heating SSANGYONG MUSSO 1998 Workshop Repair Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 1998, Model line: MUSSO, Model: SSANGYONG MUSSO 1998Pages: 1463, PDF Size: 19.88 MB

Page 1 of 1463

SERVICEMANUAL

FOREWORD

This manual includes procedure for mainte-

nance, adjustment, service operation and re-

moval and installation of components.

All information, illustrations and specifications

contained in this manual are based on the latest

product information available at the time of

manual approval.

The right is reserved to make changes at any

time without notice.

SECTION INDEX

DRIVE LINE/AXLE

BRAKES

TRANSMISSION

STEERING

HVAC

(HEATING, VENTILATION,

AND AIR CONDITIONING)

RESTRAINTS

BODY AND ACCESSORIES 3

4

5

6

7

8

9

ENGINE

SUSPENSION1

2 FRONT MATTER GENERAL INFORMATION0A

0B

SSANGYONG-DAEWOO

MOTOR CO., LTD. 1998

KORANDO

MUSSO

Page 24 of 1463

0B-12 GENERAL INFORMATION

OWNER INSPECTIONS

AND SERVICES

WHILE OPERATING THE VEHICLE

Horn Operation

Blow the horn occasionally to make sure it works. Check

all the button locations.

Brake System Operation

Be alert for abnormal sounds, increased brake pedal

travel or repeated puling to one side when braking. Also,

if the brake warning light goes on, or flashes, something

may be wrong with part of the brake system.

Exhaust System Operation

Be alert to any changes in the sound of the system or

the smell of the fumes. These are signs that the system

may be leaking or overheating. Have the system

inspected and repaired immediately.

Tires, Wheels and Alignment Operation

Be alert to any vibration of the steering wheel or the

seats at normal highway speeds. This may mean a wheel

needs to be balanced. Also, a pull right or left on a

straight, level road may show the need for a tire pressure

adjustment or a wheel alignment.

Steering System Operation

Be alert to changes in the steering action. An inspection

is needed when the steering wheel is hard to turn or

has too much free play, or is unusual sounds are noticed

when turning or parking.

Headlight Aim

Take note of the light pattern occasionally. Adjust the

headlights if the beams seem improperly aimed.

AT EACH FUEL FILL

A fluid loss in any (except windshield washer) system

may indicate a problem. Have the system inspected and

repaired immediately.

Engine Oil Level

Check the oil level and add oil if necessary. The best

time to check the engine oil level is when the oil is warm.

1. After stopping the engine, wait a few minutes for the

oil to drain back to the oil pan.

2. Pull out the oil level indicator (dip stick).

3. Wipe it clean, and push the oil level indicator back

down all the way.

4. Pull out the oil level indicator and look at the oil level

on it.5. Add oil, if needed, to keep the oil level above the

lower mark. Avoid overfilling the engine, since this

may cause engine damage.

6. Push the indicator all the way back down into the

engine after taking the reading.

If you check the oil level when the oil is cold, do not run

the engine first. The cold oil will not drain back to the

pan fast enough to give a true oil level reading.

Engine Coolant Level and Condition

Check the coolant level in the coolant reservoir tank

and add coolant if necessary. Inspect the coolant.

Replace dirty or rusty coolant.

Windshield Washer Fluid Level

Check the washer fluid level in the reservoir. Add fluid if

necessary.

AT LEAST TWICE A MONTH

Tire And Wheel Inspection and Pressure

Check

Check the tire for abnormal wear or damage. Also check

for damaged wheels. Check the tire pressure when the

tires are cold ( check the spare also, unless it is a

stowaway). Maintain the recommended pressures. Refer

to “Tire and Wheel” is in section 0B.

AT LEAST MONTHLY

Light Operation

Check the operation of the license plate light, the

headlights (including the high beams), the parking lights,

the fog lights, the taillight, the brake lights, the turn

signals, the backup lights and the hazard warning flasher.

Fluid Leak Check

Periodically inspect the surface beneath the vehicle for

water, oil, fuel or other fluids, after the vehicle has been

parked for a while. Water dripping from the air

conditioning system after use is normal. If you notice

fuel leaks or fumes, find the cause and correct it at once.

AT LEAST TWICE A YEAR

Power Steering System Reservoir Level

Check the power steering fluid level. Keep the power

steering fluid at the proper level. Refer to

Section 6A,

Power Steering System.

Brake Master Cylinder Reservoir Level

Check the fluid and keep it at the proper level. A low

fluid level can indicate worn disc brake pads which may

need to be serviced. Check the breather hole in the

reservoir cover to be free from dirt and check for an

open passage.

Page 318 of 1463

1B3-16 OM600 ENGINE MECHANICAL

16. Remove the power steering pump lines.

Notice

Completely drain the fluid.

17. Disconnect the fuel feed line with prefilter from the feed

pump on injection pump.

18. Vehicle with automatic transmission.

Remove the hydraulic lines (19, 20) from oil cooler (2).

19. Disconnect the engine harness.

20. Disconnect the preheating time relay cable.

Page 320 of 1463

1B3-18 OM600 ENGINE MECHANICAL

27. Disconnect the preheating time relay sensor plug.

28. Disconnect the coolant temperature sensor plug.

29. Disconnect the accelerator cable from the control linkage.

Installation Notice

Tightening Torque 8 - 18 Nm

30. Loosen the connection of control pressure cable (an arrow)

used in auto transmission.

Page 401 of 1463

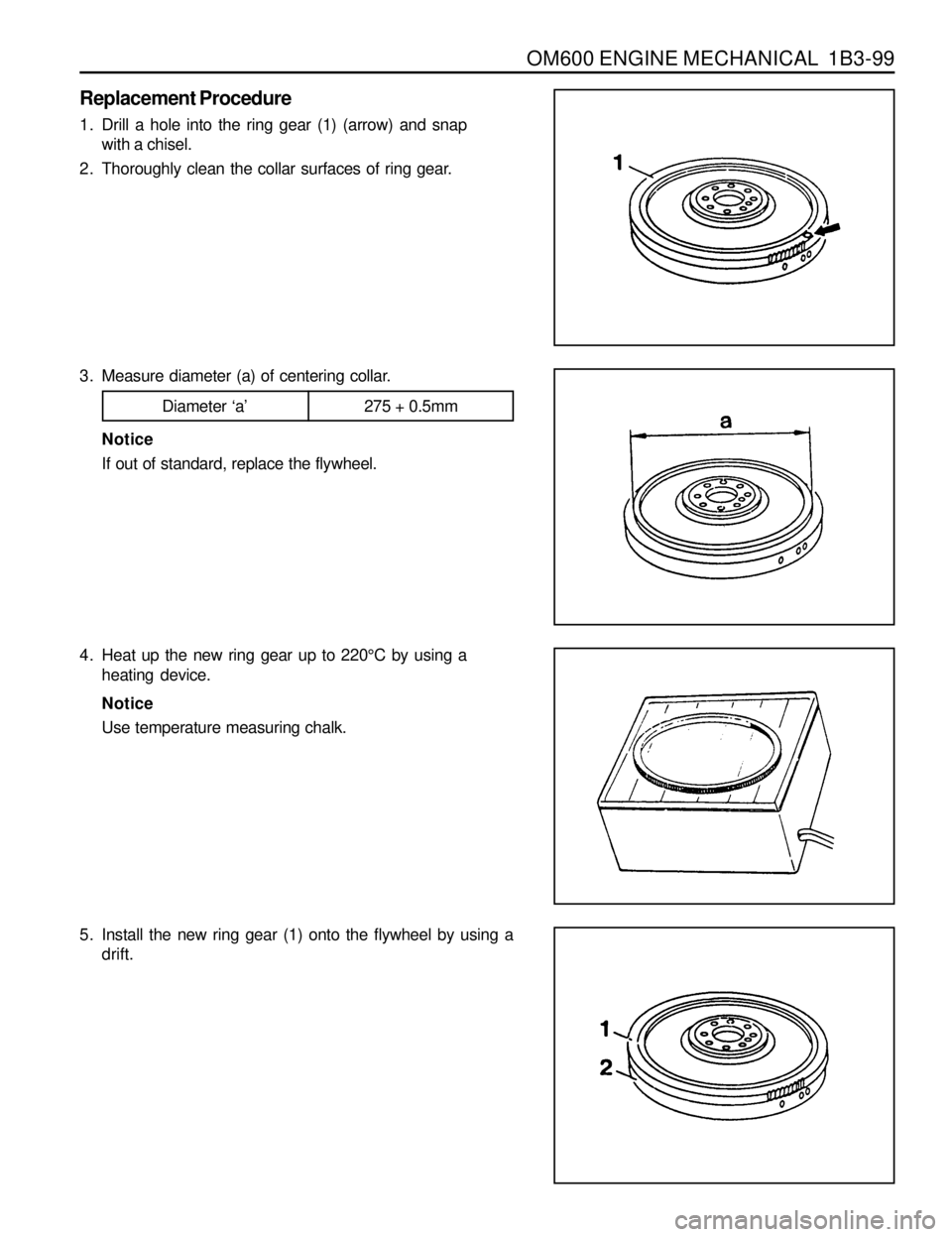

OM600 ENGINE MECHANICAL 1B3-99

Diameter ‘a’ 275 + 0.5mm

Replacement Procedure

1. Drill a hole into the ring gear (1) (arrow) and snap

with a chisel.

2. Thoroughly clean the collar surfaces of ring gear.

3. Measure diameter (a) of centering collar.

Notice

If out of standard, replace the flywheel.

4. Heat up the new ring gear up to 220°C by using a

heating device.

Notice

Use temperature measuring chalk.

5. Install the new ring gear (1) onto the flywheel by using a

drift.

Page 564 of 1463

1E3-2 OM600 ENGINE ELECTRICAL

Preheating System

General information

The preheating system consists of control, coolant temperature

sensor and glow plugs.

lControl relay - preheating time.

lCoolant temperature sensor.

lGlow plug.

GLOW PLUG

1 Wiring Harness

2 Nut .............................................................. 4 Nm3 Wire Terminal

4 Glow Plug

MAINTENANCE AND REPAIR

ON-VEHICLE SERVICE

Page 565 of 1463

OM600 ENGINE ELECTRICAL 1E3-3

1. Preheating time - control relay.

Control relay functions as followings :

lSwitching of preheating current.

lIndication of preheating finish.

lControl of preheating sequence.

lIndication of fault.

2. Coolant temperature sensor.

Coolant temperature sensor senses coolant’s temperature

and signals it to the preheating relay continuously.

3. Glow plug

The glow plug parts are housing with M12 ´ 1.25 thread

and heating pin in housing. It is connected in a parallel circuit

with the specified voltage of 11.5V.

The heating element has a heating coil and a control coil

and they are connected in series.

1. Control Coil

2. Heater Coil

4. Current and temperature of glow plug

lCurrent of glow plug

While the preheating system operates, current of about

30A flows in each glow plug and temperature of heating

coil rises very fast.

Due to the rise of temperature, the resistance of control

coil increases therefore the current is controlled to

about 8~15A and that protects the glow plug from over-

heating.

lTemperature of glow plug

The temperature of the glow plug reaches up to 900°C

after about 9 seconds and up to 1,050°C after 30

seconds.

Page 566 of 1463

1E3-4 OM600 ENGINE ELECTRICAL

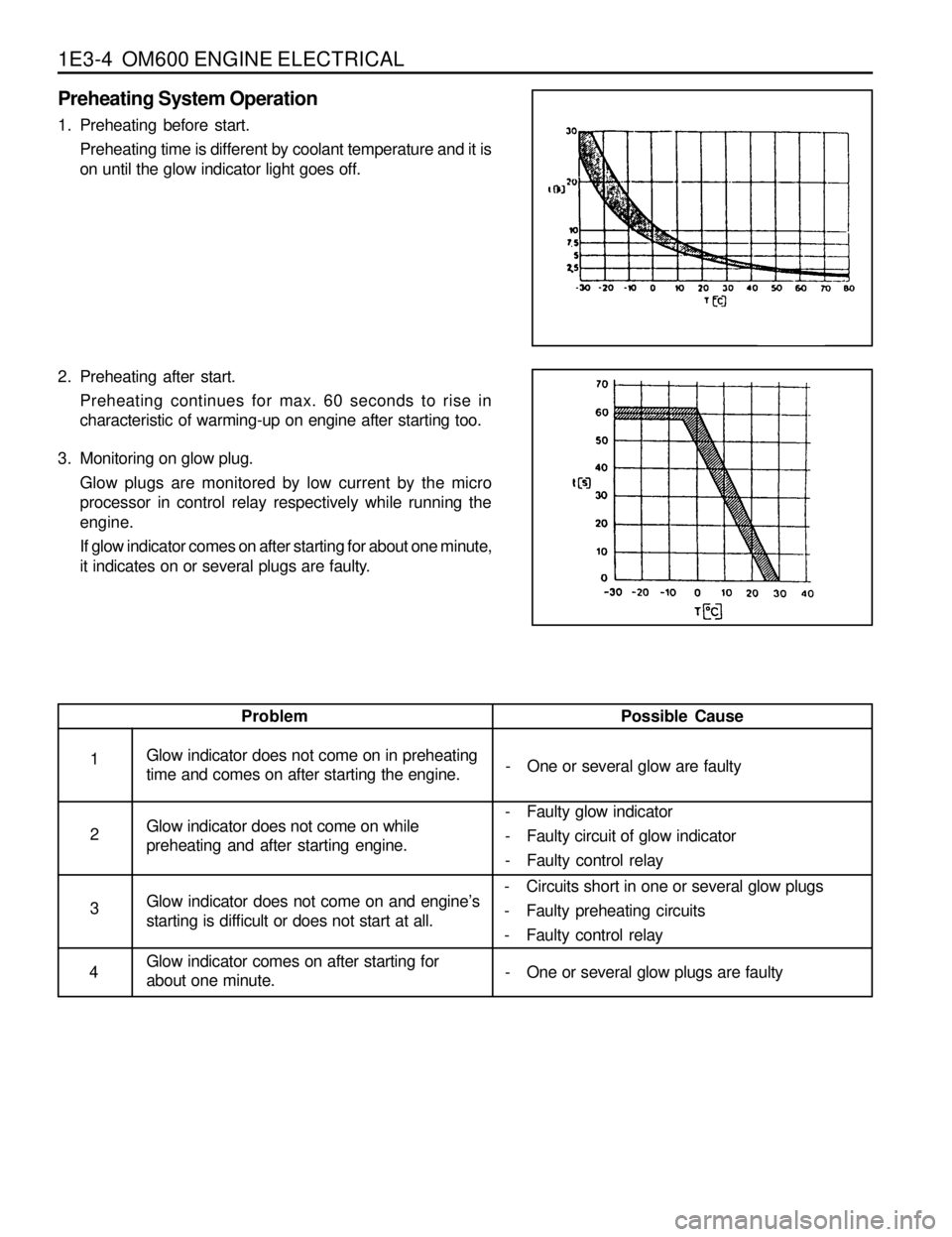

Preheating System Operation

1. Preheating before start.

Preheating time is different by coolant temperature and it is

on until the glow indicator light goes off.

2. Preheating after start.

Preheating continues for max. 60 seconds to rise in

characteristic of warming-up on engine after starting too.

3. Monitoring on glow plug.

Glow plugs are monitored by low current by the micro

processor in control relay respectively while running the

engine.

If glow indicator comes on after starting for about one minute,

it indicates on or several plugs are faulty.

Possible Cause

- One or several glow are faulty Problem

Glow indicator does not come on in preheating

time and comes on after starting the engine.

Glow indicator does not come on while

preheating and after starting engine.

Glow indicator does not come on and engine’s

starting is difficult or does not start at all.

Glow indicator comes on after starting for

about one minute.1

2

3

4- Faulty glow indicator

- Faulty circuit of glow indicator

- Faulty control relay

- Circuits short in one or several glow plugs

- Faulty preheating circuits

- Faulty control relay

- One or several glow plugs are faulty

Page 584 of 1463

1F1-14 M162 ENGINE CONTROLS

Failure

codeItemChecking method Test

stepRequirementSpecified

valuePossible cause

Þ 9.0· Keep the engine run

above 2 minutes in

over 80°C of coolant

temperature.6.0 - 7.0 V· ECU

· Cable

· Oxygen sensor

· ·· ·

· Oxygen

sensor:

- Signal80,

81,

82,

83,

89,560

Þ 8.0· Engine:in cranking or

idle

560· Cable

· ECU

· ·· ·

· ECU:

- RPM signal

output32,

33,refer to figure

2

Þ 10.0· Keep the engine run

above 2 minutes in

over 80°C of coolant

temperature.· ·· ·

· Oxygen

sensor:

- Heating

function

operated

Þ 11.0· ·· ·

· No.1

cylinder

injector:

- Operating &

injection

time· When the coolant

temperature is

approx. 20°C:

- Engine:in cranking8.0 ms· Cable

· ECU

· No.1 Injector

· Coolant

temperature sensor

· Oxygen sensor

· Intake air

temperature sensor

- Voltage· Engine:in cranking

or idle

(above 5V in idling)

16 17

59

911

· Ignition:ON11 - 14 V

· ECU

· Cable

· Oxygen sensor

- Current

consumption0.2 - 2.0 A

72,

73,

63 11

· When the coolant

temperature is

approx. 80°C:

- Engine:at idling

speed

- Engine:at sharp

acceleration(full

throttle)

(refer to figure 3 and

4)approx.

2.7 - 5.0ms

approx.

14ms There will be a

voltage

fluctuation in

the range of

- 0.2 -1.0V

85,

86,

87,

Page 607 of 1463

M162 ENGINE CONTROLS 1F1-37

Pin No.Abbreciation Description

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20-

TM.50

-

-

GND

-

-

-

LSH1

TM.31

TM.87

TM.30

WFS I/O

WFS O

-

GND

LS1

-

-

- -

Starter motor TM.50

-

-

Electronic ground

-

-

-

Lambda probe 1 heating

Power ground TM.31

V-BATTERY TM.87

V-BATTERY TM.30

Immobilizer crypto read

Immobilizer crypto write

-

Lambda probe 1 ground

Lambda probe 1 signal

-

-

-

ECU Pin Numbers and Descriptions

Vehicle Connector