fuel pump SSANGYONG MUSSO 1998 Workshop Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 16 of 1463

0B-4 GENERAL INFORMATION

Specifications

RACK & PINION

0 - 4 mm

2°30’± 30’

0° ± 30’

1L Application

Gear Type

Wheel Alignment:

Front Toe-in

Front Caster

Front Camber

Oil Capacity

Steering System

Application

Front Type

Rear Type

Suspension

Specifications

Double Wishbone

5 - Link

Application

Fuel Pump Type

Fuel Filter Type

Fuel Capacity

Specifications

Electric Motor Pump

Cartridge

70 L

Fuel System

Lubricating Type

Oil Pump Type

Oil Filter Type

Oil Capacity (L) (Including Oil Filter)

Lubricating System

661LA

8.0662NA

9.0662LA

9.52.0L DOHC

7.22.3L DOHC

7.53.2L DOHC

8.2

External Gear pump

Combination(Full & Part)

Full Flow

Cooling Type

Coolant Capacity (L)

Radiator Type

Water Pump Type

Cooling System

661LA

9.5-10662NA

10.5662LA

10.5-112.0L DOHC

10.52.3L DOHC

10.53.2L DOHC

11.3

Forced Circulation

Centrifugal

Application

Battery (MF)

Generator

Starter

Electric System

661LA

75A

2.2kw662NA

75A

2.2kw662LA

75A

2.2kw2.0L DOHC

115A

1.2kw2.3L DOHC

115A

1.2kw3.2L DOHC

115A

1.7kw

12V - 90AH12V - 75AH

Page 33 of 1463

1A1-2 GENERAL ENGINE INFORMATION

Application

Idle Speed (rpm)

Fuel Injection Pressure (kg/cm²)

Oil Capacity (liter)

Lubrication Type

Oil Filter Type

Fuel

ENGINE SPECIFICATIONS (Cont'd)

E32 Engine

700 ± 50

3 - 4

8.2

Forced by Gear Pump

Full Flow with Paper Filter

Unleaded Gasoline

MSE 3.62S/3.53S (Motorsteuer Elektronik : German)

MSE : Engine Control Electronic

3.62S : 6 Cylinder Version

3.53S : 4 Cylinder Version

Page 46 of 1463

1A2-2 GENERAL ENGINE INFORMATION

E20 Engine

¬

¬

¬

¬

¬

¬ Application

Idle Speed (rpm)

Fuel Injection Pressure (kg/cm²)

Oil Capacity (liter)

Lubrication Type

Oil Filter Type

Fuel

ENGINE SPECIFICATIONS (Cont'd)

E23 Engine

750 ± 50

3.2 - 4.2

7.5

Forced by Gear Pump

Full Flow with Paper Filter

Unleaded Gasoline

MSE 3.62S/3.53S (Motorsteuer Elektronik : German)

MSE : Engine Control Electronic

3.62S : 6 cylinder version

3.53S : 4 cylinder version

Page 47 of 1463

GENERAL ENGINE INFORMATION 1A2-3

COMPONENT LOCATOR

FRONT VIEW

1 HFM Sensor

2 Intake Air Duct

3 Cylinder Head Cover

4 Ignition Coil

5 Spark Plug Connector

6 Fuel Distributor

7 Injector

8 Exhaust Camshaft

9 Intake Camshaft

10 Valve Tappet

11 Intake Valve12 Intake Manifold

13 Cylinder Head

14 Exhaust Manifold

15 Dipstick Guide Tube and Gauge

16 Connecting Rod

17 Crankshaft

18 Engine Mounting Bracket

19 Starter

20 Crankcase

21 Oil Pump Sprocket

22 Oil Pan

Page 60 of 1463

1A3-2 GENERAL ENGINE INFORMATION

OM 662 LA

720 - 820

135 - 143

8.0 - 9.5

Forced by Gear Pump

Combined Full-Flow and Partial Flow

Filter

Diesel Application

Idle Speed (rpm)

Fuel Injection Pressure (bar)

Oil Capacity (liter)

Lubrication Type

Oil Filter Type

Fuel

ENGINE SPECIFICATIONS (Cont'd)

OM661LA

750 - 850

135 - 143

6.5 - 8.0

Forced by Gear Pump

Combined Full-Flow and Partial Flow

Filter

Diesel

Page 70 of 1463

1A3-12 GENERAL ENGINE INFORMATION

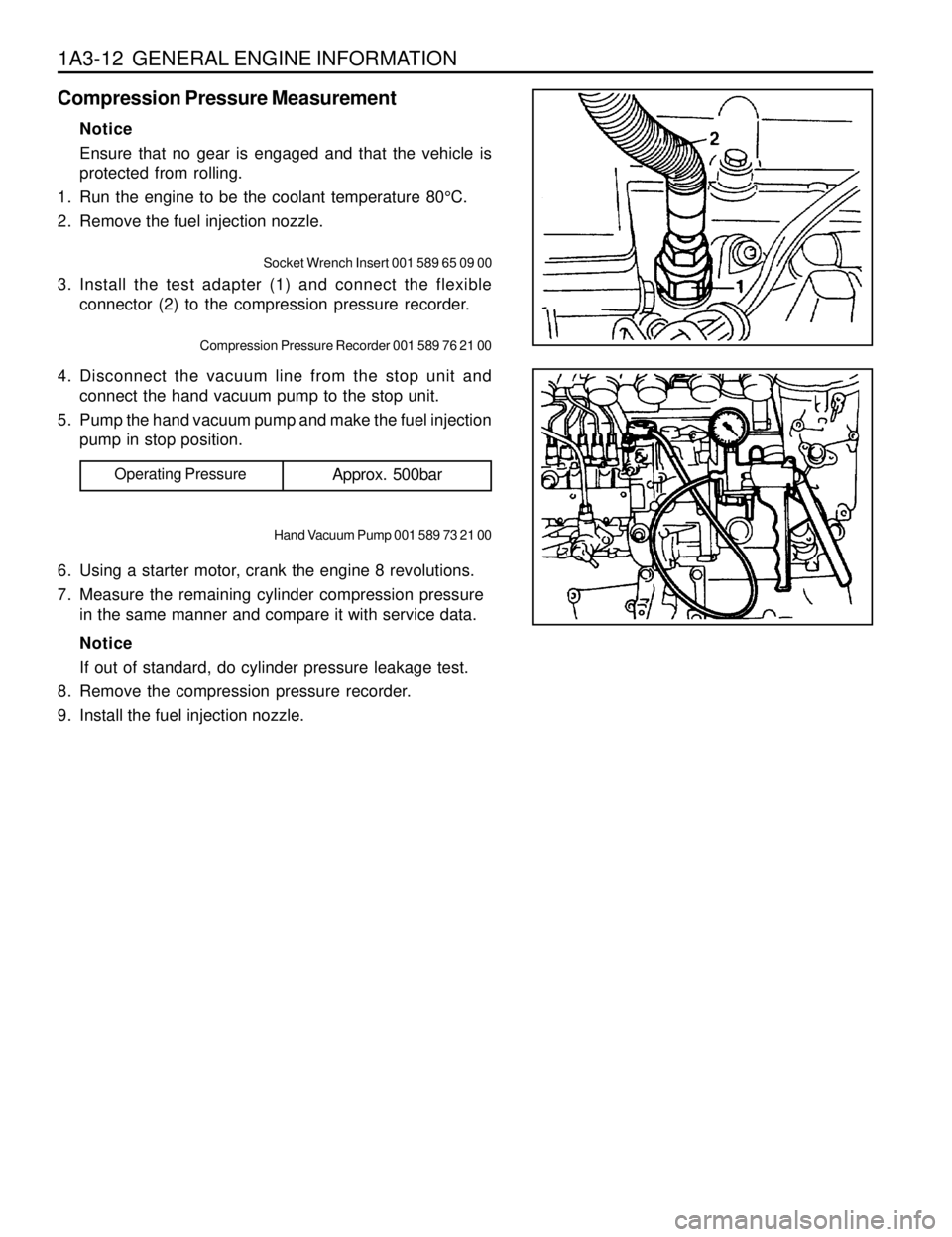

Compression Pressure Measurement

Notice

Ensure that no gear is engaged and that the vehicle is

protected from rolling.

1. Run the engine to be the coolant temperature 80°C.

2. Remove the fuel injection nozzle.

Socket Wrench Insert 001 589 65 09 00

3. Install the test adapter (1) and connect the flexible

connector (2) to the compression pressure recorder.

Compression Pressure Recorder 001 589 76 21 00

4. Disconnect the vacuum line from the stop unit and

connect the hand vacuum pump to the stop unit.

5. Pump the hand vacuum pump and make the fuel injection

pump in stop position.

Operating PressureApprox. 500bar

Hand Vacuum Pump 001 589 73 21 00

6. Using a starter motor, crank the engine 8 revolutions.

7. Measure the remaining cylinder compression pressure

in the same manner and compare it with service data.

Notice

If out of standard, do cylinder pressure leakage test.

8. Remove the compression pressure recorder.

9. Install the fuel injection nozzle.

Page 75 of 1463

1B1-2 M162 ENGINE MECHANICAL

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

N

· ·· ·

·m

35 - 40

10 - 15

5 - 10

21 - 25

30

56 - 66

50 - 60

10 - 15

41.5 - 49.5

22.5 - 27.5

22.5 - 27.5

9 - 11

9 - 11

22.5 - 27.5

9 - 11

22.5 - 27.5

10

+90°

55

+90°

+90°

22.5 - 27.5

22.5 - 27.5

9 - 10

9 - 10

200

+90°

40

+90°

45

+90°

35

9 - 11

20

+90°

20

+90°

20 / + 90°

20 / + 90°

22.5 - 27.5Application

Power Steering Hydraulic Lines

A/C High Pressure and Liquid Hose

Radiator Support Menber Bolt

Fuel Supply and Return Hose to Fuel Distributor

Exhaust Manifold and Pipe

Propeller Shaft to Transmission

Engine Mounting Nut

Alternator Carrier Bolt

Belt Pulley Bolt

Steering Pump Bolt

A/C Bracket Bolt

Intake Air Duct Bolt

Ignition Cable Cover Bolt

Cylinder Head Cover Bolt

Camshaft Adjuster Bolt

Cylinder Head Front Cover Bolt

Flange Bolt in Exhaust Camshaft Sprocket

Cylinder Head Bolt

Cooling Fan Bracket Bolt

Timing Gear Case Cover Bolt M8

M6

Crankshaft Rear Cover Bolt

Vibration Damper Center Bolt

Connecting Rod Bearing Cap Bolt

Flywheel Stretch Bolt

Amarture Bolt in Flywheel

Ring and Seal Cover Nut in Flywheel

Sprocket Bolt to Exhaust Camshaft

Camshaft Adjuster Flange Bolt

Intake Flange Shaft Bolt

Exhaust Camshaft Sprocket Bolt

Camshaft Bearing Cap Bolt

Page 191 of 1463

1B2-2 M161 ENGINE MECHANICAL

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

N

· ·· ·

·m

35 - 40

10 - 15

5 - 10

21 - 25

30

56 - 66

50 - 60

22.5 - 27.5

41.5 - 49.5

22.5 - 27.5

22.5 - 27.5

9 - 11

9 - 11

9 - 11

9 - 11

22.5 - 27.5

10

+90°

55

+90°

+90°

22.5 - 27.5

22.5 - 27.5

9 - 10

9 - 10

200

+90°

40

+90°

45

+90°

35

9 - 11

20

+90°

20

+90°

20 / + 90°

20 / + 90°

22.5 - 27.5Application

Power Steering Hydraulic Lines

A/C High Pressure and Liquid Hose

Radiator Support Menber Bolt

Fuel Supply and Return Hose to Fuel Distributor

Exhaust Manifold and Pipe

Propeller Shaft to Transmission

Engine Mounting Nut

Alternator Carrier Bolt

Belt Pulley Bolt

Steering Pump Bolt

A/C Bracket Bolt

Intake Air Duct Bolt

Ignition Cable Cover Bolt

Cylinder Head Cover Bolt

Camshaft Adjuster Bolt

Cylinder Head Front Cover Bolt

Flange Bolt in Exhaust Camshaft Sprocket

Cylinder Head Bolt

Cooling Fan Bracket Bolt

Timing Gear Case Cover Bolt M8

M6

Crankshaft Rear Cover Bolt

Vibration Damper Center Bolt

Connecting Rod Bearing Cap Bolt

Flywheel Stretch Bolt

Amarture Bolt in Flywheel

Ring and Seal Cover Nut in Flywheel

Sprocket Bolt to Exhaust Camshaft

Camshaft Adjuster Flange Bolt

Intake Flange Shaft Bolt

Exhaust Camshaft Sprocket Bolt

Camshaft Bearing Cap Bolt

Page 304 of 1463

1B3-2 OM600 ENGINE MECHANICAL

SPECIFICATIONS

FASTENER TIGHTENING SPECIFICATIONS

N

· ·· ·

·m

28 - 47

30

3 - 7

8 - 18

20 - 34

30

70 - 80

81 - 84

50 - 75

N

· ·· ·

·m

10

23

200 / 90°

10

55 / 90°

45 / 90°

25 / 90°

25

N

· ·· ·

·m

35 / 90°

N

· ·· ·

·m

45 / 90°Application

Skid Plate Bolt

Drain Plug Bolt

Coolong Fan Shroud Bolt

Control Linkage Nut

Clutch Linkage Cylinder Nut

Exhaust Manifold Bolt

Propeller Shaft Bolt & Nut (Axle)

Propeller Shaft Bolt & Nut(T/C)

Engine Mounting Nut

Application

Cooling Fan Belt Pulley Bolt

Socket Bolt

Tighten The Bolt

End Cover Bolt

Crankshaft Bearing Cap Bolt

Ball Bearing

Camshaft Sprocket Bolt

Oil Pump Sprocket Bolt

Application

Connecting Rod Bolt

Application

12-Sided Stretch Bolt

Engine Assembly

Crankshaft Assembly

Piston

Flywheel

Cylinder Head

Application

Prechamber Threaded Ring

Cylinder Head Cover Bolt

Fuel Injsction Pipe Nut

Socket Bolt

Fuel Filter Pipe Bolt

Idle Pulley Bolt

Damper BoltN

· ·· ·

·m

130

10

18

25

25

23

21

Page 318 of 1463

1B3-16 OM600 ENGINE MECHANICAL

16. Remove the power steering pump lines.

Notice

Completely drain the fluid.

17. Disconnect the fuel feed line with prefilter from the feed

pump on injection pump.

18. Vehicle with automatic transmission.

Remove the hydraulic lines (19, 20) from oil cooler (2).

19. Disconnect the engine harness.

20. Disconnect the preheating time relay cable.