heater SSANGYONG MUSSO 1998 Workshop User Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 1277 of 1463

MANUAL & SEMIAUTO-HVAC 7B/C-3

Application

Type

Expansion Valve

Resistance

Thermo AmpDescription

Tank laminated

Uniform external pressure type (1.5 RT)

4 stage (Coil resistance)

Sensor type OFF : 2±0.5°C, DIFF : 2±0.5°C

EVAPORATOR

Application

Heater Core Type

Heating Capacity

Heater Core Size (LxWxT)Description

2-ROW

4,600 kcal/h (AT 300 CMH)

219.5 x 151.8 x 52.0

HEATER UNIT

Application

Condenser Bolt

Condenser Fan Nut

Condenser Bolt

Receiver Drier Pipe Bolt

Receiver Drier Pipe Bolt (Condenser)

Pressure Pipe Bolt

Pressure Mounting BoltNlm

4-6

4-6

4-6

5-8

4-6

20-30

20-26

FASTENER TIGHTENING SPECIFICATIONS

Page 1279 of 1463

MANUAL & SEMIAUTO-HVAC 7B/C-5

Action

Clean oily plate using cleaning agent.

Charge battery or check for cause.

Check wire continuity

Check A/C switch and fan switch for continuity and ground.

DEFECTIVES IN FAN MOTOR CIRCUIT

Fan Motor Does Not Run

Checks

Blown fuse

Battery voltage is low

Faulty wiring

Faulty groundAction

Check for short and replace fuse.

Check battery voltage.

Check connectors’ connection.

Do not apply grease. This can cause voltage down.

Remove body painting and completely ground,

Tighten ground bolts and make sure body ground connection.

Checks

Blown resister temperature fuse

Air leakage in parts connection

Action

Replace resistor.

Check heater, cooling unit and blower for proper connection.

Fan Motor Runs in ‘4’position Only (‘3’, ‘2’, ‘1’ : Does Not Run)

Frosted Evaporator

DEFECTIVES IN COMPRESSOR CIRCUIT

Compressor Does Not Run

Checks

Faulty thermo ampAction

Frosted evaporator reduces cooling capacity.

Off compressor and maximize blowing capacity

Checks

Faulty high/low pressure

Faulty A/C relayAction

Check compressor magnet voltage supply.

A/C relay.

Checks

Oily clutch plate

Low voltage

Faulty electric connection or operation

Magnetic Clutch Slips /Idles

Checks

Clogged or blocked intake grilleAction

Clogged or blocked intake grille reduces blowing capacity.

Motor Runs With Poor Blowing

Checks

Excessive clearance between

Clutch plate and clutch coilAction

Adjust clutch clearance (0.2-0.6mm).

Magnetic Clutch Plays By Hand Only

Page 1282 of 1463

7B/C-8 MANUAL & SEMIAUTO-HVAC

AIR CONDITIONER SYSTEM

DIESEL ENGINE

1 Compressor

2 High Pressure Hose

3 Condenser Fan

4 Condenser

5 Liquid Pipe (A)

6 Receiver Drier

7 Liquid (B)

8 Evaporator Assembly

9 Low Pressure Hose10 Water Inlet Hose

11 Water Outlet Hose

12 Control Assembly

13 Heater Unit Amplifier

14 Mix Actuator Assembly

15 Blower Unit

16 Heater Unit

17 Mode Actuator Assembly

Page 1283 of 1463

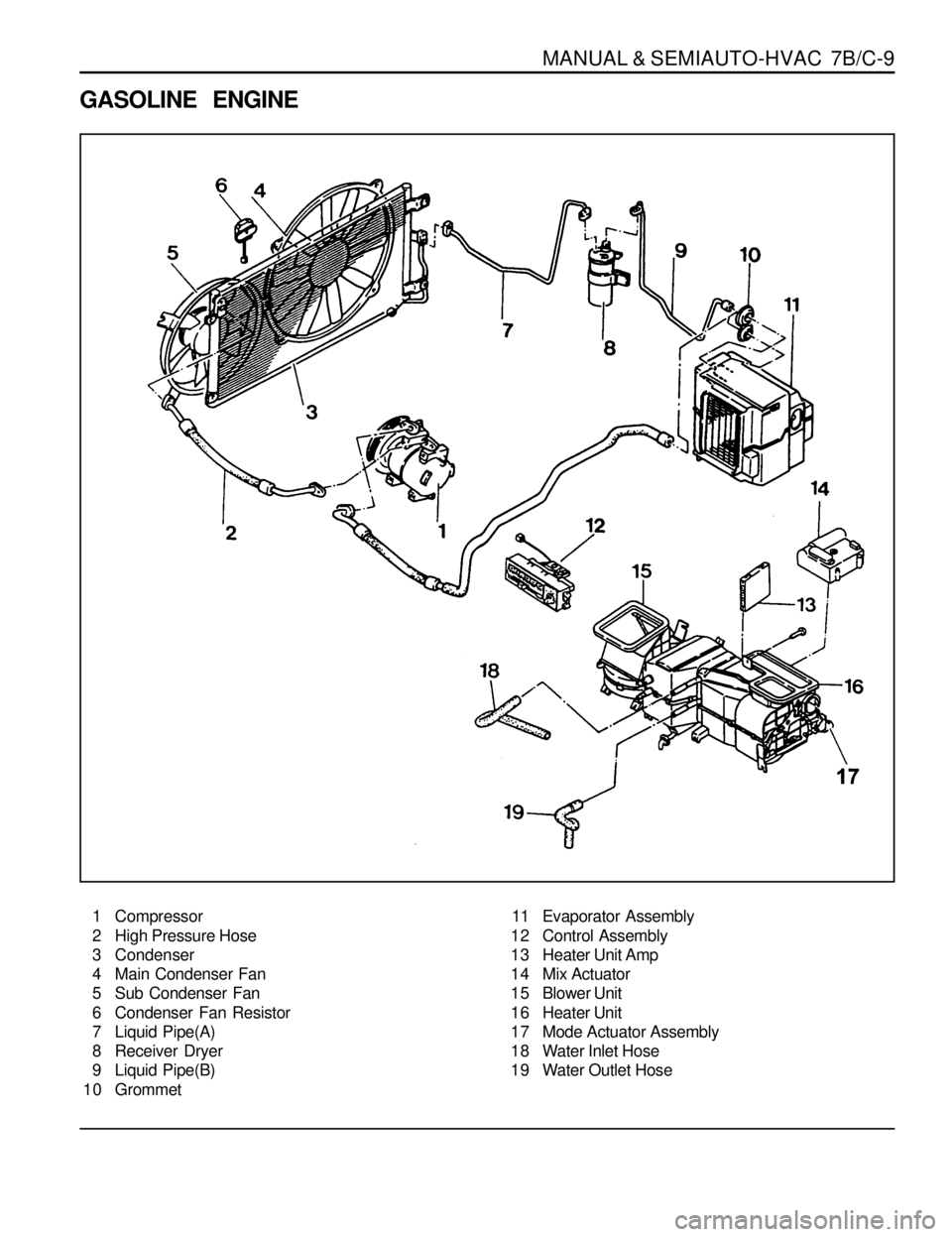

MANUAL & SEMIAUTO-HVAC 7B/C-9

GASOLINE ENGINE

1 Compressor

2 High Pressure Hose

3 Condenser

4 Main Condenser Fan

5 Sub Condenser Fan

6 Condenser Fan Resistor

7 Liquid Pipe(A)

8 Receiver Dryer

9 Liquid Pipe(B)

10 Grommet11 Evaporator Assembly

12 Control Assembly

13 Heater Unit Amp

14 Mix Actuator

15 Blower Unit

16 Heater Unit

17 Mode Actuator Assembly

18 Water Inlet Hose

19 Water Outlet Hose

Page 1299 of 1463

MANUAL & SEMIAUTO-HVAC 7B/C-25

HEATER AND AIR CONDITIONER CONTROL BOX

1 Blower Switch

2 Recirculation Switch

3 Mode Switch4 A/C Switch

5 Temperature Control Lever

6 In-vehicle Sensor

MANUAL

SATC

Page 1325 of 1463

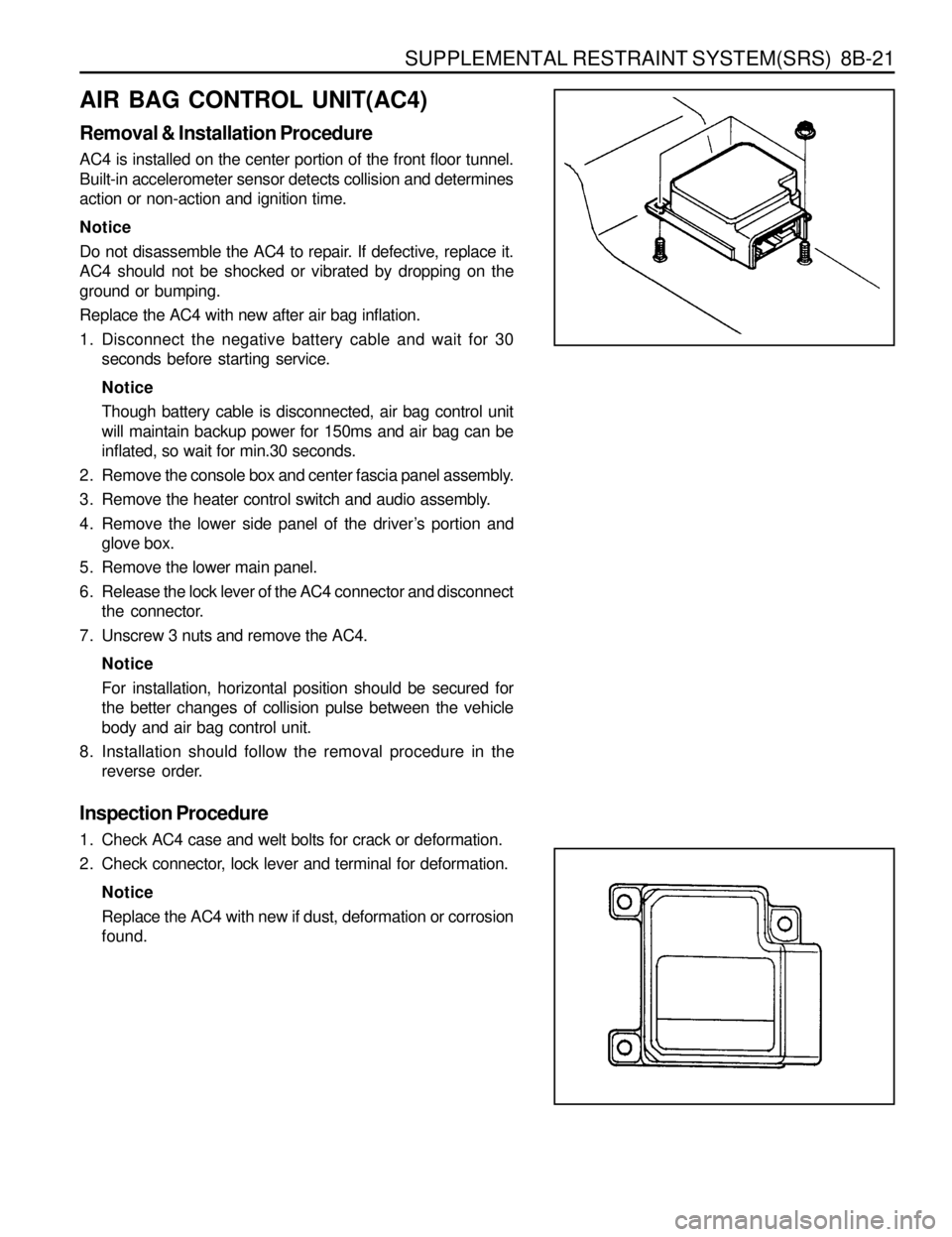

SUPPLEMENTAL RESTRAINT SYSTEM(SRS) 8B-21

AIR BAG CONTROL UNIT(AC4)

Removal & Installation Procedure

AC4 is installed on the center portion of the front floor tunnel.

Built-in accelerometer sensor detects collision and determines

action or non-action and ignition time.

Notice

Do not disassemble the AC4 to repair. If defective, replace it.

AC4 should not be shocked or vibrated by dropping on the

ground or bumping.

Replace the AC4 with new after air bag inflation.

1. Disconnect the negative battery cable and wait for 30

seconds before starting service.

Notice

Though battery cable is disconnected, air bag control unit

will maintain backup power for 150ms and air bag can be

inflated, so wait for min.30 seconds.

2. Remove the console box and center fascia panel assembly.

3. Remove the heater control switch and audio assembly.

4. Remove the lower side panel of the driver’s portion and

glove box.

5. Remove the lower main panel.

6. Release the lock lever of the AC4 connector and disconnect

the connector.

7. Unscrew 3 nuts and remove the AC4.

Notice

For installation, horizontal position should be secured for

the better changes of collision pulse between the vehicle

body and air bag control unit.

8. Installation should follow the removal procedure in the

reverse order.

Inspection Procedure

1. Check AC4 case and welt bolts for crack or deformation.

2. Check connector, lock lever and terminal for deformation.

Notice

Replace the AC4 with new if dust, deformation or corrosion

found.

Page 1332 of 1463

9A-6 BODY WIRING SYSTEM

Engine Room Fuse (EF) and Relay Box

1 Fuse (15A) : ABS, ABD

2 Fuse (20A) : Sun Roof

3 Fuse (10A) : Air Bag

4 Fuse (15A) : Audio, Clock, Out Side Mirror

5 Fuse (30A) : Cigarette lighter, Power Socket

6 Fuse (30A) : Heater

7 Fuse (15A) : Door Lock

8 Fuse (30A) : Rear Heated

9 Fuse (10A) : Audio, Buzzer, Chime, Clock

10 Fuse (30A) : Power Window

11 Fuse (10A) : Immobilizer

12 Fuse (20A) : T/C

13 Fuse (15A) : Interior Lamp

14 Fuse (15A) : Hazard Lamp

15 Fuse (15A) : Stop Lamp

16 Fuse (15A) : Turn signal Lamp, Head Lamp

17 Fuse (10A) : Back up Lamp

18 Fuse (15A) : Cluster, STICS

19 Fuse (15A) : A/T, Diagnosis

20 Fuse (15A) : Over Voltage Protection Relay

(Gasolin Only)

21 Fuse (15A) : Seat Heater

22 Fuse (15A) : ECS

23 Fuse (15A) : Front Wiper & Washer

24 Fuse (10A) : Rear Wiper & Washer, A/C

25 Relay : Front Wiper26 Relay : ABS Warning Lamp

27 Relay : Flasher Unit

28 Relay : Fuel Pump (Gasoline Only)

29 Relay : Shift Lock (A/T)

30 Relay : Clutch Interlock & Neutral

31 Relay : Sun Roof

32 Relay : A/T ‘B’ Interlock (MB A/T)

33 Relay : Power Window

34 Relay : Rear Fog Lamp

35 Relay : ECS

36 Relay : Compressor (Diesel E/G)

Condenser Fan (Gasoline E/G)

37 Relay : Condenser Fan

38 Relay : Air Conditioner

39 Fuse (10A) : Tail Lamp

40 Fuse (15A) : Head Lamp(LH)

41 Fuse (15A) : Head Lamp(RH)

42 Fuse (15A) : Front Fog Lamp

43 Fuse (10A) : Horn

44 Fuse (10A) : Compressor

45 Relay : Resistor with Diode (Gasoline E/G)

46 Relay : Front fog Lamp

47 Relay : Condenser Fan

48 Relay : Tail Lamp

49 Relay : Horn

Page 1335 of 1463

BODY WIRING SYSTEM 9A-9

44 Joint Connector.................................................... Ground

45 Door Unlock Switch

46 Front Fog Lamp Switch

47 Rear Defogger Switch

4 8 ECS Switch

49 Rear Fog Lamp Switch........................................Rear Fog Lamp

50 Digital Clock

51 Thermo Amplifier

52 Glove Box Lamp Switch

53 Air Conditioner Wiring Connetor

54 Glove Box Lamp

55 Ground 6

56 Ground 6.............................................................Gasoline E/G

57 Ground 7.............................................................Gasoline E/G

58 Wheel Speed Sensor (FR)..................................ABS 5.0 or ABD 5.0

59 O

2 Sensor............................................................E32 Gasoline E/G

60 Engine Main Wiring Connector............................Gasoline E/G with MSE ECU

61 HFM .....................................................................Gasoline E/G with HFM ECU

61-1 MSE .....................................................................Gasoline E/G with MSE ECU

62 Front Door Wiring Connector (Passenger Side)

63 Front door Wiring Connector (Passenger Side)

64 Joint Connector (B+)

65 Audio

66 Audio

67 Air Bag Wiring Connector

68 Chime Bell

6 9 Buzzer

70 Kick Down Switch.................................................Automatic Transmission

71 Diode 2................................................................Manual Transmission

72 Ground 3

73 Ground 4

74 Front Cigarette Lighter

75 Diode 3................................................................Automatic Transmission, MB

76 S/E Mode Selector Switch....................................Automatic Transmission

76-1Mode Switch........................................................Automatic Transmission

77 “B” Position Switch..............................................Automatic Transmission

78 “P” Position Switch..............................................Automatic Transmission

79 Shift Lock Solenoid Valve.....................................Automatic Transmission

8 0 TCCU

81 Ground 5.............................................................Gasoline E/G

81-1Ground 7.............................................................Diesel E/G

82 Seat Extension Wiring Connector

83 Transmission Extension Wiring Connector...........E23 & E32 Gasoline E/G with Manual Transmission

83-1 Transmission Extension Wiring Connector...........Diesel E/G with MB A/T

84 Transmission Extension Wiring Connector...........Gasoline E/G with Manual Transmission

84-1 Transmission Extension Wiring Connector...........Diesel E/G with Manual Transmission or BTRE A/T

85 Transmission Extension Wiring Connector...........E23 & E32 Gasoline E/G with A/T

85-1 Transmission Extension Wiring Connector...........Diesel E/G with BTRE A/T

86 Transfer Case Motor

87 Transfer Case Motor

88 Vehicle Speed Sensor

89 Fuel Gauge

90 Acceleration Sensor.............................................ABS 5.0

91 Seat Belt Switch (Passenger)

92 Seat Heater Switch

93 Head Lamp Leveling Device Switch.....................Leveling Device

Page 1352 of 1463

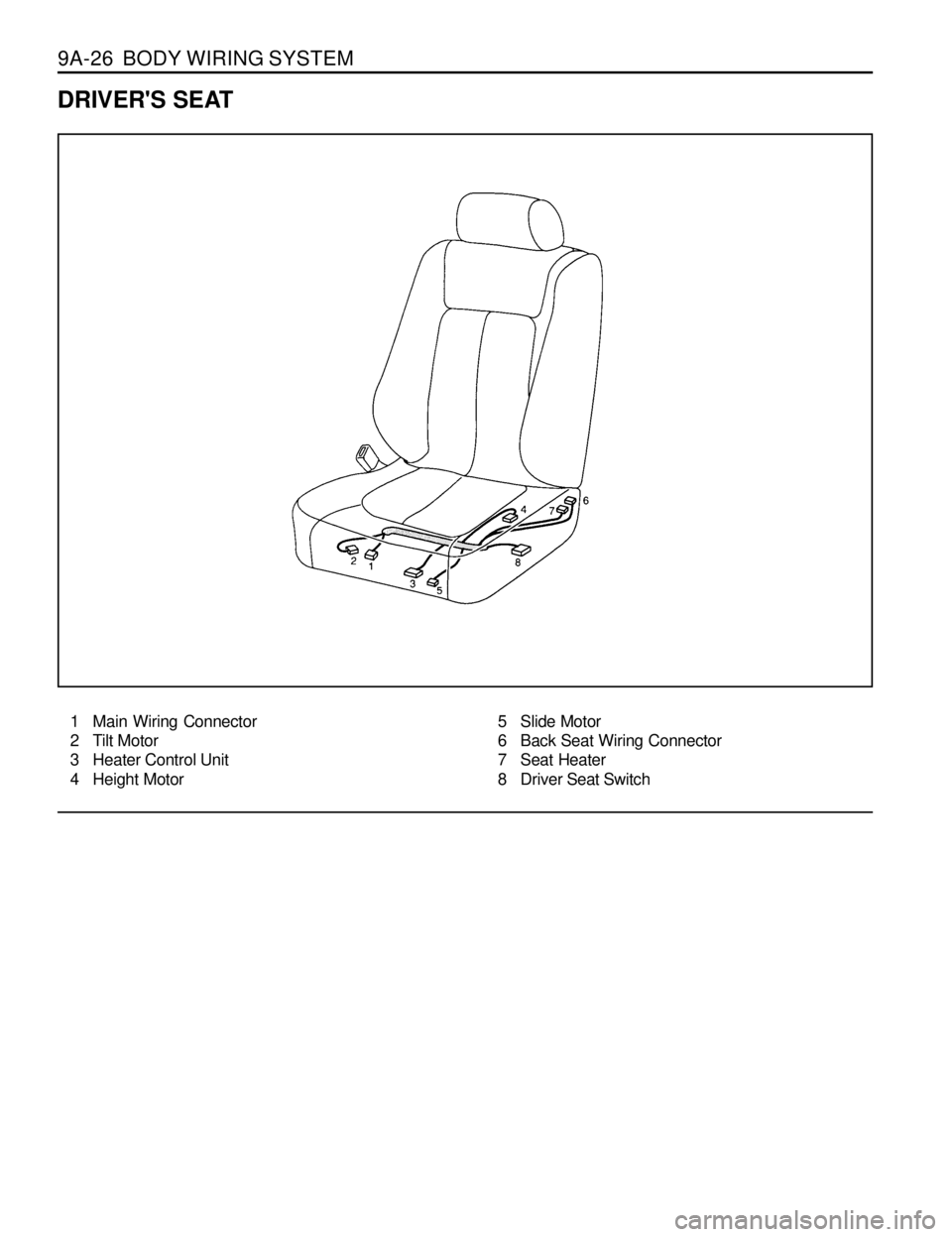

9A-26 BODY WIRING SYSTEM

DRIVER'S SEAT

1 Main Wiring Connector

2 Tilt Motor

3 Heater Control Unit

4 Height Motor5 Slide Motor

6 Back Seat Wiring Connector

7 Seat Heater

8 Driver Seat Switch

Page 1382 of 1463

SECTION 9H

SEATS

Caution: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise

noted.

TABLE OF CONTENTS

Specifications . . . . . . . . . . . . . . . . . . . . . . . . 9H-1

General Specifications . . . . . . . . . . . . . . . . . . 9H-1

Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . 9H-2

Schematic and Routing Diagrams . . . . . . . . 9H-3

Power Seat . . . . . . . . . . . . . . . . . . . . . . . . . . . 9H-3

Seat Warmer . . . . . . . . . . . . . . . . . . . . . . . . . . 9H-4Seat Belt & Tension Reducer Circuit . . . . . . . . 9H-5

Component Locator . . . . . . . . . . . . . . . . . . . 9H-6

Front Seat & Rear Seat . . . . . . . . . . . . . . . . . 9H-6

Maintenance and Repair . . . . . . . . . . . . . . . 9H-7

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . . 9H-7

SPECIFICATIONS

GENERAL SPECIFICATIONS

Slide

Tilt

Height

Tilt and Height(up)

Slide

Slide

Tilt and Height

Load Rating

Operating Temperature Range

Switch Operating Force Application

Deseription

DC11 - 15V

-30°C - 80°C

20 ± 7mm/sec

10.6 ± 5mm/sec

7 ± 2mm/sec

Tilt:35 ± 2mm, Height:35 ± 2mm

Forward:230mm

Less Then 7A

Less Then 7A

DC12V 1A

-30°C - 80°C

0.3 - 0.7Kgf Operating Voltage

Operating Temperature Range

Seat Operating Speed(at 13.5V)

Seat Operating Distance

Operating Current(at 13.5V)

Seat Heater Switch