cruise control SSANGYONG MUSSO 1998 Workshop Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 578 of 1463

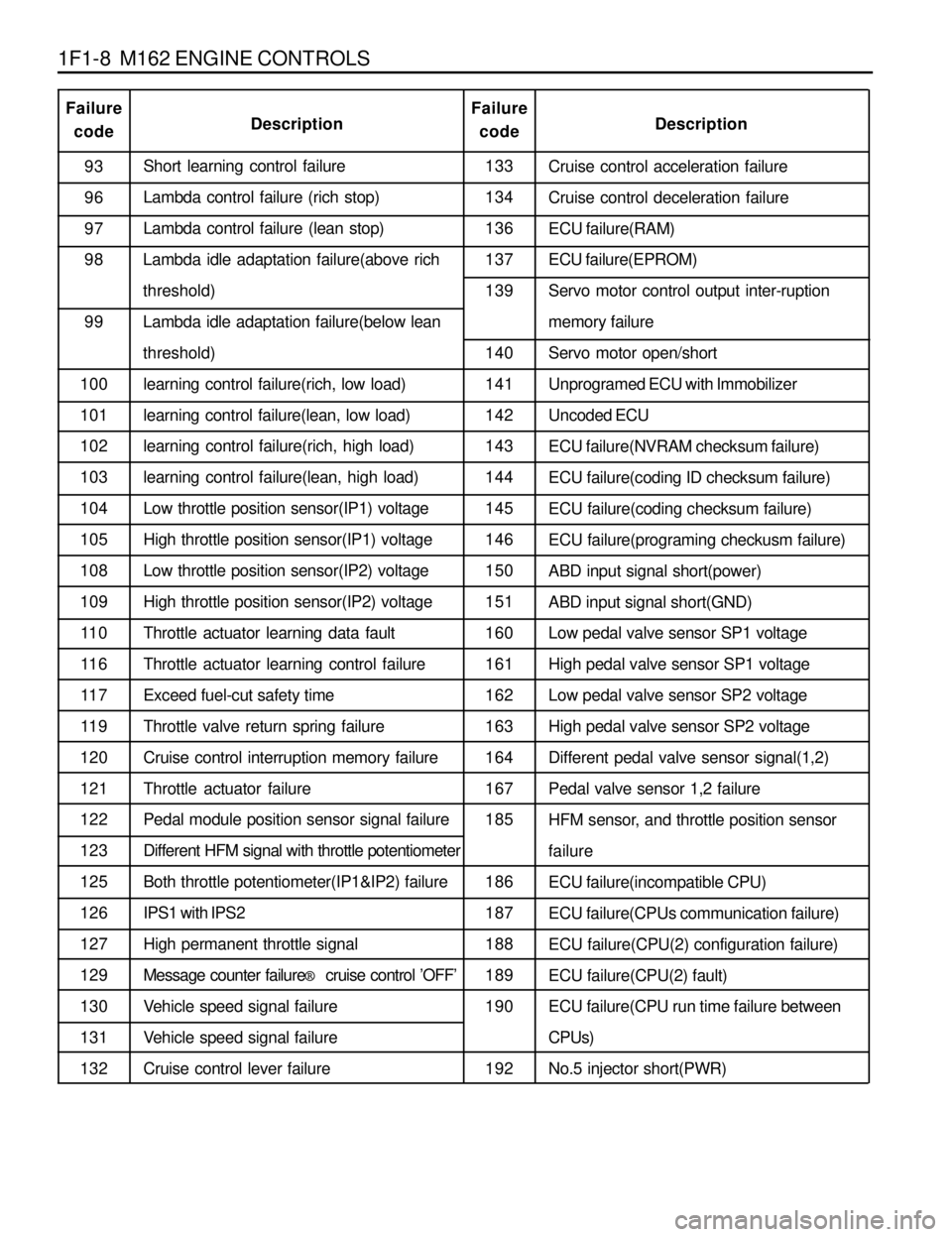

1F1-8 M162 ENGINE CONTROLS

Cruise control acceleration failure

Cruise control deceleration failure

ECU failure(RAM)

ECU failure(EPROM)

Servo motor control output inter-ruption

memory failure

Servo motor open/short

Unprogramed ECU with Immobilizer

Uncoded ECU

ECU failure(NVRAM checksum failure)

ECU failure(coding ID checksum failure)

ECU failure(coding checksum failure)

ECU failure(programing checkusm failure)

ABD input signal short(power)

ABD input signal short(GND)

Low pedal valve sensor SP1 voltage

High pedal valve sensor SP1 voltage

Low pedal valve sensor SP2 voltage

High pedal valve sensor SP2 voltage

Different pedal valve sensor signal(1,2)

Pedal valve sensor 1,2 failure

HFM sensor, and throttle position sensor

failure

ECU failure(incompatible CPU)

ECU failure(CPUs communication failure)

ECU failure(CPU(2) configuration failure)

ECU failure(CPU(2) fault)

ECU failure(CPU run time failure between

CPUs)

No.5 injector short(PWR) 93

96

97

98

99

100

101

102

103

104

105

108

109

11 0

11 6

11 7

11 9

120

121

122

123

125

126

127

129

130

131

132Short learning control failure

Lambda control failure (rich stop)

Lambda control failure (lean stop)

Lambda idle adaptation failure(above rich

threshold)

Lambda idle adaptation failure(below lean

threshold)

learning control failure(rich, low load)

learning control failure(lean, low load)

learning control failure(rich, high load)

learning control failure(lean, high load)

Low throttle position sensor(IP1) voltage

High throttle position sensor(IP1) voltage

Low throttle position sensor(IP2) voltage

High throttle position sensor(IP2) voltage

Throttle actuator learning data fault

Throttle actuator learning control failure

Exceed fuel-cut safety time

Throttle valve return spring failure

Cruise control interruption memory failure

Throttle actuator failure

Pedal module position sensor signal failure

Different HFM signal with throttle potentiometer

Both throttle potentiometer(IP1&IP2) failure

IPS1 with IPS2

High permanent throttle signal

Message counter failure® cruise control ’OFF’

Vehicle speed signal failure

Vehicle speed signal failure

Cruise control lever failure133

134

136

137

139

140

141

142

143

144

145

146

150

151

160

161

162

163

164

167

185

186

187

188

189

190

192

Failure

codeDescriptionFailure

codeDescription

Page 608 of 1463

1F1-38 M162 ENGINE CONTROLS

Pin No.Abbreciation Decription

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60BRS

-

-

-

-

-

KLIKU

-

-

-

GND

SP1+5V

KP

TEV

ML

-

CAN L

CAN H

-

-

-

-

KPI

KLIMA

KLIMA

-

SP1S

SP2S

BLS

GND

SP2+2.5V

S+B

WA

S-B

KSK

-

AUS

DIAG

V-SIG

TN-SIG Brake switch

-

-

-

-

-

Air conditioning clutch relay

-

-

-

Pedal potentiometer 1 ground

Pedal potentiometer 1 supply

Fuel pump relay

Tank purge valve

Engine fan (H1)

-

CAN-Low

CAN-High

-

-

-

-

Clutch switch

Air conditioning

Electronic traction signal

-

Pedal potentiometer 1 signal

Pedal potentiometer 2 signal

Brake light switch

Pedal potentiometer 2 ground

Pedal potentiometer 2 supply

Cruise accelerate/Set

Cruise resume

Cruise decelerate/Set

Cruise safety contact switch

-

Cruise off switch

Diagnostics (k-line)

Vehicle speed signal

Engine speed signal

Page 612 of 1463

1F1-42 M162 ENGINE CONTROLS

Pin No.Description

Pedal potentiometer 1 ground

Pedal potentiometer 1 supply

Fuel pump relay

Tank purge valve

Engine fan

-

CAN-Low

CAN-High

-

-

-

-

Clutch switch

Air conditioning

Electronic traction signal(ABD)

-

Pedal potentiometer 1 signal

Pedal potentiometer 2 signal

Brake light switch

Pedal potentiometer 2 ground

Pedal potentiometer 2 supply

Cruise accelerate/Set

Cruise resume

Cruise decelerate/Set

Cruise safety contact switch

-

Cruise off switch

Diagnostics(K-line)

Vehicle speed signal

Engine speed signal31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60GND

SP1+5V

KP

TEV

ML

-

CAN L

CAN H

-

-

-

-

KPL

KLIMA

ETS

-

SP1S

SP2S

BLS

GND

SP2+2.5V

S+B

WA

S-B

KSK

-

AUS

DIAG

V-SIG

TN-SIGl

l

l

l

l

-

l

l

-

-

-

-

¡

l

¡

-

l

l

¡

l

l

¡

¡

¡

¡

-

¡

l

l

ll

l

l

l

l

-

l

l

-

-

-

-

¡

l

¡

-

l

l

¡

l

l

¡

¡

¡

¡

-

¡

l

l

l

Remarks

AbbreviationE32 ENG,

5speed M/T E32 ENG,

4speed A/T

(BTRA)

Page 657 of 1463

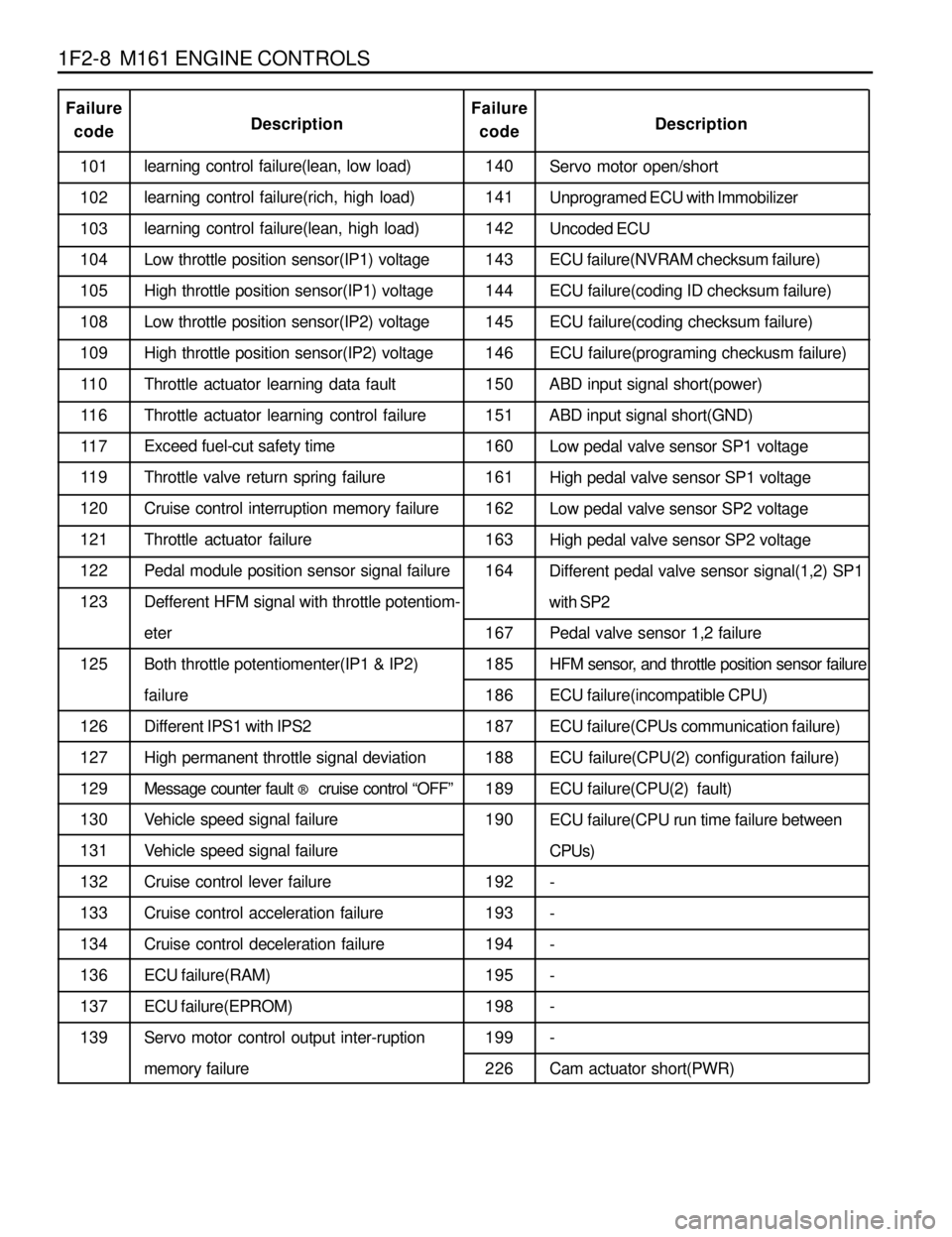

1F2-8 M161 ENGINE CONTROLS

Servo motor open/short

Unprogramed ECU with Immobilizer

Uncoded ECU

ECU failure(NVRAM checksum failure)

ECU failure(coding ID checksum failure)

ECU failure(coding checksum failure)

ECU failure(programing checkusm failure)

ABD input signal short(power)

ABD input signal short(GND)

Low pedal valve sensor SP1 voltage

High pedal valve sensor SP1 voltage

Low pedal valve sensor SP2 voltage

High pedal valve sensor SP2 voltage

Different pedal valve sensor signal(1,2) SP1

with SP2

Pedal valve sensor 1,2 failure

HFM sensor, and throttle position sensor failure

ECU failure(incompatible CPU)

ECU failure(CPUs communication failure)

ECU failure(CPU(2) configuration failure)

ECU failure(CPU(2) fault)

ECU failure(CPU run time failure between

CPUs)

-

-

-

-

-

-

Cam actuator short(PWR) 101

102

103

104

105

108

109

11 0

11 6

11 7

11 9

120

121

122

123

125

126

127

129

130

131

132

133

134

136

137

139140

141

142

143

144

145

146

150

151

160

161

162

163

164

167

185

186

187

188

189

190

192

193

194

195

198

199

226 learning control failure(lean, low load)

learning control failure(rich, high load)

learning control failure(lean, high load)

Low throttle position sensor(IP1) voltage

High throttle position sensor(IP1) voltage

Low throttle position sensor(IP2) voltage

High throttle position sensor(IP2) voltage

Throttle actuator learning data fault

Throttle actuator learning control failure

Exceed fuel-cut safety time

Throttle valve return spring failure

Cruise control interruption memory failure

Throttle actuator failure

Pedal module position sensor signal failure

Defferent HFM signal with throttle potentiom-

eter

Both throttle potentiomenter(IP1 & IP2)

failure

Different IPS1 with IPS2

High permanent throttle signal deviation

Message counter fault ® cruise control “OFF”

Vehicle speed signal failure

Vehicle speed signal failure

Cruise control lever failure

Cruise control acceleration failure

Cruise control deceleration failure

ECU failure(RAM)

ECU failure(EPROM)

Servo motor control output inter-ruption

memory failure

Failure

codeDescriptionFailure

codeDescription

Page 658 of 1463

M161 ENGINE CONTROLS 1F2-9

227

228

229

232

233

234

235

236

237

238

239

240

241Cam actuator open/short(GND)

A/C compressor relay short(PWR)

A/C compressor relay open/short(GND)

Decel limit defected by CPU2

Accel limit defected by CPU2

Cruise control lever double input(CPU2)

Cruise control lever safety terminal

failure(CPU2)

Unusual pedal position variation(CPU2)

Unusual throttle position variation(CPU2)

Unusual throttle control data(CPU2)

Unusual pedal position sensor(CPU2)

Throttle potentiometer fault(CPU2)

Unusual CPU communication(CPU2)242

243

244

245

246

247

248

249

250

251Unusual CPU configuration(CPU2)

AD converter failure(CPU2)

Pedal position sensor setpoint fault berween

CPU1 and CPU2

Position setpoint fault berween CPU1 and

CPU2

-

Idle controller setpoint fault berween CPU1

and CPU2

AD converter overflow degected by CPU2

ROM fault degected by CPU2

RAM fault degected by CPU2

Cycle monitor fault degected by CPU2

Failure

codeDescriptionFailure

codeDescription

Page 686 of 1463

M161 ENGINE CONTROLS 1F2-37

Pin No.Abbreviation Description

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60BRS

-

-

-

-

-

KLIKU

-

-

-

GND

SP1+5V

KP

TEV

ML

-

CAN L

CAN H

-

-

-

-

KPI

KLIMA

ETS

-

SP1S

SP2S

BLS

GND

SP2+2.5V

S+B

WA

S-B

KSK

-

AUS

DIAG

V-SIG

TN-SIG Brake switch

-

-

-

-

-

Air conditioning clutch relay

-

-

-

Pedal potentiometer 1 ground

Pedal potentiometer 1 supply

Fuel pump relay

Tank purge valve

Engine fan(High)

-

CAN-Low

CAN-High

-

-

-

-

-

Air conditioning

Electronic traction signal

-

Pedal potentiometer 1 signal

Pedal potentiometer 2 signal

Brake light switch

Pedal potentiometer 2 ground

Pedal potentiometer 2 supply

Cruise accelerate/Set

Cruise resume

Cruise decelerate/Set

Cruise safety contact switch

-

Cruise off switch

Diagnostics(K-Line)

Vehicle speed signal

Engine speed signal

Page 690 of 1463

M161 ENGINE CONTROLS 1F2-41

Pin No.Abbreviation Description

Pedal potentiometer 1 ground

Pedal potentiometer 1 supply

Fuel pump relay

Tank purge valve

Engine fan

-

CAN-Low

CAN-High

-

-

-

-

-

Air conditioning

Electronic traction signal(ABD option only)

-

Pedal potentiometer 1 signal

Pedal potentiometer 2 signal

Brake light switch(Cruisel option only)

Pedal potentiometer 2 ground

Pedal potentiometer 2 supply

Cruise accelerate/Set(Cruisel option only)

Cruise resume(Cruisel option only)

Cruise decelerate/Set(Cruisel option only)

Cruise safety contact switch(Cruisel option only)

-

Cruise off switch(Cruisel option only)

Diagnostics(K-Line)

Vehicle speed signal

Engine speed signal31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

51

52

53

54

55

56

57

58

59

60GND

SP1+5V

KP

TEV

ML

-

CAN L

CAN H

-

-

-

-

-

KLIMA

ETS

-

SP1S

SP2S

BLS

GND

SP2+2.5V

S+B

WA

S-B

KSK

-

AUS

DIAG

V-SIG

TN-SIGl

l

l

l

l

-

l

l

-

-

-

-

-

l

¡

-

l

l

¡

l

l

¡

¡

¡

¡

-

¡

l

l

ll

l

l

l

l

-

l

l

-

-

-

-

-

l

¡

-

l

l

¡

l

l

¡

¡

¡

¡

-

¡

l

l

l

E23 ENG,

4speed A/T E23 ENG,

5speed A/T

Page 995 of 1463

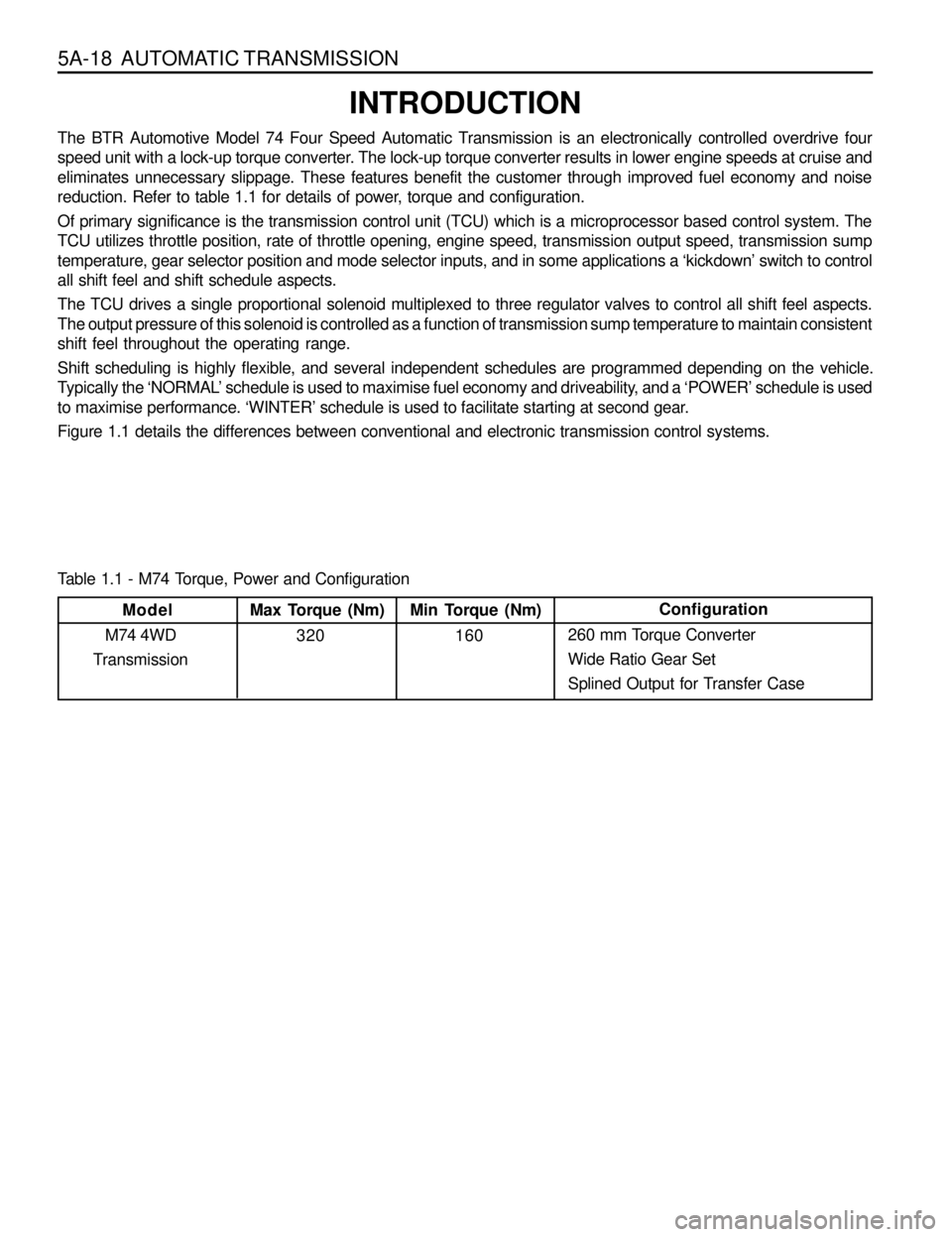

5A-18 AUTOMATIC TRANSMISSION

INTRODUCTION

The BTR Automotive Model 74 Four Speed Automatic Transmission is an electronically controlled overdrive four

speed unit with a lock-up torque converter. The lock-up torque converter results in lower engine speeds at cruise and

eliminates unnecessary slippage. These features benefit the customer through improved fuel economy and noise

reduction. Refer to table 1.1 for details of power, torque and configuration.

Of primary significance is the transmission control unit (TCU) which is a microprocessor based control system. The

TCU utilizes throttle position, rate of throttle opening, engine speed, transmission output speed, transmission sump

temperature, gear selector position and mode selector inputs, and in some applications a ‘kickdown’ switch to control

all shift feel and shift schedule aspects.

The TCU drives a single proportional solenoid multiplexed to three regulator valves to control all shift feel aspects.

The output pressure of this solenoid is controlled as a function of transmission sump temperature to maintain consistent

shift feel throughout the operating range.

Shift scheduling is highly flexible, and several independent schedules are programmed depending on the vehicle.

Typically the ‘NORMAL’ schedule is used to maximise fuel economy and driveability, and a ‘POWER’ schedule is used

to maximise performance. ‘WINTER’ schedule is used to facilitate starting at second gear.

Figure 1.1 details the differences between conventional and electronic transmission control systems.

Max Torque (Nm)

320Configuration

260 mm Torque Converter

Wide Ratio Gear Set

Splined Output for Transfer CaseMin Torque (Nm)

160 Model

M74 4WD

Transmission Table 1.1 - M74 Torque, Power and Configuration