lock SKODA YETI 2010 1.G / 5L Technical Change

[x] Cancel search | Manufacturer: SKODA, Model Year: 2010, Model line: YETI, Model: SKODA YETI 2010 1.G / 5LPages: 18, PDF Size: 0.88 MB

Page 2 of 18

Introduction1

IntroductionThis supplement replaces the Owner's manual YETI Edition 05.10 referred to in the

following as the Owner's manual.

The information given in this supplement takes preference over the information in the

Owner's manual.

Special equipment is marked with the symbol *.

We wish you a good journey

Škoda Auto a.s.Fuel gaugeThe fuel tank has a capacity of about 55 litres or 60 litres

1).

Multi-functional indicator (onboard computer)*Multi-functional indicator (onboard comput er) is only available as a special equip-

ment item.Safelock

Note

When activating the Safelock function after you lock the vehicle, the message CHECK

SAFELOCK will appear in the display of the inst rument cluster. In vehicles equipped

with a MAXIDOT info display*, the message Check deadlock! Owner's manual!

(Observe SAFE locking! Car documentation!) appears.

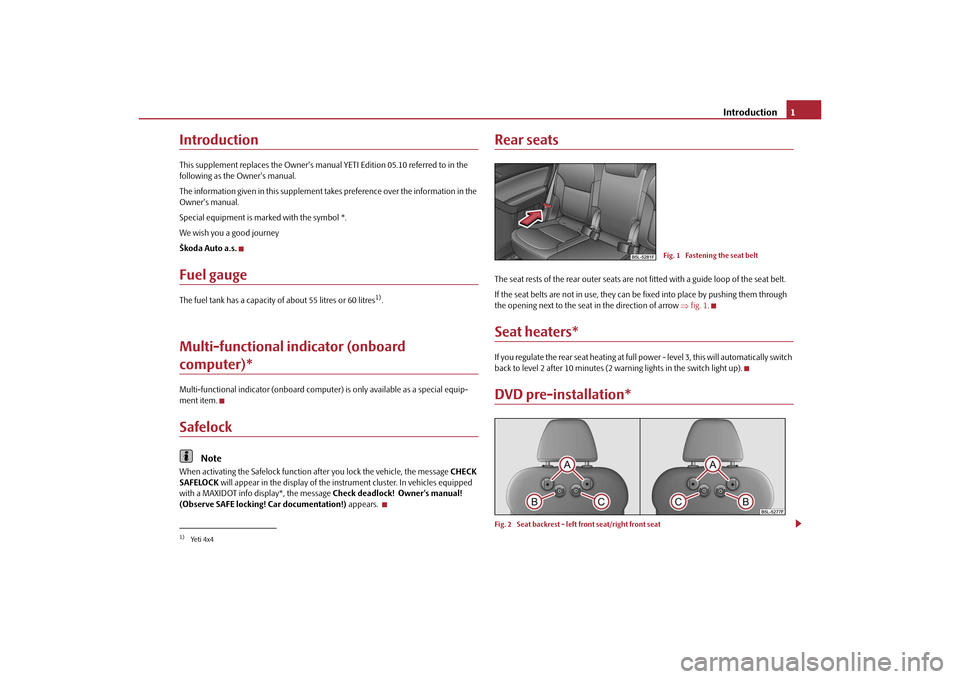

Rear seatsThe seat rests of the rear outer seats are not fitted with a guide loop of the seat belt.

If the seat belts are not in use, they can be fixed into place by pushing them through

the opening next to the seat in the direction of arrow fig. 1 .Seat heaters*If you regulate the rear seat heating at full power - level 3, this will automatically switch

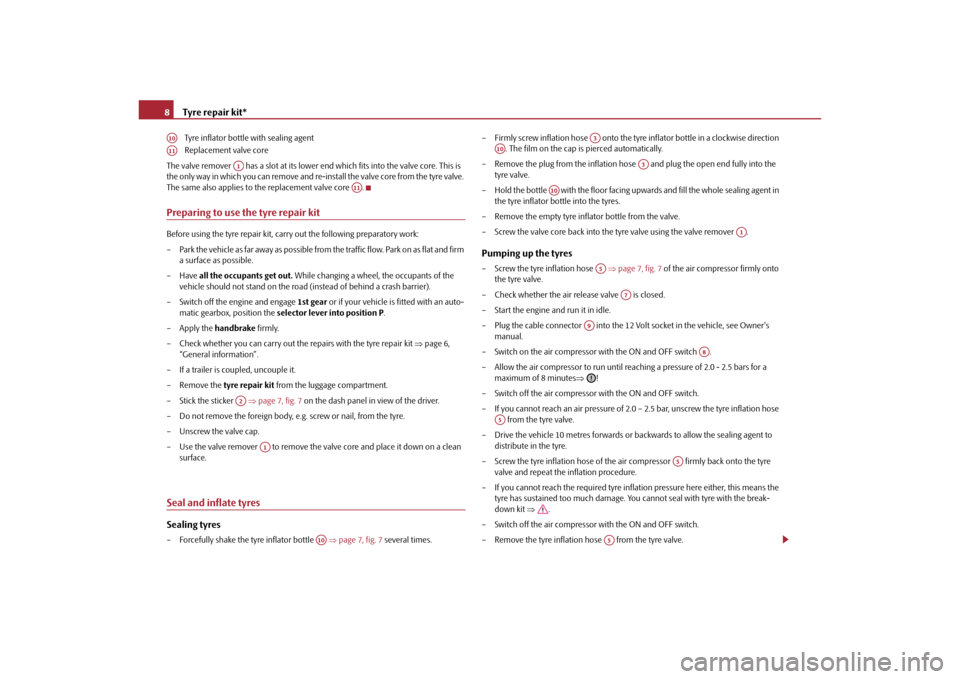

back to level 2 after 10 minutes (2 wa rning lights in the switch light up).DVD pre-installation*Fig. 2 Seat backrest - left front seat/right front seat

1)Ye t i 4 x 4

Fig. 1 Fastening the seat belt

s35k.9.book Page 1 Thursday, September 16, 2010 10:24 AM

Page 9 of 18

Tyre repair kit*

8 Tyre inflator bottle with sealing agent

Replacement valve core

The valve remover has a slot at its lower end which fits into the valve core. This is

the only way in which you can remove and re-i nstall the valve core from the tyre valve.

The same also applies to the replacement valve core .

Preparing to use the tyre repair kitBefore using the tyre repair kit, carry out the following preparatory work:

– Park the vehicle as far away as possible from the traffic flow. Park on as flat and firm a surface as possible.

–Have all the occupants get out. While changing a wheel, the occupants of the

vehicle should not stand on the road (instead of behind a crash barrier).

– Switch off the engine and engage 1st gear or if your vehicle is fitted with an auto-

matic gearbox, position the selector lever into position P .

– Apply the handbrake firmly.

– Check whether you can carry out the repairs with the tyre repair kit page 6,

“General information”.

– If a trailer is coupled, uncouple it.

– Remove the tyre repair kit from the luggage compartment.

– Stick the sticker page 7, fig. 7 on the dash panel in view of the driver.

– Do not remove the foreign body, e.g. screw or nail, from the tyre.

– Unscrew the valve cap.

– Use the valve remover to remove the va lve core and place it down on a clean

surface.Seal and inflate tyresSealing tyres– Forcefully shake the tyre inflator bottle page 7, fig. 7 several times. – Firmly screw inflation hose onto the tyre inflator bottle in a clockwise direction

. The film on the cap is pierced automatically.

– Remove the plug from the inflation hose and plug the open end fully into the tyre valve.

– Hold the bottle with the floor facing upwards and fill the whole sealing agent in the tyre inflator bottle into the tyres.

– Remove the empty tyre inflator bottle from the valve.

– Screw the valve core back into the tyre valve using the valve remover .

Pumping up the tyres– Screw the tyre inflation hose page 7, fig. 7 of the air compressor firmly onto

the tyre valve.

– Check whether the air re lease valve is closed.

– Start the engine and run it in idle.

– Plug the cable connector into the 12 Vo lt socket in the vehicle, see Owner's

manual.

– Switch on the air compressor with the ON and OFF switch .

– Allow the air compressor to run until reac hing a pressure of 2.0 - 2.5 bars for a

maximum of 8 minutes !

– Switch off the air compressor with the ON and OFF switch.

– If you cannot reach an air pressure of 2.0 – 2.5 bar, unscrew the tyre inflation hose from the tyre valve.

– Drive the vehicle 10 metres forwards or backwards to allow the sealing agent to

distribute in the tyre.

– Screw the tyre inflation hose of the air compressor firmly back onto the tyre

valve and repeat the inflation procedure.

– If you cannot reach the required tyre inflation pressure here either, this means the tyre has sustained too much damage. You cannot seal with tyre with the break-

down kit .

– Switch off the air compressor with the ON and OFF switch.

– Remove the tyre inflation hose from the tyre valve.

A10A11

A1

A11

A2

A1

A10

A3

A10

A3

A10

A1

A5

A7

A9

A8

A5

A5

A5

s35k.9.book Page 8 Thursday, September 16, 2010 10:24 AM