SSANGYONG MUSSO 1998 Workshop Repair Manual

MUSSO 1998

SSANGYONG

SSANGYONG

https://www.carmanualsonline.info/img/67/57510/w960_57510-0.png

SSANGYONG MUSSO 1998 Workshop Repair Manual

Page 397 of 1463

OM600 ENGINE MECHANICAL 1B3-95

3. Remove the flywheel (3), if equipped with manual

transmission.

Installation Notice

Correctly align the position of dowel pin (2).

Tools Required

602 589 00 40 00 Engine Lock

Removal & Installation Procedure

1. Install the engine lock.

Engine Lock 602 589 02 40 00

2. Remove the 12-sided stretch bolts (4).

Installation Notice

Tightening Torque 45 Nm + 90°

Notice

If the length ‘L’ of bolts exceeds 22.5mm, replace the bolts.

Page 398 of 1463

1B3-96 OM600 ENGINE MECHANICAL

4. Remove the flywheel (6) and driven plate (5), if equipped

with automatic transmission.

Installation Notice

Correctly align the position of dowel pin (2).

5. Installation should follow the removal procedure in the

reverse order.

Page 399 of 1463

OM600 ENGINE MECHANICAL 1B3-97

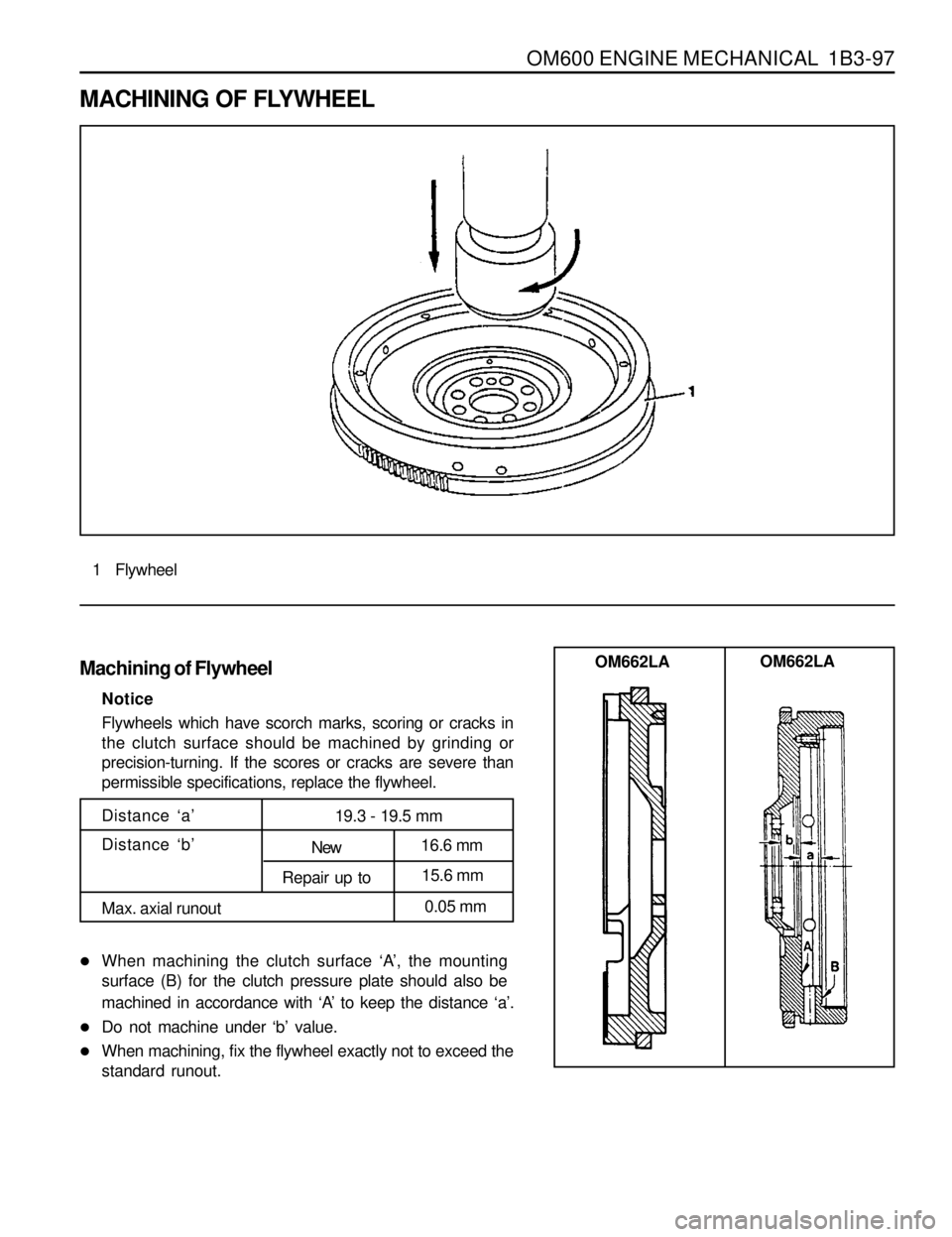

MACHINING OF FLYWHEEL

1 Flywheel

Machining of Flywheel

Notice

Flywheels which have scorch marks, scoring or cracks in

the clutch surface should be machined by grinding or

precision-turning. If the scores or cracks are severe than

permissible specifications, replace the flywheel.

lWhen machining the clutch surface ‘A’, the mounting

surface (B) for the clutch pressure plate should also be

machined in accordance with ‘A’ to keep the distance ‘a’.

lDo not machine under ‘b’ value.

lWhen machining, fix the flywheel exactly not to exceed the

standard runout.

OM662LA

OM662LA

Max. axial runout

Distance ‘a’

New

Repair up to19.3 - 19.5 mm16.6 mm

15.6 mm

0.05 mmDistance ‘b’

Page 400 of 1463

1B3-98 OM600 ENGINE MECHANICAL

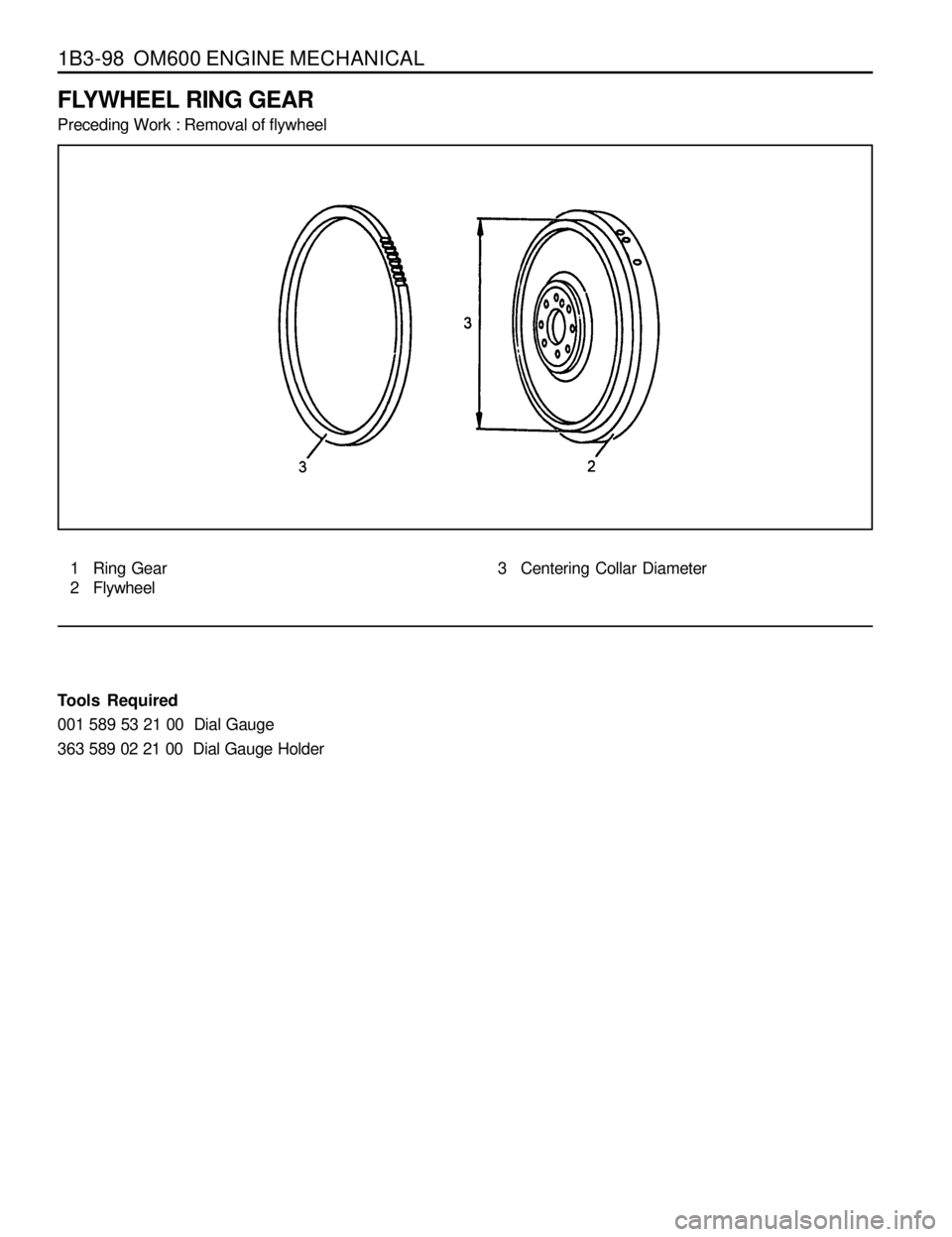

FLYWHEEL RING GEAR

Preceding Work : Removal of flywheel

1 Ring Gear

2 Flywheel3 Centering Collar Diameter

Tools Required

001 589 53 21 00 Dial Gauge

363 589 02 21 00 Dial Gauge Holder

Page 401 of 1463

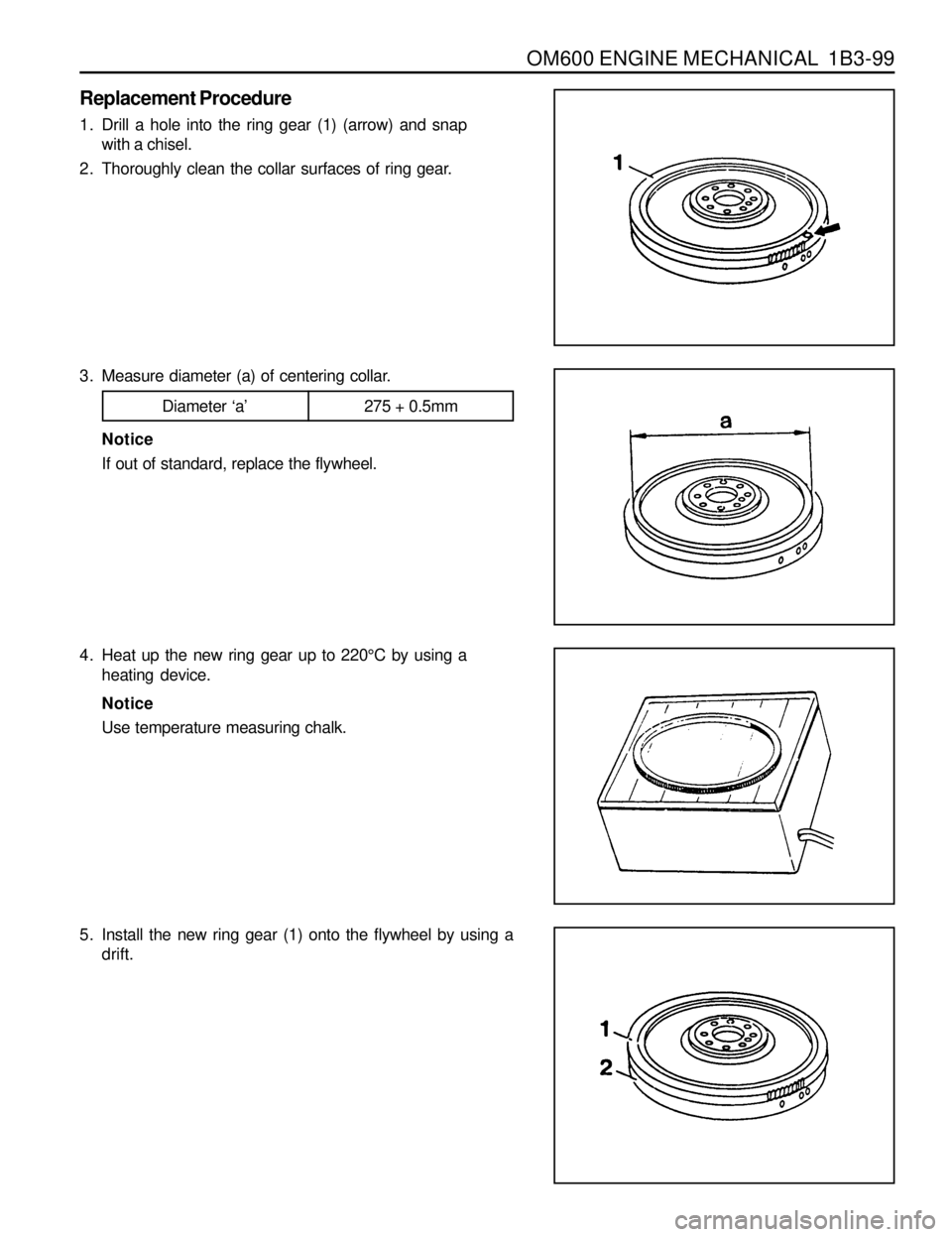

OM600 ENGINE MECHANICAL 1B3-99

Diameter ‘a’ 275 + 0.5mm

Replacement Procedure

1. Drill a hole into the ring gear (1) (arrow) and snap

with a chisel.

2. Thoroughly clean the collar surfaces of ring gear.

3. Measure diameter (a) of centering collar.

Notice

If out of standard, replace the flywheel.

4. Heat up the new ring gear up to 220°C by using a

heating device.

Notice

Use temperature measuring chalk.

5. Install the new ring gear (1) onto the flywheel by using a

drift.

Page 402 of 1463

1B3-100 OM600 ENGINE MECHANICAL

6. Measure axial runout of ring gear (1) on a surface plate.

Limit Max. 0.4mm

Notice

For correct measurement, put the flywheel on the flat

measuring board.

Dial Gauge 001 589 53 21 00

Dial Gauge Holder 363 589 02 21 00

Page 403 of 1463

OM600 ENGINE MECHANICAL 1B3-101

HYDRAULIC VALVE CLEARANCE COMPENSATION ELEMENT CHECK

1 Cylinder Head Cover

2 Bolt............................................................10Nm

3 Gasket ................................................... Replace4 Valve Tappet

5 Cylinder Head

Page 404 of 1463

1B3-102 OM600 ENGINE MECHANICAL

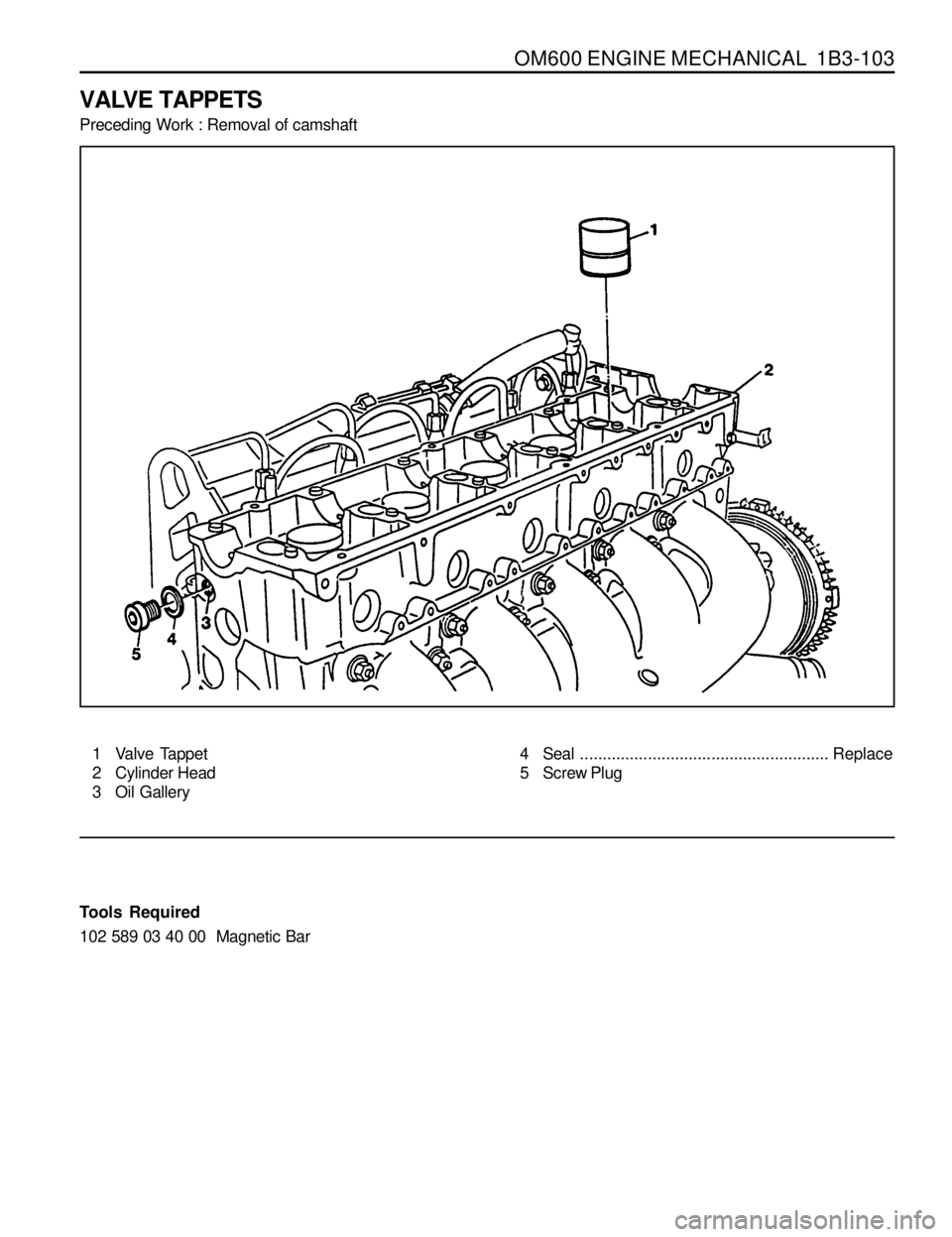

Checking

Notice

The noise which continues short time during short travel

(frequent starting of the engine) or engine starting after a

long time storage is normal operating conditions. So, it does

not need to be repaired. Determine the malfunctions in valve

clearance compensation device with noise through following

tests. If defective, replace as respectively.

1. Run the engine at more than 3000rpm for approx. 4 minutes.

2. Stop the engine. After 5minutes, check the engine oil level

and adjust if necessary.

3. Remove the cylinder head cover.

4. Check the valve tappets at TDC position of each cylinders.

5. Using a drift, lightly press the valve tappet and measure

clearance between the cam and valve tappet.

Notice

If the clearance exceeds 0.4mm, replace the valve tappet.

6. If a valve tappet moves down too far in comparison to the

others, replace the valve tappet.

7. Rotate the engine and check the remaining valve tappets.

Notice

lUnnecessary rotation of the engine will damage the valve

tappets.

lDo not rotate the engine by using the camshaft sprocket

bolt or to the opposite direction of the engine rotation.

Page 405 of 1463

OM600 ENGINE MECHANICAL 1B3-103

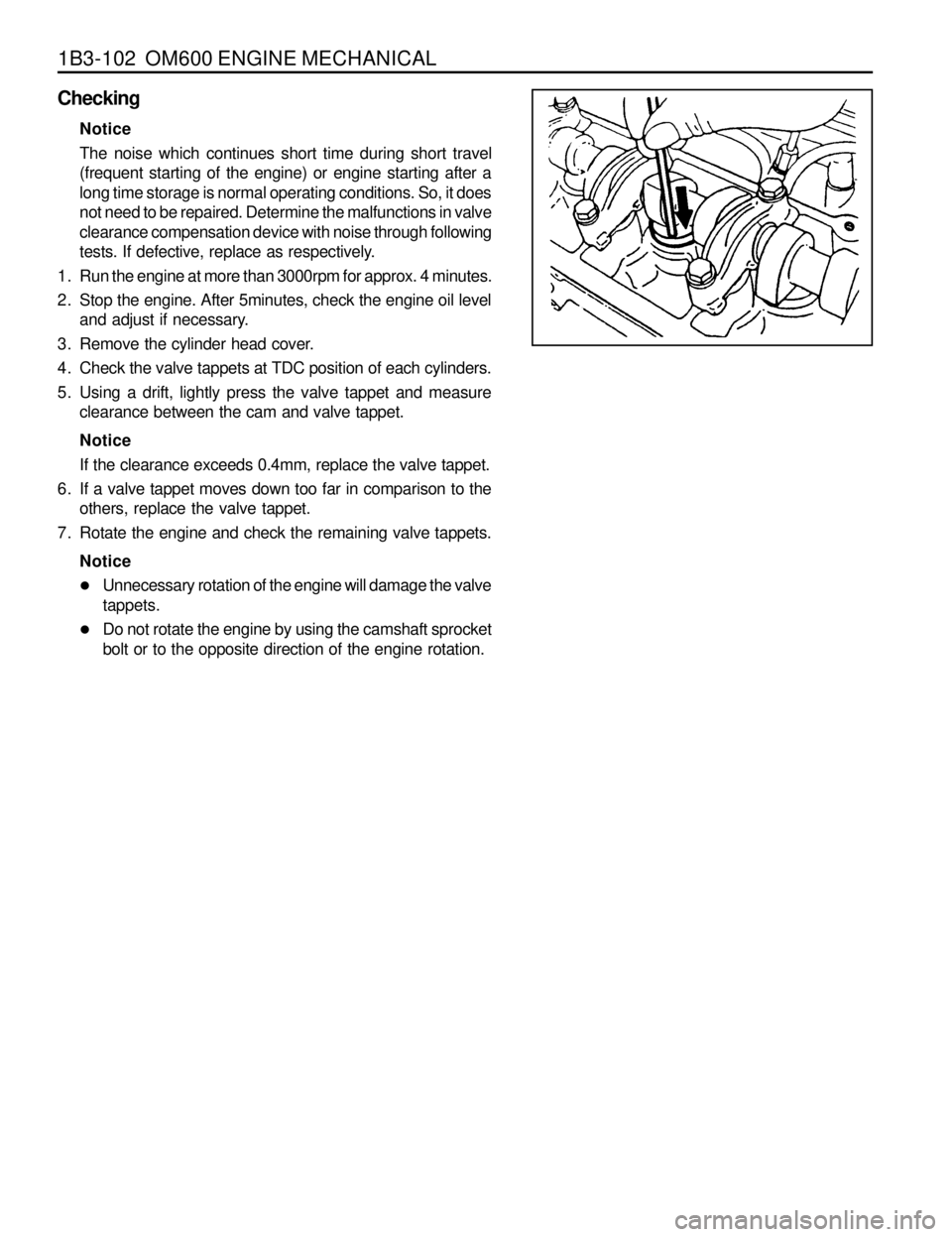

VALVE TAPPETS

Preceding Work : Removal of camshaft

1 Valve Tappet

2 Cylinder Head

3 Oil Gallery4 Seal....................................................... Replace

5 Screw Plug

Tools Required

102 589 03 40 00 Magnetic Bar

Page 406 of 1463

1B3-104 OM600 ENGINE MECHANICAL

Replacement Procedure

1. Pull out the valve tappet (1).

Magnetic Bar 102 589 03 40 00

2. Remove the plug (5) and blow compressed air into the oil

gallery (3). At this time, check that the outlet bores(arrow)

at the seat of the valve tappet are clear.

3. Replace the seal (4) and tighten the plug (5).

4. Insert the new valve tappet.

Notice

Coat the valve tappet with oil.