air bleeding SSANGYONG MUSSO 1998 Workshop Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 916 of 1463

SECTION 4A

HYDRAULIC BRAKES

Specifications . . . . . . . . . . . . . . . . . . . . . . . . 4A-1

General Specifications . . . . . . . . . . . . . . . . . . 4A-1

Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . 4A-2

Noise or Vehicle Vibration When Applied

Brake . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4A-2

Pulls to One Side When Braking . . . . . . . . . . . 4A-2

Poor Braking . . . . . . . . . . . . . . . . . . . . . . . . . . 4A-2

Increasing Pedal Stroke (Pedal Goes to

Floor) or Brake Dragging . . . . . . . . . . . . . . . 4A-3

Poor Braking of Parking Brake . . . . . . . . . . . . 4A-3

TABLE OF CONTENTS

Component Locator . . . . . . . . . . . . . . . . . . . 4A-4

ABS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4A-4

ABS / ABD . . . . . . . . . . . . . . . . . . . . . . . . . . . 4A-5

Non-ABS / ABD . . . . . . . . . . . . . . . . . . . . . . . . 4A-6

Maintenance and Repair . . . . . . . . . . . . . . . 4A-7

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . . 4A-7

Bleeding the Brakes . . . . . . . . . . . . . . . . . . . . 4A-7

Brake Pedal . . . . . . . . . . . . . . . . . . . . . . . . . . 4A-9

LCRV (Load Conscious Reducing Valve) . . . 4A-12

Caution: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this

cable will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK

unless otherwise noted.

Type

Pedal Ratio

Pedal Stroke

Pedal Freeplay

Type

Inner Diameter

Type

Ratio

Type

I.D. of Caliper Cylinder

Thickness of Brake Pad

Thickness of Disc Plate

Type

I.D. of Caliper Cylinder

Thickness of Brake Pad

Thickness of Disc Plate

Type

Operation

SpecificationPBR Brake

4.3 : 1

132 mm

f23.81 mm

5.0 : 1

f60.4 mm

¬

f40.5 mm

9.5 mm

¬ Suspended

1 - 4 mm

Tandem Type with Lever Sensor

Vacuum Booster Type

Ventilated Disc

10 mm

24 mm

Rear Wheel Internal Expansion Type

Mechanical

SAE J1703, DOT3

SPECIFICATIONS

GENERAL SPECIFICATIONS

Brake Pedal

Master Cylinder

Brake Booster

Front Brake

Rear Brake

Parking Brake

Brake FluidMANDO Brake

4.3 : 1

138 mm

f25.4 mm

5.6 : 1

f60 mm

Solid Disc

f38.2 mm

10.0 mm

10.4 mm

Application

Page 917 of 1463

4A-2 HYDRAULIC BRAKES

Check

Dirty or Lack of Fluid

Air in Brake System

Faulty Brake Booster

Poor Contact of Pad or Lining

Oil or Grease on Pad

Faulty Auto Adjuster

Over Heated Rotor Due to Dragging Pad or Lining

Clogging Brake Line

Faulty Proportioning ValveCheck

Incorrect Tire Pressure Between Left and Right

Poor Contact of Pad or Lining

Oil or Grease is Applied to Pad or Lining

Bent or Uneven Wear of Drum

Incorrectly Mounted Wheel Cylinder

Faulty Auto AdjusterAction

Repair

Retighten

Replace

Replace

Repair

Repair

Lubricate

Retighten Check

Incorrectly Mounted Back Plate or Caliper

Loosened Bolt of Back Plate or Caliper

Crack or Uneven Wear of Brake Drum or Disc

Pad or Lining Sticking to Contact Surface

Excessive Clearance Between Caliper and Pad

Uneven Contact of Pad

Lack of Lubrication

Loosened Suspension

DIGNOSIS

NOISE OR VEHICLE VIBRATION WHEN APPLIED BRAKE

PULLS TO ONE SIDE WHEN BRAKING

Action

Adjust

Repair

Replace

Replace

Repair

Replace

Action

Replenish or Replace(Check eventual leakage)

Bleeding

Replace

Repair

Replace

Replace

Repair

Repair

Repair

POOR BRAKING

( If low cut-in : Adjust )

( If Leakage : Replace )

Page 918 of 1463

HYDRAULIC BRAKES 4A-3

Check

Air in Brake system

Fluid Leaking

Excessive Clearance Between Push Rod and M/cylinder

Parking Brake is not Fully Released

Incorrect Adjustment of Parking Brake

Weak Return Spring of Brake Pedal

Incorrect Pedal Freeplay

Broken Rear Drum Brake Shoe Return Spring

Lack of Lubrication

Damaged Master Cylinder Check Valve or Piston Return SpringAction

Bleeding

Repair

Adjust

Repair

Adjust

Replace

Repair

Replace

lubricate

Replace

INCREASING PEDAL STROKE (PEDAL GOES TO FLOOR)

OR BRAKE DRAGGING

Check

Insufficient Clearance Between Push Rod and Master Cylinder

Worn Brake Lining

Oil or Grease on Lining

Binding Parking Brake Cable

Faulty Auto Adjuster

Excessive Lever StrokeAction

Adjust

Replace

Replace

Replace

Replace

Adjust or Check Cable

POOR BRAKING OF PARKING BRAKE

Page 922 of 1463

HYDRAULIC BRAKES 4A-7

MAINTENANCE AND REPAIR

ON-VEHICLE SERVICE

BLEEDING THE BRAKES

For Master Cylinder Replacement

1. Add oil after master cylinder replacement.

2. Run the engine and depress the brake pedal several times

to build pressure and then keep the pedal fully depressed.

3. Loosen the screws of primary and secondary pipe at the

master cylinder outlets to bleed air.

4. Repeat above step No.3 several times until there are no

more air bubbles.

5. Bleed air in the system at the hydraulic unit outlet pipe and

wheel if pressure building is not enough by depressing the

pedal only after above air bleeding.

For Caliper and Brake Hose Replacement

1. Check the oil level from the oil reservoir and refill if necessary.

2. Run the engine and depress the pedal several times to

build pressure and then keep the pedal fully depressed.

3. Connect a vinyl tube to the caliper breather and prepare a

container to coentain brake oil.

4. Loosen the breather screw until there are no more bubbles.

5. Bleed air in the system at four (4) wheels in order as shown

in right figure if pressure building is not enough by depressing

the pedal after above air bleeding.

Tightening Torque

9 - 14 Nm

Item

Front Bleeder Screw

Rear Bleeder Screw

Notice

lDo not reuse the bled brake fluid.

lAlways bleed the air after replacing brake fluid or

master cylinder, caliper, brake hose and pipe.

lAlways operate in normal order.

Page 923 of 1463

4A-8 HYDRAULIC BRAKES

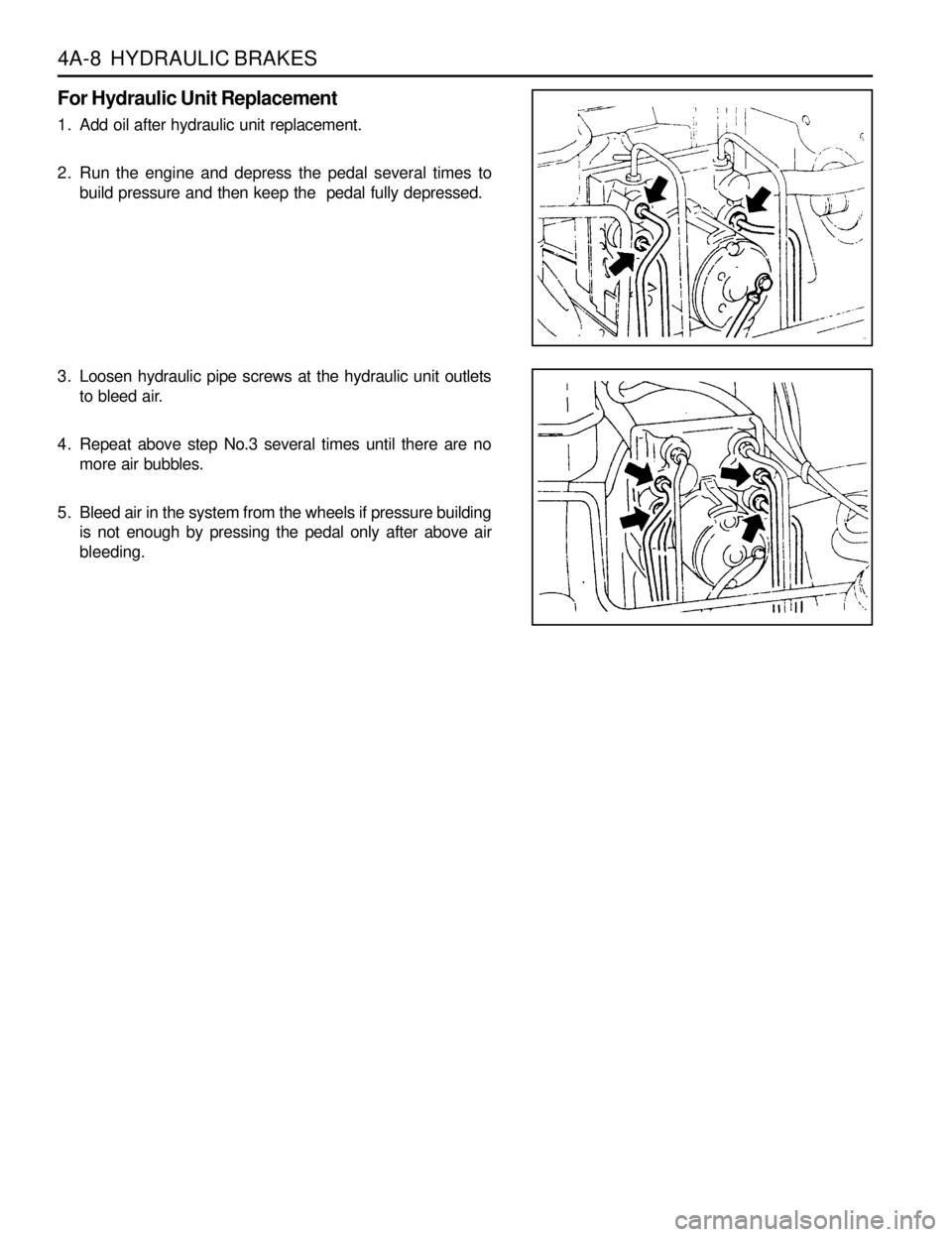

For Hydraulic Unit Replacement

1. Add oil after hydraulic unit replacement.

2. Run the engine and depress the pedal several times to

build pressure and then keep the pedal fully depressed.

3. Loosen hydraulic pipe screws at the hydraulic unit outlets

to bleed air.

4. Repeat above step No.3 several times until there are no

more air bubbles.

5. Bleed air in the system from the wheels if pressure building

is not enough by pressing the pedal only after above air

bleeding.

Page 928 of 1463

HYDRAULIC BRAKES 4A-13

Construction

LCRV consists of sensing part and hydraulic control part.

1. Sensing Part

It detects the changes of vehicle height caused by vehicle

load. It consists of load sensing spring and control lever

which change according to vehicle load.

2. Hydraulic Control Part

It consists of valve stem devices which controls hydraulic

pressure according to load detected by sensing part.

Trouble Shooting

Poor Braking

Possible Cause

Air in Brake System

Poor Adjustment of Sensor Spring

Damaged Sensor Spring

Fluid Leaking from LCRVRemedy

Bleeding

Adjust

Replace

Replace

Possible Cause

Poor Adjustment of Sensor Spring

Internal Fluid Leaking of LCRVRemedy

Adjust

Replace

Abnormal Locking

Page 1154 of 1463

Type

Clutch Pedal

Clutch Disc

Clutch Master Cylinder

Clutch Release Cylinder

Clutch FluidDescription

Hydraulic

Suspended

158 mm

5 - 10 mm

Single Dry Diaphragm

9.85 - 10.2 mm

9.2 mm

19.8 mm

f15.87 mm

14.0 mm

f17.46 mm

SAE J1703 / DOT3

SECTION 5C

CLUTCH

TABLE OF CONTENTS

Specifications . . . . . . . . . . . . . . . . . . . . . . . . 5C-1

General Specifications . . . . . . . . . . . . . . . . . . 5C-1

Fastener Tightening Specifications . . . . . . . . . 5C-2

Special Tools . . . . . . . . . . . . . . . . . . . . . . . . 5C-3

Special Tools Table . . . . . . . . . . . . . . . . . . . . . 5C-3

Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . 5C-4

Clutch Slips . . . . . . . . . . . . . . . . . . . . . . . . . . . 5C-4

Poor Disengagement . . . . . . . . . . . . . . . . . . . 5C-4

Hard to Shift or Will not Shift . . . . . . . . . . . . . . 5C-4

Clutch Chatters When Starting . . . . . . . . . . . . 5C-4

Difficult Pedal Operation . . . . . . . . . . . . . . . . . 5C-5

SPECIFICATIONS

GENERAL SPECIFICATIONS

Caution: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this

cable will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK

unless otherwise noted.

Application

Type

Max. Pedal Stroke

Pedal Free Play

Type

Thickness of Disc

Stroke

Inner Diameter

Stroke

Inner DiameterFree

With Load

Clutch Noisy . . . . . . . . . . . . . . . . . . . . . . . . . . 5C-5

Component Locator . . . . . . . . . . . . . . . . . . . 5C-6

Clutch Assembly . . . . . . . . . . . . . . . . . . . . . . . 5C-6

Pedal and Master Cylinder . . . . . . . . . . . . . . . 5C-7

Maintenance and Repair . . . . . . . . . . . . . . . 5C-8

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . . 5C-8

Bleeding of Clutch System . . . . . . . . . . . . . . . 5C-8

Clutch Disc . . . . . . . . . . . . . . . . . . . . . . . . . . . 5C-9

Master Cylinder . . . . . . . . . . . . . . . . . . . . . . 5C-13

Clutch Pedal . . . . . . . . . . . . . . . . . . . . . . . . . 5C-15

Clutch Oil Chamber . . . . . . . . . . . . . . . . . . . 5C-17

Page 1161 of 1463

5C-8 CLUTCH

MAINTENANCE AND REPAIR

ON-VEHICLE SERVICE

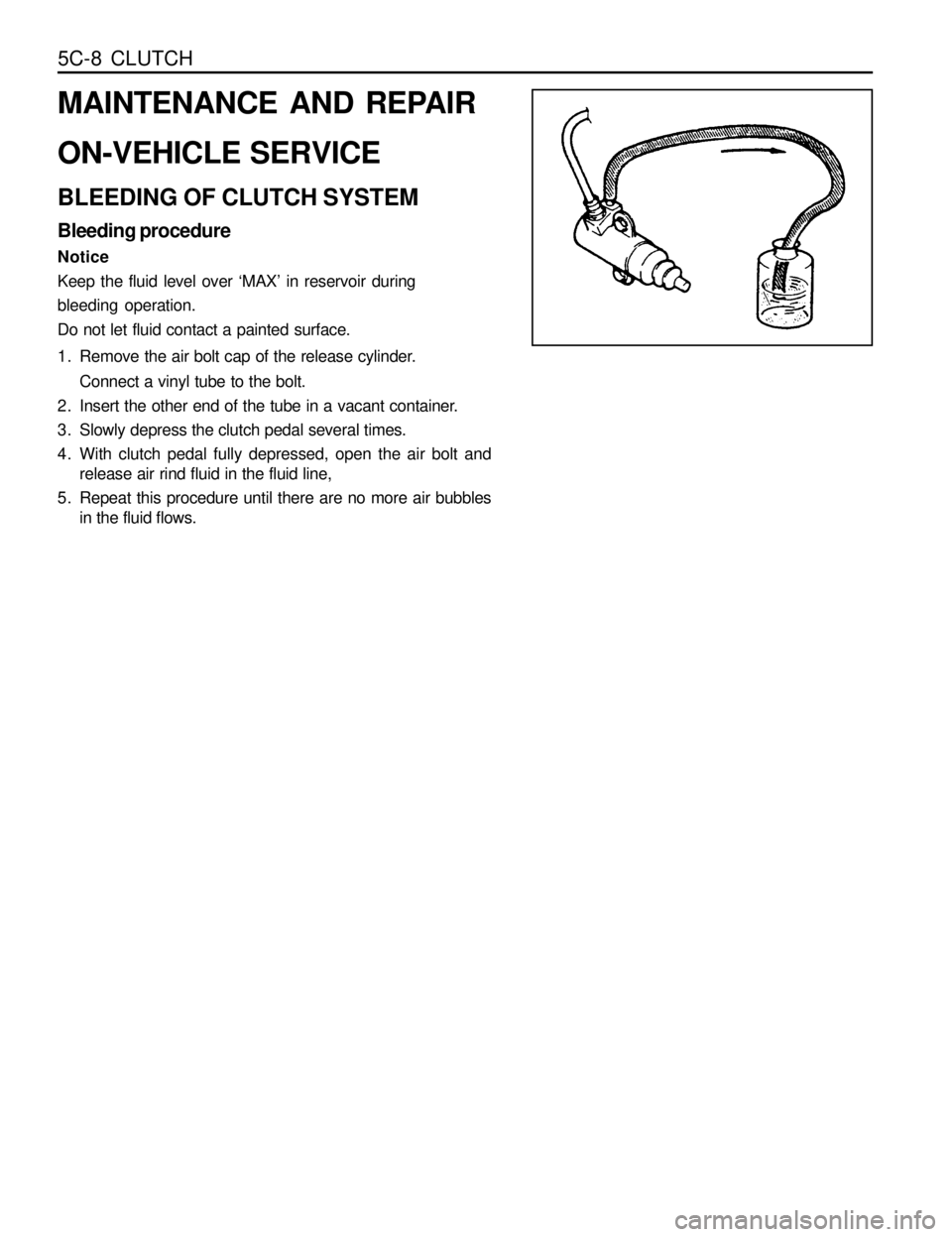

BLEEDING OF CLUTCH SYSTEM

Bleeding procedure

Notice

Keep the fluid level over ‘MAX’ in reservoir during

bleeding operation.

Do not let fluid contact a painted surface.

1. Remove the air bolt cap of the release cylinder.

Connect a vinyl tube to the bolt.

2. Insert the other end of the tube in a vacant container.

3. Slowly depress the clutch pedal several times.

4. With clutch pedal fully depressed, open the air bolt and

release air rind fluid in the fluid line,

5. Repeat this procedure until there are no more air bubbles

in the fluid flows.

Page 1261 of 1463

Application

Steering Wheel

Steering Gear Box

Oil Pump

Steering Column

Minmum Turning Radius

Oil

SECTION 6A

POWER STEERING SYSTEM

TABLE OF CONTENTS

Specifications . . . . . . . . . . . . . . . . . . . . . . . . 6A-1

General Specifications . . . . . . . . . . . . . . . . . . 6A-1

Fastener Tightening Specifications . . . . . . . . . 6A-1

Diagnosis . . . . . . . . . . . . . . . . . . . . . . . . . . . 6A-2

Hard Steering . . . . . . . . . . . . . . . . . . . . . . . . . 6A-2

Steering Pulls to One Side . . . . . . . . . . . . . . . 6A-2

Excessive Wheel Play . . . . . . . . . . . . . . . . . . . 6A-2

Poor Return of Steering Wheel . . . . . . . . . . . . 6A-2

Steering Wheel Shimmy . . . . . . . . . . . . . . . . . 6A-3

SPECIFICATIONS

GENERAL SPECIFICATIONS

Abnormal Noise From Steering System . . . . . 6A-3

Component Locator . . . . . . . . . . . . . . . . . . . 6A-4

Steering System . . . . . . . . . . . . . . . . . . . . . . . 6A-4

Maintenance and Repair . . . . . . . . . . . . . . . 6A-5

On-Vehicle Service . . . . . . . . . . . . . . . . . . . . . 6A-5

Inspection . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6A-5

Oil Pump Pressure Check . . . . . . . . . . . . . . . . 6A-6

Bleeding of Power Steering System . . . . . . . . 6A-6

Steering Gear Box . . . . . . . . . . . . . . . . . . . . . 6A-7

Number of Spoke

Outer Diameter

Type

Gear Ratio

Inner Steering Angle

Outer Steering Angle

Type

Maximum Pressure

Upper Tilting Angle

Lower Tilting Angle

Type

Capacity

Change Interval

Description

4

396 mm

Rack and Pinion

¥

33°37'

31°50'

Vane

75-82 kg/cm

2

4.646°

6.969°

5.25m

ATF DEXRON II

1 L

Every 24,000 km

FASTENER TIGHTENING SPECIFICATIONS

Application

Steering Shaft Bolt

Pressure Hose Bolt

Return Pipe Nut

Slotted Nut

Steering Gearbox BoltNlm

30 - 40

12 - 18

12 - 18

35 - 45

35 - 45

Page 1266 of 1463

6A-6 POWER STEERING SYSTEM

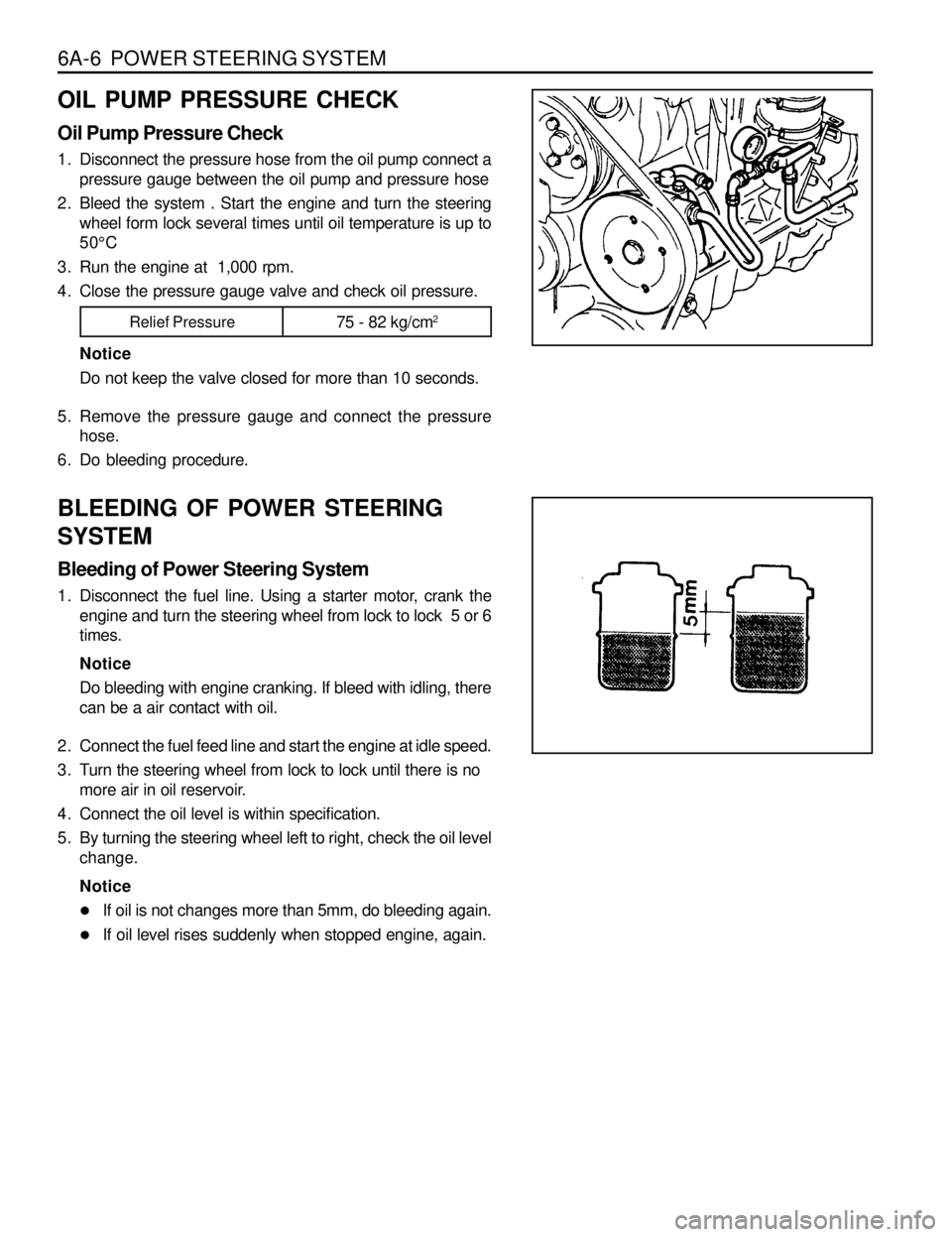

OIL PUMP PRESSURE CHECK

Oil Pump Pressure Check

1. Disconnect the pressure hose from the oil pump connect a

pressure gauge between the oil pump and pressure hose

2. Bleed the system . Start the engine and turn the steering

wheel form lock several times until oil temperature is up to

50°C

3. Run the engine at 1,000 rpm.

4. Close the pressure gauge valve and check oil pressure.

Notice

Do not keep the valve closed for more than 10 seconds.

5. Remove the pressure gauge and connect the pressure

hose.

6. Do bleeding procedure.

BLEEDING OF POWER STEERING

SYSTEM

Bleeding of Power Steering System

1. Disconnect the fuel line. Using a starter motor, crank the

engine and turn the steering wheel from lock to lock 5 or 6

times.

Notice

Do bleeding with engine cranking. If bleed with idling, there

can be a air contact with oil.

2. Connect the fuel feed line and start the engine at idle speed.

3. Turn the steering wheel from lock to lock until there is no

more air in oil reservoir.

4. Connect the oil level is within specification.

5. By turning the steering wheel left to right, check the oil level

change.

Notice

lIf oil is not changes more than 5mm, do bleeding again.

lIf oil level rises suddenly when stopped engine, again.

Relief Pressure75 - 82 kg/cm2