timing SSANGYONG KORANDO 2013 User Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2013, Model line: KORANDO, Model: SSANGYONG KORANDO 2013Pages: 1336, PDF Size: 92.18 MB

Page 436 of 1336

1116-01

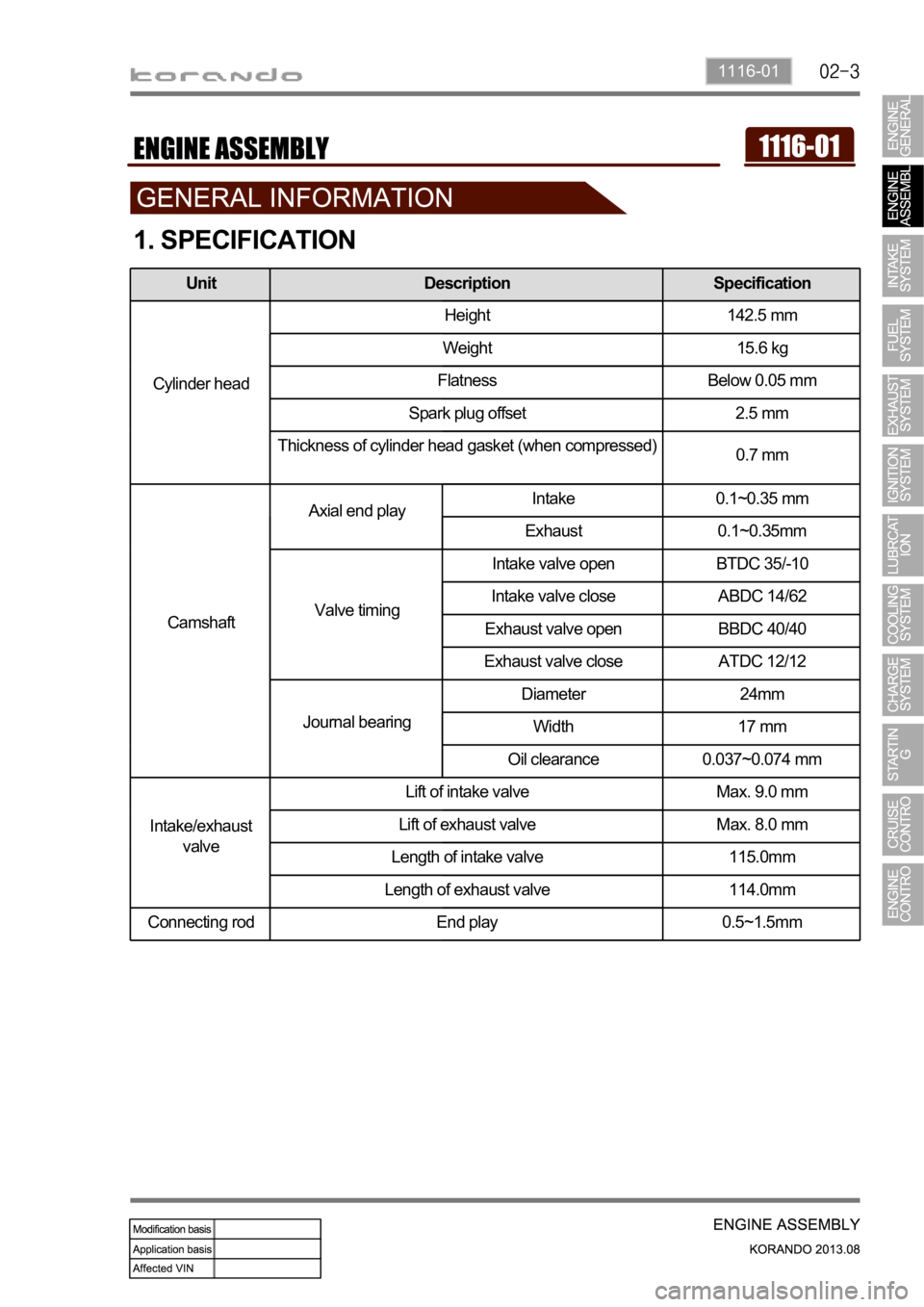

1. SPECIFICATION

Unit Description Specification

Cylinder headHeight 142.5 mm

Weight 15.6 kg

Flatness Below 0.05 mm

Spark plug offset 2.5 mm

Thickness of cylinder head gasket (when compressed)

0.7 mm

CamshaftAxial end playIntake 0.1~0.35 mm

Exhaust 0.1~0.35mm

Valve timingIntake valve open BTDC 35/-10

Intake valve close ABDC 14/62

Exhaust valve open BBDC 40/40

Exhaust valve close ATDC 12/12

Journal bearingDiameter 24mm

Width 17 mm

Oil clearance 0.037~0.074 mm

Intake/exhaust

valveLift of intake valve Max. 9.0 mm

Lift of exhaust valve Max. 8.0 mm

Length of intake valve 115.0mm

Length of exhaust valve 114.0mm

Connecting rod End play 0.5~1.5mm

Page 444 of 1336

1337-04

3) Crankshaft Pulley (CRS)

The strut type tensioner automatically adjusts the belt tension to provide the reliability and durability for

the system. And, the belt tension is decreased to minimize the friction loss and improve the belt

operating noise.Overview

Location

Crankshaft pulley (CRS)

Timing mark

Page 451 of 1336

3) Camshaft Assembly

Overview

The camshaft is hollow type, and contains the cam, octagon cam, OCV gallery, cam position rotor. The

camshaft operates the intake and exhaust valves.

Location

Exhaust camshaft

Intake camshaft

Timing marks

Align the timing marks (A) on the camshaft

flange and camshaft cap when installing the

intake/exhaust camshaft.

Page 454 of 1336

1311-01

The drive chain is single chain drive system with simple design and variable performance, and it utilizes

the hydraulic tensioner to reduce the wave impact generated by the chain. The silent chain provides the

silence during the operation. To improve NVH, the shoulder bolt has been introduced. Overview

Layout and Components

Hydraulic tensioner

Consists of tensioner housing

plug, spring, check valve, and

operated by hydraulic

pressure and spring in

tensioner

Timing chain

Chain type: Silent chain type

Links: 146 ea

Tensioner rail

Installed between exjaust

camshaft sprocket and

crankshaft sprocket

Crankshaft sprocket

Teeth: 21 ea

Oil pump sprocket

Teeth: 28 ea

Exhaust camshaft

sprocket

Teeth:42 eaIntake camshaft

sprocket

CVVT

Teeth: 42 ea

OCV

Controls the hydraulic circuit

to control the intake cam

sprocket variably

Clamping rail

Installed between intake

camshaft sprocket and

crankshaft sprocket

Mechanical tensioner

Operated by spring in

tensioner

Oil pump chain

Chain type: Silent chain type

Links: 58 ea

Page 455 of 1336

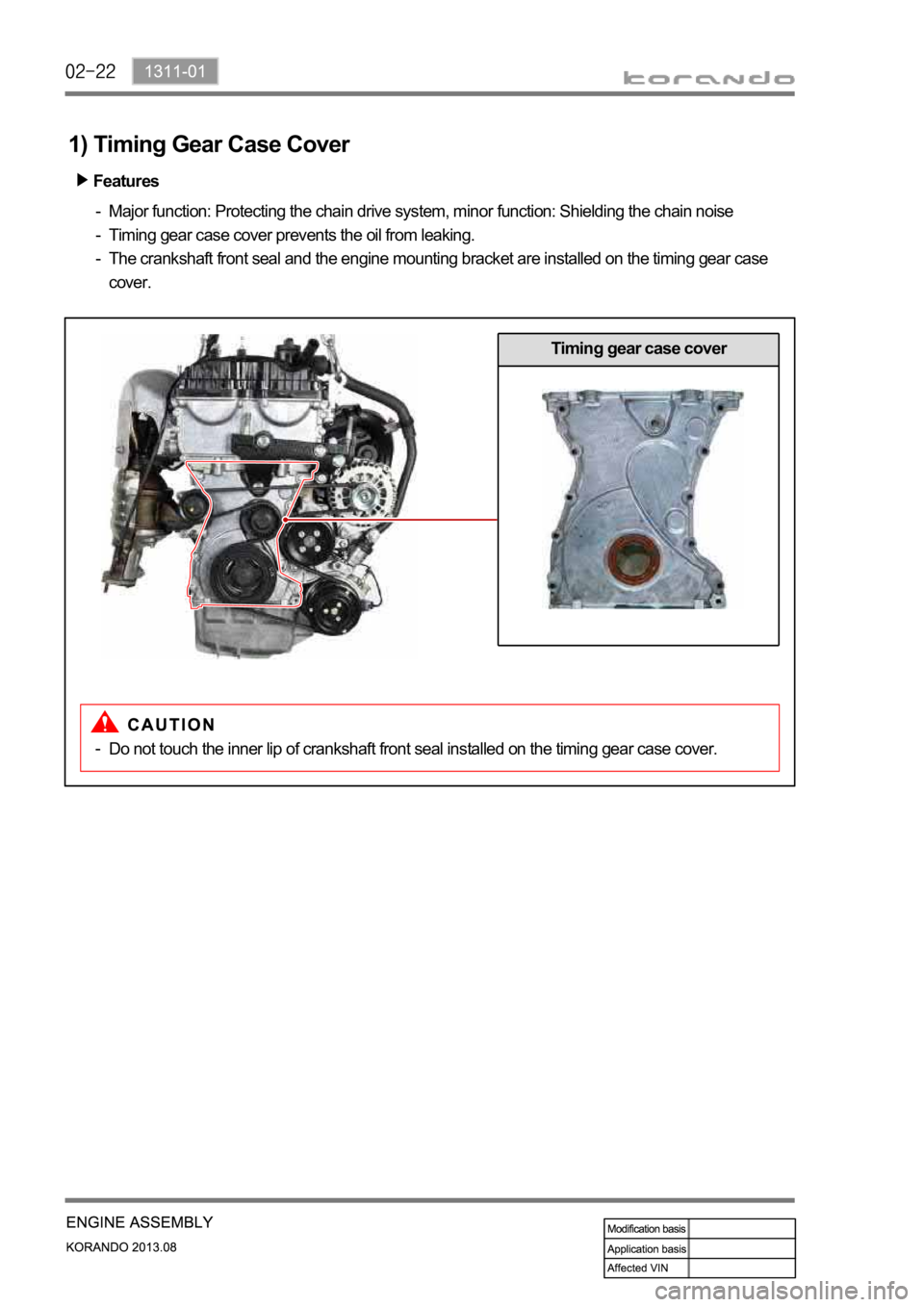

1) Timing Gear Case Cover

Features

Major function: Protecting the chain drive system, minor function: Shielding the chain noise

Timing gear case cover prevents the oil from leaking.

The crankshaft front seal and the engine mounting bracket are installed on the timing gear case

cover. -

-

-

Timing gear case cover

Do not touch the inner lip of crankshaft front seal installed on the timing gear case cover. -

Page 458 of 1336

1311-01

A. Timing chain

B. Oil pump chain

4) Timing Chain and Gear

Timing chain

Simple layout provides the optimized timing.

Decreased chain vibration and noise

Single stage layout: minimized chain load -

-

- Teeth: 146 ea

Teeth: 58 ea

Page 500 of 1336

1443-01

1. OVERVIEW

The ignition system is to supply high voltage generated from the ignition coil to the spark plug. The

G20DF engine is equipped with the independent type direct ignition system that the ignition coil is

installed in each cylinder.

The basic ignition timing in each cylinder is determined by the signals from camshaft position sensor and

crankshaft position sensor.

This ignition system controls the electronic ignition timing received from the engine ECU. To control the

ignition timing precisely, the ECU use the information below:

Engine load

Coolant temperature

Intake air temperature

Engine rpm

Camshaft position sensor (CPS)

Crankshaft position sensor (CKS) -

-

-

-

-

-

If the signal from the camshaft position sensor is not delivered to the engine ECU, the ignition coil and

fuel system cannot be operated.

Page 563 of 1336

1490-00

3. ECU CONTROL

1) Functions

ECU receives and analyzes signals from various sensors and then modifies those signals into

permissible voltage levels and analyzes to control respective actuators.

ECU microprocessor calculates injection period and injection timing proper for engine piston speed and

crankshaft angle based on input data and stored specific map to control the engine power and emission

gas.

Output signal of the ECU microprocessor activates the injector solenoid valve to control the fuel injection

period and injection timing; so controls various actuators in response to engine changes.

Auxiliary function of ECU has adopted to reduce emission gas, improve fuel economy and enhance

safety, comforts and conveniences. For example, there are autocruise and immobilizer and adopted

CAN communication to exchange data among electrical systems (automatic T/M and brake system) in

the vehicle fluently. And the diagnostic tool can be used to diagnose vehicle status and defectives.

water and electromagnetism and there should be no mechanical shocks.

2) Control Functions

Controls by operating stages:

To make optimum combustion under every operating stage, ECU should calculate proper injection

volume in each stage by considering various factors.

Starting injection volume control:

During initial starting, injecting fuel volume will be calculated by function of temperature and engine

cranking speed. Starting injection continues from when the ignition switch is turned to ignition

position to till the engine reaches to allowable minimum speed.

Driving mode control:

If the vehicle runs normally, fuel injection volume will be calculated by accelerator pedal travel and

engine rpm and the drive map will be used to match the drivers inputs with optimum engine power. -

-

-

Page 564 of 1336

3) Injection Volume Control

(1) Overview

To keep the best engine conditions and to reduce the emission gas, ECU determines the injection

volume and timing.

(2) Components

Input Components

Accelerator pedal

position sensorFront oxygen

sensorCoolant temperature

sensorCrankshaft position

sensor

Camshaft position

sensorKnock sensorT-MAP sensorElectronic throttle

body

Output Components

Page 569 of 1336

0000-00

(4) Features

Determines the ignition timing according to input signal

The ECU always analyzes the following elements when determining the ignition timing. 1.

Crankshaft position sensor

Camshaft position sensor

Coolant temperature sensor

Intake air temperature/air mass -

-

-

-

Warm-up of catalytic converter

The ignition timing is retarded for about 20 seconds to operate the catalytic converter according to the

operating temperature under the following conditions: 2.

The idle speed is increased by the idle speed control to help warming up of the catalytic converter -

-

Idle speed control

The ignition timing control can be performed faster than the control through the throttle valve.

Fuel cut-off in deceleration

The ignition timing is retarded temporarily to prevent abrupt increase of the torque when the

combustion is restarted.

Intake air temperature/coolant temperature

The ignition timing is retarded to prevent knocking if the intake air temperature or coolant temperature

is high. The ignition timing is retarded in the following cases. 3.

4.

5.

-

-

The ignition timing retard for intake air temperature and for coolant temperature is added up for

correction.

ESP/ASR control mode

The ignition timing is retarded to reduce engine torque as fast as possible under the ESP/ASR

control mode.

Knocking control

If knocking occurs in the cylinder, the ignition angle of the corresponding cylinder is retarded. The

6.

7.