (cm3

)

77/4400 250/1500-2500 4/1598Performances

Superb MG5 Superb MG5 GreenLine Combi MG5 Combi MG5 GreenLine

Top speed (km/h) 189192187190

Acceleration 0 - -100 km/h (s) 12.512.512.6 12.6

Permissible trailer load, braked (kg) 1500a)

/1700 b)

Permissible trailer load, unbraked (kg) 750a)

Uphills up to 12 %

b) Uphills up to 8 % £222

Technical data

Page 225 of 235

2.0 ltr./103 kW TDI CR DPF engine

Output (kW per rpm) Max. torque (Nm at rpm)Number of cylinders/Displacement (cm3

)

103/4200 320/1750-2500 4/1968Performances

Superb MG6 Superb DSG6Su-

perb DSG6 4x4 Combi MG6 Combi DSG6 Combi DSG6 4x4

Top speed (km/h) 208/211a)

206 204205/209a)

203 201

Acceleration 0 - -100 km/h (s) 10.110.2 10.710.2 10.310.8

Permissible trailer load, braked (kg) 18002000 18002000

Permissible trailer load, unbraked (kg) 750a)

Applies to vehicles with a Green-tec package.

2.0 ltr./125 kW TDI CR DPF engine Output (kW per rpm) Max. torque (Nm at rpm)Number of cylinders/Displacement (cm3

)

125/4200 350/1750-2500 4/1968Performances

Superb MG6 Superb DSG6Su-

perb MG6 4x4 Combi MG6 Combi DSG6 Combi MG6 4x4

Top speed (km/h) 222220 219220 218217

Acceleration 0 - -100 km/h (s) 8.88.89.0 8.98.9 9.1

Permissible trailer load, braked (kg) 18002000 18002000

Permissible trailer load, unbraked (kg) 750 Ð

223

Technical data