alternator SSANGYONG NEW ACTYON SPORTS 2013 Service Manual

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2013, Model line: NEW ACTYON SPORTS, Model: SSANGYONG NEW ACTYON SPORTS 2013Pages: 751, PDF Size: 72.63 MB

Page 21 of 751

01-4

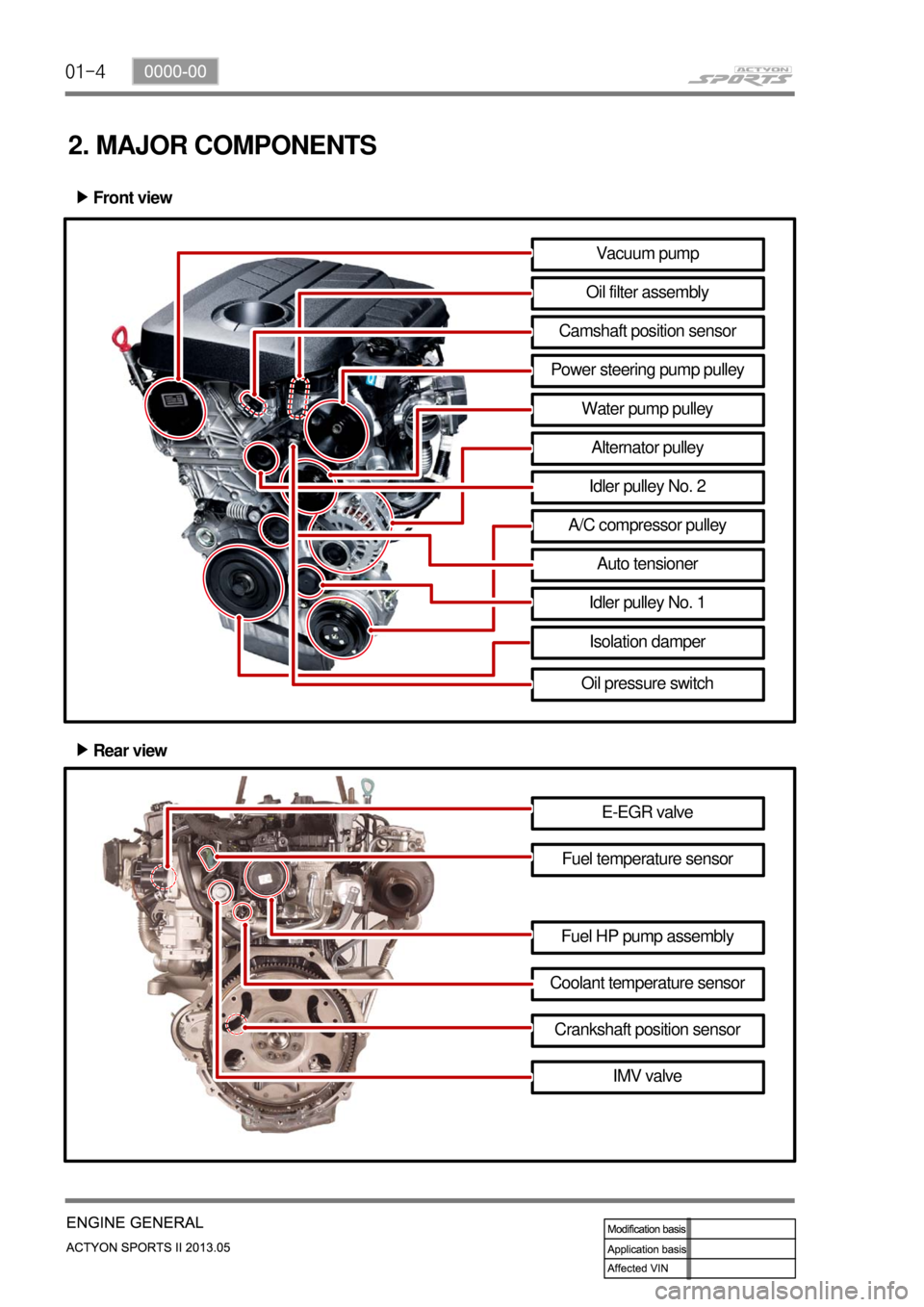

2. MAJOR COMPONENTS

Front view ▶

Vacuum pump

Oil filter assembly

Camshaft position sensor

Power steering pump pulley

Water pump pulley

Alternator pulley

Idler pulley No. 2

A/C compressor pulley

Auto tensioner

Idler pulley No. 1

Isolation damper

Rear view ▶

E-EGR valve

Fuel temperature sensor

Fuel HP pump assembly

Coolant temperature sensor

IMV valve Crankshaft position sensor

Oil pressure switch

Page 29 of 751

01-12

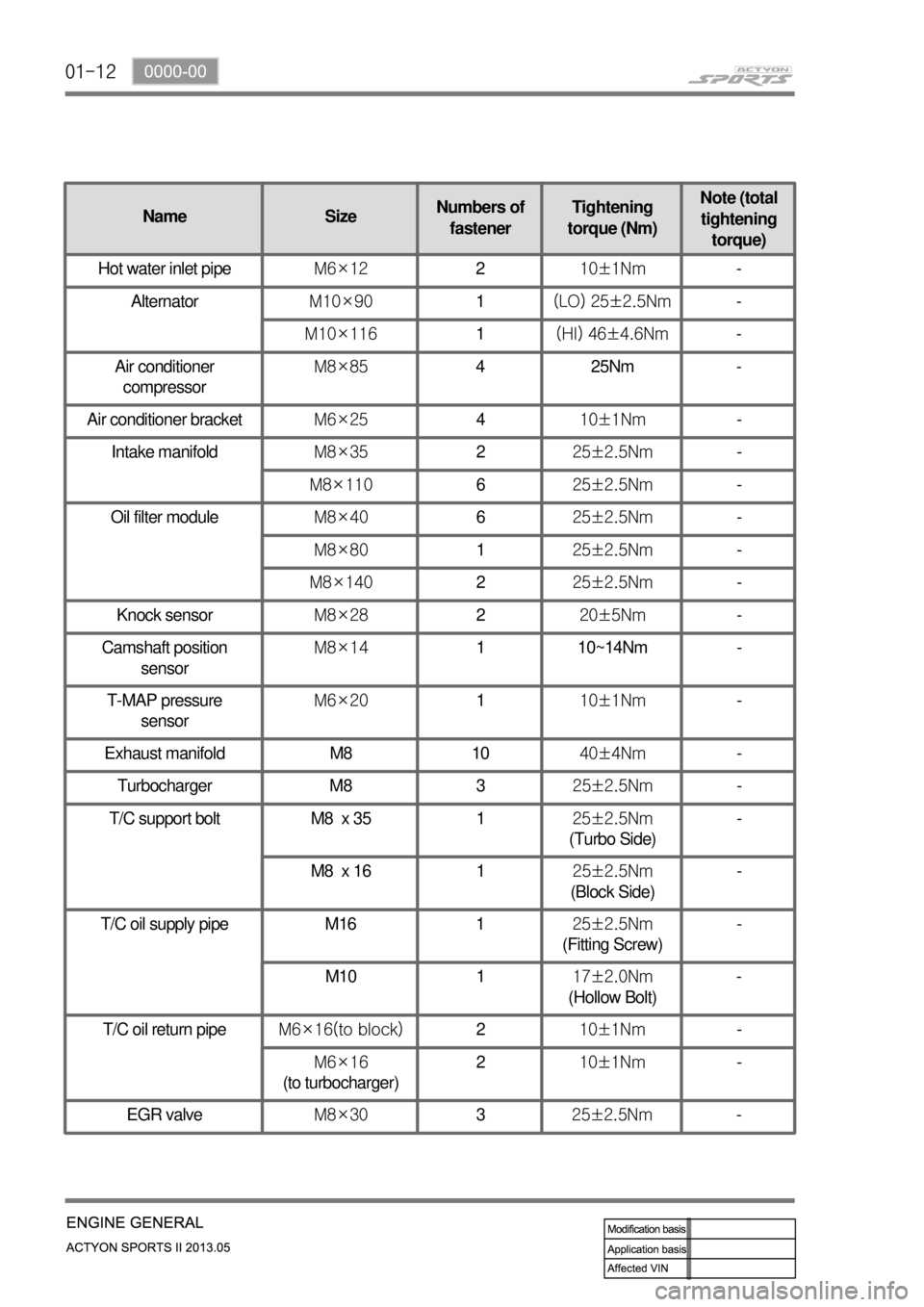

T/C oil supply pipeM161 25±2.5Nm

(Fitting Screw) -

M10 1 17±2.0Nm

(Hollow Bolt) -

T/C oil return pipe M6×16(to block) 2 10±1Nm -

M6×16

(to turbocharger) 2

10±1Nm -

EGR valve M8×303 25±2.5Nm -

Name SizeNumbers of

fastener Tightening

torque (Nm) Note (total

tightening torque)

Hot water inlet pipe M6×12210±1Nm -

Alternator M10×901(LO) 25±2.5Nm -

M10×116 1(HI) 46±4.6Nm -

Air conditioner compressor M8×85

425Nm -

Air conditioner bracket M6×25410±1Nm -

Intake manifold M8×35225±2.5Nm -

M8×110 625±2.5Nm -

Oil filter module M8×40625±2.5Nm -

M8×80 125±2.5Nm -

M8×140 225±2.5Nm -

Knock sensor M8×28220±5Nm -

Camshaft position sensor M8×14

110~14Nm -

T-MAP pressure sensor M6×20

110±1Nm -

Exhaust manifold M81040±4Nm -

Turbocharger M8325±2.5Nm -

T/C support bolt M8 x 35125±2.5Nm

(Turbo Side) -

M8 x 16 125±2.5Nm

(Block Side) -

Page 36 of 751

02-50000-00

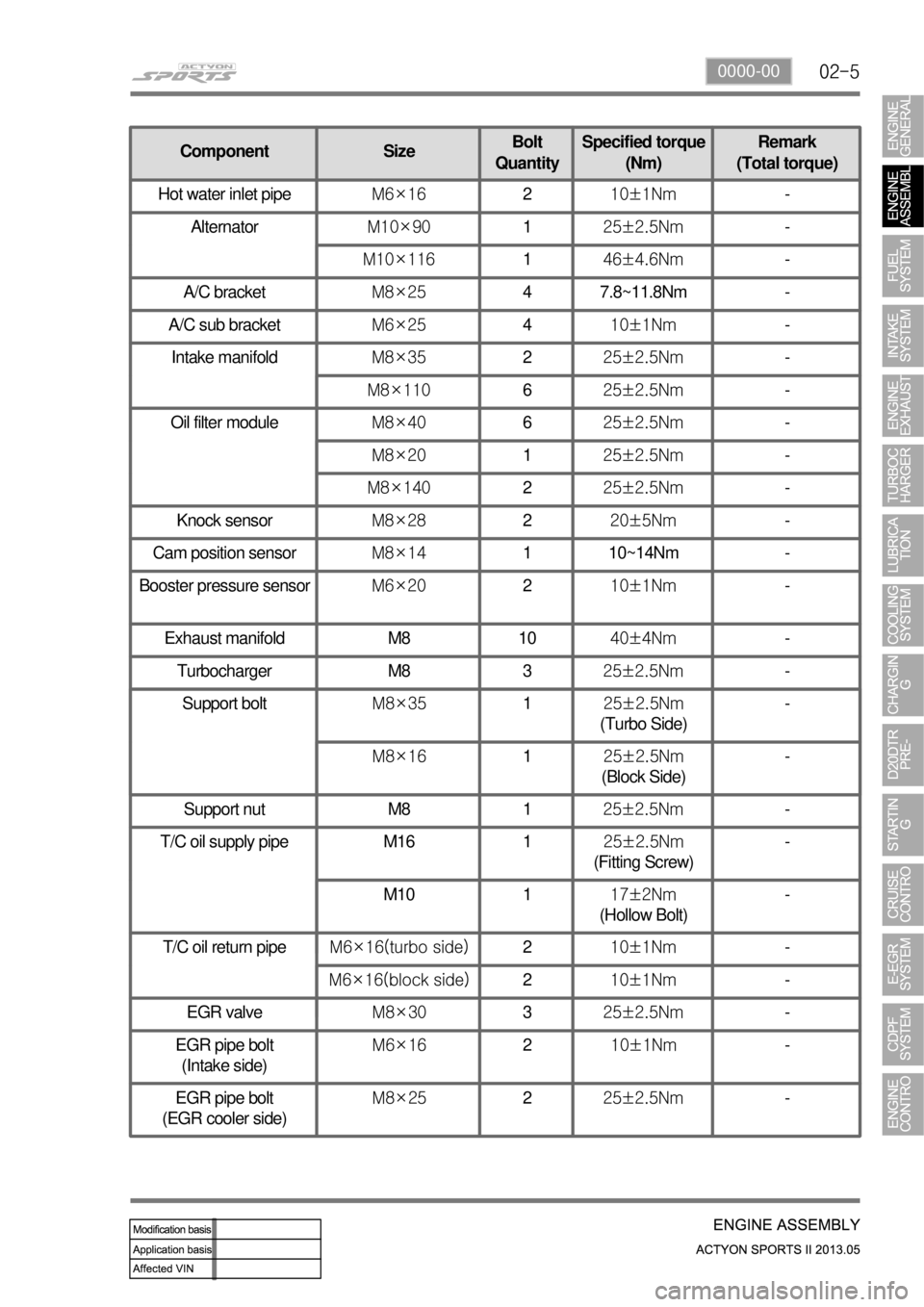

ComponentSizeBolt

Quantity Specified torque

(Nm) Remark

(Total torque)

Hot water inlet pipe M6×16 2 10±1Nm -

Alternator M10×90 1 25±2.5Nm -

M10×116 1 46±4.6Nm -

A/C bracket M8×25 4 7.8~11.8Nm -

A/C sub bracket M6×25 4 10±1Nm -

Intake manifold M8×35 2 25±2.5Nm -

M8×110 6 25±2.5Nm -

Oil filter module M8×40 6 25±2.5Nm -

M8×20 1 25±2.5Nm -

M8×140 2 25±2.5Nm -

Knock sensor M8×28 2 20±5Nm -

Cam position sensor M8×14 1 10~14Nm -

Booster pressure sensor M6×20 2 10±1Nm -

Exhaust manifold M810 40±4Nm -

Turbocharger M83 25±2.5Nm -

Support nut M81 25±2.5Nm -

T/C oil supply pipe M161 25±2.5Nm

(Fitting Screw) -

M10 1 17±2Nm

(Hollow Bolt) -

T/C oil return pipe M6×16(turbo side) 2 10±1Nm -

M6×16(block side) 2 10±1Nm -

EGR valve M8×30325±2.5Nm -

EGR pipe bolt (Intake side) M6×16

2 10±1Nm -

EGR pipe bolt

(EGR cooler side) M8×25

2 25±2.5Nm -

Support bolt M8×35125±2.5Nm

(Turbo Side) -

M8×16 125±2.5Nm

(Block Side) -

Page 44 of 751

02-130000-00

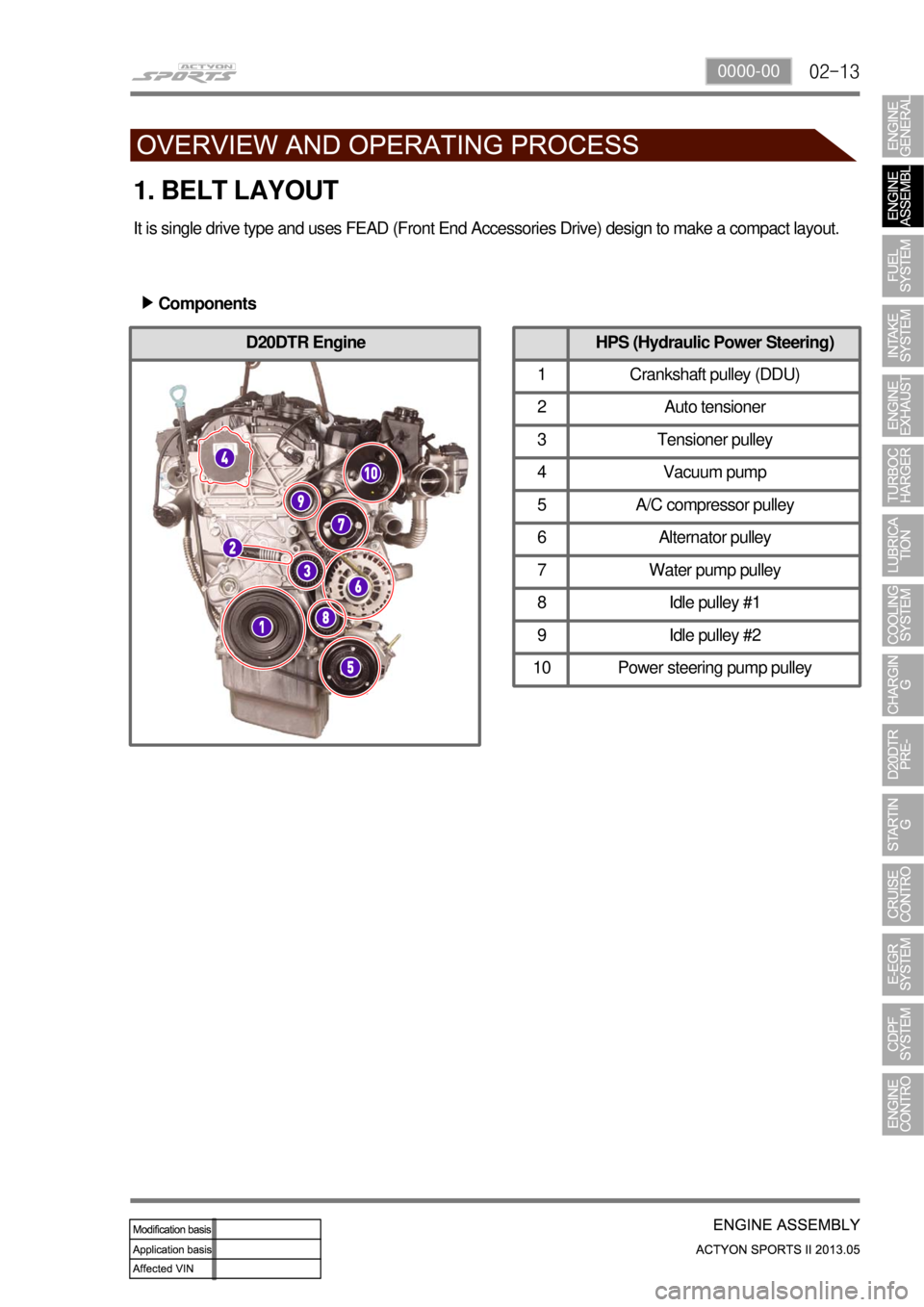

D20DTR Engine

1. BELT LAYOUT

It is single drive type and uses FEAD (Front End Accessories Drive) design to make a compact layout.

Components ▶

HPS (Hydraulic Power Steering)

1 Crankshaft pulley (DDU)

2 Auto tensioner

3 Tensioner pulley

4 Vacuum pump

5 A/C compressor pulley

6 Alternator pulley

7 Water pump pulley

8 Idle pulley #1

9 Idle pulley #2

10 Power steering pump pulley

Page 148 of 751

09-31451-01

1. SPECIFICATION

AlternatorCrankshaft pulley : Alternator pulley 1 : 2.94

Normal output (idling/2200 rpm) 70/120 A

Regulator voltage 14.6 V

BrushLength 12.5 mm

Wear limit 7 mm

BatteryType MF

Capacity 90 AH

Unit Description Specification

Page 149 of 751

09-4

2. INSPECTION

1) Alternator Output Test

Item How to check DTC set value / Action

Output

current

B terminal

current

Rotor

coil

resistance

L terminal

voltage

Disconnect the cable connected to the B

terminal on the alternator. Connect one end

of the ammeter to the B terminal and the

other end to the cable connected to the B

terminal.

Measure the maximum output value.

(Maintain the engine speed between 2,500

and 3,000 rpm.)

(Turn the headlamp and all the electrical

switches on.) 1.

2.Pass: If the measured current is 45

A or higher.

Fail: If the measured current is less

than 45 A.

Check the current of the B terminal. -

-

-

Move the gear selector lever to the neutral

position.

Maintain the engine speed at 2,500 rpm

with the vehicle unloaded.

(Turn all the electrical switches off.) 1.

2.Open circuit: If the measured

current is 5 A or higher. -

Disconnect the negative cable from the

battery.

Remove the B terminal and turn off the

ignition switch.

Measure the resistance between the L and

F terminals with an ohmmeter. 1.

2.

3.Pass: If the measured resistance is

between 3 and 6 Ω.

Faulty rotor coil or slip ring: If the

measured resistance is less than

3 Ω or greater than 6 Ω. -

-

Connect the B terminal wiring.

Measure the voltage with the engine running. 1.

2.Specification: 12.5 V to 14.5 V

Faulty IC regulator or field coil: If

the measured voltage is 14.5 V or

higher. -

-

Disconnect the negative battery cable.

Connect the negative cable again after connecting the ammeter. -

-

Page 150 of 751

09-51451-01

2) Troubleshooting for Alternator

Item Cause Action

Overcharged batteryDefective alternator voltage regulator

Replace the alternator

Defective voltage detection wiring Repair or replace

Loose alternator drive belt Adjust the belt tension or replace

Discharged batteryPoor connection of related circuit or open

circuitRetighten the loose connection or

repair open circuit

Defective alternator voltage regulator

Replace the alternator

Defective alternator voltage regulator

Replace the alternator

Terminated battery Replace the battery

Defective ground Repair

Charge warning

lamp does not come

on when turning on

ignition switch with

engine stoppedDefective alternator voltage regulator

Replace the alternator

Open circuit in charge warning lamp, fuse

or wiringReplace or repair the charge warning

lamp or fuse

Defective ignition switch Replace the ignition switch

Defective ground of alternator circuit Repair

Charge warning

lamp is not turned

off after starting

engineDefective alternator voltage regulator

Replace the alternator

Corroded or worn battery cableRepair or replace the battery cable

Loose alternator drive belReplace the batteryAdjust the belt

tension or replace the belt

Defective wiring harness Repair or replace

Page 152 of 751

09-71451-01

(1) Checking

Using battery tester ▶

PASS (11.0 V or more): Explain to the customer that the battery is reusable.

Need to be charged (9.0 to 11.0 V): Charge the battery with a charger and reinstall it. Explain it to the

customer.

Need to be replaced (9.0 V or more): The battery should be replaced due to overdischarging. -

-

-

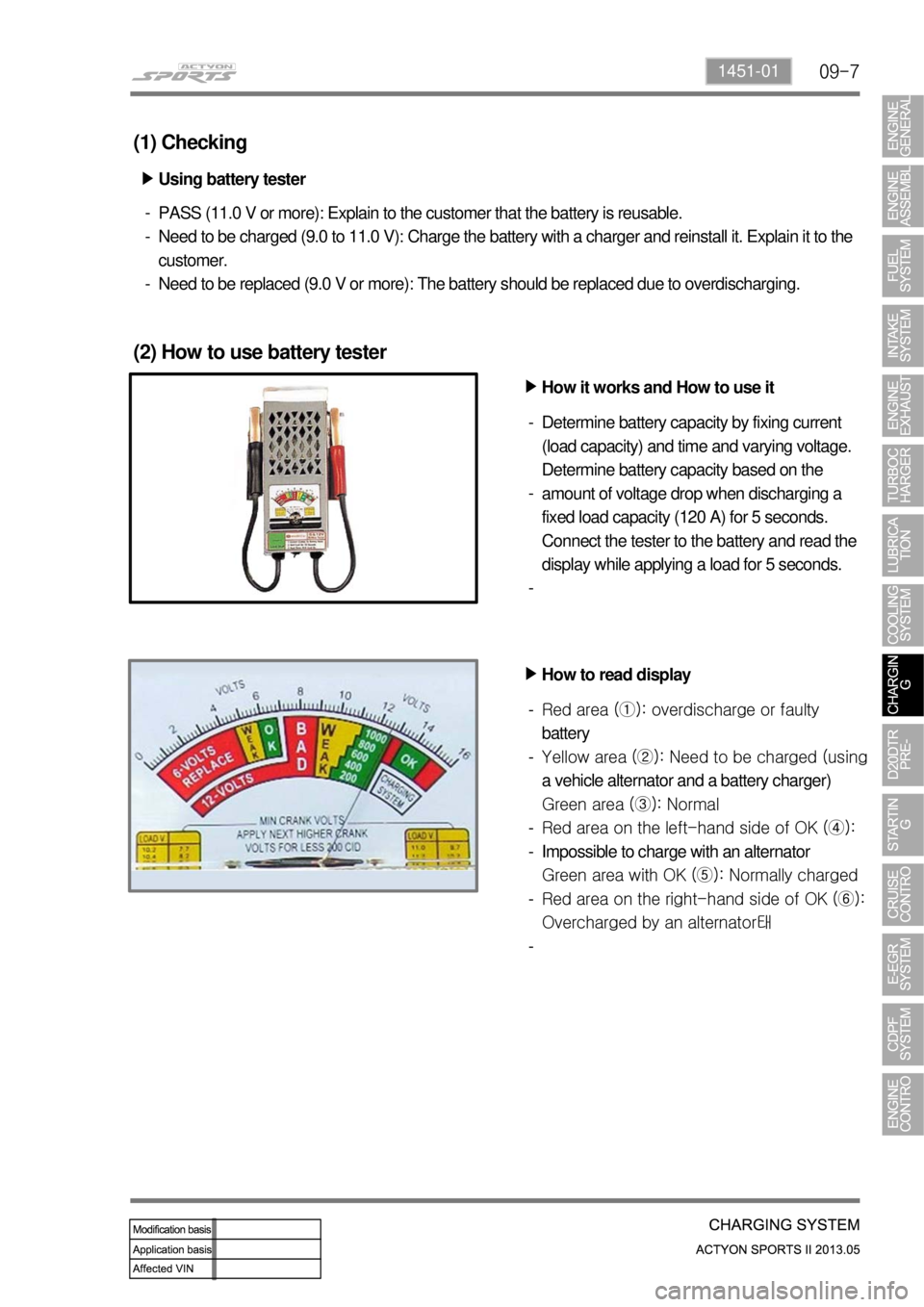

(2) How to use battery tester

How it works and How to use it ▶

Determine battery capacity by fixing current

(load capacity) and time and varying voltage.

Determine battery capacity based on the

amount of voltage drop when discharging a

fixed load capacity (120 A) for 5 seconds.

Connect the tester to the battery and read the

display while applying a load for 5 seconds. -

-

-

How to read display ▶

Red area (①): overdischarge or faulty

battery

Yellow area (②): Need to be charged (using

a vehicle alternator and a battery charger)

Green area (③): Normal

Red area on the left-hand side of OK (④):

Impossible to charge with an alternator

Green area with OK (⑤): Normally charged

Red area on the right-hand side of OK (⑥):

Overcharged by an alternator태 -

-

-

-

-

-

Page 155 of 751

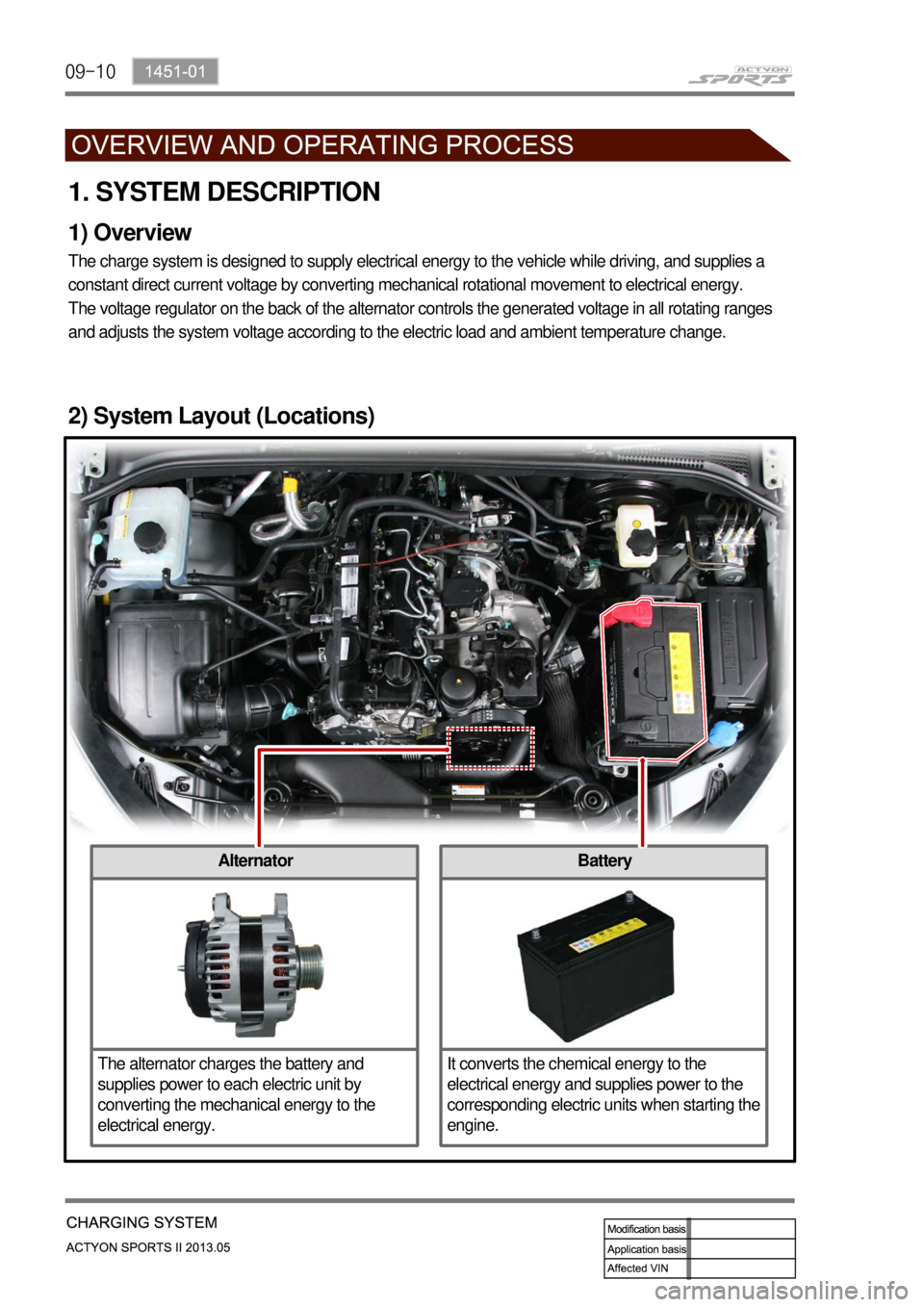

09-10

Alternator

The alternator charges the battery and

supplies power to each electric unit by

converting the mechanical energy to the

electrical energy.

1. SYSTEM DESCRIPTION

1) Overview

The charge system is designed to supply electrical energy to the vehicle while driving, and supplies a

constant direct current voltage by converting mechanical rotational movement to electrical energy.

The voltage regulator on the back of the alternator controls the generated voltage in all rotating ranges

and adjusts the system voltage according to the electric load and ambient temperature change.

2) System Layout (Locations)

Battery

It converts the chemical energy to the

electrical energy and supplies power to the

corresponding electric units when starting the

engine.

Page 157 of 751

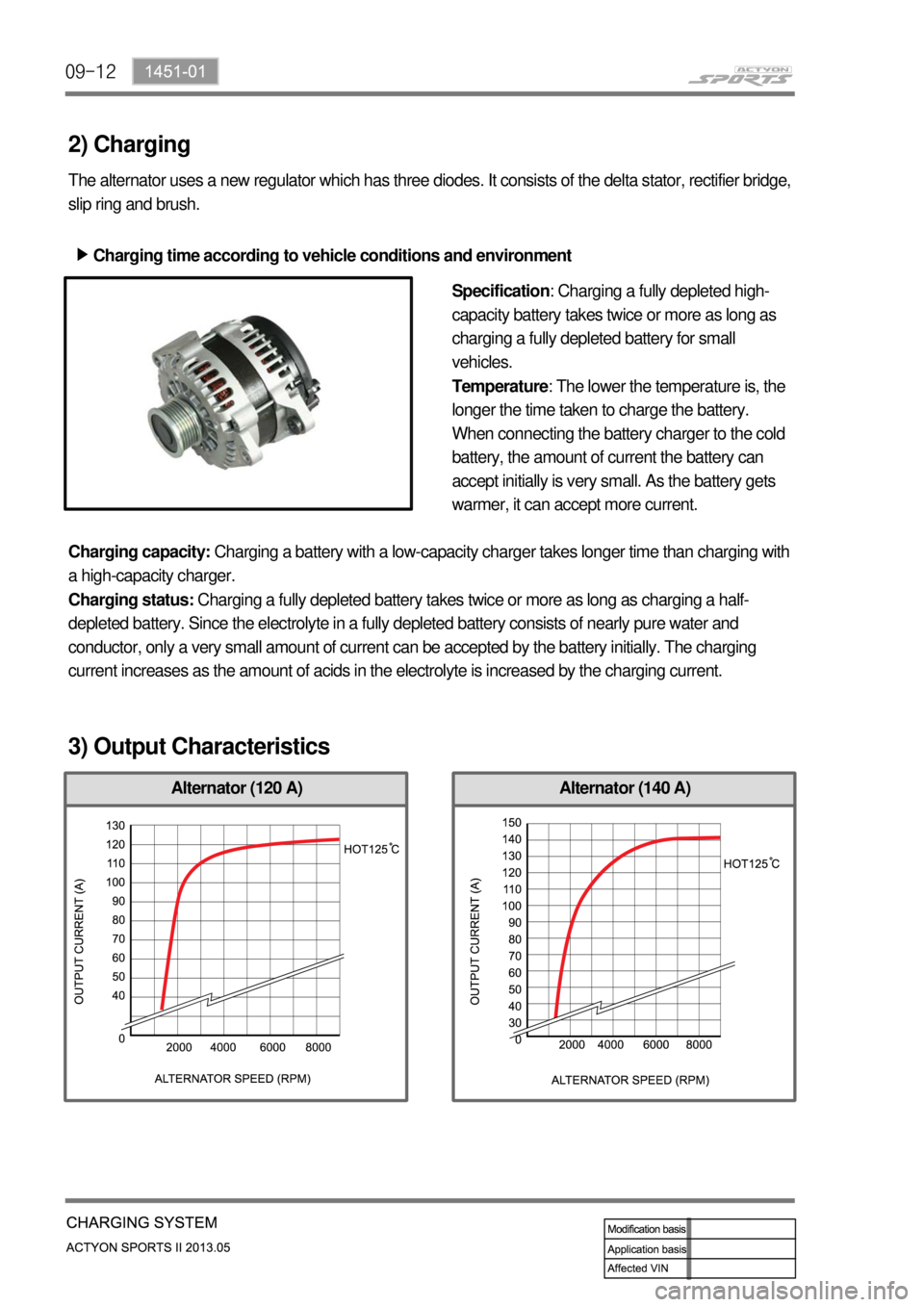

09-12

Alternator (140 A)Alternator (120 A)

2) Charging

The alternator uses a new regulator which has three diodes. It consists of the delta stator, rectifier bridge,

slip ring and brush.

Charging time according to vehicle conditions and environment ▶

Specification: Charging a fully depleted high-

capacity battery takes twice or more as long as

charging a fully depleted battery for small

vehicles.

Temperature: The lower the temperature is, the

longer the time taken to charge the battery.

When connecting the battery charger to the cold

battery, the amount of current the battery can

accept initially is very small. As the battery gets

warmer, it can accept more current.

Charging capacity: Charging a battery with a low-capacity charger takes longer time than charging with

a high-capacity charger.

Charging status: Charging a fully depleted battery takes twice or more as long as charging a half-

depleted battery. Since the electrolyte in a fully depleted battery consists of nearly pure water and

conductor, only a very small amount of current can be accepted by the battery initially. The charging

current increases as the amount of acids in the electrolyte is increased by the charging current.

3) Output Characteristics