battery location SSANGYONG MUSSO 1998 Workshop Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 44 of 1463

GENERAL ENGINE INFORMATION 1A1-13

GENERAL INFORMATION

CLEANLINESS AND CARE

An automobile engine is a combination of many

machined, honed, polished and lapped surfaces with

tolerances that are measured in the ten-thousanths of

an inch. When any internal engine parts are serviced,

care and cleanliness are important. A liberal coating of

enigne oil should be applied to friction areas during

assembly, to protect and lubricate the surfaces on initial

operation. Proper cleaning and protection of machined

surfaces and friction areas is part of the repair

procedure. This is considered standard shop practice

even if not specifically stated.

Whenever valve train components are removed for

service, they should be kept in order. They should be

installed in the same locations, and with the same mating

surfaces, as when they were removed.Battery cables should be disconnected before any major

work is performed on the engine. Failure to disconnect

cables may result in damage to wire harness or other

electrical parts.

ON-ENGINE SERVICE

Caution: Disconnect the negative battery cable

before removing or installing any electrical unit, or

when a tool or equipment could easily come in

contact with exposed electrical terminals.

Disconnecting this cable will help prevent personal

injury and damage to the vehicle. The ignition must

also be in LOCK unless otherwise noted.

Notice: Any time the air cleaner is removed, the intake

opening should be covered. This will protect against

accidental entrance of foreign material, which could

follow the intake passage into the cylinder and cause

extensive damage when the engine is started.

Page 58 of 1463

1A2-14 GENERAL ENGINE INFORMATION

GENERAL INFORMATION

CLEANLINESS AND CARE

An automobile engine is a combination of many

machined, honed, polished and lapped surfaces with

tolerances that are measured in the ten-thousanths of

an inch. When any internal engine parts are serviced,

care and cleanliness are important. A liberal coating of

enigne oil should be applied to friction areas during

assembly, to protect and lubricate the surfaces on initial

operation. Proper cleaning and protection of machined

surfaces and friction areas is part of the repair

procedure. This is considered standard shop practice

even if not specifically stated.

Whenever valve train components are removed for

service, they should be kept in order. They should be

installed in the same locations, and with the same mating

surfaces, as when they were removed.

Battery cables should be disconnected before any major

work is performed on the engine. Failure to disconnect

cables may result in damage to wire harness or other

electrical parts.

ON-ENGINE SERVICE

Caution: Disconnect the negative battery cable be-

fore removing or installing any electrical unit, or

when a tool or equipment could easily come in con-

tact with exposed electrical terminals. Disconnect-

ing this cable will help prevent personal injury and

damage to the vehicle. The ignition must also be in

LOCK unless otherwise noted.

Notice: Any time the air cleaner is removed, the intake

opening should be covered. This will protect against

accidental entrance of foreign material, which could

follow the intake passage into the cylinder and cause

extensive damage when the engine is started.

Page 73 of 1463

GENERAL ENGINE INFORMATION 1A3-15

GENERAL INFORMATION

CLEANLINESS AND CARE

An automobile engine is a combination of many

machined, honed, polished and lapped surfaces with

tolerances that are measured in the ten-thousanths

of an inch. When any internal engine parts are

serviced, care and cleanliness are important. A liberal

coating of enigne oil should be applied to friction areas

during assembly, to protect and lubricate the surfaces

on initial operation. Proper cleaning and protection

of machined surfaces and friction areas is part fo the

repair procedure. This is considered standard shop

practice even if not specifically stated.

Whenever valve train components are removed for

service, they should be kept in order. They should be

installed in the same locations, and with the same

mating surfaces, as when they were removed.Battery cables should be disconnected before any

major work is performed on the engine. Failure to

disconnect cables may result in damage to wire

harness or other electrical parts.

ON-ENGINE SERVICE

Caution: Disconnect the negative battery cable

before removing or installing any electrical unit,

or when a tool or equipment could easily come in

contact with exposed electrical terminals.

Disconnecting this cable will help prevent

personal injury and damage to the vehicle. The

ignition must also be in LOCK unless otherwise

noted.

Notice: Any time the air cleaner is removed, the intake

opening should be covered. This will protect against

accidental entrance of foreign material, which could

follow the intake passage into the cylinder and cause

extensive damage when the engine is started.

Page 606 of 1463

1F1-36 M162 ENGINE CONTROLS

Location

Engine ECU is located at the inside of cowl side trim in right

bottom of instrument panel of passenger side.

Removal & Installation Procedure

1. Turn the ignition switch to "OFF" position.

2. Disconnect the battery negative cable

3. Remove the cowl side trim form passenger side.

4. Unscrew four securing nuts for ECU from mounting bracket.

Installation Notice

5. Pulling out the ECU from bracket.

6. Disconnect the vehicle side coupling(B).

7. Installation should follow the removal procedure in the

reverse order.

Tightening Torque 9 - 11 Nm

Page 684 of 1463

M161 ENGINE CONTROLS 1F2-35

Location

Engine ECU is located at the inside of cowl side trim in right

bottom of instrument panel of passenger side.

Removal & Installation Procedure

1. Turn the ignition switch to "OFF" position.

2. Disconnect the battery negative cable

3. Remove the cowl side trim form passenger side.

4. Unscrew four securing nuts for ECU from mounting bracket.

Installation Notice

5. Pulling out the ECU from bracket.

6. Disconnect the vehicle side coupling(B).

7. Installation should follow the removal procedure in the

reverse order.

Tightening Torque 9 - 11 Nm

Page 963 of 1463

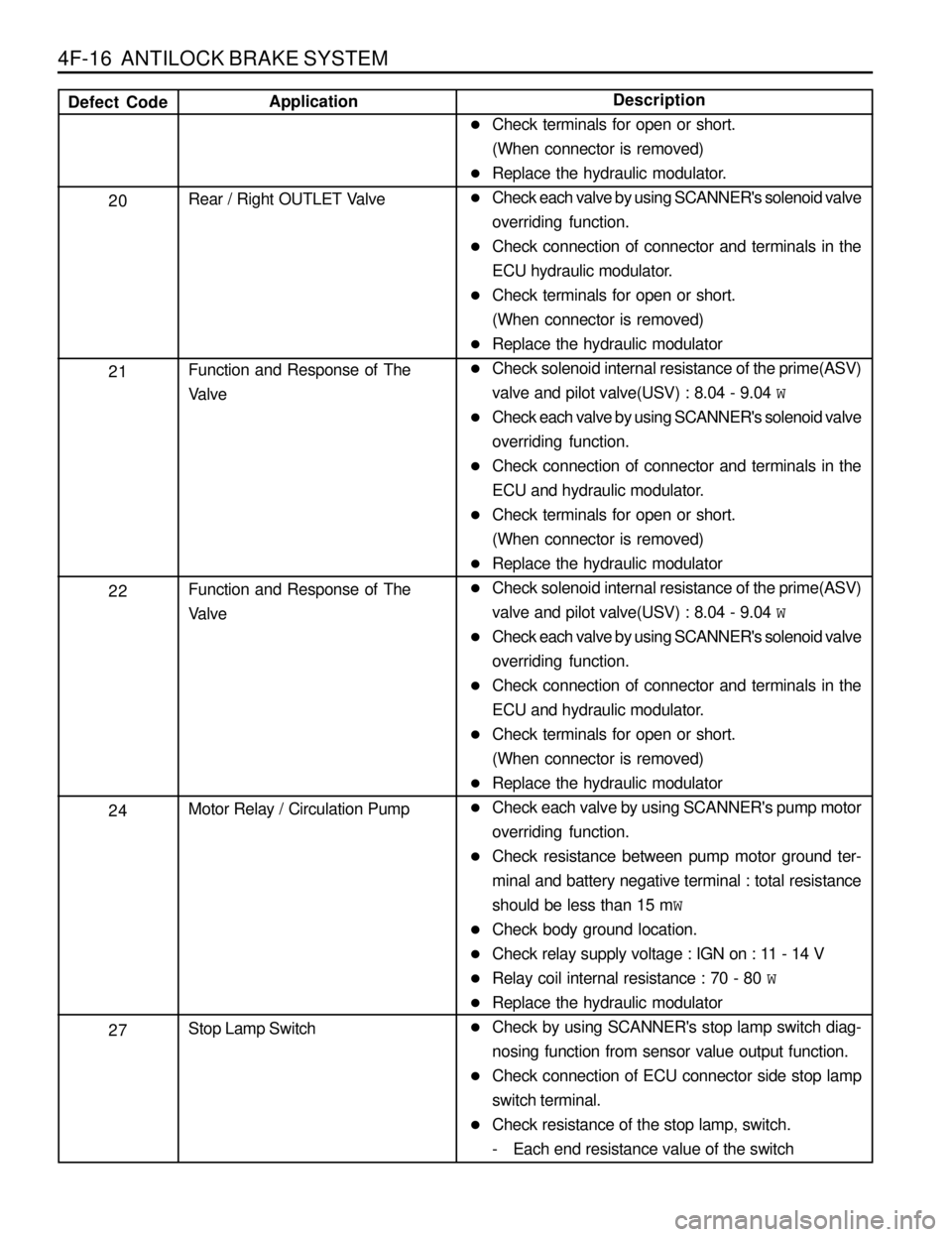

4F-16 ANTILOCK BRAKE SYSTEM

Description

lCheck terminals for open or short.

(When connector is removed)

lReplace the hydraulic modulator.

lCheck each valve by using SCANNER's solenoid valve

overriding function.

lCheck connection of connector and terminals in the

ECU hydraulic modulator.

lCheck terminals for open or short.

(When connector is removed)

lReplace the hydraulic modulator

lCheck solenoid internal resistance of the prime(ASV)

valve and pilot valve(USV) : 8.04 - 9.04 W

lCheck each valve by using SCANNER's solenoid valve

overriding function.

lCheck connection of connector and terminals in the

ECU and hydraulic modulator.

lCheck terminals for open or short.

(When connector is removed)

lReplace the hydraulic modulator

lCheck solenoid internal resistance of the prime(ASV)

valve and pilot valve(USV) : 8.04 - 9.04 W

lCheck each valve by using SCANNER's solenoid valve

overriding function.

lCheck connection of connector and terminals in the

ECU and hydraulic modulator.

lCheck terminals for open or short.

(When connector is removed)

lReplace the hydraulic modulator

lCheck each valve by using SCANNER's pump motor

overriding function.

lCheck resistance between pump motor ground ter-

minal and battery negative terminal : total resistance

should be less than 15 mW

lCheck body ground location.

lCheck relay supply voltage : IGN on : 11 - 14 V

lRelay coil internal resistance : 70 - 80 W

lReplace the hydraulic modulator

lCheck by using SCANNER's stop lamp switch diag-

nosing function from sensor value output function.

lCheck connection of ECU connector side stop lamp

switch terminal.

lCheck resistance of the stop lamp, switch.

- Each end resistance value of the switch Application

Rear / Right OUTLET Valve

Function and Response of The

Valve

Function and Response of The

Valve

Motor Relay / Circulation Pump

Stop Lamp Switch

Defect Code

20

21

22

24

27

Page 1004 of 1463

AUTOMATIC TRANSMISSION 5A-27

Shift Lever Position

Manual 1

Manual 2

Manual 3

Drive

Netural

Reverse

ParkResistance (OHMS)

1k - 1.4k

1.8k - 2.2k

3k - 3.4k

4.5k - 4.9k

6.8k - 7.2k

10.8k - 11.2k

18.6k - 19k

Table 3.3 - Readings for Resistance/Shift Lever Positions

Diagnostics Inputs

The diagnostics control input or K-line is used to initiate the outputting of diagnostics data from the TCU to a diagnostic

test instrument. This input may also be used to clear the stored fault history data from the TCU’s

retentive memory. Connection to the diagnostics input of the TCU is via a connector included in the vehicle’s wiring

harness or computer interface. Refer to the vehicle manufacturer’s manual for the location of the self test

connectors.

Battery Voltage Monitoring Input

The battery voltage monitoring input connects to the positive side of the battery. The signal is taken from the

main supply to the TCU.

If operating conditions are such that the battery voltage at the TCU falls below 11.3V the transmission will adopt a ‘low

voltage’ mode of operating in which shifts into first gear are inhibited. All other shifts are allowed but may not occur

because of the reduced voltage. This condition normally occurs only when the battery is in poor condition.

When system voltage recovers, the TCU will resume normal operation after a 3 second delay period.

TCU Outputs

The outputs from the TCU are supplied to the components described below:

Solenoids

The TCU controls seven solenoids. Solenoids 1 to 6 (S1 to S6) are mounted in the valve body, while Solenoid 7 (S7)

is mounted in the pump cover. The normal state (OPEN/CLOSED) and the functions associated with the solenoids

are detailed in table 3.4. Table 3.5 details the S1 and S2 logic for static gear states. The logic during gear changes for

S1 to S4 and S7 is detailed in table 3.6.

Page 1327 of 1463

SECTION 9A

BODY WIRING SYSTEM

Schematic and Routing Diagrams . . . . . . . . 9A-2

Power Distribution . . . . . . . . . . . . . . . . . . . . . . 9A-2

Starting & Charging (Gasoline HFM) . . . . . . . 9A-3

Starting & Charging (Diesel) . . . . . . . . . . . . . . 9A-4

Fuse Box and Relay . . . . . . . . . . . . . . . . . . . 9A-5

Location of Connectors by

Wiring Harness . . . . . . . . . . . . . . . . . . . . . 9A-7

Main . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9A-7

Engine Room . . . . . . . . . . . . . . . . . . . . . . . . 9A-11

Floor . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9A-13

Roof . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9A-14

Driver's Door . . . . . . . . . . . . . . . . . . . . . . . . . 9A-15

Passenger's Door . . . . . . . . . . . . . . . . . . . . . 9A-15

TABLE OF CONTENTS

Caution: Disconnect the negative battery cable before removing or installing any electrical unit or when a

tool or equipment could easily come in contact with exposed electrical terminals. Disconnecting this cable

will help prevent personal injury and damage to the vehicle. The ignition must also be in LOCK unless otherwise

noted.

Rear Left Door . . . . . . . . . . . . . . . . . . . . . . . 9A-16

Rear Right Door . . . . . . . . . . . . . . . . . . . . . . 9A-16

Tail Gate . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9A-17

Semi Automatic Air Conditioner . . . . . . . . . . 9A-18

Full automatic Air Conditioner . . . . . . . . . . . . 9A-19

Gasoline Engine (MSE) . . . . . . . . . . . . . . . . 9A-20

Gasoline Engine (HFM) . . . . . . . . . . . . . . . . 9A-21

Diesel Engine . . . . . . . . . . . . . . . . . . . . . . . . 9A-22

Manual Transmission . . . . . . . . . . . . . . . . . . 9A-23

Automatic Transmission (BENZ) . . . . . . . . . . 9A-24

Automatic Transmission (BTRA) . . . . . . . . . . 9A-25

Driver's Seat . . . . . . . . . . . . . . . . . . . . . . . . . 9A-26