Oil SKODA SUPERB 2015 3.G / (B8/3V) User Guide

[x] Cancel search | Manufacturer: SKODA, Model Year: 2015, Model line: SUPERB, Model: SKODA SUPERB 2015 3.G / (B8/3V)Pages: 276, PDF Size: 42.14 MB

Page 194 of 276

ŠKODA Service Partners are liable for any defects of ŠKODA Genuine Accesso-

ries for a period of 2 years after installation or delivery in accordance with the

materials defect liability, unless agreed otherwise in the purchase agreement

or any other agreements. You should keep the approved warranty certificate

and the invoices for these accessories for this period of time, so that the com-

mencement of the term can be verified.

ŠKODA Service Partners also stock a range of suitable car care products and all

parts that are subject to natural wear-and-tear, such as tyres, batteries, bulbs

and wiper blades.

Note

The accessories authorized by the company ŠKODA AUTO a.s. will be offered

by the ŠKODA Partners in all countries where the company ŠKODA AUTO a.s.

has a sales and after-sales service network. This will usually be in the form of a

printed catalogue of ŠKODA Genuine Accessories, in the form of separate prin-

ted brochures or in the form of ŠKODA Genuine Accessories on the ŠKODA

Partner websites.

Spoiler

Read and observe

on page 190 first.

If your new vehicle is fitted with a spoiler on the front bumper in combination

with the spoiler on the luggage compartment lid, the following instructions

must be adhered to. ▶ For safety reasons, the vehicle must only be fitted with a spoiler on the front

bumper in combination with the associated spoiler on the luggage compart-

ment lid.

▶ This kind of spoiler cannot be left on the front bumper either on its own, in

combination with another spoiler not on the luggage compartment lid or in

combination with an unsuitable spoiler on the luggage compartment lid.

▶ We recommend that you consult the ŠKODA Service Partner for any repairs

to or replacement, addition or removal of spoilers.

WARNING■ If work on your vehicle's spoilers is not carried out properly, this can lead

to operational faults - risk of accident and serious injuries.■

If a front spoiler, full wheel trim, etc. is mounted retrospectively, it must

be ensured that the air supply to the front wheel brakes is not reduced.

The front brakes may overheat which can have a negative impact on the

functioning of the braking system – risk of accident!

Component protection

Read and observe

on page 190 first.

Some electronic vehicle components (such as the instrument cluster) are fac-

tory-equipped with component protection.

Component protection has been developed as a protection mechanism for the

following situations. ▶ Impairment of factory- or garage-fitted electronic components after installa-

tion in another vehicle (for example, after a theft).

▶ Impairment of electronic components used outside the vehicle.

▶ The possibility of a legitimate installation or change of electronic compo-

nents for repairs at a specialist garage.

The activated component protection can be realized by functional limitations

of the specific electronic component. Seek help from a specialist garage.

Airbags

Read and observe

on page 190 first.

WARNING■Modifications, repairs and technical alterations that have been carried out

unprofessionally can cause damage and operational faults, and can also se-

riously impair the effectiveness of the airbag system – risk of accident and

fatal injury!■

A change to the vehicle's wheel suspension, including the use of non-ap-

proved wheels and tire combinations, can alter the functioning of the air-

bag system - risk of accident and fatal injury!

WARNINGInformation on the use of the airbag system■Never install any airbag parts into the vehicle that have been removed

from old cars or have been recycled.■

Never install damaged airbag parts in the vehicle. The airbags may then

not be deployed properly or even at all in the event of an accident.

192General Maintenance

Page 196 of 276

Clean wheels, door sills and similar parts last. Use a second sponge for such

areas.

Give the vehicle a good rinse after washing it and dry it off using a chamois

leather.WARNINGProtect your hands and arms from sharp-edged metal parts when cleaning

the under floor or the inside of the wheel housings or the wheel trims – risk

of cuts!

CAUTION

■ Only apply slight pressure when cleaning the vehicle's paintwork.■Do not wash your vehicle in bright sunlight – risk of paint damage.

Automatic car wash systems

Read and observe

and on page 193 first.

The usual precautionary measures must be taken before washing the vehicle

in an automatic car wash system (e.g. closing the windows and the sliding/tilt-

ing roof etc.).

If your vehicle is fitted with any particular attached parts, such as a spoiler,

roof rack system, two-way radio aerial etc., it is best to consult the operator of

the car wash system beforehand.

After an automatic wash with wax treatment, the lips of the wipers should be

cleaned with cleaning agents specially designed for the purpose, and then de-

greased.

CAUTION

Before driving through a car wash fold in the exterior mirrors - there is a risk of

damage.

Washing with a high-pressure cleaner

Read and observe

and on page 193 first.

When washing the vehicle with a high-pressure cleaner, the instructions for

use of the equipment must be observed. This applies in particular to the pres-

sure used and to the spraying distance .

Maintain a sufficiently large distance to the parking aid sensors and soft mate-

rials such as rubber hoses or insulation material.

CAUTION

■ The films should not be washed with any high-pressure cleaners - risk of

damage » page 195 .■

Do not aim the water jet directly at the lock cylinders or the door or opening

joints when washing the vehicle in the winter – there is a risk of freezing.

■

The sensors of the parking aid can be sprayed only for a short time and there

must be a minimum distance of 10 cm - there is a risk of damage.

■

When washing the vehicle, do not point the water jet directly at the tow bar

or the trailer socket - there is a risk of seal damage or washing out the grease.

Cleaning vehicle exterior

Introduction

This chapter contains information on the following subjects:

Vehicle paint work

195

Films

195

Plastic parts

196

Rubber seals

196

Chrome and anodized parts

196

Windows and external mirrors

196

Headlight glasses

197

Camera lens

197

Door closing cylinder

197

Cavity protection

197

Jack

197

Wheels

197

Under-body protection

198

Wiper blades

198

We recommend using vehicle care products from ŠKODA Original Accessories.

These are available from ŠKODA Partners. The usage instructions on the pack-

age must be observed.

194General Maintenance

Page 200 of 276

Regularly remove salt and brake abrasion, otherwise the rim material will be

corroded.

Light alloy wheel trims

After washing thoroughly and treat the wheel rims with a protective product

for light alloy wheels.

For the treatment of wheel rims do not use products which may cause damage

to the paint on the rims.

CAUTION

■ Damage to the paint layer on the wheel rims must be touched up immediate-

ly.■

Severe layers of dirt on the wheels can also result in wheel imbalance. This

may show itself in the form of a wheel vibration which is transmitted to the

steering wheel which, in certain circumstances, can cause premature wear of

the steering. This means it is necessary to remove the dirt.

Under-body protection

Read and observe

and on page 195 first.

The underside of your vehicle is already permanently protected by the factory

against chemical and mechanical influences.

It is not possible to guarantee that the protective coating will not suffer any

damage as the vehicle is driven.

We recommend having the protective coating underneath the vehicle and the

chassis checked — preferably before the beginning of winter and at the end of

winter.

WARNINGNever use additional underbody protection or anti-corrosion agents for ex-

haust pipes, catalytic converters, diesel particle filters or heat shields.

When the engine reaches its operating temperature, these substances may ignite - risk of fire!Wiper blades

Read and observe

and on page 195 first.

Clean the wiper blades regularly with a glass cleaner. The wiper blades should

be cleaned with a sponge or cloth if they are heavily soiled by insect residues,

for example.

The wiper blades can become soiled with wax residues after washing in auto-

matic vehicle wash systems for example.

Interior care

Introduction

This chapter contains information on the following subjects:

Natural leather

199

Artificial leather, materials and Alcantara ®

199

Seat covers

200

Safety belts

200

We recommend using vehicle care products from ŠKODA Original Accessories.

These are available from ŠKODA Partners. The usage instructions on the pack-

age must be observed.

WARNING■ Vehicle care products may be harmful to your health if not used according

to the instructions.■

Always keep the vehicle care products safe from people who are not com-

pletely independent, e.g. children - there is a danger of poisoning!

■

Air fresheners and scents can be hazardous to heath when the tempera-

ture inside the vehicle is high.

CAUTION

■ Be sure to check clothing for colour fastness to avoid any damage or visible

stains on the material (leather), panels and textiles.■

Remove fresh stains such as those from ball-point pens, ink, lipstick, shoe

polish, etc., from the material (leather), panels and textiles as quickly as possi-

ble.

■

Do not attach scents or air fresheners to the dash panel – there is a risk of

damage to the dash panel.

198General Maintenance

Page 201 of 276

■Do not attach any stickers to the filaments or glass antenna - there is risk of

damage.■

Do not clean the roof panelling with a brush – risk of damage to the surface

of the panelling.

■

Cleaner that contain solvents can damage the material being cleaned.

■

Apply only a small amount of the cleaning and care product.

Note

Due to the special tools and knowledge required, and to avoid any potential

problems with the cleaning and care of the interior of your vehicle, we recom-

mend that cleaning and care of the interior of your vehicle be carried out by a

ŠKODA service partner.

Natural leather

Read and observe

and on page 198 first.

The leather needs, depending on the strain placed on it, regular cleaning and

maintenance.

Dust and dirt in pores and creases cause abrasions on the surface and lead to

premature embrittlement of the leather surface. Therefore, they must be re-

moved regularly at short intervals with a cloth or vacuum cleaner.

Clean soiled leather surfaces with a water-dampened cotton or woollen cloth

and then dry with a clean, dry cloth »

.

Clean severely soiled areas with a cloth soaked in a mild soap solution (2 ta-

blespoons of neutral soap to 1 litre of water).

To remove stains , use a cleaning agent specially designed for this purpose.

Treat the leather periodically with a suitable leather protector and use a skin

care cream with light blocker and impregnation after each cleaning.

CAUTION

■ Ensure that no part of the leather is soaked through during cleaning and that

no water gets into the seams. Otherwise, the leather could become brittle or

cracked.■

Avoid leaving the vehicle for lengthy periods in bright sunlight to avoid the

leather from bleaching. If the vehicle is parked in the open for lengthy periods,

protect the leather from direct sunlight by covering it.

■

The use of an additional mechanical steering wheel lock may damage the

leather surface of the steering wheel.

■ Some clothing materials, e.g. dark denim, do not have sufficient colour fast-

ness. This can cause damage or clearly visible discolouration to seat covers,

even when used correctly. This applies particularly to light-coloured seat cov-

ers. This does not relate to a fault in the seat cover, but rather to poor colour

fastness of the clothing textiles.■

Sharp-edged objects on items of clothing such as zip fasteners, rivets, sharp-

edged belts etc. may leave permanent scratches or signs of rubbing on the

surface or damage these. Such damage cannot be subsequently recognised as

a justified complaint.

Note

When using the vehicle, minor visible changes may occur to the leather parts

of the covers (e.g. wrinkles or creases) as a result of the stress applied to the

covers.

Artificial leather, materials and Alcantara ®

Read and observe

and on page 198 first.

Artificial leather

Clean artificial leather with a damp cloth.

If this method does not completely clean the artificial leather, use a mild soap

solution or cleaning products specially designed for this purpose.

Fabric

Clean upholstery cover materials and cloth trims on doors, boot cover, etc. us-

ing specific cleaning agents, e.g., dry foam.

Use a soft sponge, brush, or commercially available microfibre cloth.

Use a cloth and a cleaning agent specifically designed for this purpose to clean

the roof trim.

Remove any lumps on the cover fabric and any fabric residue using a brush.

Remove stubborn hair using a “cleaning glove”.

Alcantara ®

Dust and dirt in pores, creases and seams may chafe and damage the surface.

Therefore, they must be removed regularly at short intervals with a cloth or

vacuum cleaner.

Minor changes in colour caused by use are normal.

199Care and maintenance

Page 210 of 276

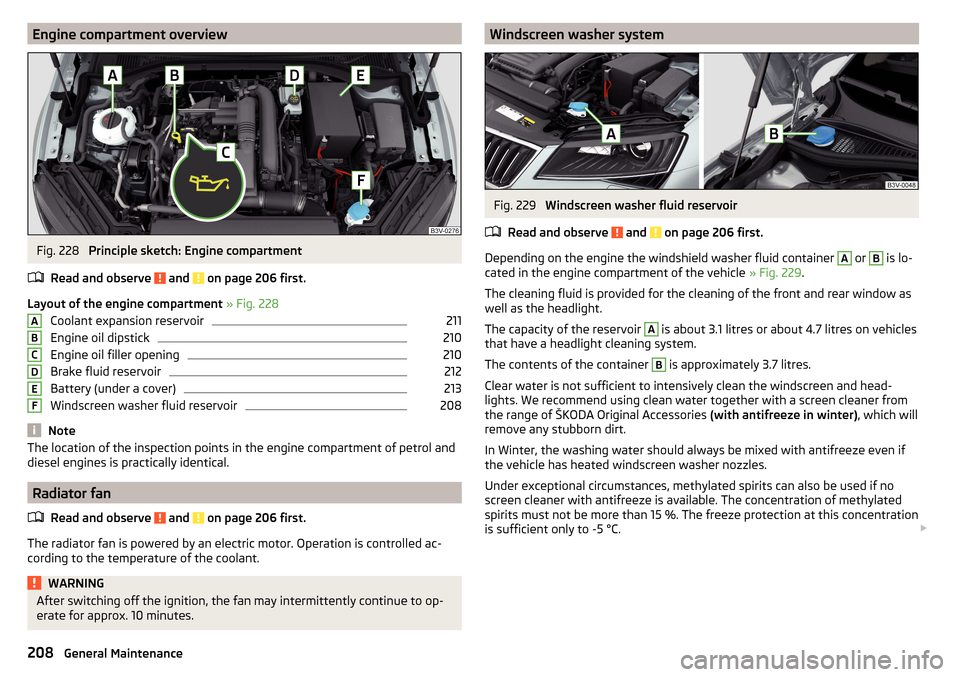

Engine compartment overviewFig. 228

Principle sketch: Engine compartment

Read and observe

and on page 206 first.

Layout of the engine compartment » Fig. 228

Coolant expansion reservoir

211

Engine oil dipstick

210

Engine oil filler opening

210

Brake fluid reservoir

212

Battery (under a cover)

213

Windscreen washer fluid reservoir

208

Note

The location of the inspection points in the engine compartment of petrol and

diesel engines is practically identical.

Radiator fan

Read and observe

and on page 206 first.

The radiator fan is powered by an electric motor. Operation is controlled ac-

cording to the temperature of the coolant.

WARNINGAfter switching off the ignition, the fan may intermittently continue to op-

erate for approx. 10 minutes.ABCDEFWindscreen washer systemFig. 229

Windscreen washer fluid reservoir

Read and observe

and on page 206 first.

Depending on the engine the windshield washer fluid container

A

or

B

is lo-

cated in the engine compartment of the vehicle » Fig. 229.

The cleaning fluid is provided for the cleaning of the front and rear window as

well as the headlight.

The capacity of the reservoir

A

is about 3.1 litres or about 4.7 litres on vehicles

that have a headlight cleaning system.

The contents of the container

B

is approximately 3.7 litres.

Clear water is not sufficient to intensively clean the windscreen and head-

lights. We recommend using clean water together with a screen cleaner from

the range of ŠKODA Original Accessories (with antifreeze in winter), which will

remove any stubborn dirt.

In Winter, the washing water should always be mixed with antifreeze even if

the vehicle has heated windscreen washer nozzles.

Under exceptional circumstances, methylated spirits can also be used if no

screen cleaner with antifreeze is available. The concentration of methylated

spirits must not be more than 15 %. The freeze protection at this concentration

is sufficient only to -5 °C.

208General Maintenance

Page 211 of 276

CAUTION■Under no circumstances must radiator antifreeze or other additives be added

to the windscreen washer fluid.■

If the vehicle is fitted with a headlight cleaning system, only cleaning prod-

ucts which do not attack the polycarbonate coating of the headlights must be

added to the windscreen washer fluid.

■

Do not remove the filter from the windscreen washer fluid reservoir when re-

filling, as this may cause contamination of the liquid transportation system,

leading in turn to a windscreen washer system malfunction.

Engine oil

Introduction

This chapter contains information on the following subjects:

Specification

209

Checking the oil level

210

Replenishing

210

The engine has been factory-filled with a high-grade oil that can be use

throughout the year - except in extreme climate zones.

The engine oils are undergoing continuous further development. Thus the in- formation stated in this Owner's Manual is only correct at the time of publica-

tion.

ŠKODA Service Partners are informed about the latest changes by the manu-

facturer. We therefore recommend that the oil change be completed by a

ŠKODA Service Partner.

The specifications (VW standards) stated in the following can be indicated sep-

arately or together with other specifications on the bottle.

The engine oil should be changed after specified service intervals » page 49.

WARNINGThe engine compartment of your car is a hazardous area. The following

warning instructions must be followed at all times when working in the en-

gine compartment » page 206.

CAUTION

Do not pour any additives into the engine oil – risk of serious damage to the

engine parts.Note■ Before a long drive we recommend that you purchase and carry with you en-

gine oil which complies with the specification for your vehicle.■

We recommend that you use oils from ŠKODA Original Accessories.

■

If oil comes into contact with your skin, the affected area must be washed

thoroughly.

Specification

Read and observe

and on page 209 first.

Vehicles with variable service intervals

Petrol enginesSpecification1.4 l / 92 kW TSI

VW 504 00

1.4 l/110 kW TSI1.8 l/132 kW TSI2.0 l/162, 206 kW TSIDiesel enginesSpecification1.6 ltr. / 88 kW TDI CRVW 507 002.0 l/110, 130, 140 kW TDI CR

Vehicles with fixed service intervals

Petrol enginesSpecification1.4 l / 92 kW TSI

VW 502 00

1.4 l/110 kW TSI1.8 l/132 kW TSI2.0 l/162, 206 kW TSIDiesel enginesSpecification1.6 ltr. / 88 kW TDI CRVW 507 002.0 l/110, 130, 140 kW TDI CR

Engine oil VW 505 01 can optionally be used in diesel engines without a DPF.

209Inspecting and replenishing

Page 212 of 276

CAUTION■In an emergency, another engine oil to be refilled. To prevent damage to the

engine, a maximum of 0.5 litres only of the following engine oils may be used:

■ For petrol engine models: ACEA A3/ACEA B4 or API SN, (API SM);

■ For diesel engine models: ACEA C3 or API CJ-4.

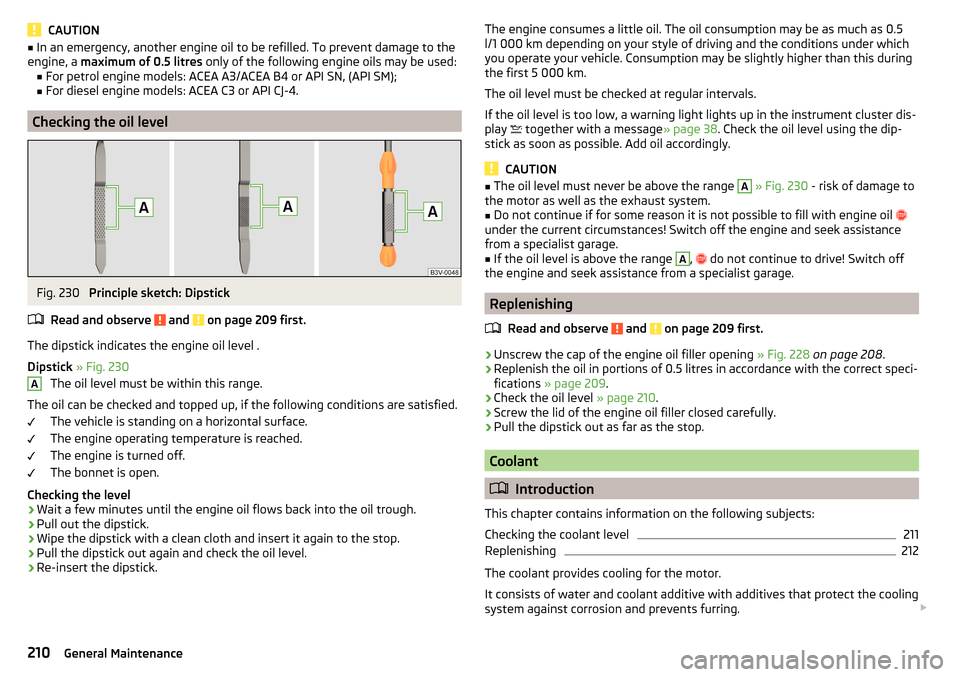

Checking the oil level

Fig. 230

Principle sketch: Dipstick

Read and observe

and on page 209 first.

The dipstick indicates the engine oil level .

Dipstick » Fig. 230

The oil level must be within this range.

The oil can be checked and topped up, if the following conditions are satisfied. The vehicle is standing on a horizontal surface.

The engine operating temperature is reached.

The engine is turned off.

The bonnet is open.

Checking the level

›

Wait a few minutes until the engine oil flows back into the oil trough.

›

Pull out the dipstick.

›

Wipe the dipstick with a clean cloth and insert it again to the stop.

›

Pull the dipstick out again and check the oil level.

›

Re-insert the dipstick.

AThe engine consumes a little oil. The oil consumption may be as much as 0.5

l/1 000 km depending on your style of driving and the conditions under which

you operate your vehicle. Consumption may be slightly higher than this during

the first 5 000 km.

The oil level must be checked at regular intervals.

If the oil level is too low, a warning light lights up in the instrument cluster dis-

play

together with a message » page 38. Check the oil level using the dip-

stick as soon as possible. Add oil accordingly.

CAUTION

■ The oil level must never be above the range A » Fig. 230 - risk of damage to

the motor as well as the exhaust system.■

Do not continue if for some reason it is not possible to fill with engine oil

under the current circumstances! Switch off the engine and seek assistance

from a specialist garage.

■

If the oil level is above the range

A

,

do not continue to drive! Switch off

the engine and seek assistance from a specialist garage.

Replenishing

Read and observe

and on page 209 first.

›

Unscrew the cap of the engine oil filler opening » Fig. 228 on page 208 .

›

Replenish the oil in portions of 0.5 litres in accordance with the correct speci-

fications » page 209 .

›

Check the oil level » page 210.

›

Screw the lid of the engine oil filler closed carefully.

›

Pull the dipstick out as far as the stop.

Coolant

Introduction

This chapter contains information on the following subjects:

Checking the coolant level

211

Replenishing

212

The coolant provides cooling for the motor.

It consists of water and coolant additive with additives that protect the cooling

system against corrosion and prevents furring.

210General Maintenance

Page 214 of 276

Checking the level›Check the coolant level in the coolant expansion tank » Fig. 231.

If the engine is warm, the test result may be inaccurate. The level can also be

above the mark A

» Fig. 231 .

If the oil level is too low, a warning light lights up in the instrument cluster dis-

play

together with a message » page 38. We still recommend inspecting the

coolant level directly at the reservoir from time to time.

Loss of coolant

A loss of coolant is first and foremost an indication of a leak in the cooling sys-

tem. Do not merely top up the coolant. Have the cooling system checked by a

specialist garage.

Replenishing

Read and observe

and on page 211 first.

The coolant expansion tank must always contain a small amount of coolant» page 211, in section Introduction .

›

Place a cloth over the cap of the coolant expansion tank and unscrew the

cap carefully .

›

Replenish the coolant.

›

Turn the cap until it clicks into place.

Do not use an alternative additive if the specified coolant is not available. In

this case, use just water and have the correct mixing ratio of water and cool-

ant additive restored by a specialist garage as soon as possible.

Only top up with new coolant.

Brake fluid

Introduction

This chapter contains information on the following subjects:

Checking the brake fluid level

212

Specification

213

The brake fluid reservoir is located in the engine compartment » Fig. 232 on

page 212 .

WARNING■

The engine compartment of your car is a hazardous area. The following

warning instructions must be followed at all times when working in the en-

gine compartment » page 206.■

Do not use used brake fluid - the function of the brake system may be im-

paired – risk of accident!

CAUTION

■ Do not continue your journey if the fluid level has dropped below the “MIN”

marking » Fig. 232 on page 212 , - there is a risk of an accident! Seek help

from a specialist garage.■

Brake fluid damages the paintwork of the vehicle.

Note

■ The brake fluid is changed as part of a compulsory inspection service.■We recommend using oils from the ŠKODA Original Accessories range.

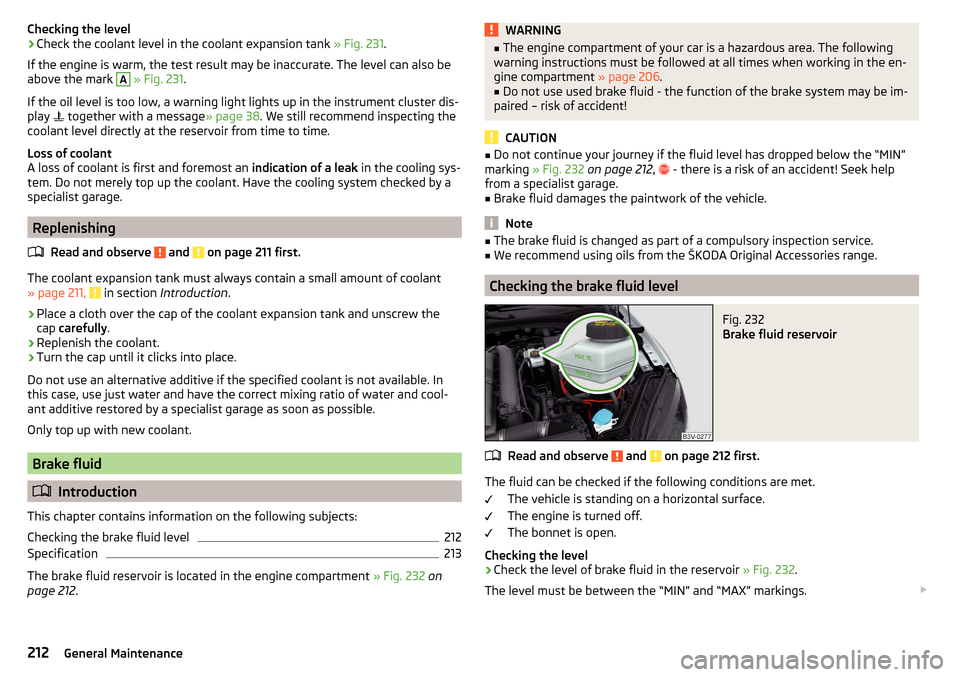

Checking the brake fluid level

Fig. 232

Brake fluid reservoir

Read and observe and on page 212 first.

The fluid can be checked if the following conditions are met.

The vehicle is standing on a horizontal surface.

The engine is turned off.

The bonnet is open.

Checking the level

›

Check the level of brake fluid in the reservoir » Fig. 232.

The level must be between the “MIN” and “MAX” markings.

212General Maintenance

Page 221 of 276

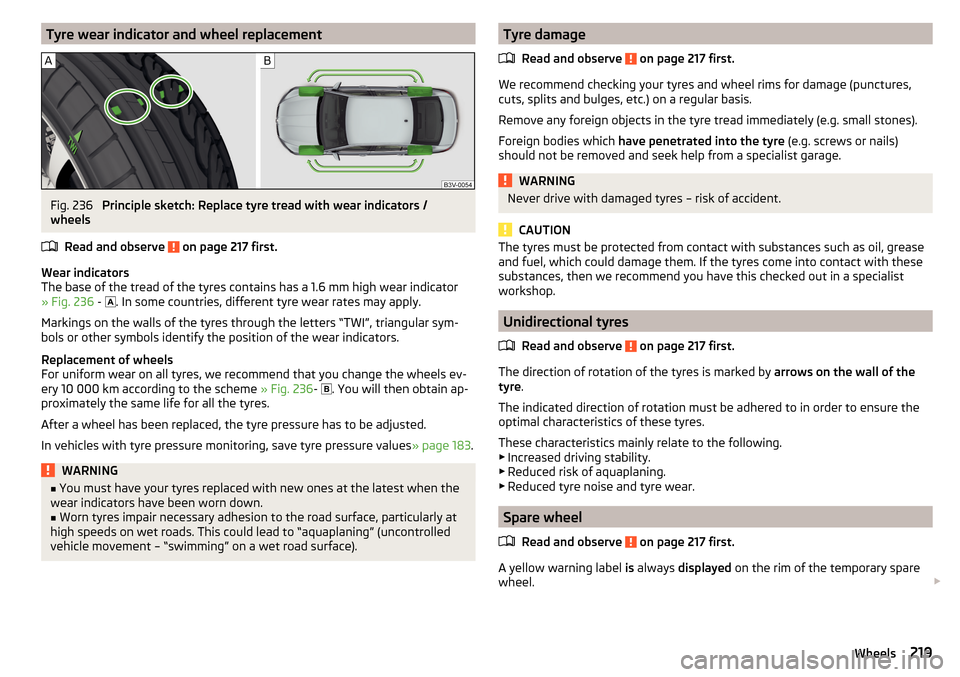

Tyre wear indicator and wheel replacementFig. 236

Principle sketch: Replace tyre tread with wear indicators /

wheels

Read and observe

on page 217 first.

Wear indicators

The base of the tread of the tyres contains has a 1.6 mm high wear indicator

» Fig. 236 -

. In some countries, different tyre wear rates may apply.

Markings on the walls of the tyres through the letters “TWI”, triangular sym-

bols or other symbols identify the position of the wear indicators.

Replacement of wheels

For uniform wear on all tyres, we recommend that you change the wheels ev-

ery 10 000 km according to the scheme » Fig. 236-

. You will then obtain ap-

proximately the same life for all the tyres.

After a wheel has been replaced, the tyre pressure has to be adjusted.

In vehicles with tyre pressure monitoring, save tyre pressure values » page 183.

WARNING■

You must have your tyres replaced with new ones at the latest when the

wear indicators have been worn down.■

Worn tyres impair necessary adhesion to the road surface, particularly at

high speeds on wet roads. This could lead to “aquaplaning” (uncontrolled vehicle movement – “swimming” on a wet road surface).

Tyre damage

Read and observe

on page 217 first.

We recommend checking your tyres and wheel rims for damage (punctures,

cuts, splits and bulges, etc.) on a regular basis.

Remove any foreign objects in the tyre tread immediately (e.g. small stones).

Foreign bodies which have penetrated into the tyre (e.g. screws or nails)

should not be removed and seek help from a specialist garage.

WARNINGNever drive with damaged tyres – risk of accident.

CAUTION

The tyres must be protected from contact with substances such as oil, grease

and fuel, which could damage them. If the tyres come into contact with these

substances, then we recommend you have this checked out in a specialist

workshop.

Unidirectional tyres

Read and observe

on page 217 first.

The direction of rotation of the tyres is marked by arrows on the wall of the

tyre .

The indicated direction of rotation must be adhered to in order to ensure the

optimal characteristics of these tyres.

These characteristics mainly relate to the following. ▶ Increased driving stability.

▶ Reduced risk of aquaplaning.

▶ Reduced tyre noise and tyre wear.

Spare wheel

Read and observe

on page 217 first.

A yellow warning label is always displayed on the rim of the temporary spare

wheel.

219Wheels

Page 229 of 276

The mounting points are located on the metal bar » Fig. 246.›

Insert the crank

6

into the mount on the jack

5

» page 223 .

›

Support the base plate of the jack with its full area resting on level ground

and ensure that the jack is located in a vertical position at the jacking point

» Fig. 247 -

.

›

Position the lifting jack below the jacking point with the crank and move it up

until its claw encloses the web » Fig. 247 -

.

›

Continue turning up the jack until the wheel is just about lifted off the

ground.

WARNING■ If the wheel has to be changed on a slope, first of all block the opposite

wheel with a stone or similar object to prevent the vehicle from unexpect-

edly rolling away.■

Secure the base plate of the lifting jack with suitable means to prevent

possible moving. A soft and slippery ground under the base plate may move

the lifting jack, causing the vehicle to fall down. It is therefore always nec-

essary to place the lifting jack on a solid surface or use a wide and stable

base. Use a non-slip base (e.g. a rubber foot mat) if the surface is smooth,

such as cobbled stones, tiled floor, etc.

■

Only attach the lifting jack to the attachment points provided for this pur-

pose.

■

Always raise the vehicle with the doors closed.

■

Never position any body parts, such as arms or legs under the vehicle,

while the vehicle is raised with a lifting jack.

■

When the vehicle is raised, never start the engine.

CAUTION

It is important to ensure that the jack is correctly attached to the web of the

lower fork leg - risk of damage to the vehicle.

Remove the wheel / fix

When changing a wheel, the following instructions must be followed.

›

Remove the full wheel trim or the caps of the wheel bolts.

›

First of all slacken the anti-theft wheel bolt and then the other wheel bolts.

›

Jack up the vehicle until the wheel that needs changing is clear of the

ground.

›

Unscrew the wheel bolts and place them on a clean surface (cloth, paper,

etc.).

› Remove the wheel carefully.›Attach the wheel and slightly screw on the wheel bolts.›

Lower the vehicle.

›

Tighten the wheel bolts opposite each other using the wheel wrench (alter-

nating crosswise). Tighten the anti-theft wheel bolt last.

›

Replace the wheel trim or the caps.

When fitting unidirectional tyres, ensure that the direction of rotation is cor-

rect » page 219 .

All bolts must be clean and must turn easily.

If it is established when changing a wheel that the wheel bolts are corroded and difficult to move, then these must be replaced.

Under no circumstances grease or oil the wheel bolts!

WARNINGUndo the wheel bolts only a little (about one turn) as long as the vehicle

has not yet been jacked up. Otherwise the wheel could become loose and

fall off.

Follow-up tasks

After changing the wheel, the following work must be carried out.

›

Stow the replaced wheel in the wheel well and secure it with a special screw.

›

Stow the tool kit in the space provided and secure using the band.

›

Check the tyre pressure on the installed wheel as soon as possible.

›

Have the tightening torque of the wheel bolts checked with a torque wrench

as soon as possible.

After changing the wheel, the tyre pressure should be adjusted. In vehicles

with tyre pressure monitoring, save tyre pressure values » page 183.

Replace the damaged wheel or consult a specialist garage about repair op-

tions.

The prescribed tightening torque of the wheel bolts is 140 Nm.

227Emergency equipment and self-help