torque SSANGYONG NEW REXTON 2012 User Guide

[x] Cancel search | Manufacturer: SSANGYONG, Model Year: 2012, Model line: NEW REXTON, Model: SSANGYONG NEW REXTON 2012Pages: 600, PDF Size: 73.29 MB

Page 268 of 600

Name SizeNumbers of

fastenerTightening

torque (Nm)Note (total

tightening

torque)

Idler pulley/tensioner

pulley1

-

Glow plug M5 4

-

Vacuum pump

3 -

Timing gear case cover

7 -

1 -

3 -

Cylinder head cover

21 -

Oil dipstick gauge cover

1 -

Oil filter cap 1

-

Fuel rail

2 -

Injector clamp bolt

2 -

High pressure pipe

(between high pressure

pump and fuel rail

assembly)M17 1

-

High pressure pipe

(between fuel rail

assembly and injector)M17 4

-

Crankshaft position

sensor

1 -

Main wiring

5 -

Intake duct

3 -

Power steering pump

3 -

Cylinder head front cover

5 -

Page 271 of 600

2. TIGHTENING TORQUE

Component SizeBolt

QuantitySpecified torque

(Nm)Remark

(Total torque)

Main bearing cap

10 Not re-usable

Connecting rod cap

850 to 80 Nm

Rear cover

6-

Oil pump

3-

Flywheel

860 to 100 Nm

Crankshaft center bolt

1660 to 720 Nm

Not re-usable

Oil pan

18-

2-

2-

2-

2-

HP pump main nut

1-

HP pump bolt

3-

Cylinder head

12 85Nm-

Camshaft cap

16-

4-

Exhaust stud bolt 10

-

Exhaust sprocket bolt

1-

Chain tensioner screw

bolt

1-

Coolant temperature

sensor1

-

Auto tensioner

1-

1-

Coolant pump

1-

Page 272 of 600

0000-00

Component SizeBolt

QuantitySpecified torque

(Nm)Remark

(Total torque)

Hot water inlet pipe

2 -

Alternator

1 -

1 -

A/C bracket

4 7.8~11.8Nm -

A/C sub bracket

4 -

Intake manifold

2 -

6 -

Oil filter module

6 -

1 -

2 -

Knock sensor

2 -

Cam position sensor

1 10~14Nm -

Booster pressure sensor

2 -

Exhaust manifold M8 10

-

Turbocharger M8 3

-

Support bolt 1

-

Support nut M8 1

-

T/C oil supply pipe M6(block side) 1

-

M6(turbo side) 1

-

T/C oil return pipe

2 -

2 -

EGR valve

2 -

EGR pipe bolt

(Intake side)

2 -

EGR pipe bolt

(EGR cooler side)

2 -

EGR combination bolt

4 -

16 -

Idle pulley/Tensioner

pulley1

-

Page 273 of 600

Component SizeBolt

QuantitySpecified torque

(Nm)Remark

(Total torque)

Glow plug M5 4

-

Vacuum pump

3 -

Timing gear case cover

3 -

7 -

1 -

3 -

Cylinder head cover

21 -

Oil gauge tube

1 -

Oil filter cap 1

-

Fuel rail

2 -

Injector clamp bolt

2 -

High pressure pipe

(between HP pump and

fuel rail)M17 1

-

High pressure pipe

(between fuel rail and

injector)M17 4

-

Crank position sensor

1 -

Main wiring

5 -

Intake duct M8x25 4

-

Power steering pump

3 -

Cylinder head front cover

5 -

Ladder frame

5 -

Oil pump

3 -

Page 278 of 600

0000-00

4. GUIDELINES ON ENGINE SERVICE

To prevent personal injuries and vehicle damages that can be caused by mistakes during engine and

unit inspection/repair and to secure optimum engine performance and safety after service works, basic

cautions and service work guidelines that can be easily forgotten during engine service works are

described in.

Cautions before service works

For safe and correct works, you must observe the working procedures and instructions in this

manual. And, use the designated tools as follow:

Engine stand / Heavy duty engine jack

To prevent the engine from starting abruptly, do not allow anybody to get in the vehicle while

servicing in engine compartment.

Before work on engine and each electrical equipment, be sure to disconnect battery negative (-)

terminal.

Before service works, be sure to prepare the works by cleaning and aligning work areas.

Do not allow the foreign material get into the fuel injection system.

When removing the engine, use only the safety hook on engine and engine hanger. Do not support

the bottom of oil pan with a jack.

Engine and accessories

-

-

-

-

-

-

Completely drain the engine oil, coolant and fuel from engine before removal.

Before disassembling/assembling the engine components, carefully read the working procedures in

this manual.

Make sure to keep the specified tightening torques during installation.

Clean and properly lubricate the parts before reassembly.

Carefully check that there are not any interference while servicing. -

-

-

-

-

Page 284 of 600

0000-00

2) Belt Tensioner

(1) Overview

The torque deviation from crankshaft affects the components in belt drive system and the belt

movement. The auto tensioner system is to adjust this deviation automatically.

In D20DTR engine, one of the mechanical tensioner, pivot damped tensioner is used to keep the

damping force, system reliability and durability. The single belt drive system needs to use the automatic

belt tensioning device to transfer the power to pulleys effectively. To get this, the tensioner uses the

spring and damping unit.

(2) Location

Belt tensioner

Page 288 of 600

0000-00

1) Functions

Appearance Type and function

Front mounting insulator (Right side) Type: Rubber mounting

Function: Supports the torque reaction

Front mounting insulator (Left side) Type: Rubber mounting

Function: Supports the torque reaction

Rear mounting insulato Type: Rubber mounting

Function: Supports the powertrain rod

Page 304 of 600

0000-00

Torque change curve of engine and drive shaft

Compression stroke Combustion stroke

Small changes from engine (k):

Damper increases the torque changes to clutchLarge changes from engine (j):

Damper decreases the torque changes to

transaxle by absorbing the impact

3) Operation

Compensating the irregular operation of engine: The secondary flywheel operates almost evenly so

does not cause gear noises

The mass of the primary flywheel is less than conventional flywheel so the engine irregularity

increases more (less pulsation absorbing effect).

Transaxle protection function: Reduces the torsional vibration to powertrain (transaxle) by reducing

the irregularity of engine. -

-

-

Page 305 of 600

4) Features

Reduced vibration noise from the powertrain by blocking the torsional vibrations

Enhanced vehicle silence and riding comforts: reduced engine torque fluctuation

Reduced shifting shocks

Smooth acceleration and deceleration -

-

-

-

5) Advantages

Improved torque response by using 3-stage type spring: Strengthens the torque response in all

ranges (low, medium, and high speed) by applying respective spring constant at each range.

Stable revolution of the primary and secondary wheel by using planetary gear: Works as auxiliary

damper against spring changes

Less heat generation due to no direct friction against spring surface: Plastic material is covered on

the spring outer surface

Increased durability by using plastic bushing (extends the lifetime of grease) -

-

-

-

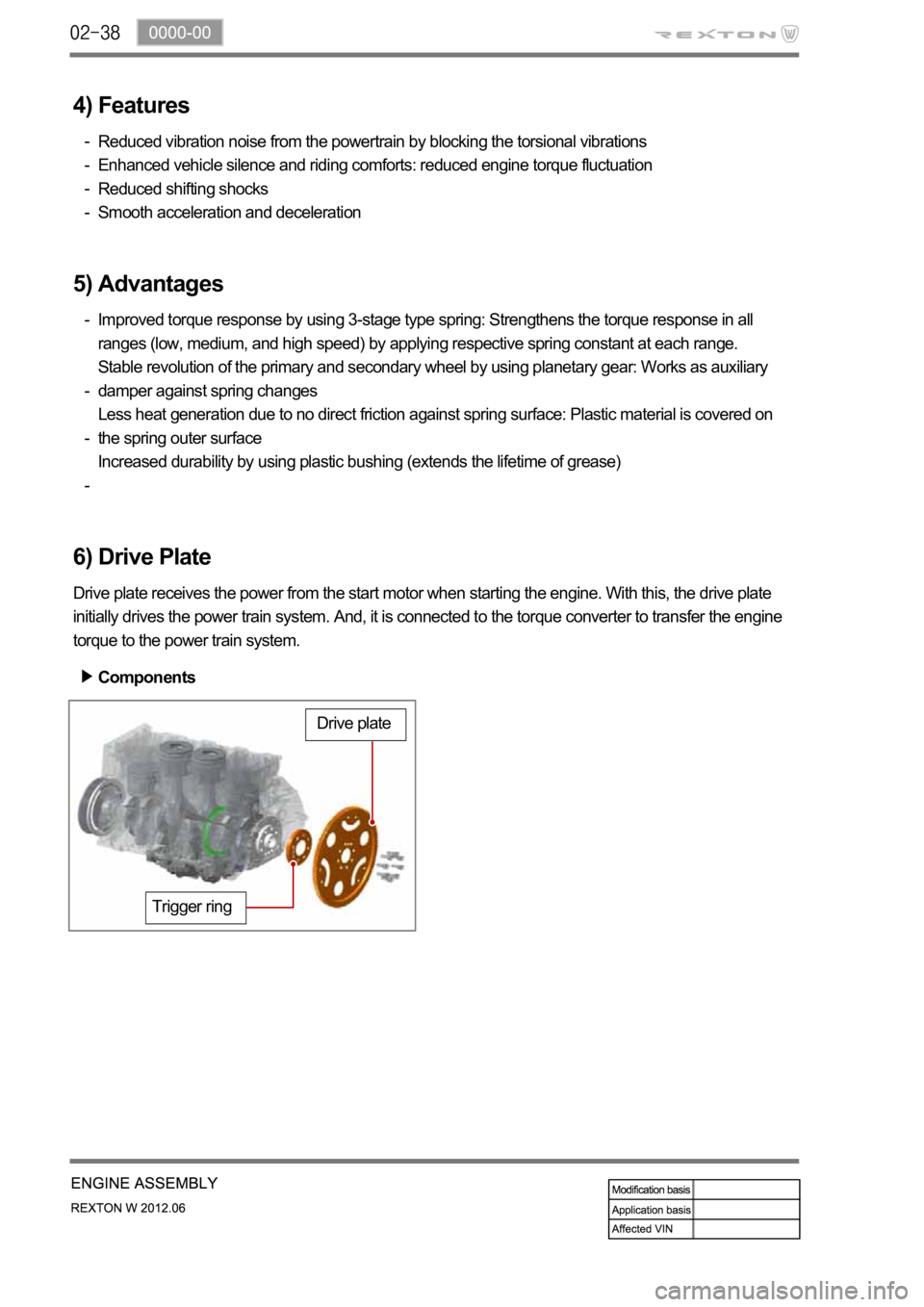

6) Drive Plate

Drive plate receives the power from the start motor when starting the engine. With this, the drive plate

initially drives the power train system. And, it is connected to the torque converter to transfer the engine

torque to the power train system.

Trigger ring

Drive plate

Components

Page 319 of 600

2210-01

Priming pump cap

Follow the job procedures. If you find a defective component, replace it with new one. 5.

Once disconnected, the fuel pipes between HP pump and fuel rail and between fuel rail and each

injector should be replaced with new ones. The pipes should be tightened tospecified tightening torques

during installation. Over or under torques out of specified range may cause damages and leaks at

connections. Once installed, the pipes have been deformed according to the force during installation,

therefore they are not reusable. The copper washer on injector should be replaced with new one. The

injector holder bolt should be tightened to specified tightening torque as well. If not, the injection point

may be deviated from correct position, and it may cause engine disorder.

Plug the removed components with clean and undamaged sealing caps and store it into the box to

keep the conditions when it was installed. 6.

To supply the fuel to transfer line of HP pump

press the priming pump until it becomes

hard. 7.

Priming pump

Fuel filter assembly

Check the installed components again and connect the negative battery cable. Start the engine and

check the operating status.

With Scan Tool, check if there are current faults and erase the history faults. 8.

9.