engine electri SSANGYONG KYRON 2008 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2008, Model line: KYRON, Model: SSANGYONG KYRON 2008Pages: 650, PDF Size: 73.24 MB

Page 190 of 650

ENGINE FUEL SYSTEM

undefined

1881-01

1881-01ENGINE FUEL SYSTEM

GENERAL

1. CAUTIONS FOR DI ENGINE

This chapter describes the cautions for DI engine equipped vehicle. This includes the water

separation from engine, warning lights, symptoms when engine malfunctioning, causes and

actions.

1) DI Engine

Comparatively conventional diesel engines, DI engine controls the fuel injection and timing

electrically, delivers high power and reduces less emission.

2) System Safety Mode

When a severe failure has been occurred in a vehicle, the system safety mode is activated to

protect the system. It reduces the driving force, restricts the engine speed (rpm) and stops

engine operation. Refer to "Diagnosis" section in this manual.

3) Water Separator Warning Light

When the water level inside water separator

in fuel filter exceeds a certain level (approx.

39 cc), this warning light comes on and

buzzer sounds.

Also, the driving force of the vehicle

decreases (torque reduction). If these

conditions occur, immediately drain the

water from fuel filter.

For the draining procedures, please refer to

"How to drain the water from fuel filter"

section.

4) Priming Pump

The priming pump installed in fuel pump is the device to fill the fuel into the fuel filter. When the

vehicle is under the conditions as below, press the priming pump until it becomes rigid before

starting the engine.

5) Conditions for Using Priming Pump

After run out of fuel

After draining the water from fuel separator

After replacing the fuel filter -

-

-

Page 193 of 650

undefined

1881-01

ENGINE FUEL SYSTEM

OVERVIEW AND OPERATION PROCESS

1. ELECTRONIC CONTROL OF FUEL SYSTEM

According to input signals from various sensors, engine ECU calculates driver's demand

(position of the accelerator pedal) and then controls overall operating performance of engine

and vehicle on that time.

ECU receives signals from sensors via data line and then performs effective engine air-fuel

ratio controls based on those signals. Engine speed is measured by crankshaft speed (position)

sensor and camshaft speed (position) sensor determines injection order and ECU detects

driver's pedal position (driver's demand) through electrical signal that is generated by variable

resistance changes in accelerator pedal sensor. Air flow (hot film) sensor detects intake ai

r

volume and sends the signals to ECU. Especially, the engine ECU controls the air-fuel ratio by

recognizing instant air volume changes from air flow sensor to decrease the emissions (EGR

valve control). Furthermore, ECU uses signals from coolant temperature sensor and ai

r

temperature sensor, booster pressure sensor and atmospheric pressure sensor as

compensation signal to respond to injection starting, pilot injection set values, various

operations and variables.Components

High pressure fuel pump

Fuel injectors -

-Fuel rail

Electronic control unit(ECU) -

-Fuel pressure sensor

Various sensors and actuators -

-Supply line

Return line

ECU connecting line

Page 199 of 650

undefined

1881-01

ENGINE FUEL SYSTEM

3) High Pressure Pipe (Fuel Pipe)

Fuel line transfers high pressure fuel.

Accordingly, it is made of steel to endure

intermittent high frequency pressure

changes that occur under maximum system

pressure and injection stops. Injection lines

between rail and injectors are all in the same

length; it means the lengths between the rail

and each injector are the same and the

differences in length are compensated by

each bending.

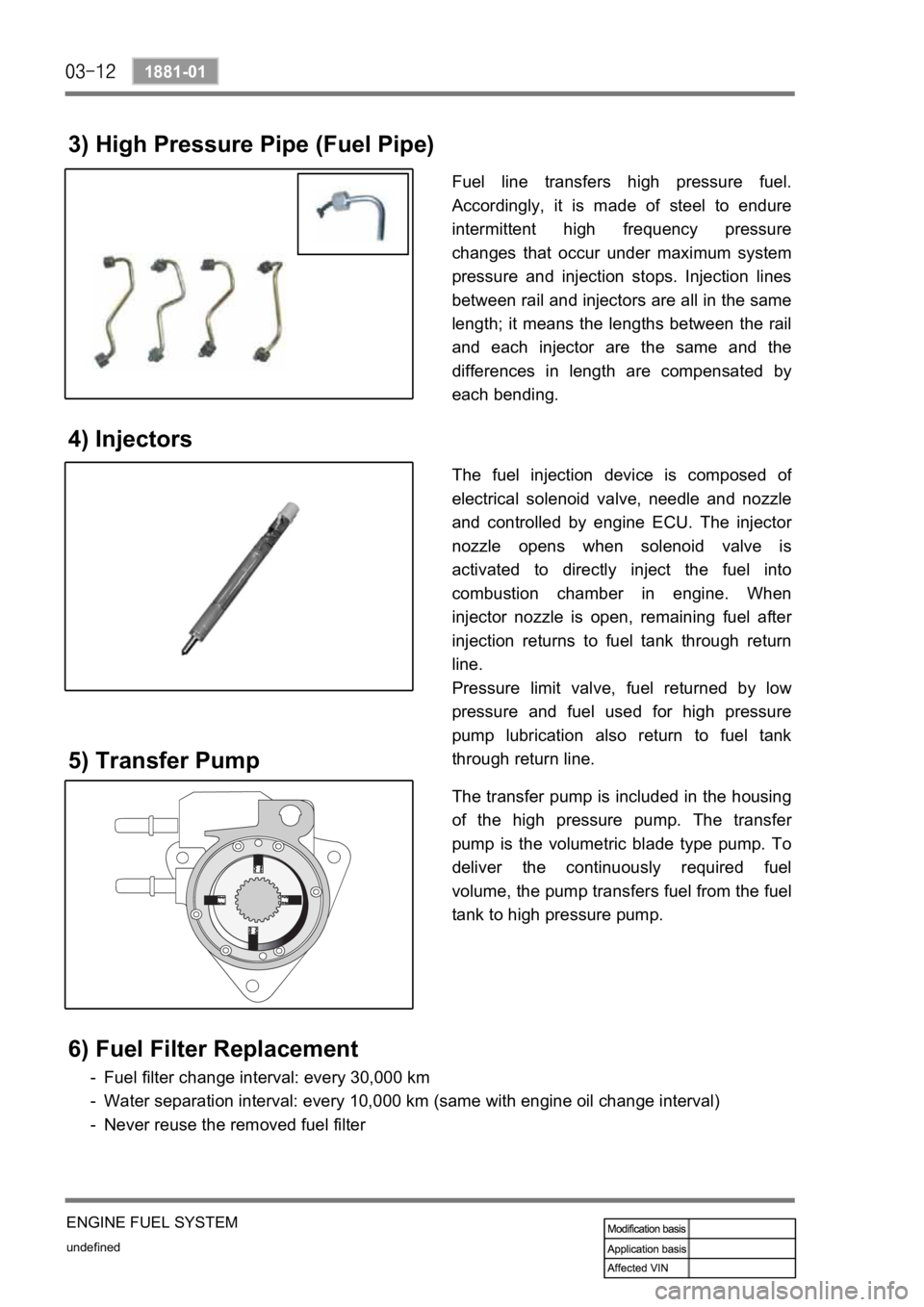

4) Injectors

The fuel injection device is composed of

electrical solenoid valve, needle and nozzle

and controlled by engine ECU. The injecto

r

nozzle opens when solenoid valve is

activated to directly inject the fuel into

combustion chamber in engine. When

injector nozzle is open, remaining fuel afte

r

injection returns to fuel tank through return

line.

Pressure limit valve, fuel returned by low

pressure and fuel used for high pressure

pump lubrication also return to fuel tank

through return line.

6) Fuel Filter Replacement

Fuel filter change interval: every 30,000 km

Water separation interval: every 10,000 km (same with engine oil change interval)

Never reuse the removed fuel filter -

-

-

The transfer pump is included in the housing

of the high pressure pump. The transfe

r

pump is the volumetric blade type pump. To

deliver the continuously required fuel

volume, the pump transfers fuel from the fuel

tank to high pressure pump.

5) Transfer Pump