brake SSANGYONG KORANDO 2013 Manual PDF

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2013, Model line: KORANDO, Model: SSANGYONG KORANDO 2013Pages: 1336, PDF Size: 92.18 MB

Page 1111 of 1336

4890-00

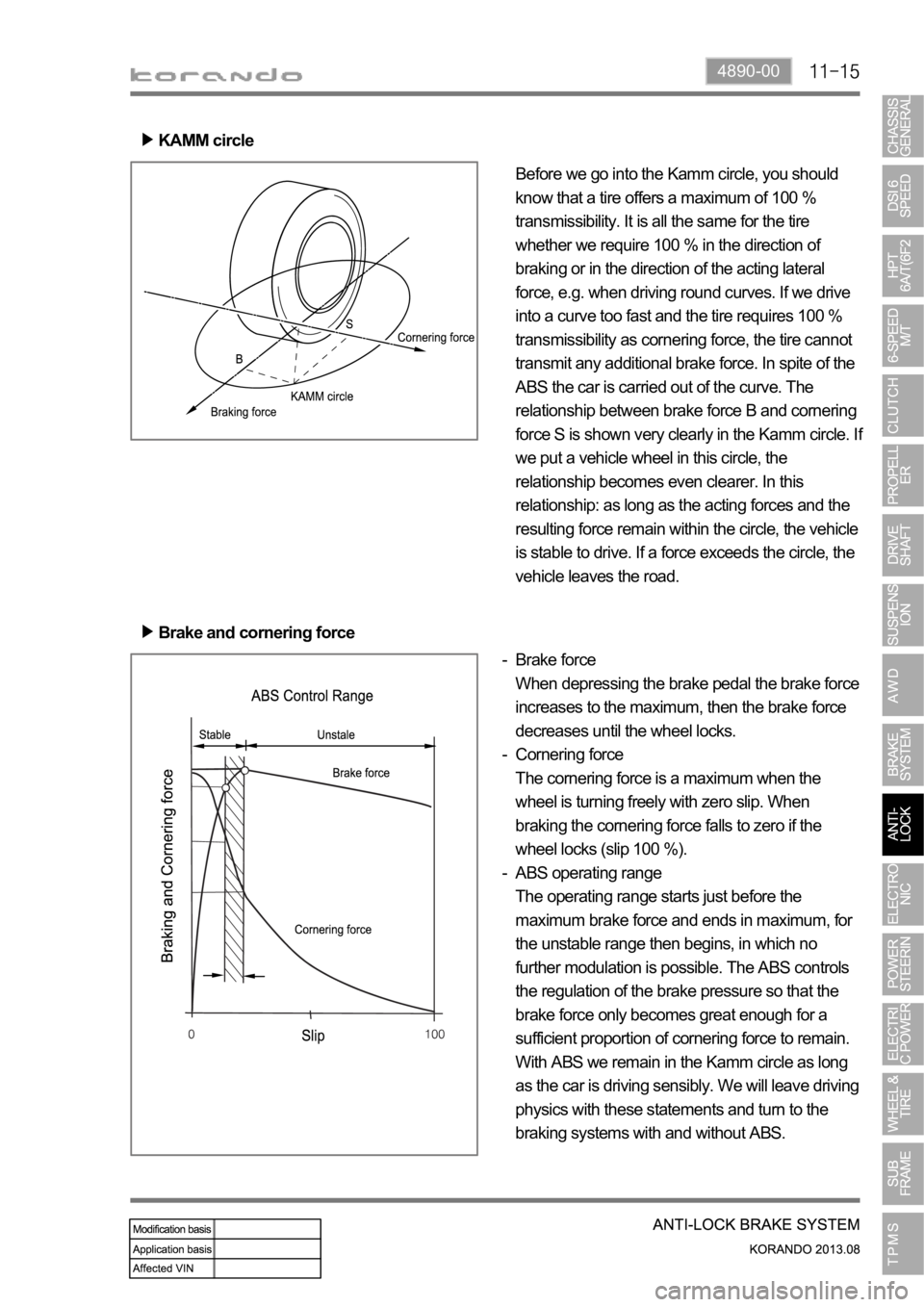

KAMM circle

Before we go into the Kamm circle, you should

know that a tire offers a maximum of 100 %

transmissibility. It is all the same for the tire

whether we require 100 % in the direction of

braking or in the direction of the acting lateral

force, e.g. when driving round curves. If we drive

into a curve too fast and the tire requires 100 %

transmissibility as cornering force, the tire cannot

transmit any additional brake force. In spite of the

ABS the car is carried out of the curve. The

relationship between brake force B and cornering

force S is shown very clearly in the Kamm circle. I

f

we put a vehicle wheel in this circle, the

relationship becomes even clearer. In this

relationship: as long as the acting forces and the

resulting force remain within the circle, the vehicle

is stable to drive. If a force exceeds the circle, the

vehicle leaves the road.

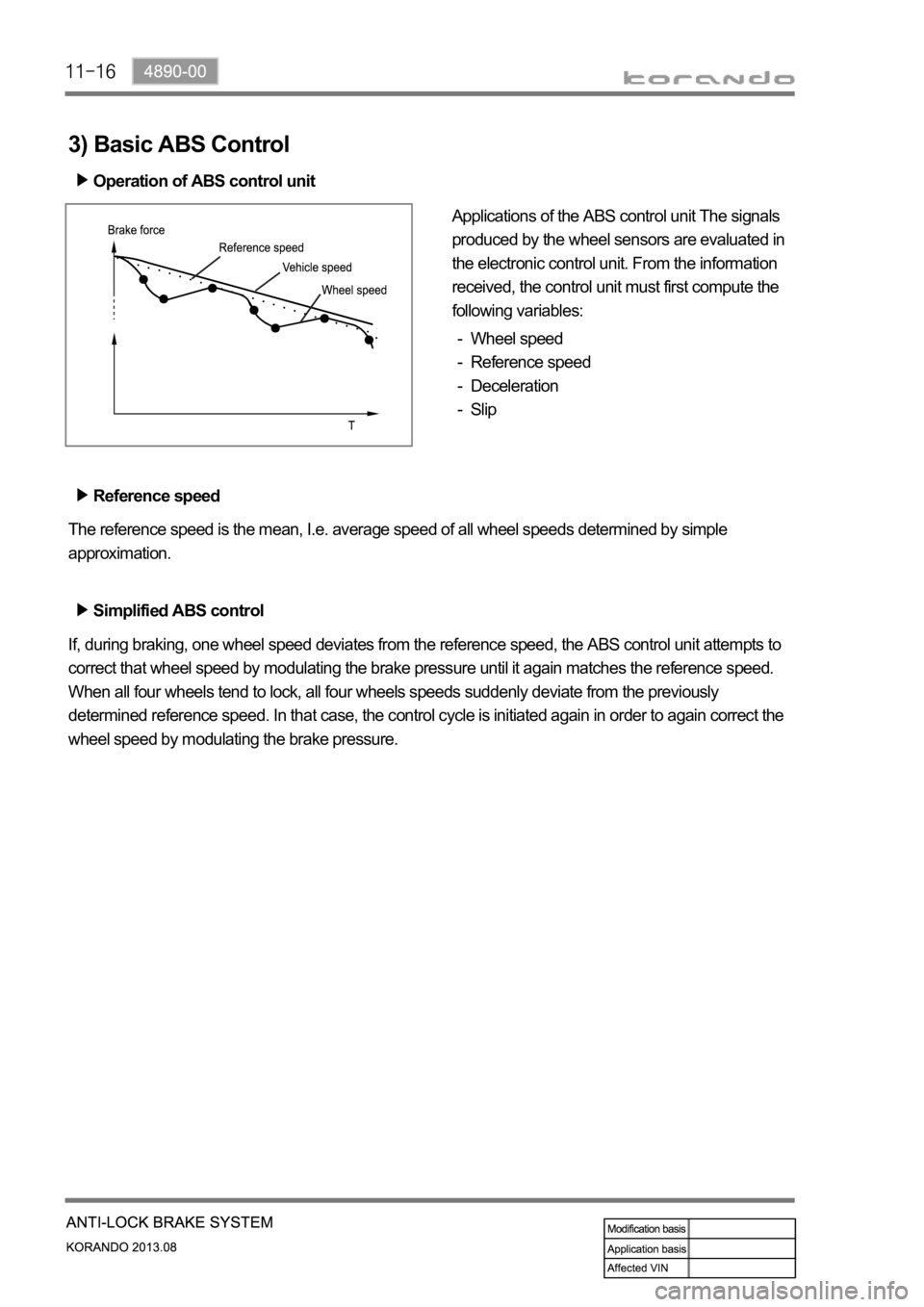

Brake force

When depressing the brake pedal the brake force

increases to the maximum, then the brake force

decreases until the wheel locks.

Cornering force

The cornering force is a maximum when the

wheel is turning freely with zero slip. When

braking the cornering force falls to zero if the

wheel locks (slip 100 %).

ABS operating range

The operating range starts just before the

maximum brake force and ends in maximum, for

the unstable range then begins, in which no

further modulation is possible. The ABS controls

the regulation of the brake pressure so that the

brake force only becomes great enough for a

sufficient proportion of cornering force to remain.

With ABS we remain in the Kamm circle as long

as the car is driving sensibly. We will leave driving

physics with these statements and turn to the

braking systems with and without ABS. -

-

- Brake and cornering force

Page 1112 of 1336

3) Basic ABS Control

Operation of ABS control unit

Applications of the ABS control unit The signals

produced by the wheel sensors are evaluated in

the electronic control unit. From the information

received, the control unit must first compute the

following variables:

Wheel speed

Reference speed

Deceleration

Slip -

-

-

-

Reference speed

The reference speed is the mean, I.e. average speed of all wheel speeds determined by simple

approximation.

Simplified ABS control

If, during braking, one wheel speed deviates from the reference speed, the ABS control unit attempts to

correct that wheel speed by modulating the brake pressure until it again matches the reference speed.

When all four wheels tend to lock, all four wheels speeds suddenly deviate from the previously

determined reference speed. In that case, the control cycle is initiated again in order to again correct the

wheel speed by modulating the brake pressure.

Page 1113 of 1336

4890-00

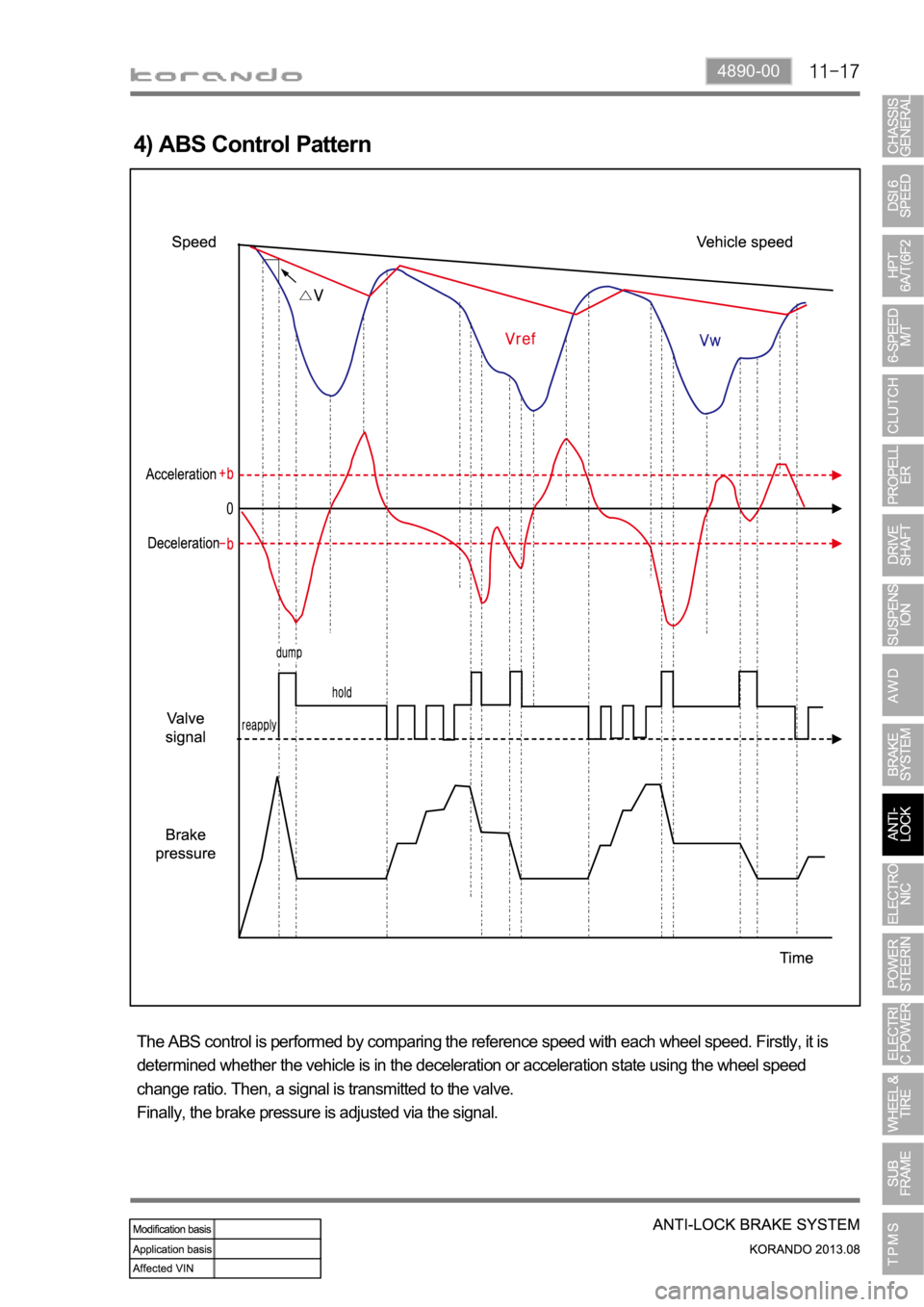

4) ABS Control Pattern

The ABS control is performed by comparing the reference speed with each wheel speed. Firstly, it is

determined whether the vehicle is in the deceleration or acceleration state using the wheel speed

change ratio. Then, a signal is transmitted to the valve.

Finally, the brake pressure is adjusted via the signal.

Page 1114 of 1336

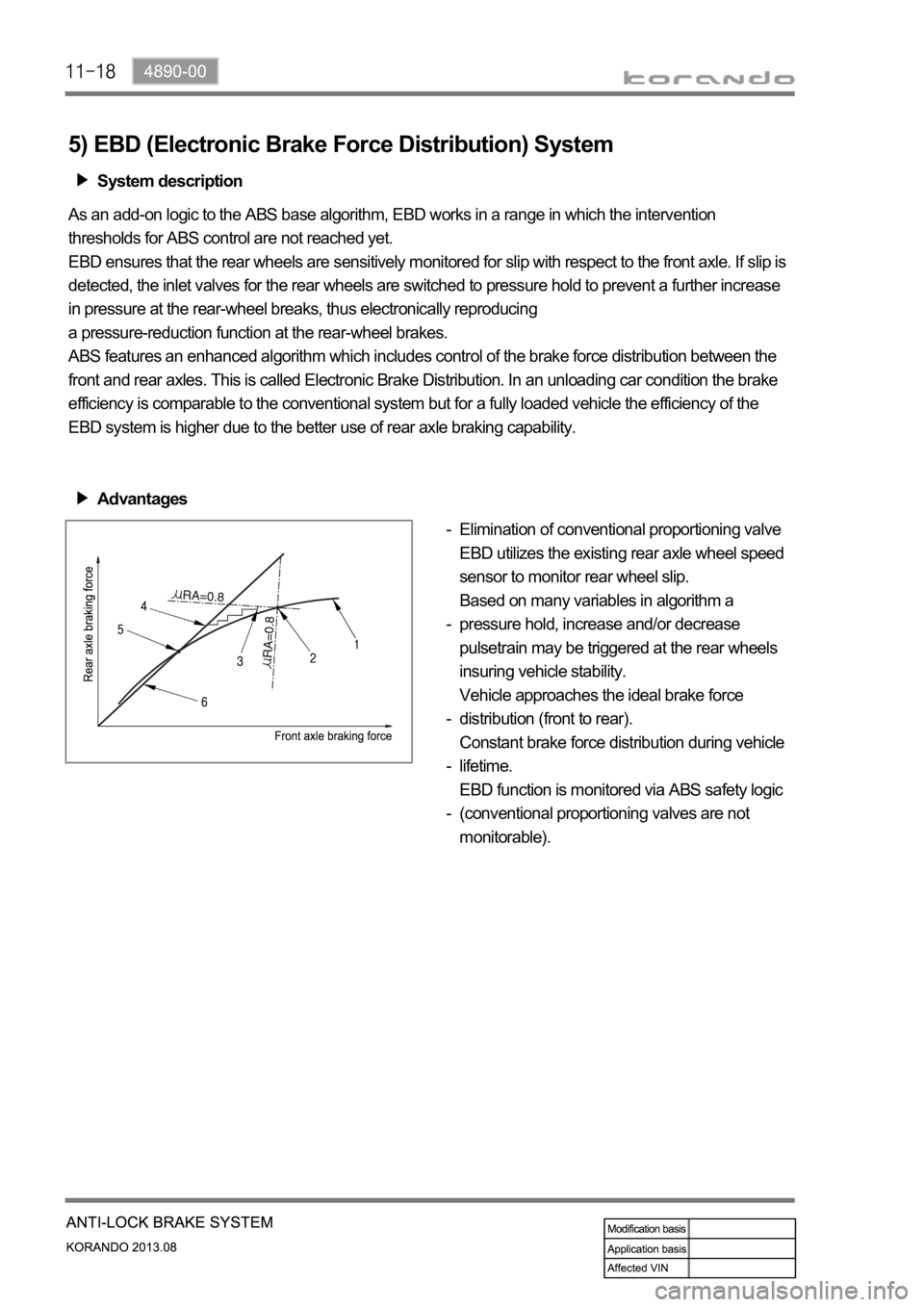

5) EBD (Electronic Brake Force Distribution) System

System description

As an add-on logic to the ABS base algorithm, EBD works in a range in which the intervention

thresholds for ABS control are not reached yet.

EBD ensures that the rear wheels are sensitively monitored for slip with respect to the front axle. If slip is

detected, the inlet valves for the rear wheels are switched to pressure hold to prevent a further increase

in pressure at the rear-wheel breaks, thus electronically reproducing

a pressure-reduction function at the rear-wheel brakes.

ABS features an enhanced algorithm which includes control of the brake force distribution between the

front and rear axles. This is called Electronic Brake Distribution. In an unloading car condition the brake

efficiency is comparable to the conventional system but for a fully loaded vehicle the efficiency of the

EBD system is higher due to the better use of rear axle braking capability.

Advantages

Elimination of conventional proportioning valve

EBD utilizes the existing rear axle wheel speed

sensor to monitor rear wheel slip.

Based on many variables in algorithm a

pressure hold, increase and/or decrease

pulsetrain may be triggered at the rear wheels

insuring vehicle stability.

Vehicle approaches the ideal brake force

distribution (front to rear).

Constant brake force distribution during vehicle

lifetime.

EBD function is monitored via ABS safety logic

(conventional proportioning valves are not

monitorable). -

-

-

-

-

Page 1115 of 1336

4890-00

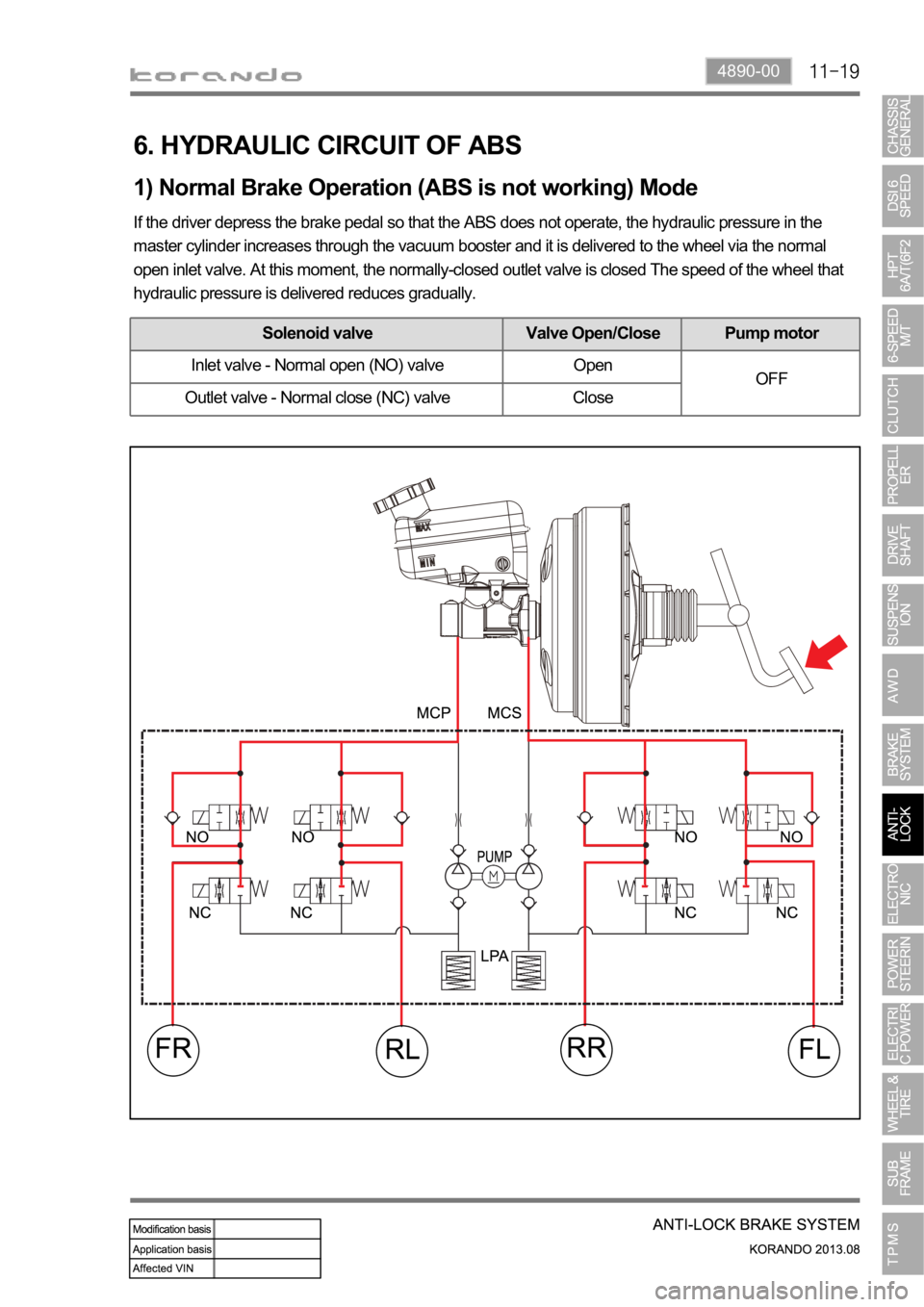

6. HYDRAULIC CIRCUIT OF ABS

1) Normal Brake Operation (ABS is not working) Mode

If the driver depress the brake pedal so that the ABS does not operate, the hydraulic pressure in the

master cylinder increases through the vacuum booster and it is delivered to the wheel via the normal

open inlet valve. At this moment, the normally-closed outlet valve is closed The speed of the wheel that

hydraulic pressure is delivered reduces gradually.

Solenoid valve Valve Open/Close Pump motor

Inlet valve - Normal open (NO) valve Open

OFF

Outlet valve - Normal close (NC) valve Close

Page 1116 of 1336

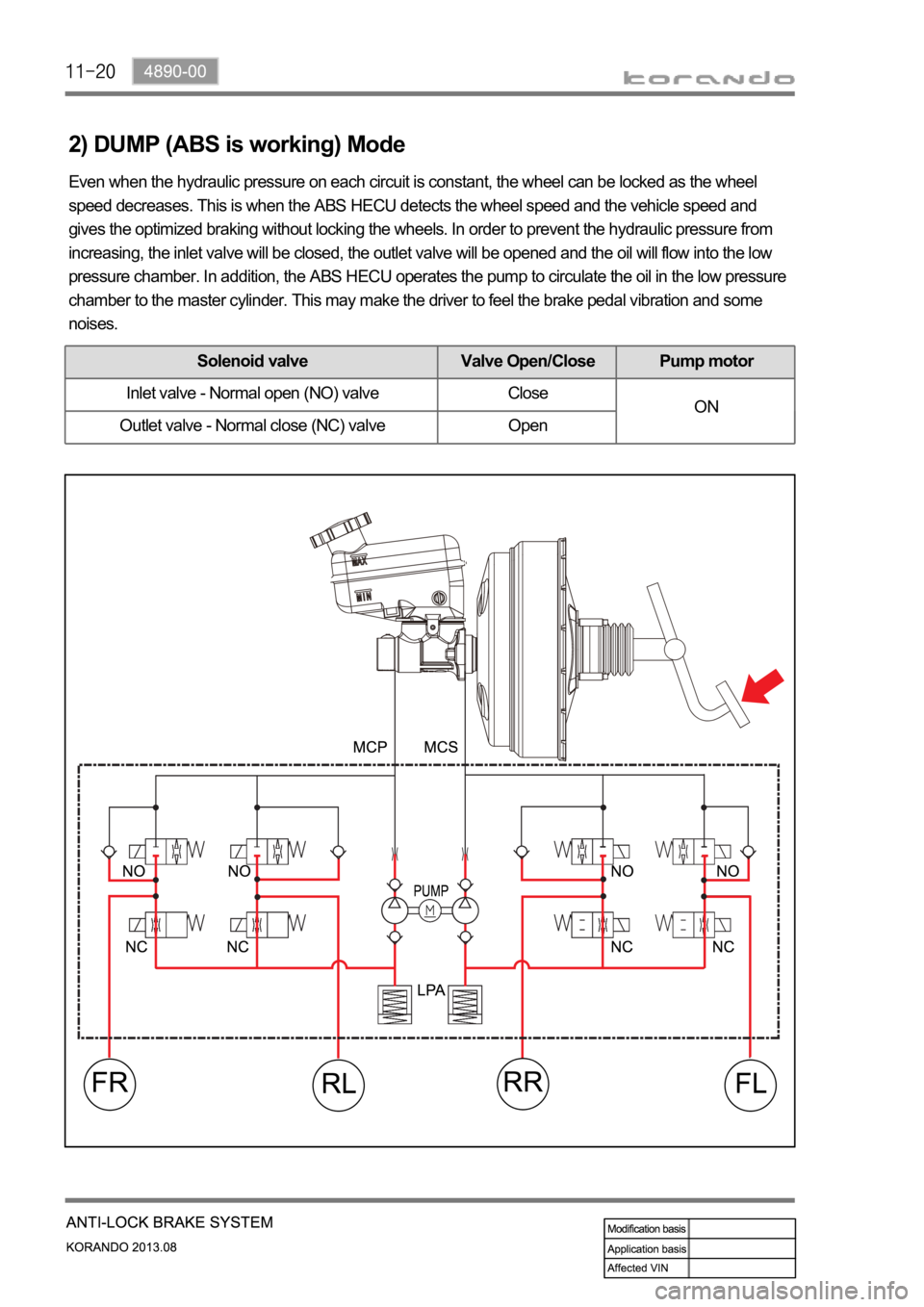

2) DUMP (ABS is working) Mode

Even when the hydraulic pressure on each circuit is constant, the wheel can be locked as the wheel

speed decreases. This is when the ABS HECU detects the wheel speed and the vehicle speed and

gives the optimized braking without locking the wheels. In order to prevent the hydraulic pressure from

increasing, the inlet valve will be closed, the outlet valve will be opened and the oil will flow into the low

pressure chamber. In addition, the ABS HECU operates the pump to circulate the oil in the low pressure

chamber to the master cylinder. This may make the driver to feel the brake pedal vibration and some

noises.

Solenoid valve Valve Open/Close Pump motor

Inlet valve - Normal open (NO) valve Close

ON

Outlet valve - Normal close (NC) valve Open

Page 1118 of 1336

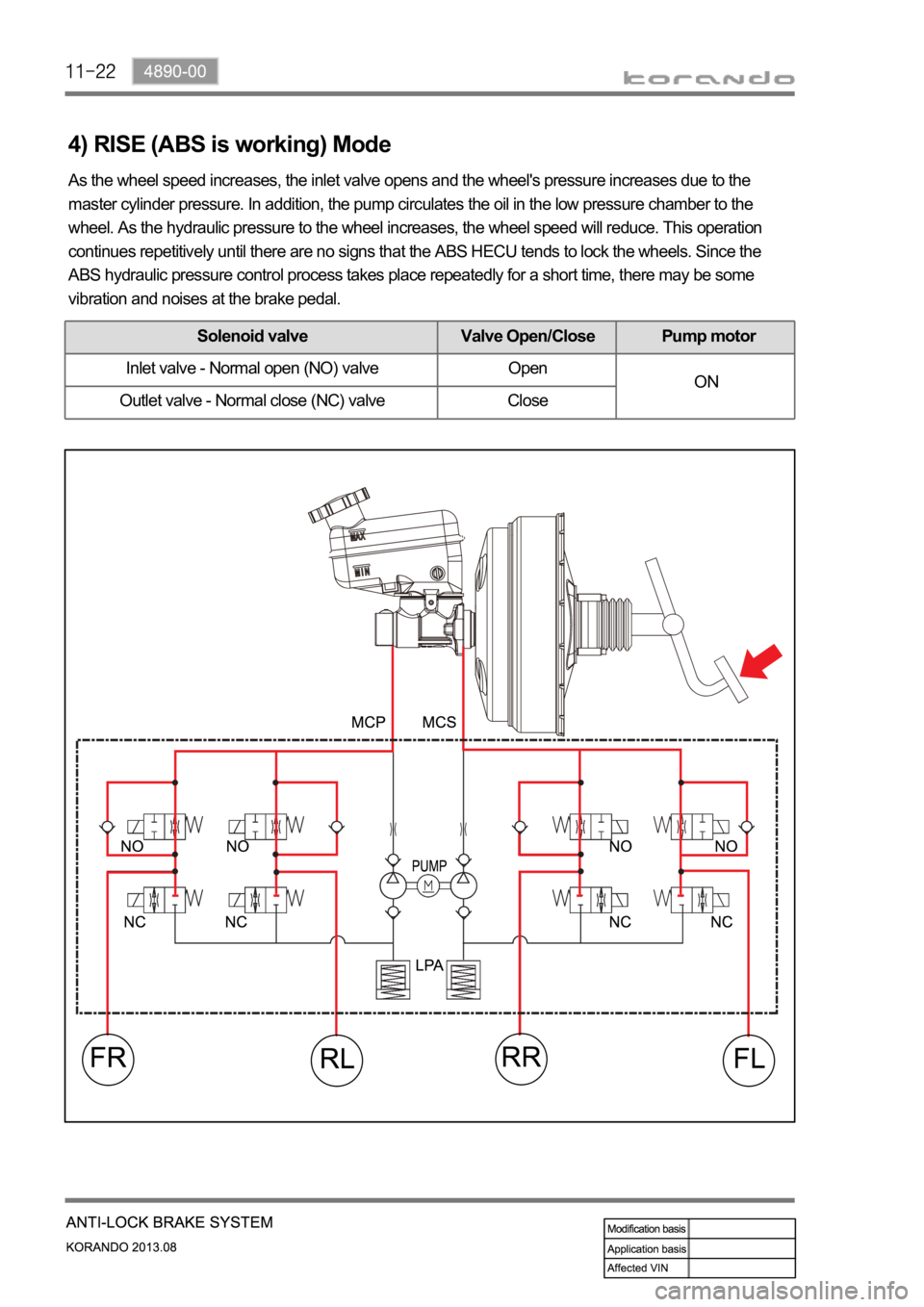

4) RISE (ABS is working) Mode

As the wheel speed increases, the inlet valve opens and the wheel's pressure increases due to the

master cylinder pressure. In addition, the pump circulates the oil in the low pressure chamber to the

wheel. As the hydraulic pressure to the wheel increases, the wheel speed will reduce. This operation

continues repetitively until there are no signs that the ABS HECU tends to lock the wheels. Since the

ABS hydraulic pressure control process takes place repeatedly for a short time, there may be some

vibration and noises at the brake pedal.

Solenoid valve Valve Open/Close Pump motor

Inlet valve - Normal open (NO) valve Open

ON

Outlet valve - Normal close (NC) valve Close

Page 1124 of 1336

0000-00

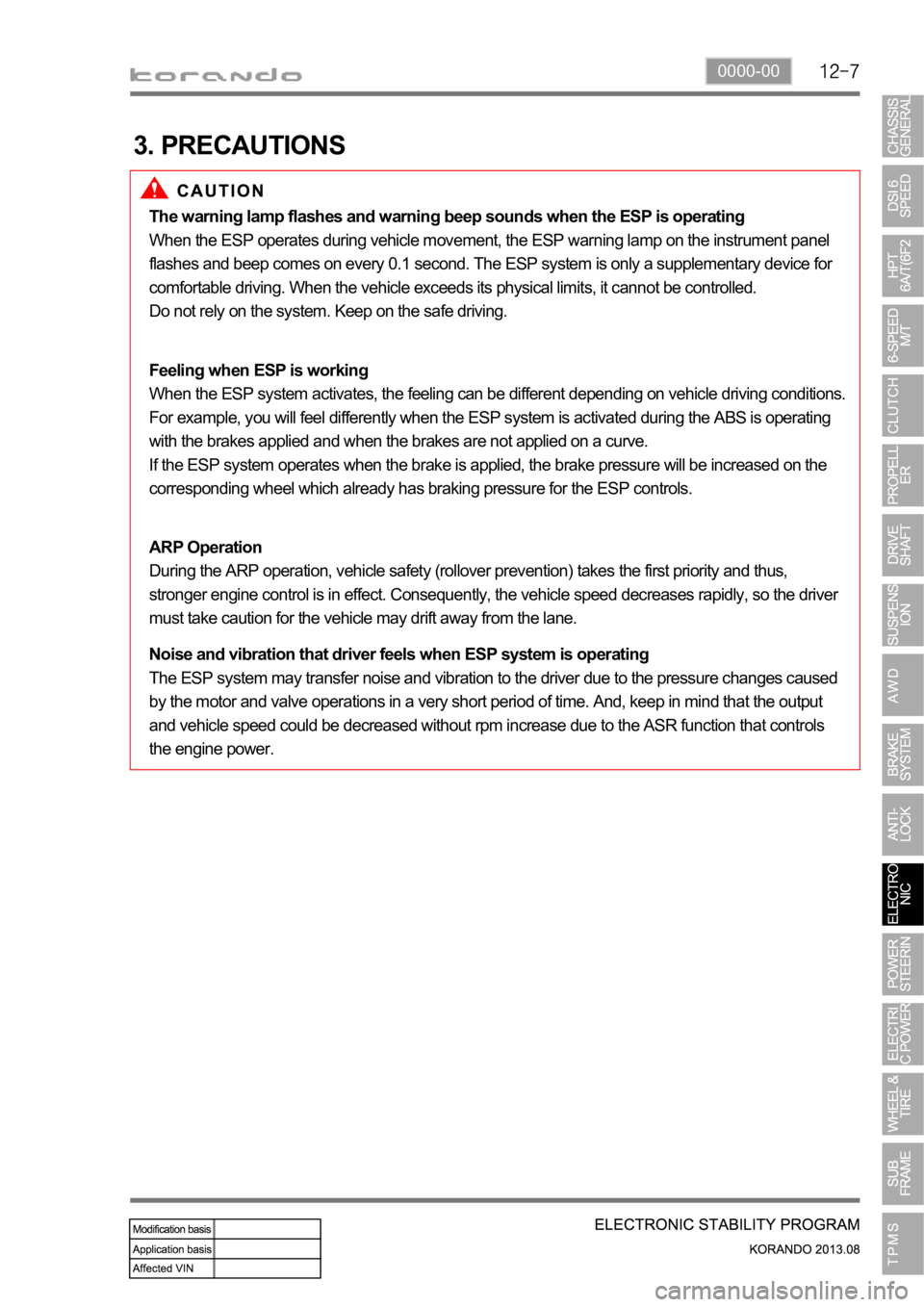

3. PRECAUTIONS

The warning lamp flashes and warning beep sounds when the ESP is operating

When the ESP operates during vehicle movement, the ESP warning lamp on the instrument panel

flashes and beep comes on every 0.1 second. The ESP system is only a supplementary device for

comfortable driving. When the vehicle exceeds its physical limits, it cannot be controlled.

Do not rely on the system. Keep on the safe driving.

Feeling when ESP is working

When the ESP system activates, the feeling can be different depending on vehicle driving conditions.

For example, you will feel differently when the ESP system is activated during the ABS is operating

with the brakes applied and when the brakes are not applied on a curve.

If the ESP system operates when the brake is applied, the brake pressure will be increased on the

corresponding wheel which already has braking pressure for the ESP controls.

ARP Operation

During the ARP operation, vehicle safety (rollover prevention) takes the first priority and thus,

stronger engine control is in effect. Consequently, the vehicle speed decreases rapidly, so the driver

must take caution for the vehicle may drift away from the lane.

Noise and vibration that driver feels when ESP system is operating

The ESP system may transfer noise and vibration to the driver due to the pressure changes caused

by the motor and valve operations in a very short period of time. And, keep in mind that the output

and vehicle speed could be decreased without rpm increase due to the ASR function that controls

the engine power.

Page 1125 of 1336

4. WARNING LAMPS

1) ABS

ABS warning lamp module indicates the self-diagnosis and malfunction.

ABS warning lamp ON: Warning Lamp

When turning the ignition switch to ON position, ABS warning lamp comes on for 3 seconds for self-

diagnosis and goes off if the system is OK (initialization mode).

When the system is defective, the warning lamp comes on.

When the self-diagnosis is performing, the warning lamp comes on.

When the HECU connector is disconnected, the warning lamp comes on.

ABS is not available during lamp ON. In this condition, Only normal brake system without ABS

function is available.

When the communication between warning lamp CAN module in meter cluster, the warning lamp

comes on. 1.

2.

3.

4.

5.

6.ABS warning lamp

Brake warning lamp

ESP OFF indicator

ESP warning lamp/indicator

EBD warning lamp 1.

2.

3.

4.

5.

Page 1126 of 1336

0000-00

2) EBD (Electronic Brake-force Distribution) Warning Lamp (Brake

Warning Lamp)

EBD warning lamp when the system perform the self diagnosis and when it detects the malfunction of

EBD system. However, the brake warning lamp comes on regardless of EBD when the parking brake is

applied.

EBD warning lamp ON:

When turning the ignition switch to ON position, ABS warning lamp and the brake warning lamp

comes on for 3 seconds for self diagnosis and goes off if the system is OK (initialization mode).

When applying the parking brake, the brake warning lamp comes on.

When the brake fluid is not sufficient, the brake warning lamp comes on.

When the self-diagnosis is performing, the warning lamp comes on.

When the HECU connector is disconnected, the warning lamp comes on.

When the system is defective, ABS warning lamp and the brake warning lamp come on

simultaneously. 1.

2.

3.

4.

5.

6.

When the solenoid valve is defective

When one or more wheel sensors are defective

When ABS HECU is defective

When the voltage is abnormal

When valve relay is defective a.

b.

c.

d.

e.

When the communication between warning lamp CAN module in meter cluster, the warning lamp

comes on. 7.

3) ESP OFF Indicator

ESP OFF indicator ON:

When turning the ignition switch to ON position, ESP warning lamp comes on for 3 seconds for self

diagnosis and goes off if the system is OK (initialization mode).

When the ESP OFF switch is pressed to turn off ESP function, ESP OFF indicator comes on. 1.

2.

4) ESP Warning Lamp

ESP warning lamp ON:

When turning the ignition switch to ON position, ESP warning lamp comes on for 3 seconds for self

diagnosis and goes off if the system is OK (initialization mode).

When the system is defective, the warning lamp comes on.

When the ESP function is activated, ESP warning lamp blinks with the interval of 2 Hz.

When the communication between warning lamp CAN module in meter cluster, the warning lamp

comes on. 1.

2.

3.

4.

5.

5) ESP OFF Switch

If ESP OFF switch is pressed, ESP function is deactivated and the ESP OFF indicator in the instrument

cluster comes on.

To resume the ESP function, press the switch again. At this time, ESP OFF indicator goes out.