tire pressure SSANGYONG MUSSO 2003 User Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2003, Model line: MUSSO, Model: SSANGYONG MUSSO 2003Pages: 1574, PDF Size: 26.41 MB

Page 799 of 1574

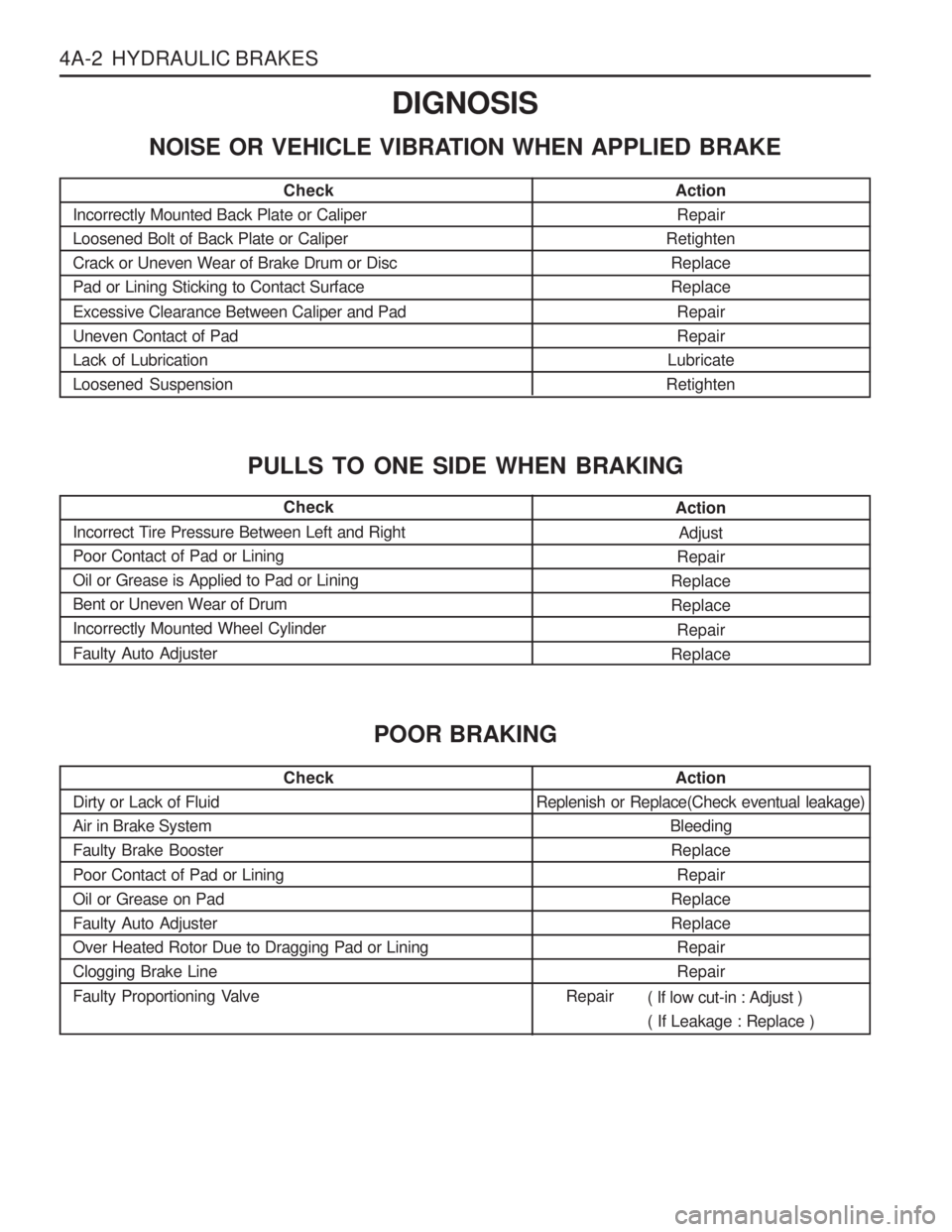

4A-2 HYDRAULIC BRAKESCheck

Dirty or Lack of Fluid Air in Brake SystemFaulty Brake Booster Poor Contact of Pad or Lining Oil or Grease on PadFaulty Auto AdjusterOver Heated Rotor Due to Dragging Pad or LiningClogging Brake Line

Faulty Proportioning Valve Check

Incorrect Tire Pressure Between Left and Right Poor Contact of Pad or LiningOil or Grease is Applied to Pad or LiningBent or Uneven Wear of DrumIncorrectly Mounted Wheel Cylinder Faulty Auto Adjuster Action

Repair

Retighten Replace Replace

RepairRepair

Lubricate

Retighten

Check

Incorrectly Mounted Back Plate or CaliperLoosened Bolt of Back Plate or CaliperCrack or Uneven Wear of Brake Drum or DiscPad or Lining Sticking to Contact Surface Excessive Clearance Between Caliper and Pad Uneven Contact of PadLack of LubricationLoosened Suspension DIGNOSIS

NOISE OR VEHICLE VIBRATION WHEN APPLIED BRAKE

PULLS TO ONE SIDE WHEN BRAKING

Action Adjust

Repair

Replace Replace

Repair

Replace

Action

Replenish or Replace(Check eventual leakage) Bleeding

Replace

Repair

Replace Replace RepairRepair

Repair

POOR BRAKING

( If low cut-in : Adjust ) ( If Leakage : Replace )

Page 1055 of 1574

TRANSFER CASE (PART TIME 4408) 5D1-3

Cannot Front Wheel Drive when Shifted 4H,4LDIAGNOSIS

Electric Shift Problems

Action

Overhaul and check, replace if necessary. Overhaul and check for wear and damage.

Replace if necessary.

Check sliding parts, replace if necessary.

Checks

Faulty or Damaged TCCU, Speed Sensor, Motor, Clutch or Internal Wirings Damaged or Worn Shift Cam, Hub, Fork and Rail Shift Binding Shift Fork, Hub Collar or Gear

Checks

Broken Drive Chain Action

Check sliding parts, replace if necessary.

Noise in 4WD Operation

Checks

Improper or low oil Loosened bolts or mounted partsNoisy T/C bearing Noisy gears Action

Drain and replace with specified oil. Retighten as specified.Disassemble bearings and parts and check for wear or

damage. Replace if necessary. Check for wear and damage including speedometer

gear, replace if necessary.

Noise in 4H or 4L

Checks

Worn or Damaged Sprockets or Drive Chain

Incorrect Tire Pressure Action

Disassemble and check for wear and damage, replace

if necessary. Adjust tire pressure.

Transfer Case Oil Leakage

Action

Replace the case. Clean case and parts and check for leakage.

Remove breather hose and clean, replace if necessary.Use specified oil and adjust oil level.Retighten Use specified sealant and retighten. Replace

Checks

Cracked Transfer CaseLeakage from Other PartsBreather CloggingImproper or too much OilLoosened Sealing Bolts Improperly Applied Sealant Worn or Damaged Oil Seal

Page 1238 of 1574

9B-10 LIGHTING SYSTEM Head Lamp Focusing When using the beam setting device

1. The head lamp focus should be adjusted by using a properbeam setting device.

2. Adjust the head lamp focus by using Up/Down, Left/Right adjusting screws.

When using the screen

1. Put the vehicle on the leveling surface.

2. One person is needed to seat on the driver's seat without other loads(CVW) and check the tire pressure if it is in the specification.

3. The distance between the headlamp and the screen is 25m.

4. Draw the vertical line (crossing the center of each headlamp) on the screen.

5. Start the engine.

6. Check if the cut-off line of the headlamp on the screen is in the specification.

1 ) Left/right direction

- The degree of the cross point at the cut-off line of theheadlamp and the vertical line should be 15.

2 ) Up/down direction - The distance between the cut-off line of the headlampand the horizontal line should be 25cm.

7. Adjust the focus if the cut-off line of the headlamp is out of

the specification by using up/down, left/right adjusting screws. A : Up/down direction adjusting screwB : Left/right direction adjusting secrw