tire type SSANGYONG KORANDO 2012 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: KORANDO, Model: SSANGYONG KORANDO 2012Pages: 1082, PDF Size: 96.1 MB

Page 103 of 1082

01-70000-00

3) General Instructions

Before lifting up the vehicle with a lift, correctly support the lifting points.

When using a jack, park the vehicle on a level ground and place the wheel chocks under the tires.

Position the jack under the frame and lift up the vehicle and then support with chassis stand before

service work.

Make sure to disconnect the negative (-) cable from the battery to prevent any damage to electric

systems.

If you have to work on vehicle, cover the seats and floor with protection covers to avoid any

damage and contamination.

Brake fluid and anti-freeze can damage the painted surface of body. So carefully handle them

during service work.

To improve the efficiency of service work, use only recommended and specified tools.

Use only Ssangyong genuine spare parts.

Never reuse the cotter pin, gasket, O-ring, oil seal, lock washer and self-locking nut. Replace them

with new ones. If reused, normal functions cannot be maintained.

Store the disassembled parts as a set based on disassembly order and unit.

Pay particular attention not to miss or mix the fasteners.

If necessary, especially for inspection, clean the removed parts completely.

Apply the oil or grease on the running and sliding surfeces before installation. Use the specified

sealant and gasket to prevent leakage if necessary.

Tighten the fasteners with the specified tightening torque.

As a final stage of service work, check if the serviced system is working properly and the problem

has been eliminated clearly. (1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(10)

(11)

(12)

(13)

(14)

(15) Remove the engine and transaxle as a set.

Korando is FF (Front Engine Front Drive) type vehicle, and engine and powertrain system are

integrated into a module. Therefore, 2-post lift and general equipment are necessary when working

on the engine and transmission.

Major equipment: Engine and transmission jack, Engine stand, Engine crane, Transmission jack,

Engine hanger -

-

Page 331 of 1082

01-70000-00

3) General Instructions

Before lifting up the vehicle with a lift, correctly support the lifting points.

When using a jack, park the vehicle on a level ground and place the wheel chocks under the tires.

Position the jack under the frame and lift up the vehicle and then support with chassis stand before

service work.

Make sure to disconnect the negative (-) cable from the battery to prevent any damage to electric

systems.

If you have to work on vehicle, cover the seats and floor with protection covers to avoid any

damage and contamination.

Brake fluid and anti-freeze can damage the painted surface of body. So carefully handle them

during service work.

To improve the efficiency of service work, use only recommended and specified tools.

Use only Ssangyong genuine spare parts.

Never reuse the cotter pin, gasket, O-ring, oil seal, lock washer and self-locking nut. Replace them

with new ones. If reused, normal functions cannot be maintained.

Store the disassembled parts as a set based on disassembly order and unit.

Pay particular attention not to miss or mix the fasteners.

If necessary, especially for inspection, clean the removed parts completely.

Apply the oil or grease on the running and sliding surfeces before installation. Use the specified

sealant and gasket to prevent leakage if necessary.

Tighten the fasteners to the specified tightening torque.

As a final stage of service work, check if the serviced system is working properly and the problem

has been eliminated clearly. (1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(10)

(11)

(12)

(13)

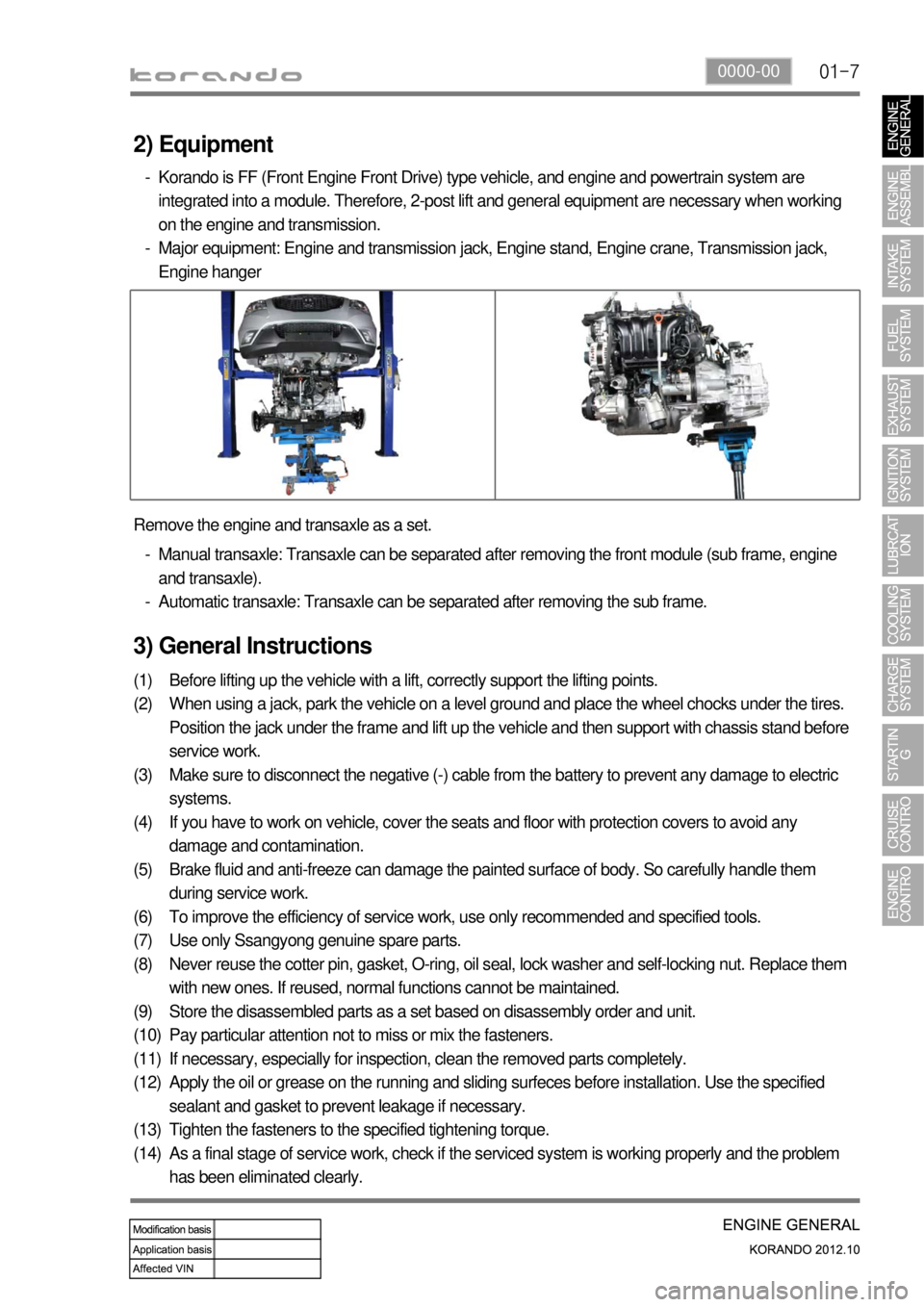

(14) Remove the engine and transaxle as a set.

Manual transaxle: Transaxle can be separated after removing the front module (sub frame, engine

and transaxle).

Automatic transaxle: Transaxle can be separated after removing the sub frame. -

-

2) Equipment

Korando is FF (Front Engine Front Drive) type vehicle, and engine and powertrain system are

integrated into a module. Therefore, 2-post lift and general equipment are necessary when working

on the engine and transmission.

Major equipment: Engine and transmission jack, Engine stand, Engine crane, Transmission jack,

Engine hanger -

-

Page 352 of 1082

02-6

3. GUIDELINES ON ENGINE SERVICE

G20DF engine is for FF (Front Engine Front Drive) type vehicle. Therefore, there are some deferent

maintenance and repair works compared to the engine for FR (Front Engine Rear Drive) type vehicle.

For safe and correct works, you must observe the working procedures and instructions in this manual.

And, use the designated tools as follow:

: Power train mounting stand / Engine hanger / Engine stand / Heavy duty engine jack.

Cautions before service works ▶

G20DF engine is FF (Front Engine Front Drive) type engine, and the engine and transmission are

integrated in a same module. Remember that there are many differences compared to

conventional engine in FR (Front Engine Rear Drive) type SUV vehicle.

To remove the engine, use the dedicated equipments such as engine jack, transmission jack,

engine stand and engine crane (1 ton).

To prevent the engine from abruptly starting during service in engine compartment, never allow

anybody to stay in the vehicle.

Make sure to disconnect the negative (-) cable from the battery to prevent any damage to electric

systems.

Make sure to clean the working area and to prepare the necessary tools before service works.

Always place the ignition switch to OFF position if not required. Otherwise, there could be

unexpected damage to electric devices or personal injuries due to short-circuit..

To prevent the foreign material from entering into the fuel injection system, completely seal the

inlets of HP pump, fuel hoses and high pressure pipes.

Do not remove the engine while supporting the oil pan with a jack. -

-

-

-

-

-

-

Lifting up the vehicle ▶

Before lifting up the vehicle with a lift, correctly support the lifting points.

To prevent the vehicle from rolling down, put the chocks under the tires (when using a 4-post lift).

Make sure to support the correct lifting points (when using a 2-post lift). -

-

-

Page 824 of 1082

01-14

Stabilizer bar assembly

The stabilizer bar assembly is not activated if the left/right

wheels move up/down simultaneously, but if both wheels

move up/down differently it is activated with frame to

minimize the tilting of the body.

5. FRONT SUSPENSION COMPONENT LAYOUT

Front suspension supports the vehicle weight and absorber the vibration from tires. And, in this type of

suspension, the steering linkage tie rod is mounted on the knuckle. The Macpherson Strut suspension

is an independent suspension which has a spring on the strut with a built-in shock absorber. The lower

arm is installed on sub frame and large strut damper is installed on the knuckle to support the tire.

Lower arm assembly

The lower arm assembly connects the frame and

knuckle. It supports the load transferred to the tire

knuckle, relieves the impact from the vehicle and ground

conditions, and ensures driving stability.

Stabilizer bar

Bushing

Clamp

Link

Page 833 of 1082

01-230000-00

3) General Instructions

Before lifting up the vehicle with a lift, correctly support the lifting points.

When using a jack, park the vehicle on a level ground and place the wheel chocks under the tires.

Position the jack under the frame and lift up the vehicle and then support with chassis stand before

service work.

Make sure to disconnect the negative (-) cable from the battery to prevent any damage to electric

systems.

If you have to work on vehicle, cover the seats and floor with protection covers to avoid any

damage and contamination.

Brake fluid and anti-freeze can damage the painted surface of body. So carefully handle them

during service work.

To improve the efficiency of service work, use only recommended and specified tools.

Use only Ssangyong genuine spare parts.

Never reuse the cotter pin, gasket, O-ring, oil seal, lock washer and self-locking nut. Replace them

with new ones. If reused, normal functions cannot be maintained.

Store the disassembled parts as a set based on disassembly order and unit.

Pay particular attention not to miss or mix the fasteners.

If necessary, especially for inspection, clean the removed parts completely.

Apply the oil or grease on the running and sliding surfeces before installation. Use the specified

sealant and gasket to prevent leakage if necessary.

Tighten the fasteners to the specified tightening torque.

As a final stage of service work, check if the serviced system is working properly and the problem

has been eliminated clearly. (1)

(2)

(3)

(4)

(5)

(6)

(7)

(8)

(9)

(10)

(11)

(12)

(13)

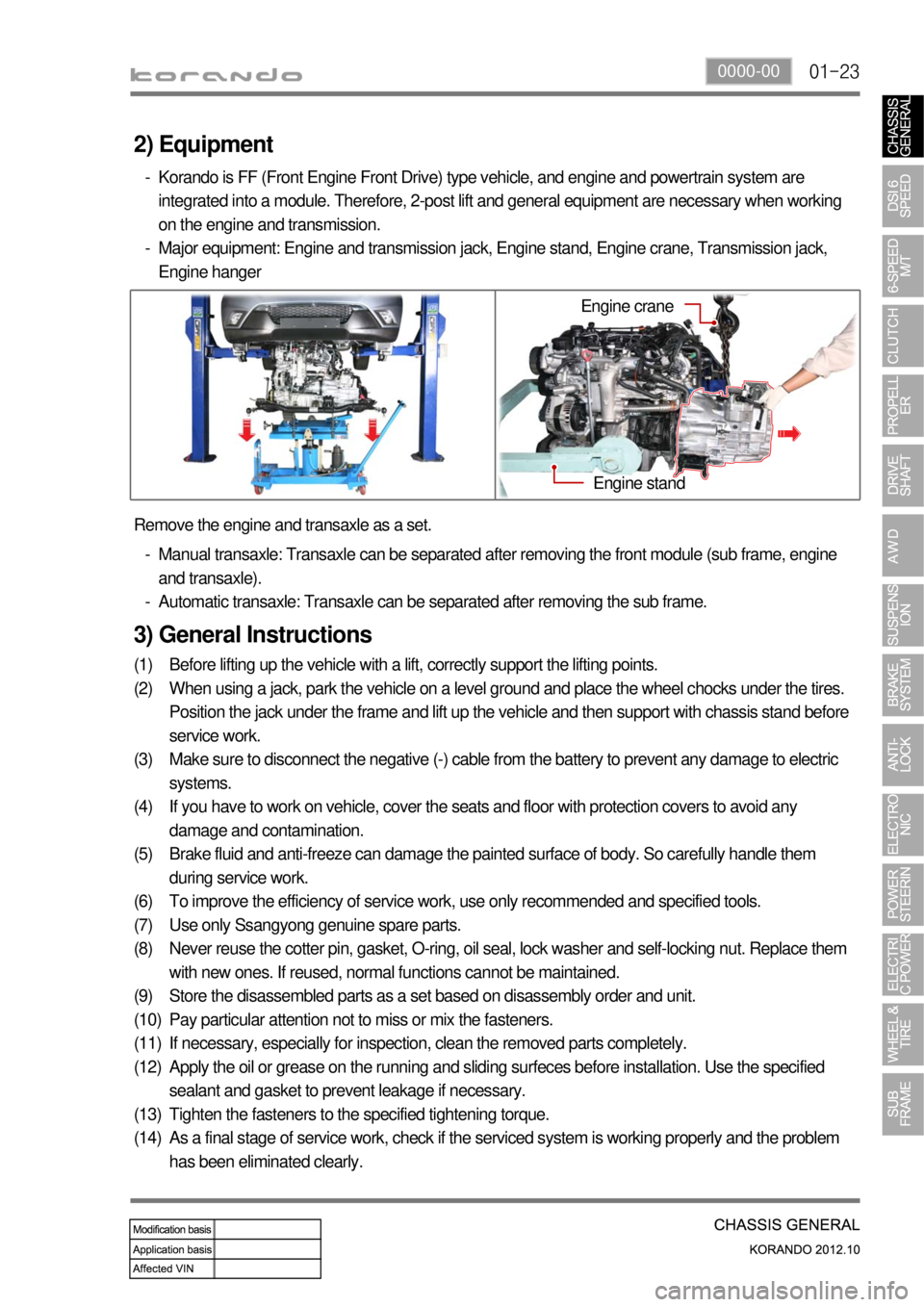

(14) Remove the engine and transaxle as a set.

Manual transaxle: Transaxle can be separated after removing the front module (sub frame, engine

and transaxle).

Automatic transaxle: Transaxle can be separated after removing the sub frame. -

-

2) Equipment

Korando is FF (Front Engine Front Drive) type vehicle, and engine and powertrain system are

integrated into a module. Therefore, 2-post lift and general equipment are necessary when working

on the engine and transmission.

Major equipment: Engine and transmission jack, Engine stand, Engine crane, Transmission jack,

Engine hanger -

-

Engine stand

Engine crane

Page 921 of 1082

08-8

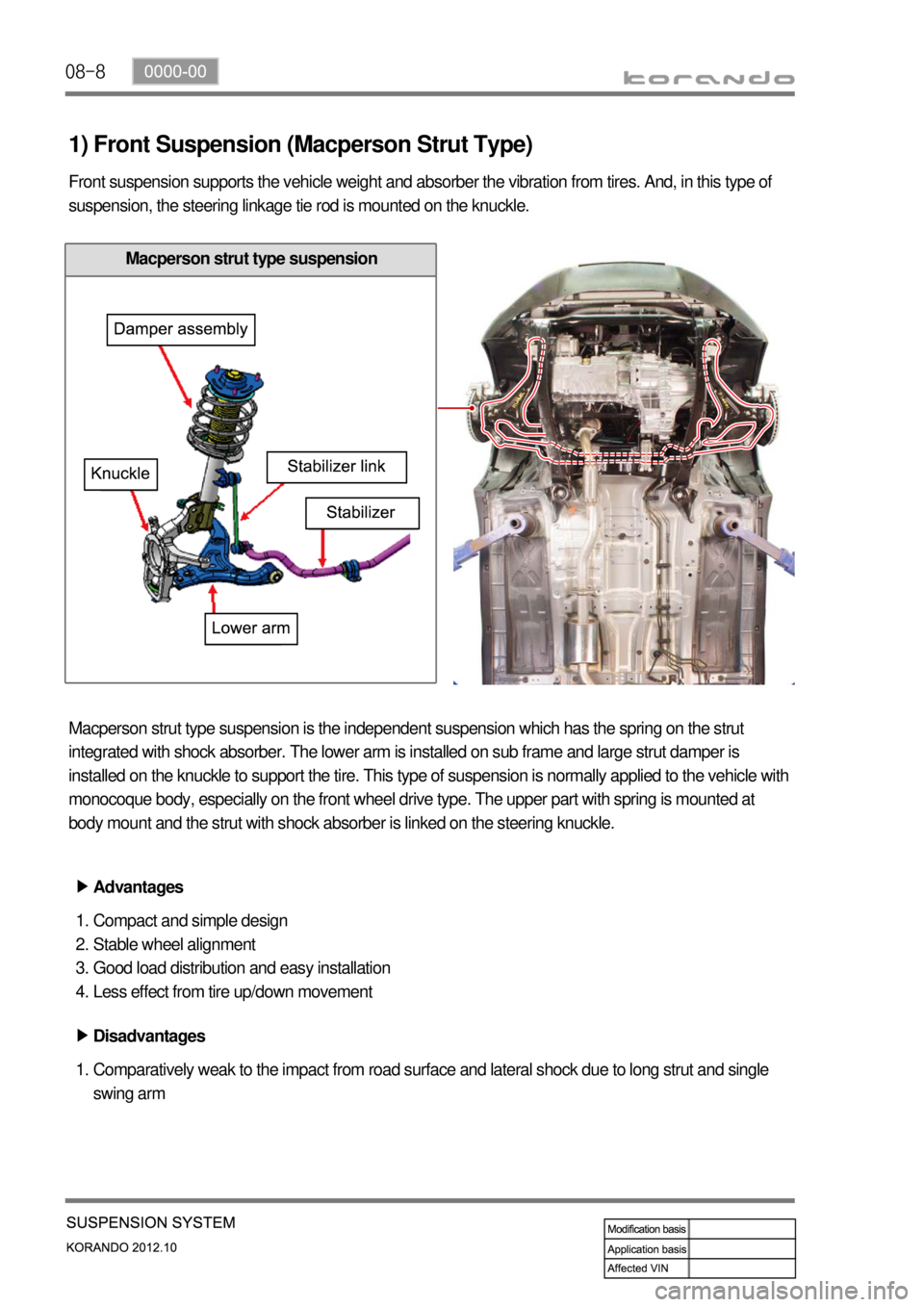

1) Front Suspension (Macperson Strut Type)

Front suspension supports the vehicle weight and absorber the vibration from tires. And, in this type of

suspension, the steering linkage tie rod is mounted on the knuckle.

Macperson strut type suspension is the independent suspension which has the spring on the strut

integrated with shock absorber. The lower arm is installed on sub frame and large strut damper is

installed on the knuckle to support the tire. This type of suspension is normally applied to the vehicle with

monocoque body, especially on the front wheel drive type. The upper part with spring is mounted at

body mount and the strut with shock absorber is linked on the steering knuckle.

Advantages ▶

Compact and simple design

Stable wheel alignment

Good load distribution and easy installation

Less effect from tire up/down movement 1.

2.

3.

4.

Disadvantages ▶

Comparatively weak to the impact from road surface and lateral shock due to long strut and single

swing arm 1.

Macperson strut type suspension

Page 991 of 1082

14-34170-00

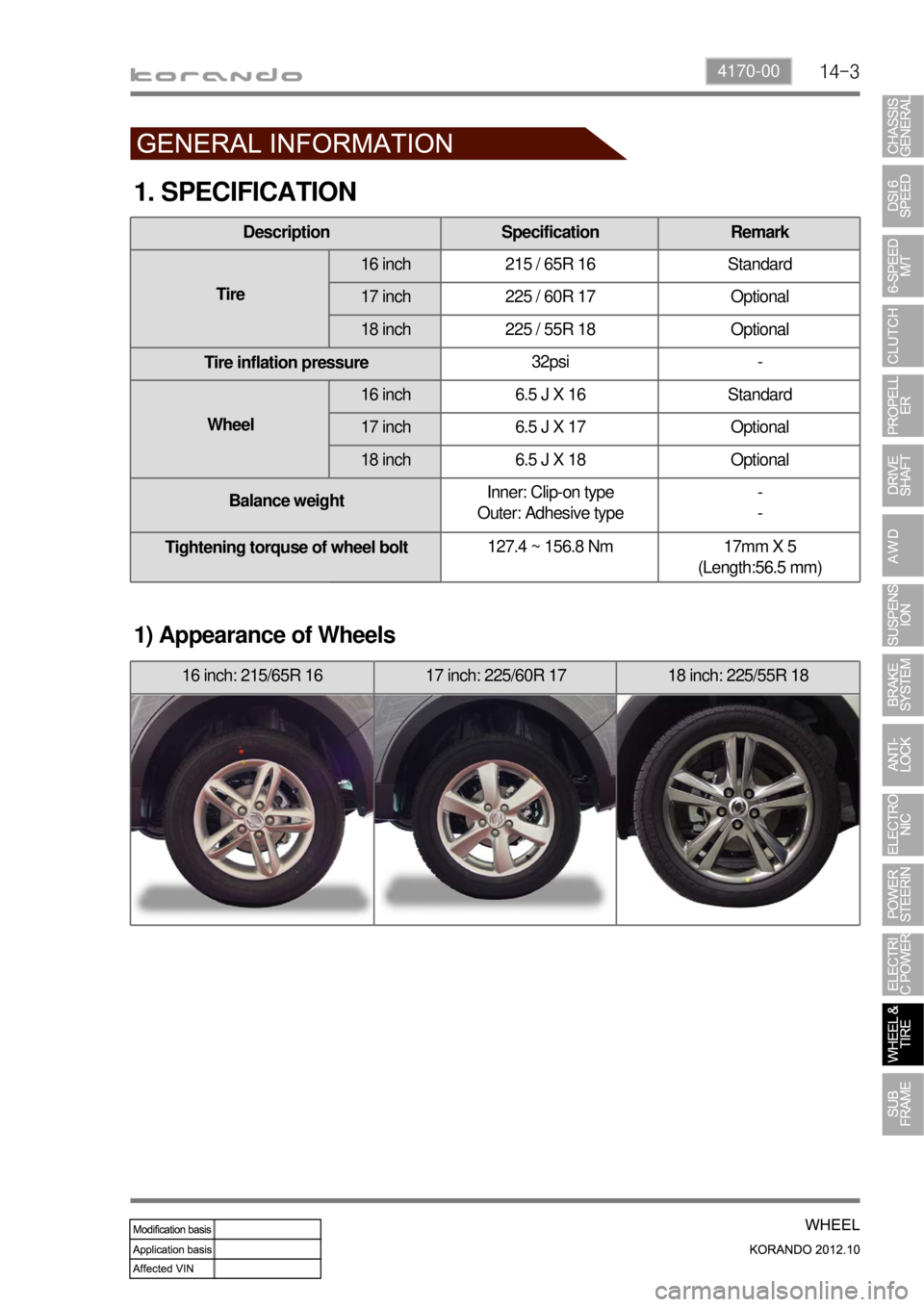

1. SPECIFICATION

1) Appearance of Wheels

16 inch: 215/65R 16 17 inch: 225/60R 17 18 inch: 225/55R 18

Description Specification Remark

Tire16 inch 215 / 65R 16 Standard

17 inch 225 / 60R 17 Optional

18 inch 225 / 55R 18 Optional

Tire inflation pressure32psi -

Wheel16 inch 6.5 J X 16 Standard

17 inch 6.5 J X 17 Optional

18 inch 6.5 J X 18 Optional

Balance weightInner: Clip-on type

Outer: Adhesive type-

-

Tightening torquse of wheel bolt127.4 ~ 156.8 Nm 17mm X 5

(Length:56.5 mm)

Page 992 of 1082

14-4

1. OVERVIEW

A radial tire uses a cord angle of 90 degrees. That is, the cord material runs in a radial or direct line from

one bead to the other across the tread. In addition, a radial tire has a belt overwrap under the tread

surface to provide greater structural stability. The belt overwrap of a radial tire distortion while the radial

structure enables high speed driving.

Tire supports the weight of the vehicle, reduces the impact from the road and at the same time,

transmits the power to propel, brake and steer on the road. It also functions to maintain a

<009d008c008f0090008a0093008c02c5009a004700940096009d008c0094008c0095009b0055004700700095004700960099008b008c00990047009b00960047008a0096009400970093008c009b008c0047009a009c008a008f0047009b0088009a009200

9a0053004700880047009b00900099008c00470094009c009a>t be structured to be a resilient

vessel of air.

There is wear limit mark on the tire, which protrudes as a strip shape located approximately 1.6 mm from

<009b008f008c0047008e009900960096009d008c004700890096009b009b0096009400550047007b008f0090009a0047009e008c0088009900470093009000940090009b0047009400880099009200470090009a004700950096009b0047009a008c008c00

950047008d0099009600940047009b008f008c00470096009c>tside so there is additional "▲"

mark on the shoulder to let the driver find the wear mark easily. To measure the tire groove depth,

measure at any point other than the point which has a wear limit mark.

The tire is worn unevenly according to the driver's driving habit, improper servicing, low tire inflation

pressure, changed tire location, etc.

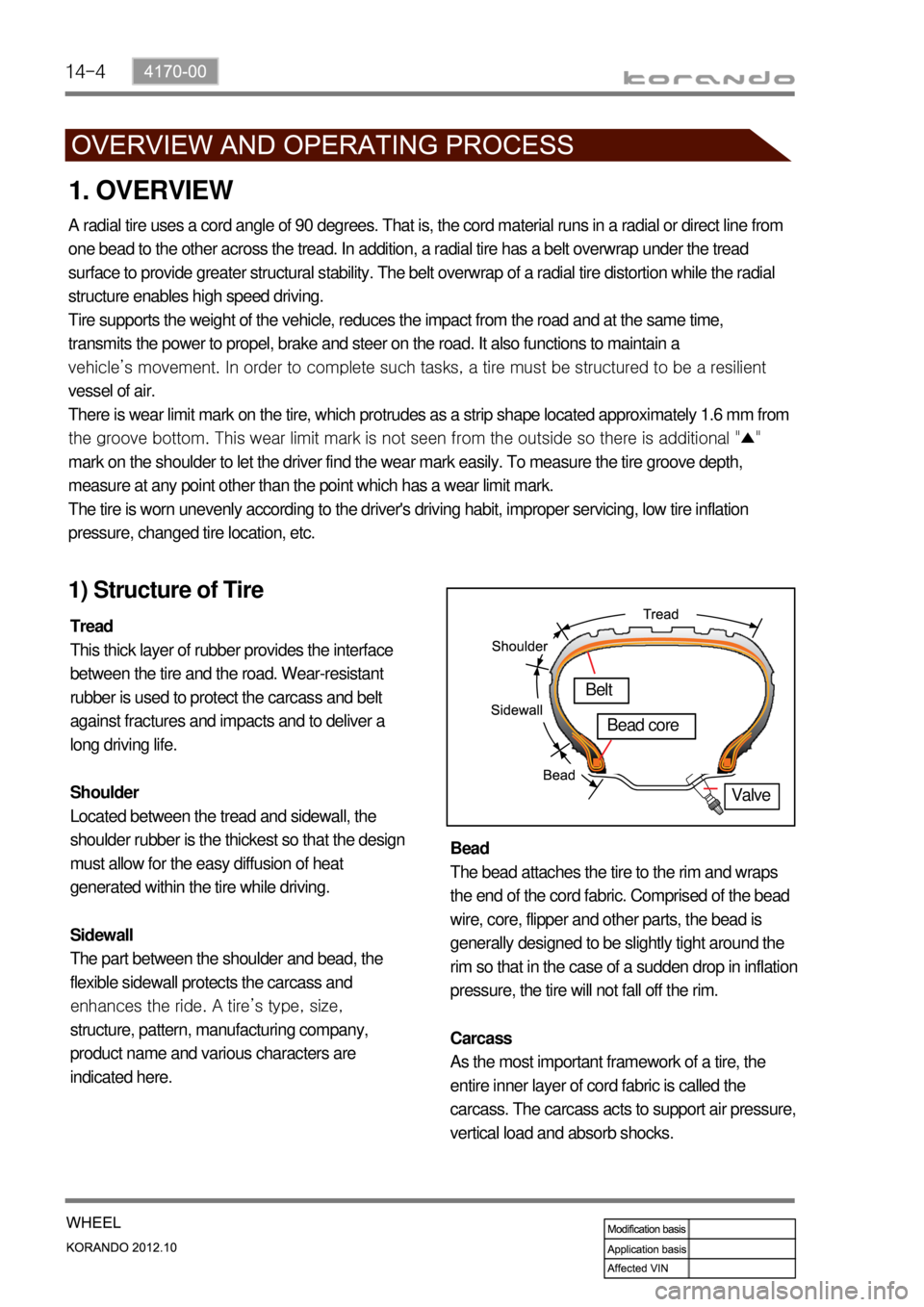

1) Structure of Tire

Tread

This thick layer of rubber provides the interface

between the tire and the road. Wear-resistant

rubber is used to protect the carcass and belt

against fractures and impacts and to deliver a

long driving life.

Shoulder

Located between the tread and sidewall, the

shoulder rubber is the thickest so that the design

must allow for the easy diffusion of heat

generated within the tire while driving.

Sidewall

The part between the shoulder and bead, the

flexible sidewall protects the carcass and

enhances the ride. A tire’s type, size,

structure, pattern, manufacturing company,

product name and various characters are

indicated here. Bead

The bead attaches the tire to the rim and wraps

the end of the cord fabric. Comprised of the bead

wire, core, flipper and other parts, the bead is

generally designed to be slightly tight around the

rim so that in the case of a sudden drop in inflation

pressure, the tire will not fall off the rim.

Carcass

As the most important framework of a tire, the

entire inner layer of cord fabric is called the

carcass. The carcass acts to support air pressure,

vertical load and absorb shocks.

Valve

Belt

Bead core

Page 996 of 1082

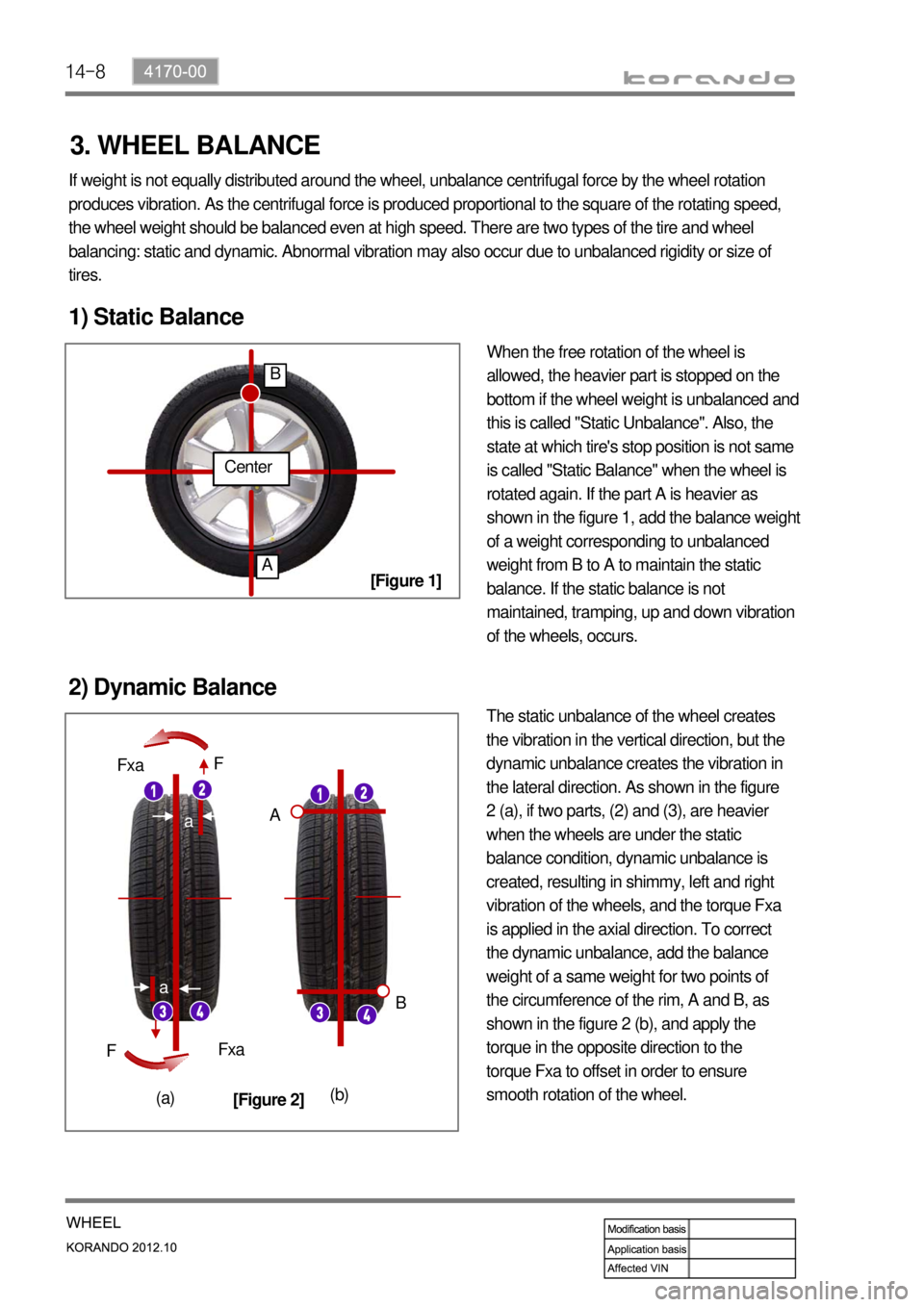

14-8

If weight is not equally distributed around the wheel, unbalance centrifugal force by the wheel rotation

produces vibration. As the centrifugal force is produced proportional to the square of the rotating speed,

the wheel weight should be balanced even at high speed. There are two types of the tire and wheel

balancing: static and dynamic. Abnormal vibration may also occur due to unbalanced rigidity or size of

tires.

1) Static Balance

When the free rotation of the wheel is

allowed, the heavier part is stopped on the

bottom if the wheel weight is unbalanced and

this is called "Static Unbalance". Also, the

state at which tire's stop position is not same

is called "Static Balance" when the wheel is

rotated again. If the part A is heavier as

shown in the figure 1, add the balance weight

of a weight corresponding to unbalanced

weight from B to A to maintain the static

balance. If the static balance is not

maintained, tramping, up and down vibration

of the wheels, occurs.

2) Dynamic Balance

The static unbalance of the wheel creates

the vibration in the vertical direction, but the

dynamic unbalance creates the vibration in

the lateral direction. As shown in the figure

2 (a), if two parts, (2) and (3), are heavier

when the wheels are under the static

balance condition, dynamic unbalance is

created, resulting in shimmy, left and right

vibration of the wheels, and the torque Fxa

is applied in the axial direction. To correct

the dynamic unbalance, add the balance

weight of a same weight for two points of

the circumference of the rim, A and B, as

shown in the figure 2 (b), and apply the

torque in the opposite direction to the

torque Fxa to offset in order to ensure

smooth rotation of the wheel.

Center

A

B

a

a

Fxa

Fxa F

F

A

B

(a)(b)

[Figure 1]

[Figure 2]

3. WHEEL BALANCE