gearbox SKODA YETI 2010 1.G / 5L Technical Change

[x] Cancel search | Manufacturer: SKODA, Model Year: 2010, Model line: YETI, Model: SKODA YETI 2010 1.G / 5LPages: 18, PDF Size: 0.88 MB

Page 9 of 18

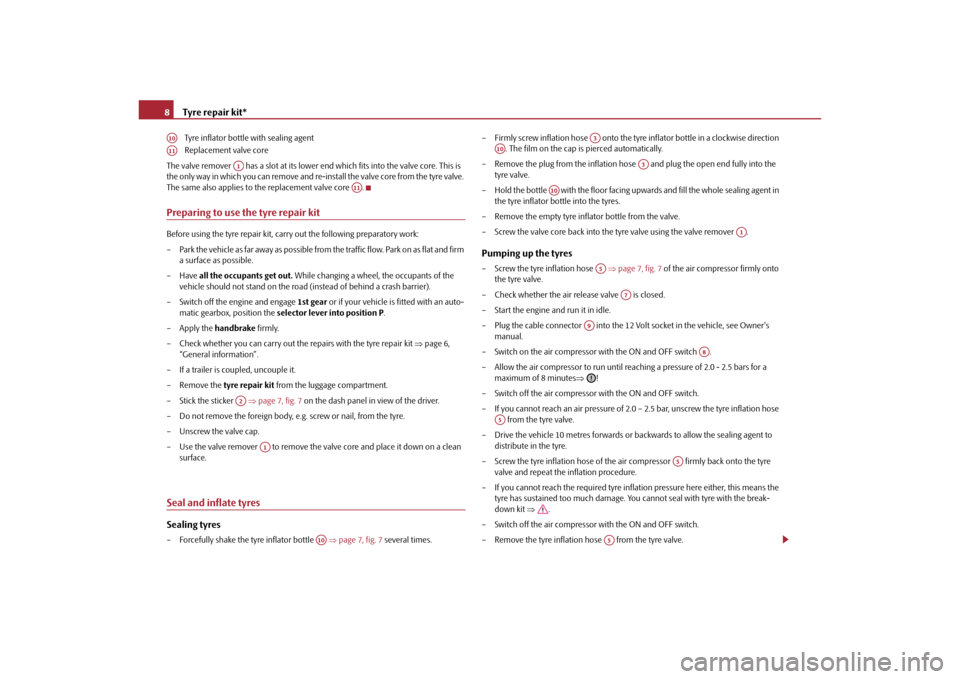

Tyre repair kit*

8 Tyre inflator bottle with sealing agent

Replacement valve core

The valve remover has a slot at its lower end which fits into the valve core. This is

the only way in which you can remove and re-i nstall the valve core from the tyre valve.

The same also applies to the replacement valve core .

Preparing to use the tyre repair kitBefore using the tyre repair kit, carry out the following preparatory work:

– Park the vehicle as far away as possible from the traffic flow. Park on as flat and firm a surface as possible.

–Have all the occupants get out. While changing a wheel, the occupants of the

vehicle should not stand on the road (instead of behind a crash barrier).

– Switch off the engine and engage 1st gear or if your vehicle is fitted with an auto-

matic gearbox, position the selector lever into position P .

– Apply the handbrake firmly.

– Check whether you can carry out the repairs with the tyre repair kit page 6,

“General information”.

– If a trailer is coupled, uncouple it.

– Remove the tyre repair kit from the luggage compartment.

– Stick the sticker page 7, fig. 7 on the dash panel in view of the driver.

– Do not remove the foreign body, e.g. screw or nail, from the tyre.

– Unscrew the valve cap.

– Use the valve remover to remove the va lve core and place it down on a clean

surface.Seal and inflate tyresSealing tyres– Forcefully shake the tyre inflator bottle page 7, fig. 7 several times. – Firmly screw inflation hose onto the tyre inflator bottle in a clockwise direction

. The film on the cap is pierced automatically.

– Remove the plug from the inflation hose and plug the open end fully into the tyre valve.

– Hold the bottle with the floor facing upwards and fill the whole sealing agent in the tyre inflator bottle into the tyres.

– Remove the empty tyre inflator bottle from the valve.

– Screw the valve core back into the tyre valve using the valve remover .

Pumping up the tyres– Screw the tyre inflation hose page 7, fig. 7 of the air compressor firmly onto

the tyre valve.

– Check whether the air re lease valve is closed.

– Start the engine and run it in idle.

– Plug the cable connector into the 12 Vo lt socket in the vehicle, see Owner's

manual.

– Switch on the air compressor with the ON and OFF switch .

– Allow the air compressor to run until reac hing a pressure of 2.0 - 2.5 bars for a

maximum of 8 minutes !

– Switch off the air compressor with the ON and OFF switch.

– If you cannot reach an air pressure of 2.0 – 2.5 bar, unscrew the tyre inflation hose from the tyre valve.

– Drive the vehicle 10 metres forwards or backwards to allow the sealing agent to

distribute in the tyre.

– Screw the tyre inflation hose of the air compressor firmly back onto the tyre

valve and repeat the inflation procedure.

– If you cannot reach the required tyre inflation pressure here either, this means the tyre has sustained too much damage. You cannot seal with tyre with the break-

down kit .

– Switch off the air compressor with the ON and OFF switch.

– Remove the tyre inflation hose from the tyre valve.

A10A11

A1

A11

A2

A1

A10

A3

A10

A3

A10

A1

A5

A7

A9

A8

A5

A5

A5

s35k.9.book Page 8 Thursday, September 16, 2010 10:24 AM