ground clearance SSANGYONG MUSSO 1998 Workshop Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 1259 of 1463

5D2-52 TRANSFER CASE (TOD)

32. Install shift shaft oil seal if it is not installed.

33. Using pliers equipped with soft jaws, rotate the triangular

shaft so it is aligned with the triangular slot in the transfer

case shift motor. If triangular shaft will not rotate, rotate

the rear output shaft.

34. Slightly loosen the two nuts that attach the slotted support

bracket to the end of the motor house.

35. Apply Black Non-Acid Cure Silicone Rubber or equivalent

to motor housing base and install on transfer case.

36. Install the transfer case shift motor and three bolts along

with speed sensor wire harness bracket and tighten.

Notice

The wire harness must be routed as shown to provide

clearance and to prevent the wire harness from grounding

the damper.

37. Holding the slotted support bracket tight against the motor

housing end, secure the bracket to the transfer case,

tightening the bolt with lockwasher to 8-11 Nm (72-96 lb-

in).

38. Retighten the two nuts that attach the slotted support

bracket to the end of the motor.

39. Install the clutch coil wire terminal and sensor wires.

Page 1265 of 1463

POWER STEERING SYSTEM 6A-5

MAINTENANCE AND REPAIR

ON-VEHICLE SERVICE

INSPECTION

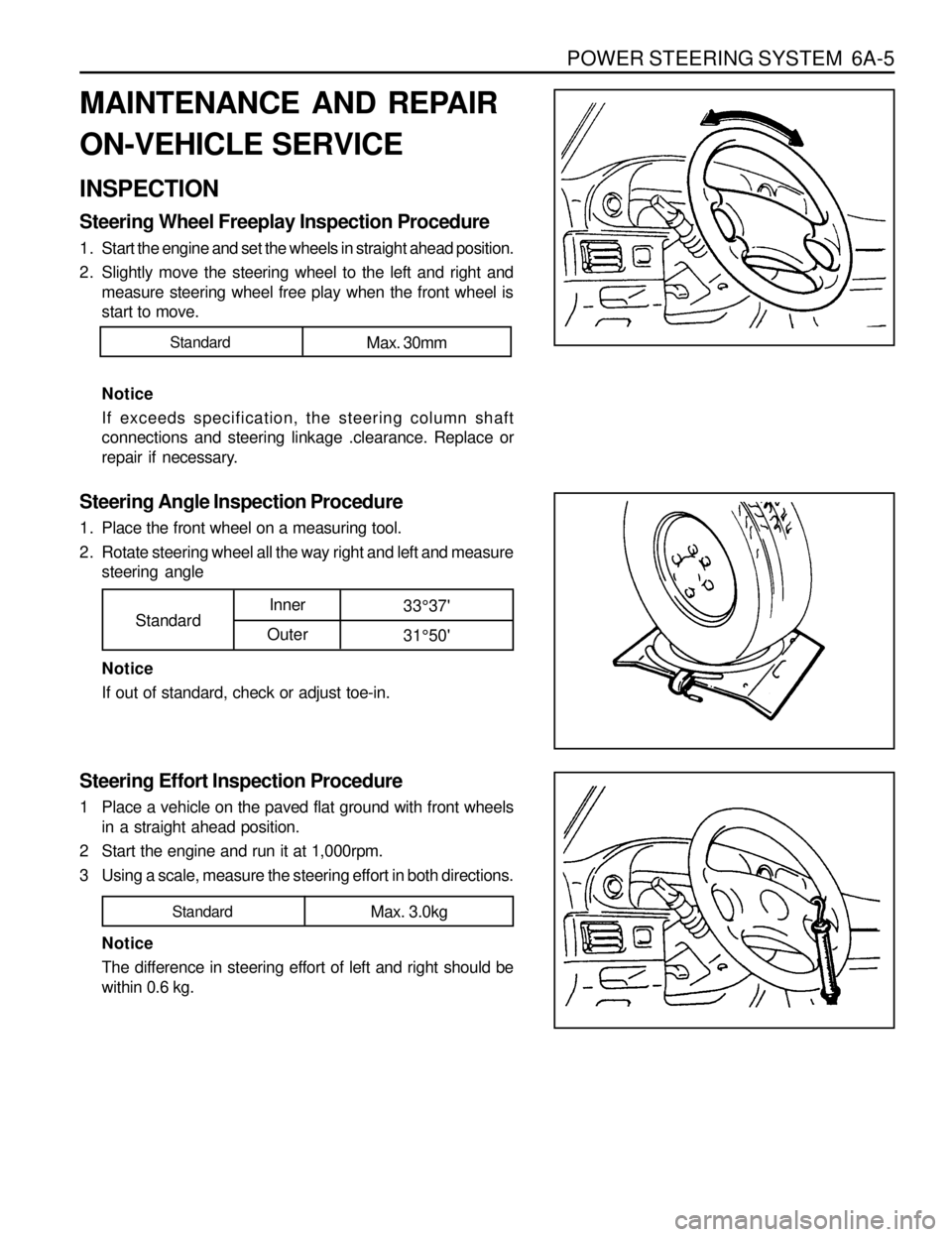

Steering Wheel Freeplay Inspection Procedure

1. Start the engine and set the wheels in straight ahead position.

2. Slightly move the steering wheel to the left and right and

measure steering wheel free play when the front wheel is

start to move.

Notice

If exceeds specification, the steering column shaft

connections and steering linkage .clearance. Replace or

repair if necessary.

Steering Angle Inspection Procedure

1. Place the front wheel on a measuring tool.

2. Rotate steering wheel all the way right and left and measure

steering angle

Notice

If out of standard, check or adjust toe-in.

Standard33°37'

31°50'Inner

Outer

Steering Effort Inspection Procedure

1 Place a vehicle on the paved flat ground with front wheels

in a straight ahead position.

2 Start the engine and run it at 1,000rpm.

3 Using a scale, measure the steering effort in both directions.

Notice

The difference in steering effort of left and right should be

within 0.6 kg.

StandardMax. 3.0kg

StandardMax. 30mm

Page 1279 of 1463

MANUAL & SEMIAUTO-HVAC 7B/C-5

Action

Clean oily plate using cleaning agent.

Charge battery or check for cause.

Check wire continuity

Check A/C switch and fan switch for continuity and ground.

DEFECTIVES IN FAN MOTOR CIRCUIT

Fan Motor Does Not Run

Checks

Blown fuse

Battery voltage is low

Faulty wiring

Faulty groundAction

Check for short and replace fuse.

Check battery voltage.

Check connectors’ connection.

Do not apply grease. This can cause voltage down.

Remove body painting and completely ground,

Tighten ground bolts and make sure body ground connection.

Checks

Blown resister temperature fuse

Air leakage in parts connection

Action

Replace resistor.

Check heater, cooling unit and blower for proper connection.

Fan Motor Runs in ‘4’position Only (‘3’, ‘2’, ‘1’ : Does Not Run)

Frosted Evaporator

DEFECTIVES IN COMPRESSOR CIRCUIT

Compressor Does Not Run

Checks

Faulty thermo ampAction

Frosted evaporator reduces cooling capacity.

Off compressor and maximize blowing capacity

Checks

Faulty high/low pressure

Faulty A/C relayAction

Check compressor magnet voltage supply.

A/C relay.

Checks

Oily clutch plate

Low voltage

Faulty electric connection or operation

Magnetic Clutch Slips /Idles

Checks

Clogged or blocked intake grilleAction

Clogged or blocked intake grille reduces blowing capacity.

Motor Runs With Poor Blowing

Checks

Excessive clearance between

Clutch plate and clutch coilAction

Adjust clutch clearance (0.2-0.6mm).

Magnetic Clutch Plays By Hand Only